Professional Documents

Culture Documents

ENS-PR-ARC-B00-DRW-10300-1.2 - Site Layout-Grey Water

Uploaded by

Iskandar HasibuanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENS-PR-ARC-B00-DRW-10300-1.2 - Site Layout-Grey Water

Uploaded by

Iskandar HasibuanCopyright:

Available Formats

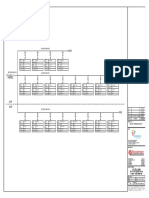

TRUCK FLOW

+41.61 STAFF VEHICLE FLOW

GUEST BUS FLOW

BOMBA ACCESS FLOW

+42.41

+41.40

EMERGENCY EXIT

( ALWAYS CLOSED)

N

WWTP SL+42.60 PER

GG SIAR

SET

BA CK L

INE

UTIL AN T

EKN

ITY 2

0'

UP

6M ACCESS DRIVEWAY

SET

OLO

DN UP

BAC GAS STATION

K LIN

TRANSFORMER

E 40

'

ROOM

B21U4000DA03

GI 6

CABLE CELLAR

CONTROL LVMSB ROOM SUBSTATION

ROOM

B21U4000DA02 B21U4000DA05 CABLE CELLAR

B21U4000CB01

TNB

SUBSTATION

B21U4000DA06

TRANSFORMER

natural

ROOM

B21U4000DA04 slope

1:2.5

BMS HUB STORE

B21U4000DA01 B21U4000CB02

SMOKING

UP

GG

AREA SL+42.00

HS RL +42.75

BUS PARKING 2 nos

GG +41.01

6M ACCESS DRIVEWAY

GG VISITOR BUS MANEUVER RL +42.15

RL +42.75

GG

UP

proposed location ADMINISTRATION

STAFF ACCESS

BUILDING

SUBSTATION

grey water tank & +42.35 GG

22%

pump room sources

COOLING

BRAINSTORM / BRAINSTORM /

CALL PODS 1 EMERGENCY

SUBSTATION

COLLABORATE PERSONAL STAIRCASE

COLLABORATEB10F4000BA02 INFORMAL /

2 5 QUICK LIFT B10F4000EA04

B10F4000BA05 B10F4000BA15CALL PODS 2 DISCUSSION B10F4000EA02 BRAINSTORM /

EXPANSION CHP TOWER

DLE B10F4000BA03 B10F4000BA21 HOT SEAT

CR

ENTRANCE STAFF & VVIP

STAIRCASE ENTRANCE

B10F4000EA05 B10F4000EA01

+42.95

from Admin Bldg

+42.95

natural

CORRIDOR

B10F4000EA03

OPEN OFFICE

TOTAL 50

slope DOCUMENT

LOCKERS

B10F4000AB01

FIXED DESK

B10F4000BA01

1:2.5 ROOM

B10F4000CA01

GG

MEETING

ROOM 2 (12P)

B10F4000BA10 RL +42.15

FUTSAL COURT BRAINSTORM / BRAINSTORM / IT WORKSHOP COPY & PRINT CALL PODS 3 BRAINSTORM / BRAINSTORM /

Alternative grey

COLLABORATE COLLABORATE B10F4000BB02 B10F4000DB01 B10F4000BA19COLLABORATE COLLABORATE

1 6 BRAINSTORM / 7 8

HOT SEAT B10F4000BA17 B10F4000BA18

B10F4000BA04 B10F4000BA16 CALL PODS 4

MEETING B10F4000BA20

ROOM 3 (6P) OPEN OFFICE

BRAINSTORM TOTAL 50

B10F4000BA11 FIXED DESK

3&4 ATM TOILET

SB.00.004 SB.00.005

OPEN OFFICE B10F4000BA13 B10F4000BA01

HOT SEAT

water tank sources

MEETING

55%

TOTAL 30P

PANTRY & ROOM 1 (20P)

B10F4000BA14 SERVER BREAKOUT

RL +42.15

SAFETY

B10F4000BA09 CONTROL

ROOM & IT INDUCTION

ROOM B10F4000BB01 SB.00.003

TOILET B10F4000DA01

ROOM

SB.00.002

BA.00.011

MEETING SECURITY

ROOM

ROOM 4 (6P) SB.00.001

B10F4000BA12

11% 19%

LOCKER

from Admin Building

+0.750

CHILLER

EXPANSION BA.00.012

EXPANSION

EXPANSION

CHILLED ROOM

FFL-0.050

proposed location

OFFICE STORE

WATER TANK

BMS BA.00.010 BA.00.009 BA.00.004

BA.00.007

HS

BA.00.013

HS JANITOR

BA.00.014

SMOKING JANITOR

B10F4000AB05 FIRST AID FOCUS PODS 3 FOCUS PODS 1

FOCUS PODS 2

SHAFT

TOILET MALE ROOM B10F4000BA08 B10F4000BA06

grey water tank & PARKING 194 nos RL +42.15

PROD B10F4000BA07

CR

BOILER ROOM B10F4000AB03

AREA EMPLOYEE B10F4000BA22

MOTORCYCLE

ENTRANCE

ELECT. ROOM MDF ROOM

STAFF PARKING 124 nos RL +42.15

TOILET

STORE

BA.00.003 WORKSHOP B10F4000DA03 B10F4000DA02 B10F4000CA05

FEMALE B10F4000EA06

LACTATION

DW

FOOD

B10F4000AB04

ROOM RECEIVING

SHAFT

BA.00.001 B10F4000AB02 WASTE ROOM B10F4000CA03 GAS STORAGE

B10F4000CA04 B10F4000CA02

DW

10000

pump room sources

from Production

RL +42.75

GG GG RL +42.15 CR

6M ACCESS DRIVEWAY Bldg

CONTRACTOR PARKING 41 nos RL +42.15

HAZARDOUS CR

NITROGEN LIQUID VESSEL

CONCENTRATE ACID

20,000L

CONCENTRATE LYE

20,000L

SECONDARY FENCING

GG

NITROGEN

GG

TR-1 TR-1

SWITCHGEAR TRANSFORMER

WASTE

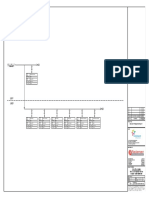

Section F3-F3 33/11 kV 33/11 kV

480Kg. per load points

UNLOADING 3500 kVA

ROOM3500 kVA

PI

2.06 2.06

ROOM

GG DN50

DN65

HW

RL +42.75

PUMP

CLUSTER

500 L

FUME HOODS DECONTAMINATION

PI

HW TANK

MSB-A CAP BANK-A

COMPRESSOR R&D OFFICE / WASHING

PI

ROOM LV MSB ROOM MOJONNIER ROOM

8000 L

PILOT PLANT PB PB

H = 1650mm

RMT

50m3

FFL±0.000

PI

Section F2-F2

480Kg. per load points AIR RECEIVER CAP BANK-B MSB-B

PB PB

RIO 1

AIR

+42.36

H = 4400mm COMPRESSOR

1.021.02 2.01

2200 Nm3/h SPARE PARTS MEDIA PREP

CLEANING ROAD (CR)

CORRIDOR

Section F1-F1

AIR DRYER

F1-F1

PI

700Kg. per load points

ROOM GENERAL

1980 m3/h

H = 1650mm

INGREDIENT SENSORY PHY - CHEM

PI

2.07 DIN80 DN80 DN80

MICRO LAB.

2.07

DN50

DN80

DN50

DN80

FFL±0.000 ROOM FFL±0.000 LABORATORY

PI

DN80 DN80

AIR

DN80 DN80

PRODUCTION INCUBATION &

PI

2.02

1.01 DN80 DN80 DN80

1.01 DN80

PI

DN65 DN80

DN65

PI

DN50 DN50 DN80

AIR COMPRESSOR COMPRESSOR

DN80

PREPARING FFL±0.000

PI

SPACE FOR AMF DRUM UNLOADING

SAMPLE STORE

SPACE FOR AMF DRUM LOADING

ROOM 197.56

U102

READING

AMF MELTING TUNNEL

2.10 RIO 2

2.08

AIR DRYER

APC

m² 4500

2200 Nm3/h

1980 m3/h

F1-F1 2.09 APC SC

DN50

1.08

TECHNICAL

H = 1650mm

EMPTY ROOM 1 SELF LIFE

PI

2.08-2.09

WASTE SPACE

GARDENING (GG)

PERSIARAN TEKNOLOGI 5

CORRIDOR & PALM OIL PALM OIL

AMF STORAGE

AIR

ENGINEERING ROOM CORRIDOR

COMPACTOR CHEMICAL

TANK 30m3

RM SAMPLING 30,000L TANK 30,000L 8000 L WORKSHOP

AMF MELTING AMF MELTING CH ROOM COMPRESSOR

STORAGE AREA

BASIC CARE MEDIUM CARE FFL±0.000 ELECTCOMPLAINT

AIR RECEIVER

2200 Nm3/h SELF LIFE CHANGE ROOM

COLD STORE H = 4400mm

STORE RECORD ELECTRICAL GENERAL

RM SAMPLING

RM SAMPLING

Section F-F

700Kg. per load points

PCS OFFICE ROOM MICRO LAB &

PALLET WASH PLANTING

MAL PAL CORRIDOR STAIR 2 LIFT DW

HOSE STATION (HS)

PI

WASTE PRODUCTION

DN80

DIN130

DIN130

DIN80

DIN65

DN80

DN80

EMPTY ROOM 2

50NB

LOADING AMF MAL

PACKAGING SPINE

MATERIAL

BUILDING

NITROGEN

CHWR

CHWS

HWSR

WAREHOUSE FFL±0.000

HWS

PW

TWR

TWS

IWR

CA

AMF PAL EMPTY ROOM 3

IW

SCOPE

CUSTOMER

+43.00

SCOPE

TP

FORKLIFT

PI

PI

PI

PI

PI

PI

PI

PI

PI

PI

REPAIR AREA LIFT

ROOM ISOLATION

STAIR 4 MAL STAIR 3 CORRIDOR EVC

PI

AND CHARGNG FFL±0.000

MAL

GG

BAY MARKET SMALL MCDONALD'S LINE MCDONALD'S LINE

150NB

RETURNS INGREDIENTS Section A-A

CHANGE ROOM

DIN200

DIN200

DIN150

DIN150

DIN150

DIN150

DIN150

DIN150

DIN150

DIN80

DIN65

DISPENSING (MEDIUM CARE)

1080Kg. per load points

FFL±0.000 FFL±0.000 FFL±0.000 PREMARY BIB FILLER

PACKAGING

FFL±0.000

DN80

DN80

DN80

DN80

DN50

DN80

PI

RIO 3 RIO 4

PI PI

65NB

MCDONALD'S LINE MCDONALD'S LINE

PRV STATION

SLURRY 1 MIX

OPERATORS ACCESS

5m3

4.08

SUGAR/PECTIN STORAGE

RL +42.75

20m3

EVC

RL +42.15

3.13

DIN65

4.05

A3-A3

3.05

PI PI

Section A3-A3 80NB

4.07 4.06 4.06 755Kg. per load points

3.06

PI

3.07 3.08

RL +42.75

DIN50

DIN100 DN65

65NB ∅76 DIN100 DN80

CFA 312

DN65

PI

∅76 DIN100 1.08

DN65 DN65

SLURRY 2 MIX

100NB

PI

DIN100 1.09

5m3

DIN100

DIN150

DN80

3.05-3.06 PI PI

PI

PI

PI

PI

PI

PRV STATION

A3-A3 3.08

4.053.07 3.12 1.09-1.10

DIN80 100NB

PI

SLURRY 2 STORAGE

DISSOLVING

20m3

TANK

DIN150

DIN150

DIN150

DIN150

PI

3m3

DIN200

DIN200

A-A A-A

RIO 6

RL +41.70

DN80

DN80

PI

HW RECOVERY

40,000L

EVC

PRV STATION

MAIN PIPE RACK

6.04

DN65

DN65

PI

RAW MATERIAL PI

3.09

80NB

STAB.

PI

PI

2000L

WAREHOUSE A2-A2

3.04

PI

Section A2-A2

3.10-3.13

9.06 500Kg. per load points

TECHNICIAL

PI PI PI

PI

PI

CFA124-36

PI

PI

DN80 DIN100 DIN50

80NB

EMUL. 65NB DN80 DIN100

DN100

1000L

2.10

1.10

PI

50NB

100NB

RECOMBINED PASTEURISER 1

DN80

DIN100

DIN100

DIN100

DIN100

DIN100

DN80

DN80

DN80

SPACE

3.01

3.02 FFL±0.000

PI

3.10 3.03

PRV STATION

DISSOLVING

6M ACCESS DRIVEWAY

TANK 3.02-3.03

3m3 A2-A2 3.01

DIN50

PI

3.04

RECOMBINED TANK RECOMBINED TANK

GG

35m3 35m3

DIN200

DIN200

DIN150

DIN150 DIN150

DIN80

DIN150

DIN150

DN80

DN80

PI

EVC

4.04

4.02

RECOMBINED TANK

5.07

PI

RECOMBINED TANK

35m3 4.03 7.06 DN65

35m3 DN65

A1-A1 4.02-4.03

3.11 4.01 Section A1-A1

PI

PI

500Kg. per load points

STAB.

2000L

4.01

65NB

DN100 DIN100

DN80

DIN100

DIN100

DIN100

DIN100

DN80

DN80

DN50

CONTROL

PI

DIN100

DIN100

80NB

DIN50

ROOM CFA124-36 FG LOADING BAY

123 PPIFP

EMUL.

PI

STAGING

PI

PI

PI

PIPE RACK

FFL±0.000

1000L

PI PI

4.04

WAREHOUSE

PI

A1-A1

CFA 124

DN80MAIN

INBOUND

DN80

DN80

DN80

DN80

DISSOLVING

DN80

DN80

DN80

DN80

DN80

DN80

DN80

DN65

RECOMBINED PASTEURISER 2

TANK

PI

3m3

STAGING AREA IPQC

GG

PI

EVC

Accumulator

150NB

ACHX30

DN50

8.04 DN65

DN65

Straw Applicator

CREAM PASTEURISER

Controlled

SA30

STAB.

2000L +825

Controlled

by FM

+825

by ACHx +825

Tray Shrink

DIN150

DIN150

5177

DIN150

DIN150

DIN150

DIN200

DIN80

SEAL WATER

0.25

1

0.5 0.25

2

0.5

2

0.5

1

TANK TS30

613121

0.25 0.25

1

TPOP

TPOP

EMUL.

LC40

0.25

1000L

0.5

1

80NB

SEAL WATER

TANK SEPARATOR 1

E-E

SMOKNG AREA

DW.00.001

1

WAITING

DRIVER

ROOM

DW.00.002

PRV STATION

Section E-E

A3/Speed Shrink Wrapper

DISSOLVING

900Kg. per load points TPOP

TANK 1

3m3

DN80

DN80

DN100

DIN80 CM/HHS TPOP

DW.00.003

DN80 DN100

°0

TOILET

DN80

9

DIN100 DN100

DN80 DN65

PSA

°0

TBA200S

DN100 DN65

9

DIN100 DN80

DN100 DN65

0001 °54

DN65 DIN100

DN100 DN80 45°

1

9

DN80

CM/HTW

°0

DN65 DN100 DN80 80NB 0002 0002 0002

9

DN65 DN100 DN80

°0

°54 0001

STAGING 45°

CM/HTW CM/HTW

1

4.057Ha

Cardboard Packer

PI

1.03 Section B-B

E-E

AREA 1080Kg. per load points

150NB

B-B

DIN150 PI

DIN50

DIN80 DIN50

DRIVER

PI

PI

PRODUCTION

DIN200 FRESH MILK PASTEURISER

PI

DIN200

PI

80NB

4.09 1.03 2.01

DIN150

WAREHOUSE 4.10

COLD WATER

4.09

1.04 5.04 UP

DN65

DN65

DN50

DN50

DIN150

DIN150

DN65

DN65

2.02

7.07

AREA

100,000L FRESH MILK/STANDARDISATION DN50

WAITING

DN80

DN50

OFFICE 60,000L DN80 DN80

PI

PI DN80 DN80

5.04

PI

DIN150

PI

9.02 9.01 SMALL PI PI PI

INGREDIENTS B-B

PI

PI

500L

+42.95 2.03-2.05

PI

FUTURE EXPANSION

1.05 - 1.07

MAIN PIPE RACK

PI

PI

SMALL

PI

SMALL

50NB

8.03 9.01 INGREDIENTS INGREDIENTS CREAM

9.02STANDARDISATION 4000L 500L 10,000L

STANDARDISATION STANDARDISATION STANDARDISATION

6.01 5.01

DIN50

60,000L 60,000L 60,000L 60,000L (FUTURE)

PI

6.02

PI

VALVE CLUSTER 5.05

PI

NO.4

DIN150

SMALL SMALL

6.01-6.02 INGREDIENTS INGREDIENTS

REMOVE COLUMN

500L 500L

7.01 5.05

E2-E2 E2-E2 C-C C-C D-D D-D

DIN50

7.05

7.02 5.01 CREAM

PI

DIN150

DIN150

DIN150

DIN65

DIN65

PALLET STORE

PI

5.04 RIO 8

DIN150

7.03 VALVE CLUSTER

10,000L

E1-E19.03 9.03

7.04 NO.1 9.04E1-E1 (FUTURE)

PI

SMALL SMALL

9.04 10.06

PI

INGREDIENTS INGREDIENTS

PI

STANDARDISATION STANDARDISATION STANDARDISATION

8.05 STANDARDISATION 500L 500L

60,000L 60,000L 60,000L

60,000L RIO 6 RECOVERY

PI

VALVE CLUSTER

HOLDING TUBE

PI

NO.5

7.01 11.02 11.01

PI

DN100

DN100

DN100

DN50

DN50

DN50

PI

DN80

DN80

DN80

DN65

7.02 PI

PI

5.02

PI

RE-PROCESS

PI

PI

TANK 15m3 PI

6.03 TUBULAR HEATER

6.05-6.07

PI

5.02

PI

VALVE CLUSTER 5.06 9.07

PI

EVC

NO.2

11.01

11.02

PI

STANDARDISATION STANDARDISATION STANDARDISATION 9.06 PI

STANDARDISATION

60,000L Section E1-E1

60,000L 60,000L

7.03 60,000L 11.03

755Kg. per load points 5.06 REC. PHE 1

VALVE CLUSTER PI

DN65

CFA 312

DN65

PHE VALVE

NO.6 RE-PROCESS

PI

CLUSTER

TANK 15m3 10.07

7.04 10.08

PI

PI

PI

4.07 REC. PHE 2

9.07 4.08 PI

PUMPS

4.10

PI

PRV STATION

VALVE CLUSTER 1.04 2.03

613120

NO.3

1.05 2.04

PI

STANDARDISATION STANDARDISATION 11.06 REC. PHE 3

STANDARDISATION STANDARDISATION 1.06 2.05 Section A-A Section C-C

RE-PROCESS

PI

60,000L 60,000L 11.07

60,000L 8.01 60,000L

FUTURE FUTURE 1.07 1080Kg. per load points 900Kg.

TANK 15m3per load points

11.08

PI

8.02 REMOVE COLUMN 6.05

5.07

Section E2-E2

PI

5.03 6.06

755Kg. per load points

8.02 8.01 6.07

11.06,11.07,11.08

5.03

9.05 11.04

Section D-D

PI

480Kg. per load points

EVC

DN65

DN65

RL +41.70 LOADING BAY

4.047Ha

CFA124-36

CR CFA 124 CR

RL +41.70

FIRE

PUMP ROOM RL +42.75 RL +42.75 GG GG RL +42.15

8M ACCESS DRIVEWAY

FIRE TANK GG

GG GG

AREA Ramp 4.07%

RL +42.15

HS

PUMP &

POTABLE FILTER

WATER ROOM (WTP)

WEIGHING

BRIDGE IN

B40.00.003

FFL-0.010

GUARD HOUSE

B40.00.001

FFL+0.000

TOILET

B40.00.002

FFL-0.020

WEIGHING

BRIDGE OUT

B40.00.004

FUTURE EXPANSION

TANK

FFL-0.960

FFL-0.810

SL+42.60

RL +43.40

© 2013 HaskoningDHV Nederland B.V. All intellectual property rights among which the copyright related to this drawing shall vest

written consent of Haskoning DHV Nederland B.V. be duplicated or published in any way in whole or in part, or be used for any

HaskoningDHV Nederland B.V.. The drawing is the property of HaskoningDHV Nederland B.V. and may not without the prior

P02 19.03.2021 RHD RFC ADDING ACCELERATE-DECELERATE LANE ON ENTRANCES

P02 15.03.2021 RHD RFC UPDATED PRODUCTION BUILDING LAYOUT

P01 10.03.2021 RHD RFC ISSUED FOR STAGE APPROVAL

BUILDING SETBACK

+42.48 6000

Designed By

MA+AN

Drawn By

AN

Checked By

AN

Approved By

DA

INFRA/UTILITY SETBACK

Entrance 6000 Client

ramp 3%

PERIMETER PLANTING

1000 FRIESLAND CAMPINA

+43.10 JALAN TEKNOLOGI 4 +42.08 +40.91 +41.33 +40.08

Project Name Subject

DUTCH LADY BIG BLUE PROJECT B00. SITE LAYOUT

SITE LAYOUT 1

N

Scale 1: 800 -

purpose other than for which it is supplied.

HASKONINGDHV SDN. BHD.

a company of :

Role Architecture

2nd Floor, Block A

Lot 2-2-3A

Stage Conceptual Design

Kolam Centre Phase 2, Off Janan Lintas

88300 Kota Kinabalu, Sabah Scale 1 : 800 Status FINAL

Industry & Buildings

T: +60 (0) 88 252 949

F: +60 (0) 88 252 948

Proj.Nr. SJ1070 Suitability S4 P.Size A1

I&B

E: info@my.rhdhv.com

W: royalhaskoningdhv.com

Drw.Nr. ENS-PR-ARC-B00-DRW-10300-1.2

in

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Ta2862-Ql-Mar-Spgn-M-0027r1 (Approval Compressed Air Valve) - Approved With Comment.Document4 pagesTa2862-Ql-Mar-Spgn-M-0027r1 (Approval Compressed Air Valve) - Approved With Comment.Iskandar HasibuanNo ratings yet

- Cargill Bromo ClashDocument10 pagesCargill Bromo ClashIskandar HasibuanNo ratings yet

- Clash FF BromoDocument27 pagesClash FF BromoIskandar HasibuanNo ratings yet

- RFI-MECH-01 Hydrant & Sprikler Layout-RHDocument3 pagesRFI-MECH-01 Hydrant & Sprikler Layout-RHIskandar HasibuanNo ratings yet

- Cella Warehouse - Manhour Estimation-PlumbingDocument19 pagesCella Warehouse - Manhour Estimation-PlumbingIskandar HasibuanNo ratings yet

- Ta2862-Ql-Mar-Spgn-M-0028r1 (Approval Industrial Waste Water Valve) - Approved With CommentDocument3 pagesTa2862-Ql-Mar-Spgn-M-0028r1 (Approval Industrial Waste Water Valve) - Approved With CommentIskandar HasibuanNo ratings yet

- Ta2862-Ql-Mar-Spgn-M-0029r1 (Approval Steam & Condensate Valve) - Approved With Comment.Document5 pagesTa2862-Ql-Mar-Spgn-M-0029r1 (Approval Steam & Condensate Valve) - Approved With Comment.Iskandar HasibuanNo ratings yet

- Penawaran ProdukDocument1 pagePenawaran ProdukIskandar HasibuanNo ratings yet

- Ta2862-Ql-Mar-Spgn-M-0026r1 (Approval Town Water Valve) - Approved With Comment.Document4 pagesTa2862-Ql-Mar-Spgn-M-0026r1 (Approval Town Water Valve) - Approved With Comment.Iskandar HasibuanNo ratings yet

- Cim-Sep-Bd00-Dd-M-055-R0 - Waste Water Site Layout Mezanine Floor-R1Document1 pageCim-Sep-Bd00-Dd-M-055-R0 - Waste Water Site Layout Mezanine Floor-R1Iskandar HasibuanNo ratings yet

- PTMC-RHI-ZZ-XX-DR-M-5030-1101 - PFD Sewage Water at Ablution AreaDocument1 pagePTMC-RHI-ZZ-XX-DR-M-5030-1101 - PFD Sewage Water at Ablution AreaIskandar HasibuanNo ratings yet

- PTMC-RHI-ZZ-XX-DR-M-5550-1107 - P&ID Fuel Distribution at Power Station AreaDocument1 pagePTMC-RHI-ZZ-XX-DR-M-5550-1107 - P&ID Fuel Distribution at Power Station AreaIskandar HasibuanNo ratings yet

- PTMC-RHI-ZZ-XX-DR-M-5550-1105 - P&ID Fuel Transfer Pump SystemDocument1 pagePTMC-RHI-ZZ-XX-DR-M-5550-1105 - P&ID Fuel Transfer Pump SystemIskandar HasibuanNo ratings yet

- PTMC-RHI-ZZ-XX-DR-M-5550-1106 - P&ID Fuel Distribution at Fuel Storage Transtank AreaDocument1 pagePTMC-RHI-ZZ-XX-DR-M-5550-1106 - P&ID Fuel Distribution at Fuel Storage Transtank AreaIskandar HasibuanNo ratings yet

- Cim-Sep-Bd00-Dd-M-072-R0 - Detail Installation Energy Column M-056-R1Document1 pageCim-Sep-Bd00-Dd-M-072-R0 - Detail Installation Energy Column M-056-R1Iskandar HasibuanNo ratings yet

- PTMC-RHI-ZZ-XX-DR-M-5550-1104 - PFD Fuel Distribution at TIA Refuelling Storage Tank AreaDocument1 pagePTMC-RHI-ZZ-XX-DR-M-5550-1104 - PFD Fuel Distribution at TIA Refuelling Storage Tank AreaIskandar HasibuanNo ratings yet

- Cim-Sep-Bd00-Dd-M-073-R0 - Schedule Installation Energy Column-R1Document1 pageCim-Sep-Bd00-Dd-M-073-R0 - Schedule Installation Energy Column-R1Iskandar HasibuanNo ratings yet

- Full Hydraulic Calculations for 3M Indonesia FactoryDocument5 pagesFull Hydraulic Calculations for 3M Indonesia FactoryIskandar HasibuanNo ratings yet

- Cim-Sep-Bd00-Dd-M-057-R0 - Compressed Air Site Layout Mezanine Floor-R1Document1 pageCim-Sep-Bd00-Dd-M-057-R0 - Compressed Air Site Layout Mezanine Floor-R1Iskandar HasibuanNo ratings yet

- K181008 UT PID DW 002 - RevA - 02aug19Document1 pageK181008 UT PID DW 002 - RevA - 02aug19Iskandar HasibuanNo ratings yet

- (Indicative Only - Package Provided by Others) : NotesDocument1 page(Indicative Only - Package Provided by Others) : NotesIskandar HasibuanNo ratings yet

- Vendors responsible for connecting utilitiesDocument1 pageVendors responsible for connecting utilitiesIskandar HasibuanNo ratings yet

- Grey Water CalculationDocument2 pagesGrey Water CalculationIskandar HasibuanNo ratings yet

- K181008 UT PID DW 003 - RevA - 02aug19Document1 pageK181008 UT PID DW 003 - RevA - 02aug19Iskandar HasibuanNo ratings yet

- Lay Out Fuel StationDocument6 pagesLay Out Fuel StationIskandar HasibuanNo ratings yet

- Comparison Rain Water CollectionDocument2 pagesComparison Rain Water CollectionIskandar HasibuanNo ratings yet

- TA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailDocument1 pageTA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailIskandar HasibuanNo ratings yet

- TA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailDocument1 pageTA2395 RHI BA ZZ DR M 5301 Collecting Pit DetailIskandar HasibuanNo ratings yet

- TA2899 RHI ZZ ZZ DR M 3001 Utilities Pipe Supply Composite Site LayoutDocument1 pageTA2899 RHI ZZ ZZ DR M 3001 Utilities Pipe Supply Composite Site LayoutIskandar HasibuanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Plumbing Code 1 - EercDocument10 pagesPlumbing Code 1 - Eercron michaelNo ratings yet

- Hydromechanical Grease InterDocument1 pageHydromechanical Grease InterUjwal KhandokarNo ratings yet

- Assessment of Drinking Water of Bhaktapur Municipality Area in Pre-Monsoon SeasonDocument6 pagesAssessment of Drinking Water of Bhaktapur Municipality Area in Pre-Monsoon SeasonTulasi sharmaNo ratings yet

- Makueni-Paul Ngei Mutwota Hydro-Report - 2Document50 pagesMakueni-Paul Ngei Mutwota Hydro-Report - 2pablo studiosNo ratings yet

- Urp 205 QuantitativeDocument4 pagesUrp 205 Quantitativesultanbadii12No ratings yet

- Emergency Eyewash & ShowerDocument26 pagesEmergency Eyewash & ShowerNaushad HaiderNo ratings yet

- Asme A112.18.3Document32 pagesAsme A112.18.3Damaso TaracenaNo ratings yet

- Internship ReportDocument13 pagesInternship ReportSajjad HaiderNo ratings yet

- Install Type C BoilersDocument76 pagesInstall Type C Boilerspvale23No ratings yet

- Cooling Circulating Water, Purge Water & Cooling Tower SystemDocument22 pagesCooling Circulating Water, Purge Water & Cooling Tower SystemSCE CCGT3No ratings yet

- Water Pollution and Its Major Sources, Its Effect On VegetationDocument6 pagesWater Pollution and Its Major Sources, Its Effect On VegetationRaheel AhmadNo ratings yet

- Barangay Planning WorkshopDocument9 pagesBarangay Planning Workshopjerdy merceneNo ratings yet

- Water Pollution ReportDocument13 pagesWater Pollution Reportkishore neelagandaNo ratings yet

- Engineering Report On Surface Water Drainage Plan, Denbigh, Clarendon July 2, 2016 - 220110 - 112838Document5 pagesEngineering Report On Surface Water Drainage Plan, Denbigh, Clarendon July 2, 2016 - 220110 - 112838mark walcottNo ratings yet

- Full Dam DetailsDocument2 pagesFull Dam DetailsboopathiNo ratings yet

- Nestle Michigan-Water Case Study: Muhammad Asim BaigDocument3 pagesNestle Michigan-Water Case Study: Muhammad Asim Baigmuhammad naeemNo ratings yet

- Kafd A1 111 Comn NSF XXXXX WSP Phe DWG 00014Document1 pageKafd A1 111 Comn NSF XXXXX WSP Phe DWG 00014YazNo ratings yet

- Sewage Disposal SystemDocument35 pagesSewage Disposal SystemKent Jonas C. GensisNo ratings yet

- Optimization in Water ResourcesDocument8 pagesOptimization in Water ResourcesRaaziaNo ratings yet

- Reducing Non-Revenue Water Through Infrastructure ImprovementsDocument30 pagesReducing Non-Revenue Water Through Infrastructure ImprovementsAkbar UzairNo ratings yet

- Impact of diversions in the Chalakudy River BasinDocument10 pagesImpact of diversions in the Chalakudy River Basinc_surendranathNo ratings yet

- Saes S 030Document9 pagesSaes S 030dyxNo ratings yet

- Acknowledgement: Shankar Ranjit, As Well As The Other Professors in The Division For Giving Us Such ADocument6 pagesAcknowledgement: Shankar Ranjit, As Well As The Other Professors in The Division For Giving Us Such AKshitiz ShresthaNo ratings yet

- Water PollutionDocument2 pagesWater PollutionT NguyênNo ratings yet

- Safe Yield & Factors-1Document18 pagesSafe Yield & Factors-1imrankhanNo ratings yet

- Dutypoint EC Technical BrochureDocument6 pagesDutypoint EC Technical BrochureDouglas AraujoNo ratings yet

- Watershed Management-Terms HandoutsDocument4 pagesWatershed Management-Terms HandoutsKaira Mae CamiletNo ratings yet

- Essential Guide to Water FeaturesDocument49 pagesEssential Guide to Water FeaturesSahar ZehraNo ratings yet

- MDP Costa Rica FinalDocument108 pagesMDP Costa Rica FinalmanuelNo ratings yet

- Fire hydrant and valve mapDocument1 pageFire hydrant and valve mapparamedic fleetplpNo ratings yet