Professional Documents

Culture Documents

Asme B36.10 - 2018

Uploaded by

ZakirUllah0 ratings0% found this document useful (0 votes)

195 views36 pagesOriginal Title

ASME B36.10_2018

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

195 views36 pagesAsme B36.10 - 2018

Uploaded by

ZakirUllahCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 36

NST ey yl ie}

(Revision of ASME B36.10M-2015)

Welded and

Seamless

Wrought Steel

Pipe

AN AMERICAN NATIONAL STANDARD

Cs) PS

Mechanical Engineers

ASME B36.10M-2018

Corer Cn acc arte)

Welded and

Seamless

Wrought Steel

Pipe

AN AMERICAN NATIONAL STANDARD

WY

CS The American Society of

Pee hte Two Park Avenue * New York, NY * 10016 USA

Date of Issuance: October 12, 2018

This Standard will be revised when the Society approves the issuance of 2 new edition.

Periodically certain actions of the ASME 832 Committee may be published as Cases. Cases are published on the ASME website

under the B32 Committee Page at http://g0.asme.org/832committee as they are issued

Errata to codes and standards may be pasted on the ASME website under the Committee Pages to provide corrections to

incorrectly published items, orto correct typographical or grammatical errorsin codes and standards. Such errata shall be used

fon the date posted,

The 832 Committee Page can be found at http://go.asme.org/832committee. There is an option available to automatically

receive an e-mail notification when errata are posted to a particular code or standard. This option can be found on the

appropriate Committee Page after selecting “Errata” in the “Publication Information” section.

ASME isthe regstered trademark of the American Society af Mechanical Engineers.

‘This code or standard was developed under procedures accredited as meting the criteria for American National Standards, The Standards

Committee that approved the cae or standard was balanced to assure that indviduals from competent andconcemmed interests havehad an

‘opportunity to participate. The propased cade or standard was mad available for publi eview and comment that provides an opportunity

{or additional public input fom industry, academia, regulatory agencies, and the publi-at-large.

[ASME does nat “approve” “rate,” or “endorse” any item, construction, proprietary device, or activity

[ASME doesnot take any position with respect tothe validity of any patent rights asserted in connection with any tems mentioned inthis.

document, and does not undertake to insure anyone utilzinga standard against lability fr infringement of any applicable letters patent, nor

assume any uch ability. Users ofa code orstandardare expressly advised thatthe determination ofthe validity of any such patertrights, and

‘the risk of infengement of such rights, is entirely their ov responsiblity

Participation by federal agency representatives) or persons) affliated with industry isnot to be interpreted as govexnment or Industey

‘endorsement of this code or standarc

[ASME accepts responsibilty for only those interpretations of this document isued in accordance with the established ASME procedures

and polices, which precludes the issuance of interpretations by individuals

[No part of this document may be reproduced in any form,

Inan electronic retrieval system or otheruis,

without the prior written permission of the publisher.

The American Society of Mechanical Engineers

‘Two Park Avenue, New York, NY 10016-5990

Copyright © 2018 by

‘THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

Al rights reserved

Printed in USA

CONTENTS

Foreword... wv

Committee Roster vi

Correspondence With the B32 Committee . vil

1 Scope se... 1

2 SMO oo eeeeeeeeeeeeeee 1

3 Materials 1

4 Wall Thickness 1

8 Welghts/Masses .. 4

6 Permissible Variations . 1

7 Pipe Threads .. 1

8 Wall-Thickness Designations . 1

9 Wall-Thickness Selection . 2

Table

a Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe 3

FOREWORD

In March 1927, the American Standards Association (ASA) authorized the organization of a Sectional Committee on

Standardization of Dimensions and Material of Wrought Steel and Wrought Iron Pipe and Tubing for the purpose of

unifying the standards of these commodities in force in this country. The American Society for Testing and Materials

(ASTM) and The American Society of Mechanical Engineers (ASME) were designated as sponsors, and the first meetingof

the Sectional Committee was held in Pittsburgh, Pennsylvania, on May 18, 1928,

‘The dimensions of commercial pipe in general use in the United States, at the time, conformed rather generally to those

recommended by the ASME Committee on Standard Pipe and Pipe Threads published in 1886 (ASME Transactions, Vol.

VILL p. 29), On these standards, an enormous industry has been built and the satisfactory use ofthis product proves the

soundness of the original design and specification.

Increasingly severe service demands, at the time of the Committee's organization, had been met by using the nearest

available pipe or tubing for heavier sections such as casing and mechanical tubing, with resulting uneconomical mult

plicity of wall thicknesses.

Subsequently, the Committee, with the cooperation of the industry,completedasurvey of existing practiceasthe logical

starting point for the development ofan American Standard. From this survey, table was designed to providea selection

‘of wall thicknesses of pipe to cover the power piping requirements of industry where strength to resist internal pressure

governs selection and was later expanded to include pipe diameters and thicknesses used in other industries.

‘The original intent of the Committee was to establish a system of Schedule Numbers for pipe size/wall thickness

combinations that would have an approximately uniform relationship equal to 1,000 times the P/S expression contained

in the modified Barlow formula for pipe wall thickness that was defined in the Appendix to this Standard, The resulting

Numbers departed so far from existing wal thicknesses in common use thatthe original intent could not be accomplished

‘The Schedule Numbers were then adopted strictly as a convenient designation system for use in ordering.

Inall cases, the designer must base his selection on the rules and allowable stresses set by the code that governs his

particular construction, The table is dimensionally complete forall sizesand wall thicknesses withinits cope, but some of

the larger, heavier wall sections are heyond the capability of seamless mill production and must be obtained from forged

and bored billets or other sources.

‘The firstissue ofthis Standard was designated American Standard “tentative” by ASA in November 1935, Subsequent

slight revisions to the table and the foomotes of the dimensional tables were approved and the ASA changed the des-

ignation to American Standard; the date of ASA approval was April 28, 1939.

Further revisions were made by the Sectional Committee. The ist of specifications in the table was revised where

necessary and slight revisions in wall thicknesses of some of the large sizes ofthe heavy schedules were made where P/S

values were out of line

twas the hope in 1939 that the designation of pipe used commercially by all industry as Standard weight, Extra-Strong,

and Double Extra-Strong would gradually be replaced by Schedule Number designation, However, owing to customs of

‘over 50 years’ standing, demand and production of pipe t these traditional dimensions was undiminished. Consequently,

in response to a demand! from users, accepted practice for dimensions and weights of commercial wrought steel and

‘welded wrought iron pipe were added. These changes were designated an American Standard on February 23, 1950.

Subcommittee No. 1 was reorganized in 1957. In addition to necessary editorial changes, a simplified format was

selected for the tables of weights and dimensions to include and identify the sizes and weights of API Standards SL and

SLX. These changes to the Standard were approved and it was designated an American Standard on December 21, 1959.

“The Standard was revised in 1969 to include uniform method to calculate the plain end weight of steel pipe and minor

adjustments were made in the tabulated weights of steel pipe to conform to this new method. Additional sizes and

thicknesses of steel pipe that had come into common use were also added. Inasmuch as API Standard SL no

longer included wroughtiron pipe, reference to that Standard wasdeleted. These changesto the Standard were approved

and it was designated an American National Standard on February 3, 1970.

‘The Standard was revised in 1975 to include additional sizes and thicknesses of steel pipe that had been added to API

specifications. The table with dimensions and weights of welded wrought iron pipe was deleted in its entirety since

wrought iron pipe is no longer produced. These changes in the Standard were approved and it was designated an

‘American National Standard on June 5, 1975,

‘The Standard was revised in 1978 to include 1 metric dimensions. The outside diameter and wall thicknesses were

converted to millimeters by multiplying the inch dimensions by 25.4, Outside diameters larger than 16 in. were rounded

to the nearest millimeter, and outside diameters 16 in. and smaller were rouncied to the nearest 0.1 mm, Wall thicknesses

‘were rounded to the nearest 0.01 mm. These converted and rounded SI metric dimensions were added. A formula to

caleulate the SI metre plain end mass, in kilograms per meter, using SI metric diameters and thicknesses was added. The

SI metric plain end mass was calculated and was added. These changes in the Standard were approved and it was

designated an American National Standard on July 18, 1978.

Further revisions were made in 1984, The American National Standards Institute (ANSI) designations, which are no

longer in use, were deleted, and the list of specifications was revised to agree with current ASTM and APL specifications.

Additional sizes and thicknesses that had heen added to APL specications were added, That edition was approved as an

‘American National Standard on August 19, 1985,

The next edition included additional wall thicknesses and was approved by ANSI on August 24, 1995,

‘The 1996 edition contained table revisions that included the addition of pipe sizes, changing some plain end weights

‘and masses, identifying metric pipe by the dimensionless designator DN, and eliminating the APL Specification caluran in

one table. The 1996 edition was approved as an American National Standard on September 23, 1996,

‘The 2000 edition contained revisions to the density for steel that was incorporated previously. Other editorial changes

to the sections were made, The 2000 edition was approved as an American National Standard on December 1, 2000.

‘The 2004 edition contained revisions that corrected the equation for nominal plain end weight and added the missing

DN schedlule numbers. The 2004 edition was approved as an American National Standard on June 23, 2004.

‘The 2015 edition contained revisions to table notes and references. The 2015 edition was approved as an American

National Standard on june 16, 2015.

‘The 2018 edition expands Table 2-1 (formerly Table 1) by adding Schedule 160.and Double Extra Strong (XXS) rows for

NPS % (DN 6), NPS % (DN 8), and NPS % (DN 10); these data were adapted from ASME B16.11-2011. A plain end weight

(mass) has been changed in Table 2-1 anda number of editorial revisions have been madett Table 2-1 and sections 1,2,5,

7, and 8. The 2018 edition was approved as an American National Standard on September 6, 2018.

ASME B32 COMMITTEE

Metal and Metal Alloy

Wrought Mill Product Nominal Sizes

(The following isthe roster ofthe Committee a te tne of approval af this Standard)

STANDARDS COMMITTEE OFFICERS

FW. Tatar, Choir

ALR Am

STANDARDS COMMITTEE PERSONNEL

ALR Amaral, The Amorican Society of Mechanical Engineers M. L Naya, NICE

D. 0, Bankston, Jr, Bechte ALP. Rangus, Bechtel

D. Frikken, Hecht Engineering Co RE Reamy, Turner Industries Group

JA. Gruber, | Gruher & Associates FW, Tatar, EM Global

RA. McLeod, General Electric Co

CORRESPONDENCE WITH THE B32 COMMITTEE

General. ASME Standards are developed and maintained with the intent to represent the consensus of concerned

Interests. As such, users of this Standard may interact with the Committee by requesting interpretations, proposing

revisions or a case, and attencling Committee meetings. Correspondence should be addressed to:

Secretary, B82 Standards Committee

‘The American Society of Mechanical Engineers

‘Two Park Avenue

New York, NY 10016-5990

hitp://goasmeorg/Inquiry

Proposing Revisions. Revisions are made periodically to the Standard to incorporate changes that appear necessary

or desirable, as demonstrated by the experience gained from the application of the Standard. Approved revisions will be

published periodically.

The Committee welcomes proposals for revisions to this Standard, Such proposals should be as specific as possible,

citing the paragraph number(s), the proposed wording, and a detailed description of the reasons for the proposal,

including any pertinent documentation.

ProposingaCase. Cases may be issued to provide alternative rules wien justified to permit early implementation of

an approved revision when the need is urgent, of to provide rules not covered by existing provisions. Cases are effective

immediately upon ASME approval and shall be posted on the ASME Committee web page.

Requests for Cases shall provide a Statement of Need and Background Information. The request should identify the

Standard and the paragraph, figure, or table number(s), and be written as a Question and Reply in the same format as

existing Cases, Requests for Cases should also indicate the applicable edition(s) ofthe Standard to which the proposed.

Case applies.

Attending Committee Meetings. The 132 Standards Committee regularly holds meetings and or telephone confer-

ences thatare opento the public. Persons wishing to attend any meeting and/or telephone conference should contact the

Secretaty ofthe B32 Standards Committee. Future Committee mecting datesand locations can be foundon the Committee

Page at http://go.asme.org/B32committee.

INTENTIONALLY LEFT BLANK

ASME 836.106.2018

WELDED AND SEAMLESS WROUGHT STEEL PIPE

1 SCOPE

‘This Standard covers the standardization of dimensions

of welded and seamless wrought steel pipe for high or low

‘temperatures and pressures.

‘The word pipe is used, as distinguished from tube, to

apply to tubular products of dimensions commonly

used for pipeline and piping systems.

2 SIZE

‘The size of all pipe in Table 2-1 Is identified by the

dimensionless designator nominal pipe size (NPS)

[diamatre nominal (DN)]. Pipe NPS 12 (DN 300) and

smaller have outside diameters numerically larger than

their corresponding sizes, In contrast, the outside

diameters of tubes are numerically identical to the size

number for all sizes,

‘The manufacture of pipe NPS % (DN 6) to NPS 12 (DN

300}, inclusive, is based on a standardized outside

diameter (0.D.). This 0.D. was originally selected so

that pipe with a standard 0.D. and having a wall thickness

that was typical of the period would have an inside

diameter (ILD.) approximately equal to the nominal

size. Although there is no such relation between the

existing standard thickness — O.D. and nominal size —

these nominal sizes and standard 0.D.s continue in use

as “standara.”

The manufacture of pipe NPS 14 (DN 350) and larger

proceeds on the basis of an 0.D. corresponding to the

nominal size.

3 MATERIALS

‘The dimensional standards for pipe deseribed here are

for products covered in ASTM specifications.

4 WALL THICKNESS:

‘The nominal wall thicknesses are given in Table 2-1

5 WEIGHTS/MASSES

‘The nominal weights (masses) of steel pipe are caleu-

lated values and are tabulated in Table 2-1,

‘The nominal plain end weight, in pounds per foot, is

calculated using the following formula:

We = 10.69(D ~ Ot

where

D = outside diameter to the nearest 0.001 in. (the

symbol D is to be used for O.D. only in mathe-

matical equations or formulas)

¢ = specified wall thickness, rounded to the nearest

0.004 in

W,. = nominal plain end weight, rounded to the

nearest 001 Ib/tt

The nominal plain end mass, in kilograms per meter, is

calculated using the following formula:

Mpe = 00246615(D ~ t

where

D = outside diameter to the nearest 0.1 mm for

outside diameters that are 16 in, (406.4 mm)

and smaller and to the nearest 1.0 mm for

outside diameters larger than 16 in. (406.4

mm) (the symbol D is to be used for 0.D,

‘only in mathematical equations or formulas)

nominal plain end mass, rounded to the nearest

0.01 kg/m

specified wall thickness, rounded to the nearest

0.01 mm

6 PERMISSIBLE VARIATIONS

Variations in dimensions differ depending upon the

method of manufacture employed in making the pipe

to the various specifications available. Permissible varia

tions for dimensions are indicated in each specification

7 PIPE THREADS

Unless otherwise specified, the threadsof threaded pipe

shall conform to ASME B1.20.1, Pipe Threads, General

Purpose (Inch).

Schedules § and 10 wall thicknesses do not permit

threading in accordance with ASME B1.20.1

8 WALL-THICKNESS DESIGNATIONS

‘The wall-thickness designations Standard, Extra

Strong, and Double Extra-Strong have been commercially

used designations for many years. As explained in the

Foreword, the Schedule Numbers were subsequently

added as a convenient designation for use in ordering.

pipe. Standard and Schedule 40 are identical for up to

NPS 10 (DN 250), inclusive. all larger sizes of Standard

have % in, (9.53 mm) wall thicknesses. Extra-Strong

and Schedule 80 are identical for up to NPS 8 (DN

200, inclusive. ll larger sizes of Extra-Strong have Ys

in, (12.70 mm) wall thicknesses.

Pipe of sizes and wall thicknesses other than those of

Standard, Bxtra-Strong, and Double Extra-Strong, and

Schedule Number, were adopted from API Specification

ASME 136.10M-2018

BL, Line Pipe, It was not considered practical to establish

Schedule Numbers or new designations for them.

9 WALL-THICKNESS SELECTION

When the selection of wall thickness depends primarily

upon capacity to resist internal pressure under given

conditions, the designer shall compute the exact value

of wall thickness suitable for conditions for which the

pipe Is required, as prescribed in detail in the ASME

Boiler and Pressure Vessel Code, ASME B31 Code for

Pressure Piping, or other similar codes, whichever

governs the construetion, A thickness shall be selected

from Table 2-1 to suit the value computed to fulfill the

conditions for which the pipe is desired,

ASME 836.106.2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steet Pipe

‘outside ‘watt aim Ena

NPs identification Schedule Diameter, “Thickness, Welght (as),

oN) note CO) No. in. (om) fa. (um) yf g/m)

0 10 ‘405 (103) 049 (1.24) 019 (028)

4o x0 ‘040s (103) 0057 (2.45) 021 (022)

4O ‘STD 40 0.405 (10.3) (0.068 (1.73) 0.24 (037)

‘0 xs 80 0405 (103) (0095 (241) 031 (047)

4O 150 (0405 (103) 0:24 (315) 037 (056)

% 2s 0.405 (10.3) 0.190 (4.83) 0.44 (0.65)

‘“@) 10 0.540 (13.7) 0.065 (1.65) 033 (049)

4@) 30 0540 (137) 0073 (285) 036 (054)

4) so 40 0540 (137) 0.088 (2.24) 043 (063)

xe xs 0 0540 (132) 0119 (202) 054 (080)

%@ 160 9540 (137) 0115 (3.68) 061 (091)

% (8) Os 0540 (13.7) 0.238 (6.05) 0.77 (LAN)

% a0) 10 0675 (172) 0065 (1.65) 042 (063)

* 00 30 0.675 (17.1) 0.073 (1.85) 0.47 (0.70)

00) sto 40 0675 (171) 0091 230) 057 (084)

% an xs 0 0675 (17.1) 03126 (320) 074 (1.40)

00 190 9675 (17.1) 0.159 (401) 087 (129)

% (a0) xs 0675 (172) 0252 (640) 14 (169)

408) 5 940 (213) 0.055 (265) 054 (080)

4.05) 10 ‘9940 (213) 0093 (211) 1967 (1.00)

405) 30 0840 (213) 6095 (241) 076 (142)

% (5) STD 40, 0.840 (21.3) 0.109 (2.7) 085 (1.27)

405) xs 80 0.840 (21.3) 0.147 (3.73) 1.09 (1.62)

(15) 160, 0.840 (21.3) 0.188 (4.78) 131 (1.95)

‘4 (5) OS 0.840 (21.3) 0.298 (747) 172 (255)

% (20) 5 1.050 (26.7) 0,065 (1.65) 0.68 (1.02)

%@0) 20 1.050 (262) o0e3 (21) 096 (1.28)

50) 30 1.050 (262), 0095 (241) 097 (La)

% 0 so 40 1.050 (267), 0113 (287) 13 (169)

20) xs 80 2.050 (267) 54 (392) 1.49 (220)

420 160, 1,050 (26.7) 0.219 (5.56) 1,95 (2.90)

en) as 1.050 (267), 0308 (7.82) 28 (64)

105) s sans (334) 0065 (2.65) 087 (129)

105) » 1315 (334) 6109 (2.77) 141 (209)

1.05) 20 215 (24) 144 (290) 246 (208)

105) sto 40 1318 (334) 0133 (838) 1.68 (250)

105) xs 0 sa1s 034) 0.179 (455) 217 (224)

1.25) 100 1315 (33.4) 0250 (635) 285 424)

105) axs 1315 34) 0358 (9.08) 3.66 (545)

1% 02) 5 1.660 (42.2) 0.085 (1.65) 1.1 (165)

1,02) 10 1.660 (622), 0109 (277) 1081 (269)

1.02) 30 1.660 (822), 117 297) 193 (287)

ASME 136.10M-2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Plain End

ps Identification Schedule Diameter, Weight (Mass),

on [Note (2)) No in, (rm) 1/8 (kg/mm)

1% G2) stb 0 1.660 (42.2) 0.140 (256) 227 (3.39)

1A G2 xs 80 1.660 (42.2) 0.191 (485) 1300 (4.47)

(32) 160 1.660 (42.2) 0.250 (635) ATT (5.61)

1%4 (32) was 1.660 (42.2) 0382 (9.70) 5:22.77)

1% (40) 5 1.900 (48.3) 0.0685 (1.65) 1.28 (1.90)

1% (40) 10 1.900 (49.3) 0.109 (277) 209 (2.11)

VA (40) 0 11900 (48.3) 0.25 (2.18) 237 (3.53)

1% (40) sro 0 1.900 (48.3) 0.145 (3.68) 272 (4.05)

1% (40) xs a0 1.900 (48.3) 200 (5.08) 363 (6.41)

1% (40) 160 1.900 (48.3) 0281 (7.18) 46 (725)

1% (40) 1s 1.900 (38.3) 400 (10.15) 641 (9.55)

260) s 2375 (603) 0.065 (1.65) 1.61 (229)

260) . 2375 (603) 0.083 (211) 203 (8.08)

260) 10 2375 (603) 0.109 (277) 2.64 (3.93)

260) 30 2375 (603) 0.25 (318) 301 (4.49)

260) 2375 (603) 0.141 58) 337 01)

250) sto 00 2375 (60:3) 0154 (391) $366 (5.49)

260) 2375 (60.3) 0.172 (437) 4405 (6.03)

250) 2375 (603) 0.188 (4.78) 440 (654)

260) xs 80 2375 (603) 0.218 (558) 503 (7.48)

2 (60) 2375 (603) 0.250 (635) 5.68 (8.45)

260) . 2375 (603) 0281 (7218) 6290.0)

260) 160 2375 (603) 0344 (874) 7a7 (4.1)

260) as 2375 (603) 0.436 (1107) 904 (13.44)

2% (65) 5 2075 (730) 083 (211) 248 (3.69)

2 (65) 2875 (730) 0.109 (277) 322 (4.80)

2% (65) 10 2875 (730) 0.20 (2.05) 353 (5.26)

2% (65) 2875 (73.0) 0.125 (3.18) 367 (6.48)

2% (65) 2875 (730) 0.141 (358) 422 613)

24 (65) 2875 (730) 0.156 (3.96) 453 06.7)

2% (65) . 2875 (73.0) 0.172 (437) 497 (7.40)

2% (65) 20 2475 (730) 0.188 (4.78) 540 (#08)

24 (65) sto 30 2875 (730) 0.203 (5.16) 580 (8.53)

2% (65) 2875 (730) 0.216 (549) 624 (0.14)

2% (65) 2875 (73.0) 0.250 (635) 702 (1044)

2% (65) xs a0 2975 (730), 0276 (7.01) 767 (14.41),

2% (65) 160 2875 (73.0) 0.375 (953) 1002 (1492)

2% (65) xs 2975 (739) sz (1402) 1371 (2039)

(40) 5 3500 (@89) 083 11) 303 (4.52)

ASME 836.106.2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Wall lain End

NPs Identification Schedule Diameter, “Thickness, Weight (Mass),

ow Note (1 No in, (mm) in. (cum) 1 (g/m)

3 (0) 3500 (889) 0.109 (2.77) 395 (588)

360) 10 3500 (888) 0.120 (305) 434 (640)

3 20) 53500 (88) 0125 (3.18) 451 (672)

3 (60) 3500 (88.9) 0.181 (358) 506 (753)

23 @0) 3.500 (888) 0.156 (396) 550 (8:0)

3 (60) 3500 (889) 0172 (437) 642 (941)

3 €€0) 30 3500 (#83) 0.189 (4.70) 6.66 (992)

360) st 40 3500 (889) 0.216 (549) 758 (11.29)

30) 3500 (889) 0.250 (635) 869 (1293)

3 a0) 3500 (889) 0.281 (7.4) 9657 (1440),

30) xs 80 3500 (888) 0.300 (7.62) 1026 (1527)

3 (€0) 160 3500 (889) 0438 (11:3) 1434 (2135)

23 (@0) xs 3500 (989) 0.600 (15:24) 18.60 (27.68),

3% (90) 5 4.000 (101.6) 0.083 (2.13) 30 (528)

34 (90) 4.000 (101.6) 0.109 (2.77 453 (675)

3, (0) 10 4.000 (101.6) 0.120 (3.05) 498 (741)

34, (00) 4.000 (101.6) 0.125 (3.18) 5:18 (772)

24, (20) 4.000 (101.6) 0.181 (358) 582 (8.65)

3%, (0) 4.000 (101.6) 0.156 (3.96) 641 (954)

3% (00) 4.000 (101.6) 0.172 (437) 7.04 (10.48)

3¥%, (90) 30 4.000 (101.6) 0.188 (4.78) 76 (11.41)

34 (90) st 40 4.000 (101.6) 0.226 (5278) 942 (135)

3% (0) ‘4000 (101.6) 0.250 (635) 1002 (1492)

3% (00) 4.000 (101.6) 0281 (7.14) 1127 (1668)

2% (90) xs 80 44.000 (101.6) 418 (Bon) 1282 (1868)

4200) 5 4500 (1143) 83 (221) 392 (584)

(100) 4500 (1143) 0.109 (2.77) 5:2 (762)

4 (200) 10 4500 (1143) 0.120 (3.05) 562 (8.37)

4200) 4500 (1143) 0.125 (310) 585 (871)

400) 4500 (1143) 0.141 (358) 657 (9.78)

4200) 4500 (1143) 0.155 (3.96) 724 (1078)

$200) 44500 (1143) 0172 (437) 796 (11.85)

+ (200) 30 4500 (1143) 0.188 (4.78) 857 (1291)

400) 4500 (1143) 0.203 (516) 9.32 (1389)

4100) 44500 (114.3) 0.219 (556) 1902 (1491),

# (200) stb 40 4500 (1143) 0.237 (602) 1030 (16.08),

#00) 4500 (1143) 0.250 (635) 11.36 (1691)

#200) 4500 (1143) 0.281 (7.4) 1267 (1887)

(200) 4500 (1143) 0.312 (792) 1397 (2078)

ASME 136.10M-2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Plain End

ps Identification Schedule Diameter, Weight (Mass),

on [Note (i)} No. in. (ou) 1 /R (g/m)

4 (100) x 80 44500 (1143) 0337 (856) 15.00 (22.32)

4 (100) 0 44500 (1143) 0438 (11413) 1902 (20.32)

4 (400) 160 44500 (114.3) 531 (1349) 2282 (2358)

400) sas 44500 (1143) 674 (17.12) ars (41.03)

5125) . 5563 (141.3) 0.083 (211) 496 (7.24)

5125) 5 5563 (141.3) 0.109 (2.77) 636 0.46)

523) 5.563 (141.3) 0.25 (3.18) 727 (1083)

5.425) 10 5563 (141.3) 0.134 (3.40) 778.1156)

52s) 5565 (141.3) 0.156 (396) 902 (13.41)

5125) 5563 (141.3) 0.18 (4.78) 10.80 (1609)

525) ° 5563 (141.3) 0.219 (556) 1251. (861)

5125) smo 0 5563 (141.3) 0258 (655) 34.63 (21.77)

5125) 5563 (141.3) 0201 (714) 35.87 (23.62)

523) 5563 (142.3) 0312 (7.92) 1751 (2605)

5.25) 5563 (141.3) 0344 (878) 19.19 (2857)

5125) x 80 5563 (141.3) 0375 (953) 2na0 (9097)

5025) 120 5563 (141.3) 1.500 (12.70) 27.06 (40.28)

525) 160 5563 (141.3) 0.625 (15.88) 32.99 (49.12)

5125) xs 5563 (141.3) 10750 (19.05) 3859 (6743)

6 (150) 66.65 (168.3) 0083 (211) 5.0 (8.65)

630) 5 6.625 (1683) 0.109 (277) 759 (131)

650) 6625 (1683) 0.125 (8.18) 869 (12.95),

6150) 10 65625 (108.3) 0.134 (340) 930 (1383)

6 (150) 16625 (168.3) 0.141 (358) 9.77 (1458)

650) 65625 (1683) 0.156 (2.96) 1079 (1605)

650) 6625 (1683) 0.172 (437) a1g7 (1767)

6 (450) 6.625 (1683) 0.18 (4.78) 1294 (1928)

6 (150) 66625 (168.3) 0203 (5.16) 1394 (2076)

650) 6625 (168.3) 0219 (556) 3500 (22.1)

650) . 6.625 (1683) 0250 (635) 17.06 (2536)

61150) sto 40 15.625 (168.3) 0.280 (711) 18:99 (2826)

6 (50) 15025 (168.3) 0312 (792) 21.06 (31.33)

650) 6625 (1683) 0344 (874) 23.10 (349)

6 (150) 65625 (1683) 0395 (953) 2505 (97.81)

6 (150) xs 80 6.625 (1683) 432 (1097) 2a.60 (4255)

6150) 6.625 (1683) 1500 (12.70) 32.74 (48.73)

61130) 20 6.625 (1683) osez (1427) 3643 (5421)

61150) 6.625 (168.3) 0.65 (15:88) 40.09 (59.69)

ASME 836.106.2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Wall lain End

NPs Identification Schedule Diameter, “Thickness, Weight (Mass),

(oxy Note (3)1 No. in, (mm) in. (um) TR (hg/m)

6 (50) 160 (66525 (168.3) 0719 (1826) 4539 (6757)

6 (50) ‘6625 (1603) 0750 (1905) 4720 (70.12)

6 (50) was 16525 (1683) 0.966 (21.95) 53.21 (7922)

650) (6625 (1683) 0975 (2223) 53.78 (80.08)

8 (200) 5 18625 (219.1) 0.109 (2.77) 992 (1478)

8 (200) 18625 (219.1) 0125 (3.18) 1126 (1693)

8 (200) 10 18.625 (219.1) 0.148 (3.76) 3341 (1997)

8 (200) £8625 (219.1) 0.156 (3.96) M42 (210)

8 (200) ‘8625 (219.1) 0.188 (4.78) 1696 (2526)

8 (200) 18625 (219.1) 0.203 (6.16) 928 (2722),

8 (200) ‘8625 (219) 0.219 (550) 19.68 (2828)

8 (200) 20 £8625 (219.1) 0.250 (635) 22.38 (98.32)

8 (200) 30 18625 (219.1) 0277 (708) 24.72 (2682)

8 (200) ‘8625 (219.4) 0312 (7.92) 27.73 (4125)

8 (200) st “0 £8625 (219.1) 0322 (6.18) 28.58 (42.5)

8 (200) 18625 (219.1) 0.344 (874) 8045 (45:34)

8 (200) 18625 (219.1) 0.375 (953) 307 (4925)

8 (200) «0 18625 (219.1) 0.406 (1031) 35.67 (58.09)

8 (200) 18625 (219) 0438 (11.13) 3833 (57.08)

8 (200) xs 80 18625 (219.1) (0500 (12:70) 43.43 (64.64)

8 (200) ‘9625 (219) 62 (1427) 40.48 (72.00)

8 (200) 100 £8625 (219.1) 0594 (15:09) 51.00 (752)

8 (200) 8625 (219.1) 0.625 (1588) 53.45 (79.59)

8 (200) 120 18625 (219.1) 0.719 (1826) 60.77 (90-44)

8 (200) 18625 (219.1) 0750 (1905) 63.14 (9898)

8 (200) 140 18625 (219) 812 (2062) 6782 (10083)

8 (200) xs 18625 (219.1) 0975 (22:28) 72.49 (107.93)

8 (200) 160 18625 (219.1) 0.906 (23.01) 74.76 (11127)

8 (200) ‘8625 (219) 1.000 (25.40) 15 (12133)

10 50) 5 10750 (2730) 0134 (3.40) 1521 (2261)

10 250) 103750 (2730) 0.155 (3.96), 1767 (2627)

10 (250) 10 10750 (2730) 0.165 (419) 1867 (27.78)

10 250) 102750 (2730) 0.188 (4.78) 21.23 (31.62)

10 @50) 10250 (2730) 0.208 (6.16) 22.89 (34.08)

10 50) 10,750 (2730) 0219 (556) 24.65 (3667)

10 (250) 20 103750 (2730) 0.250 (638) 2806 (41.76)

10 50) 10.750 (2730) 0.279 (7.09) 3.23 (4649)

10 50) 30 10750 (273.0) 0.307 (7.80) 3427 (S101)

ASME 136.10M-2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside ‘Wal Plain End

ps Identification Schedule Diameter, Thickness, Weight (Mass),

on [Note (i)} No. in. (ou) in. (a) A (g/0)

10 (250) 10750 (2730) 0344 (874) 3827 (5695)

10 (250) sro a0 10750 (2730) 0365 (927) 8082 (6029)

10 (250) 10.750 (2730) 4 (11.13) 4928 (71.89)

10 (250) xs 60 10750 (2730) 0500 (12.70) 54.79 (0153)

10 (250) . 10750 (2730) 0562 (1427) 1.21 (9105)

10 (250) 80 10750 (2730) 0.594 (15.09) 449 (95.98)

10 (250) 10.750 (2730) 0.25 (15:80) 67.65 (100.63)

10 (250) 100 10.750 (2730) 0719 (1826) 730 (11471)

10 (250) 10750 (2730) 812 (20.82) 13626 (128.38)

10 (250) 120 10.750 (2730) nes (2144) 3938 (13301),

10 (250) 10750 (2730) 0.978 (22.23) 9237 (137.48)

10 (250) . 10750 (2730) 938 (23.8) 9839 (14643)

10 (250) 1s 40 10750 (2730) 1.000 (25.40) 10423 (155.10)

10 (250) 160 10750 (2730) 125 (2858) uss (47227)

10 (250) 10750 (2730) 1.250 (31.75) 126.94 (188.90)

12.00) 5 12750 (6238) 0.156 (395) 21.00 (3124)

12 (300) 12750 (6238) 0.172 (437) 23.13 (3443)

12 (300) 10 12750 (6238) 0.180 (457) 24.19 (35.98)

12 (300) 12750 (3238) 0.88 (4.73) 2525 (97.61)

12 (300) 12750 (6238) 0203 (5.16) 2723 (4055)

12 (200) . 12750 (6238) 0219 (556) 2934 (43.08)

12 (300) 20 12750 (923.8) 0.250 (635) 3341 (49.71)

12 (300) 12750 (6238) 0281 (7.14) 3746 (5576)

12 (300) 12750 (6238) 0312 (792) 4148 (6170)

2 G00) wo 12750 (23.8) 0.330 (838) 4381 (65.19)

412 (200) 12750 (2238) 0344 (874) 4562 (679)

12 (300) smo 12750 (923.8) 0.375 (953) 49.61 (73.86)

12 (300) 0 12750 (8238) 406 (10.32) 5357 (971)

12 (300) 12750 (6238) 0438 (1143) 57.65 (05.82)

12 (300) xs . 12750 (6238) 0500 (12.70) 05.48 (97.44)

12 (300) 60 12750 (3238) sez (1427) 73.22 (10893)

12 (300) 12150 (6238) 2.625 (18.89) 101 (12059)

12 (300) 80 12750 (3238) 0.688 (17-48) 83.71 (13205)

12 (300) 12750 (6238) 0750 (19.05) 9621 (143.17)

12 (300) 12750 (6238) oaiz (20.62) 103.63 (154.17)

12 (300) 100 12750 (238) oes (2148) 10742 (159.87)

12 (300) 12750 (8238) 0.875 (22.23) 111.08 (165.83)

42 (300) 12750 (3238) 0.938 (23.8) 13844 (176.29)

ASME 836.106.2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Wall lain End

NPs Identification Schedule Diameter, “Thickness, Weight (Mass),

(oxy Note (3)1 No. in, (mm) in. (mm) T/(hg/m)

12 G00) xs 120 12.750 (3238) 1.000 (25.40) W256 (18692)

12 (00) 12750 (3238) 1.062 (2687) 152.69 (19743)

12,600) 140 12750 (3238) 125 (2888) 139.81 (20808)

12 G00) 12,750 (3238) 1.250 (31.75) 153.67 (228.68)

12,00) 160 12.750 (3238) aa1z (6332) 160.42 (238.69)

14050) 5 14000 (355.6) 0.156 (3.96), 23.09 (24:34)

14.50) 14.000 (355.6) 0.188 (4.78) 27.76 (4136)

14 50) 14000 (355.6) 0.203 (5.16) 29.94 (4459)

14.650) 14000 (355.6) 0.210 (533) 30.96 (4604)

14.650) 14000 (355.6) 0219 (556) 32.26 (48.00)

14.650) 10 14.000 (355.6) 0.250 (635) 36.75 (9409)

14.650) 14.000 (8556) 0.281 (714) 42.21 (6136)

14.50) 20 14.000 (355.6) 0312 (7.92) 45.65 (6791)

14.50) 14.000 (3556) 0.344 (878) 5022 (7476)

14.850) st 30 14.00 (355.6) 0375 (953) 54.62 (81.3)

14.650) 14000 (355.6) 0.406 (1031) 59.00 (87:79)

14.650) 40 14000 (355.6) 0438 (11.13) 63.50 (9455)

14050) 14.000 (355.6) 0.469 (1192) 6784 (10095)

14.650) s 14.000 (355.6) (0500 (12:70) 172.16 (107.40)

14 350) 14000 (355.6) 0562 (1427) 0.73 (120.12),

14.650) «0 14000 (355.6) 0594 (1509) 5.13 (12672)

14.50) 14000 (355.6) 0.605 (1588) 89.36 (133.04)

14.650) 14000 (355.6) 0.688 (17.48) 97.91 (195.76)

14650) 0 14.00 (355.5) 0.750 (1905) 308.23 (158.11)

14.650) 14000 (35556) 12 (2062) 148 (17034)

14 G50) 14.000 (355.6) 0875 (2223) 122.7 (182.76)

1450) 100 14000 (355.6) 0.938 (2343) 130.98 (194.98)

14 G50) 14000 (355.6) 4.000 (25.40) 13897 (20604)

14650) 14000 (355.6) 1062 (2697) 46.00 (21058)

14.650) 120 14.000 (355.6) 41094 (27.79) 150.93 (224.66)

14650) 14000 (355.6) 1125 (2888) 154.84 (280.49)

14 (350) 140 14.00 (355.6) 1250 (31.75) 17037 (253.58)

14.650) 160) 14.000 (355.6) 4.406 (35.71) 99.29 (281.72)

1450) 14.00 (355.6) 2.000 (5030) 256.56 (381.85)

14.650) 114000 (35556) 212s (6298) 269.76 (40152)

14650) 14000 (355.6) 2.200 (55.08) 27751 (413.08)

14.650) 14.000 (2556) 2500 (6350) 30734 (457.43)

16 400) 5 16000 (406.4) 0.185 (4.19) 27.93 (4156)

ASME 136.10M-2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Plain End

ps Identification Schedule Diameter, Weight (Mass),

on [Note (i)} No. in. (ou) Wo /R (g/m)

6 (400) 6.000 (406.4) 0:88 (478) 31.78 (47.34)

16 (400) 16000 (406.4) 0208 (5.16) 34.28 (51.00)

16 (400) 16.000 (406.4) 0.219 (556) 36.95 (5495)

16 (400) 10 16.000 (406.4) 0.250 (6.35) 42.09 (6265)

16 (400) . 160000 (406.4) 0281 (7.18) 47.22 (70.0)

16 (400) 20 16.000 (406.4) 0312 (7.92) 52.32 (77.83)

16 (400) 16.000 (406.4) 0344 (874) srt (05.71)

16 (400) smo a0 160000 (406.4) 0375 (953) 2.64 (9327)

16 (400) 16000 (406.4) 406 (10.31) 67.68 (100.71)

16 (400) 16.000 (406.4) age (11.13) 7286 (108.49)

16 (400) 16.000 (406.4) 0469 (1191) 7787 (11587)

46 (400) xs 0 160000 (406.4) 0500 (12.70) 25 (12331)

16 (400) 16.000 (406.4) sez (1427) 92.75 (138.00)

16 (400) - 16.000 (406.4) 0.25 (15.88) 0272 (15298)

16 (400) 6 160000 (406.4) 0.656 (16.66) 107.60 (160.13)

16 (400) 16000 (406.4) 8.688 (17.48) 112.62 (167.66)

16 (400) 16.000 (406.4) 10.750 (19.05) 12227 (181.98)

16 (400) 16.000 (406.4) 812 (2062) 131.86 (196.18)

16 (400) 80 16.000 (406.4) ages (2148) 13674 (20354)

16 (400) 16.000 (406.4) 97s (22.23) 14148 (210.61)

16 (400) 16.000 (406.4) 0938 (23.83) 151.03 (224.03)

16 (400) 160000 (406.4) 1.000 (25.40) 160.35 (238.66)

16 (400) 100 160000 (406.4) 1.031 (26.19) 164.98 (245.57)

16 (400) 16.000 (406.4) 1.062 (2697) 169.59 (252.37)

16 (400) 16.000 (406.4) 1.125 (2a.sa) 17889 (266.30)

16 (400) - 16.000 (406.4) 1188 (20.18) age 22001)

16 (400) 120 16.000 (406.4) 1219 (90.96) 192.61 (286.66)

16 (400) . 16000 (406.4) 1250 (31.75) 197.10 (29335)

16 (400) 140 16.000 (406.4) 1438 (96.53) 2za9s (93321)

16 (400) 160 160000 (406.4) 1.594 (4049) 24540 (365.38)

18 (450) 5 18.000 (457) 0.165 (419) 3146 (4679)

18 (450) 18.000 (457) 0.8 (4.78) 5.80 (53.1)

48 (450) . 18000 (457) 0219 (556) 1.68 (6190)

16 (450) 10 18.000 (457) 0.250 (6.35) 47.44 (2057)

18 (450) ° 18000 (457) 0201 (7.1) 5323 (7921)

18 (450) 20 18.000 (457) 0312 (7.92) 5299 (07.71)

16 (450) 18000 (457), 0.344 (874) 6493 (9662)

48 (450) sro 18.000 (457) 0375 (953) 70.65 (105.17)

10

ASME 836.106.2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Wall lain End

NPs Identification Schedule Diameter, “Thickness, Weight (Mass),

(oxy Note (3)1 No. in, (mm) in. (mm) To (hg/m)

18 (450) 18:00 (457) (0.406 (1031) 7636 (11358)

1s 450) 30 18.000 (457) 0.438 (11.3) 8223 (12238)

18 (450) 18.00 (457) 0.469 (1191) 7.89 (13093)

18 (450) xs 18.000 (457) ‘0500 (12:70) 9354 (139.26)

18 (450) 0 18.000 (457) 0562 (1427) 104.76 (155.81)

18 (450) 18.00 (457) 0.625 (1588) 31609 (172.75)

18 (450) 18.000 (457) 0.608 (1748) 32732 (19947)

18 450) 0 18.00 (457) 0750 (1905) 188.30 (205.75)

18 450) 18.000 (457) 0912 (2062) 149.20 (22191)

18 450) 18.000 (457) 0.975 (2223) 60.18 (23835)

18 (450) 80 18.000 (457) 0938 (7383) 171.08 (25457)

18 (450) 18.000 (457) 1.000 (25.40) 181.73 (27036)

18 (450) 18.000 (457) ose (2697) 192.29 (286.02)

18 (450) 18.000 (457) 12s (zee) 202.94 (301.96)

18 (450) 100 18,000 (457), 1156 (29.6) 208.15 (309.68)

18 (450) 18,000 (457) 1.188 (30.18) 213.51 (317.68)

18 (450) 18.00 (457), 41250 (31.75) 223.82 (33297)

18 (450) 120 18:00 (457) 1375 (3493) 244.37 (363.58)

18 (450) 140 18.000 (457) 562 (3967) 27448 (40828)

18 450) 160 18.000 (457) 1.701 (4524) 308,79 (459.39)

20 (500) 5 20.000 (508) 0.198 (4.78) 39.082 (99:32)

20 (500) 20.000 (508) 0.219 (556) 4631 (68.89)

20 (500) 10 20.000 (508) 0.250 (635) 52.78 (78.56)

20 (500) 20.000 (508) 0.281 (714) 59.23 (88.19)

20 (500) 20.000 (508) 0.312 (792) 65.66 (97.68)

20 (500) 20.000 (508) 0.344 (874) 72.28 (10761)

20 (S00) st 20 20.000 (508) 0375 (953) 7867 (117.8)

20 (500) 20.000 (508) 0.406 (1031) 85.04 (12654)

20 (500) 20.000 (508) 0438 (11.9) 9159 (13638)

20 (500) 20.000 (508) 0409 (1191) 97.92 (19571)

20 (500) xs 30 20.000 (508) 0500 (12:70) 104.23 (155.13)

20 (500) 20.000 (508) 0562 (1427) 116.78 (17375)

201500) 0 20.000 (508) (0594 (1509) 123.23 (183.43)

20 (500) 20.000 (508) 0.625 (15388) 12045 (192.73)

20 (500) 20.000 (508) 0.608 (17.48) 142.03 (211.45)

20 (500) 20.000 (500) 0.750 (1905) 15434 (229.73)

20 (500) © 20.000 (508) 0.812 (2062) 166.56 (247.84)

20 (500) 20.000 (508) 0875 (2223) 37889 (266.31)

u

ASME 136.10M-2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside ‘Wal Plain End

ps Identification Schedule Diameter, Thickness, Weight (Mass),

on [Note (i)} No. in. (ou) in. (aa) (g/t)

20 (500) 20.000 (508) 0938 (23.83) 191.14 (284.54)

20 (500) 200000 (508) 1.000 (25.40) 208.11 (30230)

20 (500) 80 20.000 (508) 1.031 (2619) 20906 (31119)

20 (500) 20.000 (508) 1.082 (2697) 21500 (31.94)

20 (500) 20.000 (508) 1.125 (28.50) 22700 (93791),

20 (500) 20.000 (508) 1.188 (30.18) 23891 (255.63)

20 (500) : 20.000 (S08) 1.250 (81.75) 25085 (37291)

20 (500) 100 20.000 (508) 12a (2.58) 25634 (381.55)

20 (500) 200000 (S08) 1312 (8332) 262.10 (39005),

20 (500) 20.000 (508) 1375 (2493) 27276 (40751)

20 (500) 120 20.000 (508) 1.500 (38.10) 29665 (441.52)

20 (500) 140 20.000 (508) 1.750 (44.45) 34141 (508.15),

20 (500) 160 20.000 (508) 1.969 (50.01) 27953 (56485)

22 (550) 5 22.000 (559) 0.108 (4.78) 43.84 (6533)

22 (550) 220000 (559) 0219 (658) 50.99 (75.9)

22 (550) 10 22.000 (559) 10250 (635) 58.13 (8655)

22 (550) 220000 (559) 0281 (7.14) 5.24 (97:17)

22 (550) 22.000 (559) 0312 (7.92) 7234 (107.64)

22 (650) ° 22.000 (559) 0.344 (874) 79.64 (118.60)

22 (550) sro 0 220000 (559) 0375 (953) 3669 (129.14)

22 (550) 22000 (559) 0406 (10.32) 9372 (13951)

22 (550) 220000 (559) 0438 (11.13) 100.96 (150.38)

22 (550) 220000 (559) 469 (11.91) 107.95 (160.69)

22 (550) xs 30 22000 (559) 10500 (12.70) 11492 (171.10)

22 (550) 22.000 (559) 562 (14.27) 12879 (191.70)

22 (550) 22.000 (559) 0.625 (15.88) 14281 (212.70)

22 (550) 220000 (559) 0.688 (17-48) 15674 (233.44)

22 (550) 22000 (559) 0750 (19.05) 17037 (253.67)

22 (550) 22.000 (559) oer2 (20.62) 193.92 (273.78)

22 (550) 60 220000 (559) srs (2223) 197.60 (20427)

22 (550) 22000 (559) 0938 (23.83) 2n1a9 14s)

22 (550) 22.000 (559) 1.000 (25.40) 22409 (33625)

22 (550) 22.000 (559) 11062 (2697) 237.70 (353.86)

22 (550) 80 220000 (559) 1.125 (20.50) 251.05 (973.85)

22 (550) 22.000 (559) 1.108 (30.18) 26431 (993.59)

22 (550) 22.000 (559) 1250 (91.75) 27727 (s2.88)

22 (550) : 22.000 (559) 1312 (8332) 290.15 (431.96)

22 (550) 100 220000 (559) 1.375 (24.93) 308.36 (451.45),

az

ASME 836.106.2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside Wall lain End

NPs Identification Schedule Diameter, “Thickness, Weight (Mass),

(oxy Note (3)1 No. in, (mm) in. (mm) To (he/m)

22 (550) 22.000 (559) 1438 (3653) 316.08 (470.69)

22 (550) 22.000 (555) 1.500 (88.10) 32872 (48944)

22 (550) 120 22.000 (559) 1.625 (41.28) 38294 (527.05)

22 (550) 10 22.000 (559) 1875 (47.63) 403:38 (60067)

22 (550) 160 22,000 (559) 2125 (53:98) 45149 (672.30)

24 (600) 5 24.000 (610) 0218 654) 55.42 (82.58)

24 (600) 10 24.000 (610) 0.250 (635) 3.47 (9453)

24 (600) 24.000 (610) 0.281 (7.148) 71.25 (106.15)

24 (600) 24.000 (610) 0.312 (792) 7901 (117.60)

24 (600) 24.000 (610) 0.344 (8274) 1699 (129.60)

24 (600) st 2 24.000 (610) 0375 (953) 9471 (141.12)

24 (600) 24.000 (610) 0406 (1031) 302.40 (15248)

24 (600) 24.000 (610) 0438 (11.13) 110.32 (16438)

24 (600) 24.000 (610) 0469 (1191) 117.98 (175.67)

24 (600) xs 24.000 (610) (0500 (12:70) 12561 (187.07)

24 (600) 30 24.000 (610) 0562 (1427) 40.81 (209.65)

24 (600) 24.000 (610) (0525 (1588) 156.17 (28267)

24 (600) “0 24.000 (610) 0.688 (17.48) 17145 (255.43)

24 (600) 24.000 (610) (0750 (1905) 18643 (277.63)

24 (600) 24.000 (610) 0812 (2062) 201.28 (299.71)

24 (600) 24.000 (610) 0.975 (2223) 21st (32223)

24 (600) 24.000 (610) 0.938 (2383) 231.25 (344.48)

24 (600) « 24.000 (610) 0969 (2461) 238.57 (355.28)

24 (600) 24.000 (610) 1.900 (25.40) 245.87 (366.19)

24 (600) 24.000 (610) 1.062 (2697) 260.41 (287.79)

24 (600) 24.000 (610) 1.425 (2858) 27520 (40980)

24 (600) 24.000 (610) 1.108 (30.18) 299.71 (43158)

24 (600) 0 24.000 (610) 1219 (3096) 296.96 (482.11)

24 (600) 24.000 (610) 1250 (31.75) 304.00 (45277)

24 (600) 24.000 (610) 1312 332) 1821 (47387)

24 (600) 24.000 (610) 1275 (3493) 382.86 (495.38)

24 (600) 24.000 (610) 1838 (3653) 34683 (51563)

24 (600) 24.000 (610) 4.500 (38.10) 360.79 (537.36)

24 (600) 100 24.000 (610) 1531 (9889) 367-74 (547.74)

24 (600) 24.000 (610) 11562 (3967) 374.66 (557.97)

24 (600) 10 24.000 (610) 1812 (4602) 429.79 (64007)

24 (600) 140 24.000 (610) 2.062 (5237) 440957 (72019)

24 (600) 160 24.000 (610) 2344 (5954) 542.64 (808.27)

13

ASME 136.10M-2018

Table 2-1 Dimensions and Weights (Masses) of Welded and Seamless Wrought Steel Pipe (Cont'd)

Outside ‘Wal Plain End

ps Identification Schedule Diameter, Thickness, Weight (Mass),

on [Note (i)} No. in. (ou) in. (aa) A (g/0)

26 (650) 26.000 (560) 0250 (635) sa. (102.36)

26 (650) 26.000 (660) 0281 (7.14) 77:26 (11496)

26 (650) 10 26.000 (660) 0312 (7.92) 15.68 (129.36)

26 (650) 26.000 (660) 0344 (874) 9435 (14037)

26 (650) sto 26.000 (660) 0375 (953) 102.72 (152.88)

26 (650) 26.000 (560) 8406 (10.31) 11108 (165.19)

26 (650) 26.000 (660) 0438 (11.13) 11969 (178.10),

26 (650) 26.000 (660) 0.469 (1191) 128.00 (190.36)

26 (650) xs 20 26.000 (660) 10500 (12.70) 13630 (202.74)

26 (650) 26.000 (660) 0.562 (1427) 15283 (227.25)

26 (650) 26.000 (660) 9.025 (18:88) 109.56 (252.25)

26 (650) 25.000 (660) 0.588 (17-48) 18636 (27698)

26 (650) 26.000 (660) 0750 (19.05) 20244 (901.12)

26 (650) 26.000 (660) siz (20.62) 21864 (925.18)

26 (650) 26.000 (660) 0.875 (22.23) 23501 (349.68),

26 (650) 26.000 (660) 0938 (23.8) 251.30 (97387)

26 (650) 25.000 (560) 1.000 (25.40) 26725 (39751)

26 (700) 28.000 (711) 0.250 (635) 7416 (110.35)

28 (700) 28.000 (711) 0281 (7.14) 83.26 (12394)

28 (700) 10 28.000 (711) 0312 (7.92) 9235 (13732)

28 (700) 28000 (711) 0344 (874) 101.70 (151.37)

28 (700) smo 28.000 (711) 0375 (953) 110.74 (164.86)

28 (700) 28000 (711) 406 (10.31) 119.76 (178.16)

28 (700) 28.000 (711) 43n (11.13) 12908 (192.10)

28 (700) 28.000 (711) 9469 (1191) 13803 (205.34)

28 (700) xs 2 28.000 (711) 0500 (12.70) 14699 (21871)

28 (700) o 28.000 (711) 0.62 (1427) 164.94 (245.19)

28 (700) 30 28000 (711) 0.625 (15:89) 192.90 (272.23)

26 (700) 28.000 (711) 0.08 (17.48) 20087 (298.96)

28 (700) 28000 (711) 0750 (19.05) 21n4e (325.08)

28 (700) 28.000 (711) siz (20.82) 23600 (351.07)

28 (700) 28.000 (711) 0875 (2223) 2372 (977.60)

28 (700) 28.000 (711) 2.93 (23.83) 271.36 (403.88)

28 (700) 28.000 (711) 11000 (2540) 28863 (429.46)

30 (750) 5 30.000 (762) 0250 (635) 7951 (118.34)

30 (750) ° 30.000 (762) 0201 (7218) 9927 (13292)

30 (750) 10 30.000 (762) 0312 (7.92) 9902 (14729),

30 (750) 30.000 (762) 0.344 (874) 109.06 (162.36)

uu

You might also like

- Cswip 3.1Document45 pagesCswip 3.1ZakirUllahNo ratings yet

- RobotDocument53 pagesRobotZakirUllahNo ratings yet

- Basic Welding KnowledgeDocument30 pagesBasic Welding KnowledgeZakirUllahNo ratings yet

- Syllabus-Combined-Ad-No 7-2021Document7 pagesSyllabus-Combined-Ad-No 7-2021ZakirUllahNo ratings yet

- Cswip 3.2.2 Questions and AnswersDocument8 pagesCswip 3.2.2 Questions and AnswersZakirUllah50% (2)

- Procedure For Vacuum Box TestingDocument3 pagesProcedure For Vacuum Box TestingZakirUllahNo ratings yet

- By Christopher F. SikoraDocument120 pagesBy Christopher F. SikoraZakirUllahNo ratings yet

- Payment Voucher: Tel: 021-34617110 - Fax: 021-34637722Document1 pagePayment Voucher: Tel: 021-34617110 - Fax: 021-34637722ZakirUllahNo ratings yet

- LS10-Financing BusinessDocument22 pagesLS10-Financing BusinessZakirUllahNo ratings yet

- Some Useful Definitions - How Stress Is Calculated: Strainoptic Technologies, IncDocument48 pagesSome Useful Definitions - How Stress Is Calculated: Strainoptic Technologies, IncArivarasan JCNo ratings yet

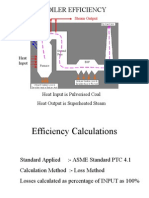

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDocument21 pagesBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamZakirUllahNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)