Professional Documents

Culture Documents

US20020188151A1

US20020188151A1

Uploaded by

Akbar0 ratings0% found this document useful (0 votes)

7 views7 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views7 pagesUS20020188151A1

US20020188151A1

Uploaded by

AkbarCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

cs) United States

US 20020188151A1

«2 Patent Application Publication (1) pub. No.: US 2002/0188151 AL

Inoue et al.

(43) Pub. Date: Dec. 12, 2002

(54) PROCESS FOR PRODUCING METHYL

METHACRYLATE

(75) Inventors: Go Inoue, Niihama-shi (JP); Katsuo

Baba, Singapore (SG); Takayuki

Moritou, Niihama-shi (IP)

Correspondence Addee:

SUGHRUE MION, PLLC

2100 PENNSYLVANIA AVENUE, N.W.

WASHINGTON, DC 20037 (US)

(73) Assignee: SUMITOMO _ CHEMICAL,

PANY , LIMITED

com.

Appl No: 10/087,888

Filed Mar. 5, 2002

Go) Foreign Application Priority Data

May 2, 2001 (IP) 2001-135628

Sep. 21, 2001 (IP) 2001-28877

Publication Classification

G1) COTE 69/52

G2) 5601205

6 ABSTRACT

‘A process for producing @ methyl methacrylate is provided,

‘hich comprises the steps of (i) decomposing methyl Lbutyl

cther fo obtain an isobutylene and a methanol, (i) oxidizing

the isobutylene to obtain at least one compound selected

from a methacrylic acid and a methacrolein and (ii) esteri-

{ying at least one compound selected from the methacrylic

acid and the methacrolein with the methanol to produce a

‘methyl methacrylate. The process in the present invention

successfully results in effective use of methanol resources

US 2002/0188151 AL

Patent Application Publication Dec. 12, 2002

<- Auatod0D

SurTToq-ubry waned <5

Lh

yuouoduos SuFTTOG

=

queuoduo

BuFTToa-uBTu- puooes

ueuoduco

ab

BuTTToq-MoT Wameg <4

6TH PFE,

i +a _ junds

— Surtroq-ubtu asz7a

“*. BUTTTOq vt

forums | ol

izoucdinco

ueuoduc’s Surttog-Mot asxzatZy|

SusTTOq-#0T

at a

brn

Ga

T *6ta

xeuze TAqng-3

t+ | fe

ir | TAuew

US 2002/0188151 AL

PROCESS FOR PRODUCING METHYL

METHACRYLATE

BACKGROUND OF THE INVENTION

[0001] 1, Field of the Invention

[0002] The present invention relates 1 a process for

producing methyl methacrylate, In particular, the present

invention relates to a process for producing methyl meth-

acrylate comprising a step of esterifying methacrylic acid

and/or methacrolein with a methanol which is recovered

from a catalytic decomposition of methyl t-butyl ether,

[0003] 2. Description of Related Art

[0004] Generally, methyl methacrylate is synthesized by

allowing methacrylic acid to react with methanol in the

presence of an acid catalyst. Industrial processes of the

production thereof are also based on such an esterification

reaction. For example, the production process comprises the

‘steps of bringing methacrylic acid and methanol into contact

‘with an esterification catalyst such asa strongly acidic eation

‘exchange resin to react them with each other; and separating

the resulting reaction mixture by distillation into a

boiling component mainly comprising uoreacted meth-

acrylic acid and a distillate containing methyl methacrylate

and water, which are reaction products, and unreacted

‘methanol. The distillate is cooled and is separated into an oil

phase and a water phase. The product, methyl methacrylate,

is isolated from the oil phase, The unreacted methanol is

recovered from the water phase and is retumed 10 the

‘esterification step, so that methanol is reused. On the other

hhand, the unreacted methacrylic acid is recovered from the

high-boiling component and is also reused in the esterifica-

tion step. In such a manner, the cost for producing methyl

methacrylate may be reduced by recovering the unreacted

raw materials, ie., methanol and methacrylic acid, from the

reaction mixture and returning them tothe esterification step

to reuse them as raw materials therein,

[0005] However, in a case that the methanol which is

recovered from a production process other than that of

methyl methacrylate is reused as it i as a raw material for

the esterification to produce methyl methacrylate te result-

ing produet (methy! methacrylate) may be contaminated

‘with impurities de tothe impurities tat have been brought

together with the reused methanol. Therefore, the obtained

seth! methacrylate usually needs to be pusilied to remove

the impurities prior tobe eeused. Ths results in the necessity

‘of an additional purification step andthe deterioration of a

Yield of the product, s0 that the production cost thereof

Jncreases. On the other hand, the recovered methanol may be

separated from the impucitcs with purification in advance

and then be used as a raw material for the esterification. In

that ease, however, there are problems such as the purifiea-

tion is complicated andior costs a lot

[0006] As described above, it has been known that the

methanol which is recovered from a production process

other than that of methyl methacrylate is difficult 10 be

roused as a raw material for the esterification 10 produce

‘methyl methacrylate without complicated and/or cost

fication. Therefore, in the indusirial process, the recovered

‘methanol may or may not be utilized for the production of

‘methyl methacrylate, depending on the complexity and the

‘cost in the purification of the recovered methanol. When

Dec. 12, 2002

there are few advantages in the reuse thereof, there is almost

nothing to do except to use the recovered methanol asa fuel

for heat recovery, which results in lost of a methanol

SUMMARY OF THE INVENTION

[0007] The inventors of the present invention have made

Studied with the object of reuse of methanol for the produc-

tion of methyl methacrylate, even if the methanol is a

‘methanol which has been recovered from a production

process other than that of methyl methacrylate. As a result,

the inventors have found that a methanol which has been

recovered from catalytic decomposition of methyl butyl

ether can be reused for the production of methyl methacry.

late in a simple manner. The present invention has been

accomplished on the basis of this finding,

[0008] By the catalytic decomposition of methyl t-butyl

cther, is provided isobutylene as well as methanol. By

catalytic vapor phase oxidation of isobutylene, are provided

methacrylic acid and methacrolein, each of which can be

used as a raw material for the production of methyl meth-

acrylate together with methanol. Inthe present invention, the

methanol recovered from the catalytic decomposition of

methyl t-butyl ether can be utilized in the production of

methyl methacrylate, which means that all the products

prodiced by the catalytic decomposition of methy! t-butyl

ether ean be effectively utilized

[0009] The present invention provides a process for pro-

ducing a methyl methacrylate, the process comprising the

steps of:

[0010] (i) decomposing methyl t-butyl ether to obtain

an isobutylene and a methanol,

[0011] (i) oxidizing the isobutylene to obtain at least,

‘one compound selected from a methacrylic acid and

a methacrolein and,

[0012] (iil) esteritying atleast one compound

selected from the methacrylic acid and the methac-

rolein with the methanol to produce a methyl meth-

acrylate

[0013] The present invention also provides an apparatus

for producing « methyl methacrylate, the apparatus. com-

prising:

[0014] (a) a reactor for catalytic decomposition of

‘methyl t-butyl ether t0 obtain a reaction mixture

containing an isobutylene and a methanol,

[0013] | (b) separation means for separating the isobu-

tylene from the reaction mixture,

[0016] (©) recovery means for recovering the metha-

nol from the reaction mixture,

[0017] (@) a reactor for oxidation of the isobutylene

to obtain at least one compound selected from a

methacrylic acid and a methacrolein and

[0018] (c) a reactor for esterification of at least one

compound selected from the methacrylic acid! and

the methacrolein with the methanol

BRIEF DESCRIPTION OF DRAWINGS

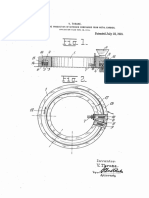

[0019] FIG. 1 is @ flow diagram illustrating a step of

recovering methanol from a reaction mixture obtained by

catalytic decomposition of methyl t-butyl ether.

US 2002/0188151 AL

DETAILED DESCRIPTION OF THE

INVENTION,

[0020] In the present invention, a methyl methacrylate is

produced in a process comprising the steps of

[0021] () decomposing methyl t-butyl ether to obt

an isobutylene anc a methanol,

[0022] (ii) oxidizing the isobutylene to obtain at least

‘one compound selected from a methacrylic acid and

methacrolein and,

[0023] (ii) esterifying at feast one compound

selected from the methacrylic acid and the methac-

rolein obtained instep (i) with the methanol

‘obiained in step (i) t0 produce a methyl metbacry-

late

[0024] ‘The catalytic decomposition of methyl t-butyl ether

and the catalytic vapor phase oxidation of the isobutylene

are not limited and may be conducted in a known method

‘Also, the esterification of the methacrylic acid andior the

methacrolein is not limited and may be conducted in a

known manner as long as the methanol recovered from the

decomposition of methyl t-butyl ether is uilized. The esteri=

fication may be conducted in the presence of an esterifica-

tion catalyst such as an acid or a cation exchange resin so as

to provide methyl methacrylate in a high yield

[0025] The process of the present invention may further

‘comprise a step of separating the isobutylene from the

‘decomposition reaction mixture prior tothe oxidation step of

the isobutylene, Moreover, the process of the present inven-

tion may comprise a step of recovering a methanol from the

remaining mixture oblained after the separation of the

isobutylene, prior to the esterification step.

[0026] The recovered! methanol may contain at least one

‘compound selected from t-butyl alcohol, water and methyl

butyl ether. Also, the recovered methanol preferably con-

tains 95% by weight or more of methanol based on the

recovered methanol.

[0027] ‘The recovered methanol may be utilized as it is for

esterification step, or may be utilized after purified. By

‘conducting the purification step of the recovered! methanol,

methyl methacrylate with an extremely slight amount of

impurities can be produced easily.

[0028] The pucified methanol may contain about 95% by

‘weight or more, preferably about 99% by weight or mor

more preferably 99.8% by weight or more and most pref

‘erably 99.9% by weight or more, of methanol based on the

purified methanol,

[0029] Specifically, the recovered methanol andlor the

purified methanol may be any component selected from the

following components (I) to (IV)

[0030] (1) a component that contains about 95% by

‘weight or more of methanol based on the component

(D) and further contains t-butyl alcohol, water and

methyl t-butyl ether;

[0031] (11) a component that is obtained by separating,

methyl t-butyl ether from component (I) and contains

about 95% by weight or more, preferably about 987%

by weight or more, of methanol based on the com=

ponent (ID;

Dec. 12, 2002

[0032] _(I11) a componeat that is obtained by separat-

ing t-butyl alcohol and water from component (D) and

contains about 95% by weight or more, preferably

about 98% by weight or more, of methanol based on

the component (IID);

[0033] (IV) a component that is obtained by separat-

ing t-butyl alcohol, water and methyl t-butyl ether

from component (I) and contains about 99% by

weight, preferably 99.8% by weight or more and

more preferably 99.9% by weight or more of metha-

‘aol based on the component (IV).

[0034] Component (IV) may contain about 10 ppm by

‘weight or less of t-butyl alcohol andior about 10 ppm by

‘weight or less of methyl t-butyl ether

[0035] ‘The separation of the isobutylene, the recovery of

the methanol and the purification of the recovered methanol

‘may be conducted in a known method such as distillation,

layer separation (for example, pervaporation) and solvent

extraction. Among them, distillation is preferred.

[0036] The present invention further provides an appara-

tus for producing a methyl methacrylate, the apparatus

comprising:

[0037] (a) a reactor for catalytic decomposition of

‘meihyl butyl ether to obtain a reaction mixture

containing an isobutylene and a methanol,

[0038] _(b) separation means for separating the isobu-

tylene from the reaction mixture,

[0039] _(c) recovery means for recovering the metha-

‘aol from the remaining mixture obtained alter the

separation of the isobutylene,

[0040] (2) a reactor for oxidation of the isobutylene

to obtain at Teast one compound selected from a

‘methacrylic acid and a methacrolein and

[0041] (¢) a reactor for esterification of at least one

‘compound selected from the methacrylic acid and

the methacrolein with the methanol.

[0042] By recovery means (©), the methanol having.»

concentration of 95% by weight may be obtained. Specifi-

cally, the above described the components (I-(IV) may be

obiained by recovery means (c). The components (1)-(IV)

‘may be utilized as the methanol in the reactor (e).

[0043] When methyl methacrylate is produced with the

Apparatus ofthe present invention, metbyl methacrylate with

high purity almost free from impurities can be obtained and

the cost for the production may be very low.

[0044] With reference to FIG. 1, a ecovery of methanol

in the preset invention may be described as below, which

should not be construed as a limitation upon the scope of the

present invention. FIG. Lis flow diagram illustrating a step

in which methanol is recovered from a reaction mixture

obtained by the catalytic decomposition of methyl butyl

ether.

[0045] The methanol to be recovered in FI

luced in the catalytic decomposition of methyl

‘The catalytic decomposition of methyl t-butyl ether can

provide an isobutylene without any problem, while the

decomposition reaction mixture may contain methanol,

isobutylene, t-butyl aloobol, water and unreacted methyl

US 2002/0188151 AL

{-butyl ether as well as isobutylene. Iti preferred that, from

the reaction mixture, the isobutylene is separated first and

then the methanol is separated and recovered. The recovered

‘methanol is reused as a raw material for esteritication

[0046] In FIG. 1, methyl t-butyl ether is supplied through

methyl t-butyl-ether supply line IL. The methyl t-butyl ether

is catalytically decomposed in reactor 1 (reactor for catalytic

decomposition) to obtain a reaction mixture (catalytic

‘decomposition step). The reaction mixture is then supplied

to isobutylene separation column 2 (isobutylene separation

means) through catalytic decomposition reaction product

supply line 12.

[0047] In isobutylene separation column 2, the reaction

mixture is separated into a first low-boiling (light) compo-

‘nent comprising isobutylene and a first high-boiling (heavy)

‘component comprising methanol, -utyl alcohol, water and

‘methyl t-butyl ether (isobutylene Separation step). The com-

ponent comprising isobutylene may be discharged from

isobutylene separation column 2 through isobutylene drain

Tine 13, followed by being oxidized to produce a methacrylic

acid andjor a methacrolein.

[0048] The first high-boiling (heavy) component is sup-

plied to methanol recovery column 3 (methanol recovery

means) through frst high-boiling component supply line 14

(methanol recovery step). In methanol recovery column 3,

the first high-boiling (heavy) component is separated into 4

second low-boiling (ight) component containing methanol

and methyl t-butyl ether and a second high-boiling (heavy)

‘component containing methanol, t-butyl alcohol and water

[0049] The second low-boiling component is contami-

rated with methyl t-butyl ether, and may contain 95% by

‘weight or more of methanol basetl on the second low-boiling

3 The methyl t-butyl ether contained in the second

1g component may be easily separated by distilla-

tion from methyl methacrylate, which is generated afier the

esterification of methacrylic acid and/or methacrolein with

‘methanol. Therefore, the second low-boiling (light) compo-

rnent may be used as 1 methanol for the esterification as itis,

For example, the second low-boiling component is dis-

‘charged from second low-boiling component drain line 15a

and is used for the esterification with the methacrylic acid

and/or the methacrolein. On the other hand, the second

high-boiling component may be discharged through second

high-boiling component drain line 16.

[0050] For prosucing methyl methacrylate containing a

smaller amount of impurities, itis preferred to purify the

second low-boiling (light) component before the esterifica-

tion step so as to remove the methyl t-hutyl ether contained

therein. In such a preferable ease, the second low-boiling

ght) component is supplied to methanol-purifying distil-

Jation column 4 (methanol purification means) through

second low-boiling component supply line 15. In methanol-

purifying distillation column 4, the second low-boiling

‘component may be separated by distillation into a third

Jow-boiling (light) component comprising methanol and

methyl t-butyl ether and a third high-boiling (heavy) com-

ponent comprising 9.8% by weight of methanol based on

the third high-boiling(heavy}eomponent. The third high-

boiling (heavy) component may be used forthe esterification

as it is. For example, the third high-boiling component is

discharged ftom third high-boiling component drain line 17a

and is used for the esterification with the methacrylic acid

Dec. 12, 2002

and/or the methacrolein. The third low-boiling component

‘may be discharged from thied Jow-boiling component drain

line 18,

[0051} ‘The third high-boiling (heavy) component may be

Contaminated wit traces of t-utyl aleohol and water. Its

possible to remove these contaminanis by purification to a

‘methanol with a very high purity before ulilized as a raw

‘material for the esterification. In such a preferable ease, the

third high-boiling (heavy) component is supplied to meta-

‘ol-purilying distillation column § through

ing component supply line 17. In methanol distillation

ccoluma § (methanol purification means), the third high-

boiling (heavy) component is separated by distillation into &

fourth low-boiling (light) component comprising 99.9% by

weight or more of methanol and a fourth high-boiling

(heavy) component comprising t-butyl aleohol and water.

‘When the fourth low-boiling (light) component is used for

the esterification, a methyl methacrylate containing an

cexiremely slight amount of impurities ean be obtained. In

such a preferable case, the fourth low-boiling componen

discharged through fourth low-boiling component draia line

19 and is used for esterification, On the other hand, the

‘ourth high-boiling component is discharged through fourth

high-boiling component drain Line 20,

[0052] In the method of recovering methanol which is

described above with reference to FIG. 1, t-butyl aleobol

and water are removed; unreacted methyl I-butyl ether is

then removed; and then again I-butyl alcohol and water are

removed, 50 as to recover and purify the methanol for the

esterification. The order of the removal of these impurities in

the methanol recovery/purification method is not restricted

to the above-described order. The order may be changed and

ny removal step may be omitted,

[0053] The components (1)-(IVy' presented below may be

used a8 a methanol for the esterification,

[0054] (1) A component that contains about 95% by

‘weight or more of methanol based on the component (2) and

further contains t-butyl alcohol, water and methyl butyl

ether.

[0085] (11)' A component that is obtained by separating

‘methyl t-butyl ether from component (I' and contains about

95% by weight or more, preferably about 98% by weight or

more, of methanol based on the component (II).

[0056] (Illy A component that is obtained by separating

{butyl aleohol and water from component (1 and contains

about 95% by weight or more, preferably about 98% by

‘weight or more, of methanol based on the component (III).

[0057] (IV) A component that is obtained by separating

butyl alcohol, water and methyl t-butyl ether from com-

ponent (I)! and contains about 99% by weight, preferably

99.8% by weight or more and more preferably 99.9% by

‘weight of more of methanol based on the component (IV).

[0058] A methacrylic acid and a methacrolein, cach of

which is another raw material forthe produetion of methyl

methacrylate, may be obtained in a known method) by

catalytic vapor phase oxidation of the isobutylene andior

t-butyl aleohol,Isobutylene can be obtained by decomposi-

tion of methyl t-butyl ether. The methacrylic acid and a

methacrolein may be obtained in a known method by

catalytic vapor phase oxidation of t-butyl alcohol andior

US 2002/0188151 AL

isobutene. Also, a methacrylic acid may be obtained in a

known method by catalytic vapor phase oxidation of meth-

acrolein or isobutyl aldehyde.

[0089] For the esterification of a methacrylic acid andor a

‘methacrolein with a methanol, an esterification catalyst such

as an acid and a cation exchange resin maybe used. Prefer-

ably, a stongly acidic cation exchange resin is used

Examples of the strongly acidic cation exchange resin

include @ porous strongly acidie cation exchange resin, for

‘example, DUOLITE C-26CH (manufactured by Sumitomo

Chemical Co., Ltd).

[0060] ‘The esterification may be carried out, using a

‘suspense bed or fixed bed, in a liquid phase at a tempera~

ture of from about 70° C. to about 120° C. A polymerization

inhibitor may be added to the esterification mixture. ‘The

polymerization inhibitor to be addled may be conventionally

known polymerization inhibitor. Examples of the polymer-

ization inhibitor include hydroquinone, phenothiazine and

‘methoquinone,

‘may be purified by distillation ia a conventional manner.

‘That is, the esterification mixture may be separated by

Aistillation into a distillate comprising methyl methacrylate

and water, both of which are generated by the esterification

reaction, and unreacted methanol; and into a high-boiling

‘component mainly comprising unreacted methacrylic acid.

‘The distillate may be separated into an oil phase and a water

phase after cooling. From the oil phase, the methyl meth-

acrylate is obtained by distillation, From the water phase, the

‘methanol is recovered by distillation. The recovered metha-

‘nol may be fed back to the esterification step and be reused

On the other hand, the high-boiling component may be fed

back to the esterification step as it is, or is preferably fed

back after recovering the methacrylic acid contained therein

by distillation

[0062] As described above, the present invention provide

4 process for producing methyl methacrylate in which a

methanol obtained by catalytically decomposing methyl

-hutyl ether is used together with a methacrylic acid and/or

a methacrolein, The methacrylic acid andjor the methac~

rolein may be obtained by catalytically decomposing methyl

{-butyl ether, followed by the catalytic vapor phase oxidation

‘of the resulting decomposition product. The process in the

present invention successfully results in effective use of

‘methanol resources.

[0063] The invention being thus described, it will be

apparent that the same may be varied in many ways, Such

variations are to be regarded as withia the spirit and! scope

of the invention, and all such modifications as would be

apparent to one skilled in the art ate intended tobe within the

‘scope of the following claims.

[0064] ‘The entire disclosure ofthe Japanese Patent Appl:

‘cation No. 2001-135628 filed on May 2, 2001 and the

‘Japanese Patent Application No. 2001-28877 filed on Sep.

21,2001, both indicating specification, claims, drawings and

Summary, are incorporated herein by reference in their

centirety.

[0065] The present invention is described in more detail

by following Examples, which should not be construed as a

limitation upon the scope of the present invention.

Dec. 12, 2002

EXAMPLE 1

[0066] ‘The catalytically decomposition of methyl t-butyl

‘ther was carried out to obtain a reaction mixture containing

isobutylene and methanol. The reaction mixture was sepa-

rated by distillation into a first high-boiling component and

4 first low-boiling component. The first high-boiling com-

ponent was then separated by distillation into a second

high-boiling component and a second low-boiling compo-

nent, The second low-boiling component contained a 98%

by weight of methanol, 0.9% by weight of methyl t-butyl

ether, 009% by weight of t-butyl alcohol, several % by

‘weight of inert components and a small amount of water.

[0067] A distillation device mainly made of glass was

prepared. The distillation device had a distillation column, a

2-1 glass flask (connected to the column a its bottom) and

‘condenser (connected tothe column at is top) cooling with

‘water. The distillation column was a cylindrical glass col

uma (inner diameter: 30 mm) which was packed with «

Dickson packing with a diameter of 3 mm toa height of 120

cm (so that the theoretical plate number is 23). Using the

distillation device, methyl t-butyl ether was removed! by

distillation from the second low-boiling component as fle

lows.

[0068] The operating pressure was set to atmospheric

pressure during the distillation. Heating of the distillation

column was carried out by heating the bottom of the flask

with an oil bath, The second low-boiling component was

supplied at @ rate of 1200 g/h to the distillation column,

‘Apart of the distillate condensed in the top condenser was

drained at a rate of 6 wh and the whole amount of the

remainder was fed back tothe distillation column, The inert

components, which were not condensed in the condenser,

were discharged from the device at a rate of 29 gb in the

form of vent gas. The bottom liquid was drained from the

flask at a rate of 1165 g/h and the aie was supplied to the

bottom of the column at a rate of 300 ml/h. When the

concentrations of methyl t-butyl ether and t-butyl alcohol in

«drain obtained from the flask became 2 ppm or fess and

0.09% by weight, respectively, the temperature atthe top of

the column was 62.5° C., the temperature of the bottom

liguid in the flask was 66:5° C., and the methanol concen-

tration in the drain obtained from the flask was 99.8% by

‘weight

EXAMPLE 2

[0069] The same disilation device as used in Example 1

‘was prepared except that a Dickson packing with a diameter

‘of 3 mm was packed in the distillation column to a height of

150 cm (60 thatthe theoretical plate number is27). Using the

distillation device, the methanol in the drain (third high-

boiling component) which had been obtained in Example 1

was purified by as follows.

[0070] The third high-boiling component was supplied at

4 rate of 325 gh to the distillation columa, A distillate

condensed in the top condenser was drained at a rate of

318.5 g/h and the remainder of the distillate was fed back to

the distillation column, The rate of discharging the bottom

liquid from the flask was set to 6.5 gh and a rate of

supplying the air from the bottom of the column was set to

the same as in Example 1. When the concentrations of

‘methyl t-butyl ether and Cbutyl alcohol in a distillate

became 2 ppm or less and 3 ppm, respectively, the tempera-

US 2002/0188151 AL

ture at the top of the column was 64.5° C., the temperature

ff the bottom liquid in the flask was 68.5° C., and the

methanol concentration in the distillate was 99.9% by

‘weight.

[0071] Production of methyl methacrylate was cartied out

by performing an esterification of the methanol obtained

above as the distillate with a methacrylic acid reagent

(special grade, manufactured by Woko Pure Chemical

Industries, Ltd.) Specifically, the esterification was carried

‘out as follows.

[0072] A solution comprising 20% by weight of the

‘methanol obtained above as the distillate ane 80% by weight

‘of the methacrylic acid reagent was prepared. Also, a fixed

bed reactor made of 3048S and having 24 mm in inner

diameter and 500 mm in height was prepared. The fixed bed

\was packed with an jon exchange resin DUOLITE (manu-

factured by Sumitomo Chemical Co., Ltd.) as an esterifica-

tion catalyst. The solution of the methanol and the meth-

acrylic acid reagent was supplied under the pressure of 245

KPa into the bottom of the fixed bed reactor to conduct the

esterification, while maintaining the reactor ata temperature

‘of 80° C, The resulting reaction product was purified by

distillation o obtain a methyl methacrylate. The conversion

‘of methacrylic acid to methyl methacrylate was from 47% to

48%, The concentrations of impurities contained in the

methyl methacrylate were obtained by gas chromatographic

analysis, whieh are shown in Table 1.

COMPARATIVE EXAMPLE 1

[0073] ‘The same process as in Example 2 was carried out

‘except that, instead of the methanol obtained in Example 2

2 the distillate, a special-grade methanol (manufactured by

Woko Pure Chemical Industries, Lid.) was used to obtain a

methyl methacrylate. The conversion of methacrylic acid to

methyl methacrylate was from 47% to 48%. The concen-

trations of impurities contained in the methyl methacrylate

were oblained by g2s chromatographie analysis, whieh are

showa ia Table 1

[0074] ‘The results in Table 1 show that, by using a

‘methanol recovered and purified from the eatalytie decom-

position of methyl t-butyl ether, the same grade of methyl

methacrylate which contains a slight amount of impurities

‘was obtained as that obtained using the special-grade metha-

nol reagent

TABLE 1

Metiyl Methyl

eBuyl busy bul

lepustien __ouaslee (3) _senbol (6) ether) ether (3)

Banple1 oom acon

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- United States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchDocument11 pagesUnited States Patent: MG, Christopher Lbecke, (58) Field of Classification SearchAkbarNo ratings yet

- Figil: %nen 2NES 3Document3 pagesFigil: %nen 2NES 3AkbarNo ratings yet

- US1957244ADocument2 pagesUS1957244AAkbarNo ratings yet

- Daftar Pustaka KorosiDocument1 pageDaftar Pustaka KorosiAkbarNo ratings yet

- Azas Teknik Kimia 1 122111Document2 pagesAzas Teknik Kimia 1 122111Akbar100% (1)