0% found this document useful (1 vote)

2K views11 pagesInnospec Statsafe Introduction

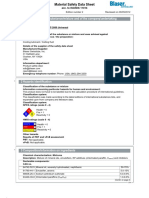

Innospec is a global specialty chemicals company with 1900 employees operating in 23 countries. It has 19 operational facilities in the US and focuses on fuel specialties, performance chemicals, oilfield services, and octane additives. Innospec provides antistatic chemicals like STATSAFETM 6000 for polyolefin processes. STATSAFETM reduces fouling and sheeting in polyolefin reactors, improving process efficiency. It is FDA approved and preferred by many petrochemical companies over other antistatic options.

Uploaded by

Sekar AyuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (1 vote)

2K views11 pagesInnospec Statsafe Introduction

Innospec is a global specialty chemicals company with 1900 employees operating in 23 countries. It has 19 operational facilities in the US and focuses on fuel specialties, performance chemicals, oilfield services, and octane additives. Innospec provides antistatic chemicals like STATSAFETM 6000 for polyolefin processes. STATSAFETM reduces fouling and sheeting in polyolefin reactors, improving process efficiency. It is FDA approved and preferred by many petrochemical companies over other antistatic options.

Uploaded by

Sekar AyuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Introduction: Introduces Innospec’s approach to safety in the polyolefin process using STATSAFE™.

- Company Overview: Gives a brief overview of Innospec, highlighting employee count, operations, and business focuses.

- Global Operations: Lists the global locations of corporate headquarters, manufacturing sites, and R&D facilities.

- Research Facilities: Details major research facilities of Innospec around the world.

- Well to Wheels: Illustrates the comprehensive process from production to end use in various transportation and storage sectors.

- Corporate Structure: Presents an overview of Innospec’s business segments: Fuel Specialties, Oilfield Services, Performance Chemicals, and Octane Additives.

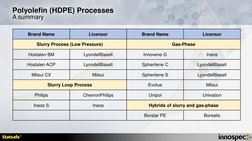

- Polyolefin Processes: Summarizes the polyolefin processes used, including slurry and gas-phase technologies.

- Advantages of STATSAFE™ 6000: Describes the benefits of STATSAFE™ 6000 in improving efficiency and safety in polyolefin production.

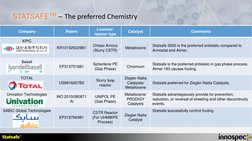

- STATSAFE™ - Preferred Chemistry: Provides detailed insights into the preferred chemistry approaches using STATSAFE™, with specific companies and patents listed.

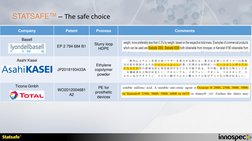

- STATSAFE™ - The Safe Choice: Explains why STATSAFE™ is regarded as the safe choice in the industry, featuring practical examples and commentary.

- Conclusion: Concludes with a statement on Innospec’s commitment to innovation and customer support in chemical solutions.