Professional Documents

Culture Documents

Manufacturing Event Guidelines

Uploaded by

Tinu MawaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing Event Guidelines

Uploaded by

Tinu MawaleCopyright:

Available Formats

MANUFACTURING EVENT

Foreword:

Manufacturing Event is conducted with the motive to inculcate the industrial approach of

manufacturing process within the students and make them industry-ready. The event also

ensures that the teams are able to visualize the manufacturing process in detail and their

design is meeting the manufacturing norms.

Manufacturing Event is an attempt to help students learn the manufacturing processes in

detail, importance of Bill of Materials, inspection methods and necessary manufacturing

details involved during the prototype and mass production of a product or sub-system.

Problem Statement:

The objective is to check how well the team understands what manufacturing techniques and

processes has gone into the development of the part or sub-system from design release stage

to final manufacturing. Team must prepare the manufacturing details of a particular sub-

system in the mass production stage. The sub-system selected for BAJA SAEINDIA 2022 event

is Drivetrain System.

The list of drive train items consists of coupling of engine and transmission assembly in detail,

connection from transmission to differential and to wheel ends at front and rear. These drive

the CVT, UJ, propeller shaft, drive-axle, differential case, satellite gears and pinion, wheels

etc. Teams are expected to do a thorough study of all drivetrain components on their shop

floor with process sheets, drawings, layout of machines and machines to be used for

manufacturing of those items including material handling and storage systems.

Mass Manufacturing

In this section, it is considered that the team is awarded a contract to manufacture 4000 units

per year of Drivetrain System for the next 5 years. For example, the gearbox casing in the

mass production will be casted part and therefore the teams must prepare the manufacturing

documents considering the operations involved in casting.

The manufacturing details of the sub-assembly in the report should include but not limited

to:

● Layout of Drive Train Components – Inhouse activities which includes machining,

component cells, process groups and assembly lines.

● Proposed Shop Area & Schematic Layout

● Bill of Material Coverage: It should include major parts and components for sub

assembly and main assembly of Drive train aggregates i.e. – Gear Box, Transfer Case,

Rear Driveshaft, along with Propeller Shaft, Differential Assembly & Front Driveshaft

for AWD/4WD teams.

● Manufacturing Processes Involved, Workflow Organization

● Raw material Selection Criteria

● Parameters for “Make or Buy” decision

● Supplier Selection Criteria

● Part Drawings, Process/Assembly Drawings

● Inspection Methods, Gauging Preparation

● Jigs and Fixtures requirement and preparation

● Identification of Critical Quality Control parameters along with the process failure

modes.

● Process Flow Chart/Control Chart

● PFMEA/MFMEA

● Welding parameters, torquing sequence, alignment processes, dimension inspection

report.

● Tools and gauges check sheets, inspection, assembly, and process check sheet.

Rules:

● Participation in this event is compulsory for the teams participating in BAJA

SAEINDIA 2022 event.

● Manufacturing Report File should be in PDF format and named in the following

format: TeamID_Team Name_Manufacturing Event Report.

● Deadline for submitting the report for the Manufacturing Event is 1st December,

2021 by 23:59 IST.

● Please click on the following link for online submission for Manufacturing Event:

https://bit.ly/ManufacturingSubmission

● The scores received in this event would be considered for calculating the Overall

Scores.

Note:

1) Teams will not be allowed for Manufacturing Event Evaluation if the report is not

submitted within the deadline.

2) All files submitted in the pdf format should have the following information: Team

Name, Team Number, College, Email Id

Manufacturing Report Guidelines

Teams have the flexibility regarding the format of the report however teams should ensure

that maximum no. of pages allowed is 25+5 (for 4WD teams only). Within the allocated pages,

teams should ensure that they are covering the parameters mentioned above in their report.

Teams can refer sample BOM template, Manufacturing Operations Sheet Template and

Process Flowchart template from the link: http://bit.ly/ManufacturingTemplate

Note: Teams can modify the templates as per their requirement.

Presentation Guidelines

Teams have the flexibility regarding the format and pages of presentation, but teams should

ensure that presentation should be explained within 25 minutes in front of a panel consisting

of judges from the automotive industry. The presentation will be done virtually over an online

platform. The schedule for the presentation slotting will be released separately on the BAJA

SAEINDIA forum.

Presentation Format:

● Each team will be evaluated over a 35 minutes time period which includes

Presentation Setup, Introduction, Presentation, Q&A and feedback by the judges.

● Maximum of 5 team members are allowed for the presentation showing teamwork.

ALL THE BEST!!

You might also like

- GM 10067Document43 pagesGM 10067francisco100% (1)

- Cost Report Guidelines ExplainedDocument3 pagesCost Report Guidelines ExplainedTinu MawaleNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessNo ratings yet

- Group TechnologyDocument26 pagesGroup TechnologyMohitNo ratings yet

- Formula Bharat Rulebook Summary UpdatedDocument12 pagesFormula Bharat Rulebook Summary UpdatedSubarna RegmiNo ratings yet

- Bajaj Auto's Lean Manufacturing TransformationDocument16 pagesBajaj Auto's Lean Manufacturing TransformationArjun K BhagatNo ratings yet

- Batch Determination of Components in The Production Order in S - 4 1709 - SAP BlogsDocument17 pagesBatch Determination of Components in The Production Order in S - 4 1709 - SAP BlogskvarjunanNo ratings yet

- 1898 Ford Operations ManagementDocument8 pages1898 Ford Operations ManagementSanthoshAnvekarNo ratings yet

- Me6703 2 Mark Questions Slow LearnersDocument10 pagesMe6703 2 Mark Questions Slow LearnersKanagarajNo ratings yet

- Make It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionFrom EverandMake It! The Engineering Manufacturing Solution: Engineering the Manufacturing SolutionNo ratings yet

- SCMH 3.2.2 FAI 9102 FAQs Rev C Dated 8FEB2021Document9 pagesSCMH 3.2.2 FAI 9102 FAQs Rev C Dated 8FEB2021John OlayNo ratings yet

- United Group TexManage ERP Commercial Proposal V1.0Document23 pagesUnited Group TexManage ERP Commercial Proposal V1.0SarkarArdhenduRiponNo ratings yet

- PsaDocument27 pagesPsaFilomeno João Colaço FaustinoNo ratings yet

- SCCAF Handbook - LetterDocument42 pagesSCCAF Handbook - LetterBruno Debonnet78% (9)

- Advanced Business ProcessDocument10 pagesAdvanced Business ProcessHarry DhaliwalNo ratings yet

- BAJA SAEINDIA Cost Guidelines 2021Document4 pagesBAJA SAEINDIA Cost Guidelines 2021Siva DanusNo ratings yet

- Square Textiles TexManage ERP Commercial Proposal V1.0Document17 pagesSquare Textiles TexManage ERP Commercial Proposal V1.0SarkarArdhenduRipon0% (1)

- Stellantis All You Need To KnowDocument40 pagesStellantis All You Need To Knowluis100% (1)

- CO: 6: Adapt Recent Practices Like CAPP, CIM, AI, RP and FOF For Effective ProductionDocument8 pagesCO: 6: Adapt Recent Practices Like CAPP, CIM, AI, RP and FOF For Effective ProductionDivyeshparmar9077No ratings yet

- Global Supplier Manual Appendix I - Mahindra and Mahindra Customer Specific Requirements For SuppliersDocument5 pagesGlobal Supplier Manual Appendix I - Mahindra and Mahindra Customer Specific Requirements For SuppliersPravin Balasaheb GunjalNo ratings yet

- PPAP Webinar Core ToolsDocument62 pagesPPAP Webinar Core ToolsDLNo ratings yet

- Estimation HandbookDocument54 pagesEstimation HandbookMathias Wafawanaka100% (1)

- Cairn Energy Seeks EOI for Digital Oil Field Integration ServicesDocument3 pagesCairn Energy Seeks EOI for Digital Oil Field Integration ServicesMygroup 5544No ratings yet

- Mmog - LeDocument7 pagesMmog - Lemrhectorviedma3No ratings yet

- ERP-Production Module: Presented To: Ms. Sudha SinghDocument41 pagesERP-Production Module: Presented To: Ms. Sudha SinghsanjibkrjanaNo ratings yet

- PDPP Unit - 5 PDFDocument25 pagesPDPP Unit - 5 PDFShreya KumariNo ratings yet

- SCMH 3.2.2 FAI 9102 Rev B FAQs 8FEB2021 Noted 7AUG2023Document9 pagesSCMH 3.2.2 FAI 9102 Rev B FAQs 8FEB2021 Noted 7AUG2023GÜRHAN EMİNNo ratings yet

- Unit Testing of Production Planning ModuleDocument22 pagesUnit Testing of Production Planning ModuleVinoth Babu ViswanathanNo ratings yet

- Introduction To Control PlansDocument6 pagesIntroduction To Control Plansamarchavan894No ratings yet

- Ceekay Daikin Ltd.Document39 pagesCeekay Daikin Ltd.TAHER3555No ratings yet

- Ppqa Titan Pneus Do Brasil Rev OriginalDocument60 pagesPpqa Titan Pneus Do Brasil Rev OriginalAnderson TpsNo ratings yet

- Cqi 11Document73 pagesCqi 11dwimukh360No ratings yet

- Group Project Om 2022 FinalDocument2 pagesGroup Project Om 2022 FinalKHUSHI MITTALNo ratings yet

- GE Money VisionPLUS Release ManagementDocument5 pagesGE Money VisionPLUS Release ManagementBharat SahniNo ratings yet

- Sample Standard Operational Procedure - Garment IndustryDocument15 pagesSample Standard Operational Procedure - Garment Industryprz_saiya88% (17)

- Process Planning Fundamentals ExplainedDocument24 pagesProcess Planning Fundamentals ExplainedJackson ..No ratings yet

- IATF 16949:2016: Quality Management Systems DocumentationDocument10 pagesIATF 16949:2016: Quality Management Systems DocumentationKhaoula RezzoukNo ratings yet

- SCCAF Handbook A4Document37 pagesSCCAF Handbook A4William Autometal100% (1)

- PowerPoint Presentation FAI AS9102Document29 pagesPowerPoint Presentation FAI AS9102Danny Fydm OliveiraNo ratings yet

- 05 ERP Scope of WorkDocument14 pages05 ERP Scope of WorkDr. Syed Masrur67% (3)

- 1.QSMl - BVQI - NUMBERINGDocument49 pages1.QSMl - BVQI - NUMBERINGtruongthi100508No ratings yet

- APQP Check ListDocument17 pagesAPQP Check ListmdjeckelNo ratings yet

- Order Split without Product Cost Collector and By-ProductDocument14 pagesOrder Split without Product Cost Collector and By-Productsrinivasa varmaNo ratings yet

- I, Ii TQMDocument2 pagesI, Ii TQMBlademer SorianoNo ratings yet

- Understanding Control PlansDocument5 pagesUnderstanding Control PlansVasant bhoknalNo ratings yet

- SupplierQuality-TataMotorsCaseStudyDocument9 pagesSupplierQuality-TataMotorsCaseStudyvaasu gargNo ratings yet

- DFMaint TutorialDocument4 pagesDFMaint Tutorialpravit08No ratings yet

- First Article Inspection SummaryDocument5 pagesFirst Article Inspection Summarypawoe3064No ratings yet

- Computer Aided Process PlanningDocument6 pagesComputer Aided Process Planningaqtu12fucNo ratings yet

- Saa P5Document12 pagesSaa P5smartguy0No ratings yet

- New Vendor System Audit Check SheetDocument6 pagesNew Vendor System Audit Check SheetJetesh Devgun83% (6)

- Gautam C.V.Document4 pagesGautam C.V.Gautam GuptaNo ratings yet

- JLR PSF-010 Capacity Analysis ReportDocument7 pagesJLR PSF-010 Capacity Analysis ReporttruongngvNo ratings yet

- Course Mba - 2 Semester Subject Assignment MB0044 - Set 1Document18 pagesCourse Mba - 2 Semester Subject Assignment MB0044 - Set 1kct_thomasNo ratings yet

- Production One: Production One With SAP Business One User Guide Version 08.21Document63 pagesProduction One: Production One With SAP Business One User Guide Version 08.21Venkata Subbareddy PoluNo ratings yet

- PPAP Process Checklist / Sign Off Sheet InstructionsDocument7 pagesPPAP Process Checklist / Sign Off Sheet InstructionsSharmad TamhaneNo ratings yet

- Sap QM Configuration PackDocument16 pagesSap QM Configuration Packsrajane_1100% (1)

- BAJA teams design specification sheetDocument27 pagesBAJA teams design specification sheetTinu MawaleNo ratings yet

- BAJA SAEINDIA 2022 - Design Comparison DocumentDocument8 pagesBAJA SAEINDIA 2022 - Design Comparison DocumentTinu MawaleNo ratings yet

- Baja Saeindia 2022 DVP&R + Dfmea TemplateDocument10 pagesBaja Saeindia 2022 DVP&R + Dfmea TemplateTinu MawaleNo ratings yet

- Locking DifferentialDocument1 pageLocking DifferentialTinu MawaleNo ratings yet

- Estimate: AMK Power Parts LLPDocument1 pageEstimate: AMK Power Parts LLPTinu MawaleNo ratings yet

- Open Differential (OD01)Document1 pageOpen Differential (OD01)Tinu MawaleNo ratings yet

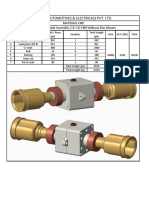

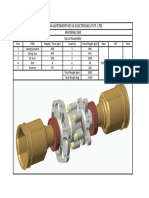

- Ekaksh Automotives & Electricals Pvt. LTD.: MATERIAL 6061 - T6 Front Knuckle AssemblyDocument1 pageEkaksh Automotives & Electricals Pvt. LTD.: MATERIAL 6061 - T6 Front Knuckle AssemblyTinu MawaleNo ratings yet

- Ekaksh Automotives & Electricals Pvt. LTD.: Casing Material 6061 4 Wheel Drive Single Stage 13.3:1 Reduction GearboxDocument1 pageEkaksh Automotives & Electricals Pvt. LTD.: Casing Material 6061 4 Wheel Drive Single Stage 13.3:1 Reduction GearboxTinu MawaleNo ratings yet

- Baja Sae Design ReportDocument14 pagesBaja Sae Design Reportlucky_agrawal45No ratings yet

- Ekaksh Automotives & Electricals Pvt. LTD.: Material En8 Spool AssemblyDocument1 pageEkaksh Automotives & Electricals Pvt. LTD.: Material En8 Spool AssemblyTinu MawaleNo ratings yet

- Semi Trail UprightDocument1 pageSemi Trail UprightTinu MawaleNo ratings yet

- Baja Sae Design ReportDocument14 pagesBaja Sae Design Reportlucky_agrawal45No ratings yet

- Ekaksh Automotives & Electricals Pvt. LTD.: Material En-8 Rear Upright AssemblyDocument1 pageEkaksh Automotives & Electricals Pvt. LTD.: Material En-8 Rear Upright AssemblyTinu MawaleNo ratings yet

- Open Differential (OD01)Document1 pageOpen Differential (OD01)Tinu MawaleNo ratings yet

- Baja Sae Design ReportDocument14 pagesBaja Sae Design Reportlucky_agrawal45No ratings yet

- Design, Analysis and Optimization of A BAJA-SAE Frame: February 2020Document11 pagesDesign, Analysis and Optimization of A BAJA-SAE Frame: February 2020Tinu MawaleNo ratings yet

- Baja Sae Design ReportDocument14 pagesBaja Sae Design Reportlucky_agrawal45No ratings yet

- Design, Analysis and Optimization of A BAJA-SAE Frame: February 2020Document11 pagesDesign, Analysis and Optimization of A BAJA-SAE Frame: February 2020Tinu MawaleNo ratings yet

- CA Sup Mto 21-Civ-03843 ComplaintDocument41 pagesCA Sup Mto 21-Civ-03843 ComplaintForkLogNo ratings yet

- DP2PN2Solver User GuideDocument1 pageDP2PN2Solver User GuideAlexander Segura BallesterosNo ratings yet

- Lexmark Cxx10 MFP: Machine Type 7527-2Xx, - 4Xx, - 63XDocument394 pagesLexmark Cxx10 MFP: Machine Type 7527-2Xx, - 4Xx, - 63XOmar SanchezNo ratings yet

- Garry Owen. - Learn To Code Learn HTML, CSS & JavaScript & Build A Website, App and Game (2022)Document247 pagesGarry Owen. - Learn To Code Learn HTML, CSS & JavaScript & Build A Website, App and Game (2022)Saju George100% (1)

- Animation Essentials-CSS Animations and TransitionsDocument96 pagesAnimation Essentials-CSS Animations and TransitionsDamian RojasNo ratings yet

- Computer LanguagesDocument6 pagesComputer LanguagesAkshita DhyaniNo ratings yet

- UENR2643UENR2643-05 - SIS Electrico Diagrama PDFDocument4 pagesUENR2643UENR2643-05 - SIS Electrico Diagrama PDFJaime LopezNo ratings yet

- SP 1207Document32 pagesSP 1207Anoop GokhaleNo ratings yet

- Online Banking Authentication System Using QR-code and Mobile OTPDocument6 pagesOnline Banking Authentication System Using QR-code and Mobile OTPግሩም ሽ.No ratings yet

- Pig Handling System Brochure PDFDocument6 pagesPig Handling System Brochure PDFKRUNAL SHAHNo ratings yet

- DC - Batman Beyond JumpChainDocument27 pagesDC - Batman Beyond JumpChainAtinder SinghNo ratings yet

- Oracle APEX Installation With ORDS & TOMCATDocument8 pagesOracle APEX Installation With ORDS & TOMCATSaad MalikNo ratings yet

- WEG CFW500 SFY2 Safety Functions Module Safety Manual 10006503387 en Es PTDocument109 pagesWEG CFW500 SFY2 Safety Functions Module Safety Manual 10006503387 en Es PTDaniel GuzmanNo ratings yet

- Homework VLSM tasks - 2010 network design solutionsDocument8 pagesHomework VLSM tasks - 2010 network design solutionsBozhidar IvanovNo ratings yet

- Navigational Aids For Offshore StructuresDocument35 pagesNavigational Aids For Offshore Structuresdebjit2001100% (1)

- Soal Engine Tune UpDocument3 pagesSoal Engine Tune UpHikmahNo ratings yet

- MT6750 Android FdfdatterDocument10 pagesMT6750 Android FdfdatterCuentaNo ratings yet

- Crocodile DIY Paper CraftDocument16 pagesCrocodile DIY Paper CraftAlireza Emami100% (1)

- SeleneiumDocument112 pagesSeleneiumdungeonmasterNo ratings yet

- Datasheet DT35S-B15551 1122103 enDocument8 pagesDatasheet DT35S-B15551 1122103 enROSSNo ratings yet

- Valnav Reserves Management 2019Document83 pagesValnav Reserves Management 2019Jorge RomeroNo ratings yet

- COMPENDIUM OF NOTES Math 9 First QRTR PDFDocument50 pagesCOMPENDIUM OF NOTES Math 9 First QRTR PDFCaleb BiagNo ratings yet

- Cisco IOS Security Command Reference - Commands A To CDocument1,000 pagesCisco IOS Security Command Reference - Commands A To CsilverclericNo ratings yet

- FortiWeb 6.3.14 Release NotesDocument19 pagesFortiWeb 6.3.14 Release Notesumbo202No ratings yet

- Lighttools Solidworks Link Module: Optimize Parts and AssembliesDocument3 pagesLighttools Solidworks Link Module: Optimize Parts and AssembliesKolin LeeNo ratings yet

- ComColor Series Parts List Rev.1.1Document99 pagesComColor Series Parts List Rev.1.1Antonio CesarNo ratings yet

- CJLIS Format Challenges of Access and Use of Electronic Information ResourcesDocument14 pagesCJLIS Format Challenges of Access and Use of Electronic Information ResourcesGoodluck OyinpreyeNo ratings yet

- APC NetBotz Compatibility Chart PDFDocument2 pagesAPC NetBotz Compatibility Chart PDFraviNo ratings yet

- Directory of Outstanding ASEAN SMEs 2011Document158 pagesDirectory of Outstanding ASEAN SMEs 2011DanaNo ratings yet

- X15 (S) T User Manual (Quick Start in English German Spanish Italian French)Document71 pagesX15 (S) T User Manual (Quick Start in English German Spanish Italian French)kala santaNo ratings yet