Professional Documents

Culture Documents

D Jetronic

D Jetronic

Uploaded by

Danno N100%(1)100% found this document useful (1 vote)

21 views31 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

21 views31 pagesD Jetronic

D Jetronic

Uploaded by

Danno NCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 31

NS

WORKSHOP MANUAL

VW-Porsche

D-Jetronic

ROBERT BOSCH

CONTENTS

How to use this Manual .

Fuel System Description

Air System Description.

Electronic System Description . _

Functional Description ..........

Wiring Harness Description...

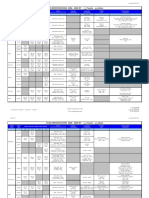

Trouble-Shooting Chart.

Component Removal and Replacement . :

TestChart.............. seeteeee = 238

Ignition and Idle Adjustments...........

Ser Parts List.

This manual is designed to assist you in the trouble-shooting and repair of vehicles

with the Robert Bosch D-Jetronic (EF!) System using mostly common workshop

tools. You should understand this fuel injection system before you begin working

on the vehicle, The Bosch Technical Instruction Booklet VDT-UBP 751/18

explains the D-Jevonic System in detail and will increase your understanding of

ths system. This will reduce repair times and facilitate the use of this Workshop

Manual

220 ROBERT BOSCH D-Jetronic

HOW TO USE THIS MANUAL

This manual ie designed to instruct the technician unfamiliar with Robert Bosch

fuel injection systems to locate faults in the system, isolate the component in-

volved, and test the component for correct function. You will need @ volt-ohm

meter and pressure gauge as well as the normal workshop tools. All measut

‘ments are made at the terminals of the large plug at the end of the wiring harness

after itis removed from the control unit. Mast components of this system cannot

be repaired and will have to be replaced once you have determined them

defective,

{f you are already familiar with the Bosch D-JETRONIC system end can identity

{and locate all the components in the vehicle, you can go directly to the Trouble-

‘Shooting Chart to track down the faulty component. Then test that component

according to the Test Chart.

If this fuel injaction system is new to you, start with the Fuel, Air and Electronic

System Descriptions, then read the section “Functional Descriation.””

‘The section entitled “Component Removal and Replacement” will help you lo-

cate each component in the vehicle. Then you can consult the Trouble-Shooting

Chart for the symptoms found on the vehicle in question. This will tell you what to

check on the vehicle and direct you to the section of the Test Chart where the

suspected component is checked for correct function.

The last section of the manual, “Ignition and Idle Adjustments,” describes the

timing and idle speed/mixture settings which should be checked ater every repair

and before the car is returned to the customer. Finally, a Service Parts List gives

you the part numbers for seals, gaskets, plugs, etc., which you will need for

replacement purposes.

D-Jetronic ROBERT BOSCH 221

FUEL SYSTEM DESCRIPTION

b

222 ROBERT BOSCH D-Jetronic

AIR SYSTEM DESCRIPTION

Four intake tubes ©, which are connected to the

intake manifold @, supply the four cylinders with air.

A pressure switch @, a pressure sensor © and the

vacuum advance of the ignition distributor are also

connected to the intake manifold

The pressure switch reacts to the difference between the

pressure in the intake manifold and the atmospheric

pressure, whilst the pressure sensor measures the actual

Dressure in the intake manifold (evacuated aneroids)

‘There is a throtile valve, operated by the accelerator

© Intake tuber

@ Intake manitolé

© Pressure switch

® Pressure sensor

® Elbow

© Air filter

© tale adjustment screw

© Auxitisry-air device (rotary valve)

DJetronic

‘pedal vis 0 bowden cable, at the mouth of the intake

‘manifold, The intake manifold ie connected to the

air filter @® by a rubber hose elbow ©.

The ilesair system is in the form of a bypass system in

the intake manifold, It joins behind the throttle valve.

Its functional cross section can be varied with the idle

adjustment screw © (idle adjustment). An auxil

ait ling from the air filter via the auxiliary-air device @

Xo the Intake manifold forms the warm-up

Its effective cross section is varied, depending on the

‘engine temperature, by the auxillary-air devies.

ROBERT BOSCH 223

ELECTRONIC SYSTEM DESCRIPTION

L H

Key w schemas of msm Intormatontor the slectronicontol nt

roa tar information Signal

© Pressure regulator engine

8 Sars comet nection vate C.D Trigger contacts Engine speed. triggeri

grrr iat wt fu sd nr afigniion diatibutor signal for

© Auxiliary-air device with electrical heating in. £ Temperature sensor! Correction of injected

twameer Takermantsu "| Geary dependerton

Sac ene auet wim momentary owiehe F empersaneseneors warm

® Ignition distributor with trigger contests (cylinder heed)

@ Thermo-time switch

Electronic control unit (ECU)

‘Temperature sensor | in intake air distributor

‘Temperature sensor I! in cylinder head

® cold-start va

® {dle adjustment sorew

From starting motor terminal 60,

G —Throttie valve switch Temporaryenrichment and

hut-offduring

L Fromstarting motor

torminal 50 when

thecmo-awitch

simultaneously closed

224 ROBERT BOSCH D-Jetronic

FUNCTIONAL DESCRIPTION

Fuel i drawn from the tank © via the filter @ by the

{uel pump © , ond fore into the ring main

The pressure rulator ©, connected tothe end of the

ring main, limits the pressre of the fuel to 28.5 psi

{2 Kgtiem*). The solenoid-operated injection valves ©

tre connected t0 the ring main via fuel distribution

Dipes ©). From the pressure regulator, surplus fuel ean

flow through a return lie inthe frame tunnel back

to the tank.

The bypass return line coming from the fuel pur leads

{nto this line. There isa tlle! valve in the fuel pump,

which come into operation when the prossue rises

Considerably above the nominal value as, for exam

ould oceur should the pressure regulator © develop 3

defect. A non-return valve in the pressure line connection

Of the fuel pump prevents the pressure inthe ring main

{rom dropping mmeditely when the pump issw'tched

off The mjectian valves © are opened electrically in

two pairs and KY By the electronic control unit and,

Ave to the fuel pressure, ful is injected, The novzle

‘uct of the injection valve is accurately ealiorated. Since

the fuel pressure iskeptcorstant, the injected fue

auantty is dependent only on the length of time the

injection valve kept open

This injection time is “computed” by the electronic

control unit. The “data” or information processed by the

electronics in the control unit comes trem the individual

Seraora onthe engine, This done in th following

‘The moment when the fuels injected is controled by

the distributor cortacs (trigger contacts) and It

(Cane 0) according tothe position of the camshaft,

These contacts ae instaled under the cenvifugal advonce

device inthe distrinutor and ate maintenance trae

The injection duration (fuel auamtity) isgoverned

basically by two factors: by the engine speed and the

load condition of the engine. The engine speed is

relayed to the eoniol unit by the distributor

Contacte | and Il. The load condition (part toxd or

full load is indicated by the pressure in the intake

‘manifold, The prevailing pressure here is converted to

Aan electrical enpulse snd alia relayed tothe contol

Unit (A and 8) by the pressure sensor @ which is

connected to the intace manifold @ by a hose. The

‘lectronie contro! unit processes this information and

Gives e signal for the injection valves to be opened for

2 longer or shorter period of time (J and K). The

Contral unit thus allows mare or fis fuel to be passed

through the solenoid-operated injection valves

Sepanding on the engine load and the ergira speed

This ishow the “basic quantity of fue” is determined,

Inaddition to the "basic quantity of fuel” an

acouretely metered quantity of fuss injected

ssitionaly (ericwnent) when starting at iow outsihe

Temperatures, when the engine is warming and

at fll toed.

The starting enrichment of the air/fuel mixture is

dependent on the engine temperature which is measured

electrically by two temperature sensors, one in the

{rankease ard the other on the cylinder head (E and)

Starting enrichment may only take place when the

starting motor s operated. The information as to

whan the starting motor i operating is relayed to the

Control unit via cable whieh is connected to

terminal 50 of the starter solenoid snitch

‘This information, too, is processed by the control unit

in elation tothe basic quantity of fuel and the

impulses are relayed electrically to the fuel injection

valves, The stme principle aplies during overrun

{braking withthe engin’: In this case no fuel must

bolinjected,

D-Jetronic

throttie valve and increased engine speed. The throttle

valve switch (G) switches off the fuel supply during

overrun, when the vehicle speed is above 1 800 rev/min,

If, during overrun, the speed drops to 1.250 rev/min

the fuel supply is switched on again so that @ smooth

transition to idle operation is guaranteed.

To keep the electronic contral unit as simple as

possibie, and the cost of the unit low as possible, the

fuel injection valves are paraliel connectad into

groups of two (group 1 ~ cylinders 1+ 4;

group 2 = evlinder: 2 + 3)

| Both fuel iniection vaives of one group inject fuel at

| the same time. The injection valves of cylinders 1 and 3

inject fuel past the open intake vaives, into the

combustion chember during the inlet stroke, whilst the

injection valves of eylindors 2 and 4 injest onto the still

clotad intake valves while the exhaust gases are being

forced out. In this latter case the fuel is “stored” at the

intake valves.

|The amount of aris controlled during vehicle operation

by the throttle valve in the intake manifold,

When idling, the throttle valve is completely closed.

The idle air can reach the intake tubes only via the

bypass system in the intake manifold, The idle speed is,

adjusted by altering the cross section of the bypass

system. For this purpose there is an adjusting serew and

lock nut on the intake manifold

‘The acjustment must be carried out only with the engine

at operating temperature

The engine, i it has not reached operating temperature,

requires an additional amount of air. This is controlled

by the auxiliary-air device (rotar

offective cross saction of the aux

accordance withthe oil temperature, The position of

the rotary valve is controlled by a bimetal spring which

protrudes into the crankcase. At ~30°C (=22"F)

the rotary valve is open and at *50°C (12°F itis

fully dosed.

ROBERT BOSCH 225

WIRING HARNESS DESCRIPTION

“The individual cables are marked with the corresponding

cable number, These cable numbars are printed about

3/8" to 3/4" from each cable end,

Cable Number From To Cable Number

1 electronic control unit temperature sensor | 1

{intake manifold)

2 rot used

3 electronic control unit injection valve cyl. 1 3

4 electronic control unit injection valve ey!. 4

5 electronic control unit injection valve cyl. 2 5

6 electronic control unit injection valve ey. 3 6

7 electronic control unit pressure sensor 7

a electronic control unit pressure sensor a

9 electronic control unit throttle valve awitch, 9

10 elecvonie control unit —_ pressure sensor 10

" electronic control unit ground (on crankcase) 11

2 electronic control uni trigger contact in 2

ignition distributor

3 electronic control unit temperature sensor | 3

(intake manifold)

“ not used

15 electronic control unit pressure sensor 16

16 electronic control unit mainrelay terminal 87 16 (via plug housing T 1)

7 electronic control unit _throttle valve switch "7

8 electronic control unit starting motor torminal 5018. (via plug housing T 1)

19 electronic control unit. pumprelay terminal 8519 (via plug housing T 1)

» elecronic control unit throttle valve switch 20

a electronic control unit trigger contact in a

Ignition distributor

2 elecvonie control unit trigger contact in 2

Ignition distributor

B elecvonic control unit temperature sensor I! 23

{cylinder head)

m4 electronic control unit mainrelay terminal 87 24 (via plug housing T 1)

B not used

8 injection valve cyl. 1 ground 26

a Injection valve cyl. 2 ground 27

B injection valve cyl. 3 ar0urd |. crankease 2B

2» Injection valve eyl. 4 round 20

30 throttle vaive switch round 30

terminal 14

a ‘cold-start valve starting motor terminal 80.31 (via plug housing T 1)

2 ccold-start valve thermo-switch 32

a7 throttle vaive switch ‘round on crankcase 7 (as from 8.71)

226 ROBERT BOSCH D/Jetronic

@ Etectric tuel pump @ Main relay

QSeleraidoprted inecon vive & Mouton switch ternal 1 (se box

Grvonte ave wich win momentary erchment «Te fine box emi 30

@ Ignition distributor with trigger contacts Fy Ponta chcutt be

tation gaint wt + Print uit bord pig comectin

15 Gabi concn

@ Electronic control unit/ECU

@ Temperature sensor Vin intake manifold

Temperature sensor Il in cylinder head

© Cold-start valve

Cables 18 and 31 from starting motor terminal 60

Pump.

D-Jetronic ROBERT BOSCH 227

TROUBLE-SHOOTING CHART

Engine has no power

With engine cold, adjust valves as accurately

{5 possible according to instructions.

‘0 instructions, Sufficient power?

No

‘With engine warm, set dwell angle and ignition point accurately according

‘Check spark plage, interference euppression resistors,

distributor rotor, ignition cables, distributor cap, con-

tact points, condenser and ignition coil

All in order?

Yes No Replace detective parts

‘Compression pressure and pressure drop correct?

Yes No Examine engine for mechanical faults.

‘A ter clogged? Clean or replace ar filter. Check if correctly fitted,

No Yes

Throttle plate fully open at full throttle?

Yes No “Adjust throttle valve cable

[ All hoses to pressure sensor and intake menifold

‘connected correctly and air taht?

Yes No ‘Check hoses and replace if necessary.

With engine running, check fuel pressu

Replace defective parts (e.g. pressure regulator or clogged fuel filter)

re, Nominal value: 2 .. 2.2 kgffem?

Chock injoction systorn. In order?

Yes No

Replace detective parts

With stroboscopic timing light check vacuum advance

(in the cate of ignition distributors with double

‘vacuum units also check retarded ignition)

Alin order?

Yes

Clean vacuum holes. Check if vacuum holes are corn

plotoly clear when throttle valve is closed. If throttle

valve fully or partly covers hole, replace air throttle

‘assembly. Check vacuum and vacuum hoses.

Let engine run at 2000 rev/min. Check voltages at

‘terminal 18 of ignition coil and terminal 87 on main

‘and pump relays.

All in order?

Yes

Eliminate contact resistances. (Check battery ter

‘minals and connections to battery and engine).

‘Check electronic control unit and pressure sensor

228 ROBERT BOSCH

D-Jetronic

Engine will not start.

Engine is cranked but does nat start.

(Tank, still has sufficient fuel)

Engine starts?

No

Start engine as follows: First fully depress accelerator pedal, then switch on ignition and oper-

ate starting motor. During starting leave the accelerator pedal fully depressed: do not pump!

Yes!

Fue? pump must run about 1 see when

‘ignition is switched on,

Pump fuse in order?

Chock cabes between }-—

pump and pump relay.

Volt

Yes

0 present?

{tisten for pump notee), No Replace fuse No Yes

‘Check fuel pressure when starting, Examine fuel hoses for Use voltmeter to ascertain if voltage

Nominal value: 2 to 2.2 kgt/em? kinks. Check fuel filter. present on fuel pump. First connect

¥ N Replacs it necessary. \oitmeter, then switch on ignition

iid eK Read voltage within 1 sec.

Voltage present?

Yes No

Replace fuel pump.

—_* Connect vokemete: to pump relay

‘Replace defective infor and within 1 see of switching on

ve No mation sensors, Jn, check voltage between

terminals 86 and 86.

No

lug in stroboscopic timing light.

Crank engine. Check for ignition sperk.

Yes No

‘Check thermo-switch and cold:start valve.

Replace datective or leaking parts. Check

‘that the correct combination of thermo-

‘switch, colé-start valve and control unit is

installed

‘Completely check over the

ignition system (spark plugs,

Interference suppression

resistors, spark plug rel

condenser. ignition coi

holders, ignition cables, Relay pulls in?

distributor rotor, distribu Voltage on terminal 87?

tor eap, contact points, Yes

Remove plug from terminals 85 and

86 of the pump relay. Use test leads

to connect terminal 85 to ground

and terminal 86 to 30/51 on the

c——

[ esta catectve etay

Engine flooded: Remove pump relay fuse,

spark plugs and distributor rotor. Operate

Starter tor 3 to 5 secs in order to pump

superfiuous petrol out ot the cylinders

Do not smoke! Danger of tire.

If the engine fires a couple of times when

starting cold but then stops duete flooding,

the thermostime switeh 0 280 130 205

can be fitted in place of the thermo-switch

(circuit: see Service Parts List,

U

{In exceptional cases, water in the fuel system can cause corrosive

‘damage to the fuel pump, injection valves, colcstart valve and,

‘regulator. Corroded parts must be replaced. Drain the tank

and clean out water and rust in the fuel lines,

DdJetronic

ROBERT BOSCH 229

Fuel consumption excessive.

Enquire from driver about Fis operation

of the vehicle and whether it isused for

local town journeys or for longer dis-

tances,

Adjust engine valves with greatest

possible precision and exactly to speci-

fication. Test compression loss.

Engine must be absolutely cold.

Set dwell angle, ignition point and

electrode gap with greatest accuracy

10 specification.

Engine warm,

Test injection system

In order?

Yer No

(Check cold-start valve and thermo-suitch,

In order?

Ye. No.

Check fuel pressure lines and connections,

In order?

Ye No

‘Check entire fuel system, injection valves,

old-stet valve, hose connections ete.

for leaks,

On vehicles with automatic transmission

check setting of engine speed regulator

and adjust If necessary.

Replace defective components.

230 ROBERT BOSCH

D/Jetronic

COMPONENT REMOVAL AND REPLACEMENT

In order to facilitate work in the engine compartment, it

is advisable to first remove the hood

The air filter must be removed before parts of the

system can be removed.

Hold plugs on both sides when pulling them out, never

pull at the cable!

When plugging-in on the individual components take

care that the rubber caps are correctly pushed over the

plugs.

Pressure sensor

Removal

The pressure sensor is installed in the R.H. side wall in

the engine compartment. On vehicles with air en-

ric¢hment during overrun, the vacuum limiter is installed

together with the pressure sensor.

Pull off plug at pressure sensor.

Pull off vacuum hose. Fully unscrew the three fastening

screws (one above, two below the pressure sensor).

Remove pressure sensor.

Note for installation

The protection sleeve on the fitting of a new pressure

sensor must only be removed immediately before

pushing on the connecting hose as otherwise the

evacuated aneroids may become contaminated.

Pressure sensor must be positioned horizontally.

D-Jetronic

Throttle valve switch

914/4 and 914—1.7

The throttle valve switch is fitted under the air throttle

assembly,

914-2.0

The throttle valve switch is installed on the side of the

air throttle assembly.

Removal

914/4 and 914—1.7

Remove air filter. Unhook return spring for the throttle

valve, Loosen bowden cable operating the throttle valve.

Serew out the two fastening screws for the air throttle

assembly (arrows)

914-2.0

Remove air filter, pull off plug at throttle valve switch,

screw out fastening screws and remove throttle valve

switch.

Adjustment

USA model up to and including July 1971.

Airthrottle assembly removed:

Connect meter between terminals 17 and 47.

Push switch onto throttle shaft and tighten the two

fastening screws slightly.

Turn switch until the indicator needle of the tester

moves from the “22” position to "0",

Turn switch one graduation = 2° counterclockwise from

this position and tighten.

Finally, check setting by operating the throttle valve.

ROBERT BOSCH 231

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- StolenVehicles5 01Document34 pagesStolenVehicles5 01Danno NNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Toyota Fluid Specs 2006-09Document4 pagesToyota Fluid Specs 2006-09Danno NNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- 4AGE To 7AGE ConversionDocument4 pages4AGE To 7AGE ConversionDanno NNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Guide Rebuild Keihin CarbsDocument16 pagesGuide Rebuild Keihin CarbsDanno NNo ratings yet

- MCN VFR Comparison 2016Document7 pagesMCN VFR Comparison 2016Danno NNo ratings yet

- cb650sc Road test82MCDocument4 pagescb650sc Road test82MCDanno NNo ratings yet

- WSMCNews 0507 Rev 3Document14 pagesWSMCNews 0507 Rev 3Danno NNo ratings yet

- Beef Stroganoff Recipe - Tin EatsDocument2 pagesBeef Stroganoff Recipe - Tin EatsDanno NNo ratings yet

- Launch Creader8001Document42 pagesLaunch Creader8001Danno NNo ratings yet

- Ironbutt 1002 62-66 HotDocument5 pagesIronbutt 1002 62-66 HotDanno NNo ratings yet

- 10 Essential Capabilities of A Modern SocDocument9 pages10 Essential Capabilities of A Modern SocDanno NNo ratings yet

- Ninja250R ServiceManual 376Document1 pageNinja250R ServiceManual 376Danno NNo ratings yet

- ClassicMechanics0603 MM CX500EDocument5 pagesClassicMechanics0603 MM CX500EDanno NNo ratings yet

- Jeremy Dennis Hass - 1936-2014 - The Santa Barbara IndependentDocument4 pagesJeremy Dennis Hass - 1936-2014 - The Santa Barbara IndependentDanno NNo ratings yet

- DIY - Oil Change - Ninja 250Document33 pagesDIY - Oil Change - Ninja 250Danno NNo ratings yet

- Numbers of Human Fatalities Injuries and Illnesses in The UniteDocument13 pagesNumbers of Human Fatalities Injuries and Illnesses in The UniteDanno NNo ratings yet

- Owners Manual 2008Document175 pagesOwners Manual 2008Danno NNo ratings yet

- Ada Pinga Hass - The Santa Barbara IndependentDocument3 pagesAda Pinga Hass - The Santa Barbara IndependentDanno NNo ratings yet

- OwnersManual1997 98Document115 pagesOwnersManual1997 98Danno NNo ratings yet

- Owners Manual 2011Document188 pagesOwners Manual 2011Danno NNo ratings yet

- Britains Highest Mileage RiderDocument4 pagesBritains Highest Mileage RiderDanno NNo ratings yet

- Car&Driver-BestHandlingImportedCar 7/1984Document11 pagesCar&Driver-BestHandlingImportedCar 7/1984Danno NNo ratings yet

- SportRider PerformanceNumbersDocument8 pagesSportRider PerformanceNumbersDanno NNo ratings yet

- TunerPro5 QuickGuide Rev1.2Document13 pagesTunerPro5 QuickGuide Rev1.2Danno NNo ratings yet

- TacTrix ECU FlashDocument2 pagesTacTrix ECU FlashDanno NNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationDanno NNo ratings yet

- Army Washracks DetergentsDocument20 pagesArmy Washracks DetergentsDanno NNo ratings yet

- Honobdapt 1.0: Intro, Summary PrototypeDocument17 pagesHonobdapt 1.0: Intro, Summary PrototypeDanno NNo ratings yet

- 2015 Scion XB User Warranty Maintenance ManualDocument62 pages2015 Scion XB User Warranty Maintenance ManualDanno NNo ratings yet