Professional Documents

Culture Documents

2001v05 Responsibilities

Uploaded by

anoopkumar0 ratings0% found this document useful (0 votes)

13 views8 pagesOriginal Title

2001v05 Responsibilities (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views8 pages2001v05 Responsibilities

Uploaded by

anoopkumarCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Duane K. Miller, Sc.D, P.E.

the main steel member itself, at a dis-

Introduction tance removed from the connection.

“I specified the use of AWS D1.1 – what

Connections often involve significant

else do you expect me to do?”

changes in load paths. In other cases,

“I don’t know anything about welding connections are the points of highest

– and I don’t want to know anything about load concentration. The method of

welding.” making the connection may introduce

“Maybe I’m supposed to do something stress concentrations. Welding intro-

as it relates to welding, but I don’t have the duces residual stresses, new materials

foggiest idea of what’s right and wrong.” (the deposited weld metal, as well as

Perhaps in jest, maybe with a bit of the heat-affected zones), and potential

intentional sarcasm, or perhaps with an stress raisers. For all of these reasons,

honest expression of a heartfelt atti- the engineer must become involved

tude, in one way or another, all of the with certain aspects of welding in a

preceding have been expressed by en- structural steel system.

gineers working on projects involving Codes and specifications, particu-

Duane K. Miller, Sc.D, P.E., is larly in a mature industry such as steel

the welding of structural steel. Regard-

Manager of The Welding Technology less of a given engineer’s level of expe- construction, do a good job of address-

rience with welding, the AWS D1.1 ing most routine applications. Codes,

Center The Lincoln Electric Com- Structural Welding Code – Steel re- however, will never be able to address

quires the engineer’s interaction on a the issues arising from innovative de-

pany Cleveland, OH. signs that press the envelope of what

variety of fabrication and erection is-

sues. This paper aims to identify exam- was considered by the code writers.

ples of such instances, and to provide Moreover, the code writers identify a

practical insights into the issues that range of options that are applicable

need to be considered when addressing only when specified by the engineer,

circumstances requiring the engineer’s knowing that they are not justified in

participation. all applications. Only the engineer is in

The need for the engineer’s involve- a position to understand the unique de-

ment in welding should not come as a mands upon a new structure, and

surprise to anyone with even a casual therefore, code writers, including those

knowledge of steel construction. Signif- of AWS D1.1, rely upon these individu-

icant effort and resources are expended als to identify specific requirements for

in determining structural systems and unique structures.

member sizes. However, in those few

situations where failures occur, they in- Unfortunate Use of Terms

evitably involve connections, whether Most code users are familiar with

the connections be riveted, bolted, or provisions that “require the approval

welded. Rarely do failures occur within of the engineer” as well as those that

Modern Steel Construction / May 2001

are applicable “when specified by the CONTRACT DOCUMENTS not mean that such prequalified details

engineer”. Unfortunately, in D1.1, The engineer is responsible for the are suitable for all applications. Specif-

sometimes the wording describing the creation of the general contract docu- ically, it states that prequalified joints “.

engineer’s responsibilities is not as de- ments that will govern the fabrication . .have repeatedly demonstrated their

finitive as it should be. and erection of a structure, and devel- adequacy in providing the conditions

The following are just a few exam- opment of the documents that address and clearances necessary for deposit-

ples in which the wording of D1.1 is welding-related issues is no different. ing and fusing sound weld metal to

weak or tentative when addressing the The engineer has the latitude, and the base metal. However, the use of these

duties of the engineer: responsibility, to add to the contract details in prequalified WPSs shall not

• “[All provisions are applicable], ex- documents any provisions not ad- be interpreted as implying considera-

cept those that the engineer specif- dressed in the code, but necessary for tion to the effects of the welding

ically modifies or exempts…” (1.1) the specific project. process on material beyond the fusion

• “The engineer shall use” (2.39.2.1) Six major topics are required by boundary, or suitability for a given ap-

• “…performance shall otherwise be to D1.1 to be addressed in contract docu- plication.” (Subsection 3.1 goes further

the satisfaction of the engineer…” ments, as follows: and states that a prequalified joint de-

(6.27.2) 1) Complete and detailed drawings tail should not be used without the ap-

• “…provided the contractor demon- 2) Determination of whether the struc- plication of engineering judgment).

strates to the engineer … ture is statically or dynamically Provision 2.2.4.3 requires that spe-

“(5.15.4.1) loaded cial joint details be shown on drawings,

• “…when requested by the 3) Inspection issues and special inspection applied to spe-

engineer…“ (5.3.1.1) 4) Alternate acceptance criteria (if ap- cific joints is required to be shown on

• “…shall be brought to the attention plicable) the drawings per provision 2.2.5.

of the engineer…“ (6.27.4) 5) Impact testing (if applicable) Skewed T-joints are required to have

• “…the engineer should evaluate …“ 6) Criteria for welding on existing special details outlined on the draw-

(C 7.6.1) structures (when applicable) ings according to provision 2.11.1.

• “The engineer may choose…“ (C It should be noted that failure to When cyclic loading is applied, subsec-

5.15.4.3) specify some of the above issues results tion 2.21 states that the engineer “. .

As the preceding examples illus- in a default condition that, depending .shall provide either complete details,

trate, it is not sufficient to simply re- on the application, may or may not be including weld sizes, or shall specify

view the code for every mention of acceptable. When the engineer chooses the planned cycle life and the maxi-

“specify” or “approve”. A comprehen- not to address a specific area and the mum range of moments, shears, and

sive understanding of the code is nec- default condition results, the conse- reactions for the connections.” While it

essary in order to make certain that quences must be understood. is not specified that this must be incor-

every interaction the code expects of porated into the design drawings, it is

the engineer is accomplished. the normal convention to do so.

Fortunately, the D1 Structural Weld- Drawings For tubular T-, Y-, or K- connections

ing Committee has recognized the con- Drawings are one of the critical the “Z” loss dimensions (a function of

fusion that could result from the means by which important information the welding process, groove angle, and

unfortunate choice of words and a sys- relating to a specific project is commu- position of welding) are listed in Table

tematic review of the entire code is un- nicated to the parties involved. This in- 2.8. Provision 2.39.2.1 requires that

derway. The goal is to create a more cludes not only data that address the “The engineer shall use [Figure 3.5] in

uniform pattern throughout the code, materials involved, sizes of members, conjunction with Table 2.8 to determine

generally using the terms “when ap- length and locations of welds, etc., but the minimum weld size in order to de-

proved by the engineer”; or, “when also provides the opportunity to in- termine the maximum weld stress . . .”

specified by the engineer”, depending clude notes that communicate detailed For evaluating the suitability of spe-

on the nature of the provision. approaches to be used when fabricat- cific joint details, whether prequalified

ing the affected member(s). or not, the commentary to provision

THE ENGINEER’S INVOLVEMENT Drawings, whether physically pre- 2.1.3 is especially helpful. Lamellar

The code invokes the engineer’s in- pared by the engineer or by a detailer, tearing in particular is discussed in

volvement in the construction process or even when prepared by the contrac- great detail, providing valuable insight

in a variety of manners, but in general, tor, are ultimately the engineer’s re- into preferred practices.

the engineer’s responsibilities can be sponsibility and are a key ingredient in

placed into one of five categories as any successful project. Static versus Cyclic Loading

contained below: D1.1 has a specific subsection (2.2) D1.1 contains criteria for both stati-

1) The engineer establishes basic con- entitled “Drawings” that details most cally and cyclically loaded members.

struction contract documents. of the requirements. Provision 2.2.1 re- Nowhere in the code is there a direct

2) The engineer specifies that certain quires that the drawings contain “full statement requiring the contract docu-

options in the code are to be applied and complete information regarding ments to specify whether the structure

to the project. location, type, size, and extent of all is statically or dynamically loaded, but

3) The engineer approves various as- welds…” Field and shop welds are to there are provisions that imply this re-

pects of the construction process. be distinguished from each other. Pro- quirement. It is undebatable, however,

4) The engineer evaluates and may ap- vision 2.2.2 requires that weld joints re- that somehow this must be communi-

prove alternatives submitted by the quiring careful attention to welding cated to those involved in the construc-

contractor . sequence be so noted. Provisions 2.2.3 tion process. Provision 2.1.1 requires

5) The engineer addresses unexpected and 2.2.4 spell out specific require- that the “base-metal stresses shall not

fabrication difficulties. ments for different weld types; and exceed those specified in the applicable

2.2.4.2 warns that just because a weld design specifications.” Provision 2.1.2

detail may be prequalified, this does warns that any increase in allowable

May 2001 / Modern Steel Construction

stress not be extended “to the stress The code provides three bases for should not obscure the relative roles of

ranges permitted for base metal or qualification of inspectors in provision the engineer and the inspector.

weld metal subject to cyclic loading.” 6.1.4.1, which also states that, “If the

Since otherwise identical steel mem- engineer elects to specify the basis of Alternate Acceptance Criteria

bers can be applied to both statically inspector qualification, then it shall be D1.1 is a workmanship standard,

and cyclically loaded applications, and so stated in contract documents.” Pro- not a fitness-for-service document. This

yet the fabrication conditions are dif- vision 6.1.4.5 authorizes the engineer to attitude is conveyed in the Commen-

ferent, this detail must be communi- verify the qualification of inspectors. tary where C5.1 states “The criteria

cated to the contractor; contract As previously mentioned in the sec- contained in Section 5, are intended to

documents are the appropriate vehicle tion on drawings, provision 2.2.5 re- provide definition to the producer, su-

for this purpose. quires “any special inspection pervisor, engineer and welder of what

requirements” to be noted on the draw- constitutes good workmanship during

ings or in the specifications. fabrication and erection.” This is fur-

Inspection ther amplified upon in C6.8, which

For those who think the engineer When the engineer specifies radi-

ographic inspection (RT), he/she may says, “The criteria in section 5 should

has no welding-related role in steel not be considered as a boundary of

construction, consider this: when the need to approve alternate locations for

image quality indicators (IQIs) [Figures suitability for service. Suitability for

engineer specifies nothing regarding service analysis would lead to widely

inspection in the contract documents, 6.11 - 6.14 and C6.17.7] , as well as al-

ternate radiographic sources (C6.17.6). varying workmanship criteria unsuit-

all that he/she will get is visual inspec- able for a standard code.” The code

tion, performed by the contractor’s in- Ultrasonic inspection (UT), when

specified by the engineer, raises a num- does permit the engineer to specify al-

spector. There will be no ternate acceptance criteria (provision

nondestructive testing, no independent ber of opportunities for the engineer’s

involvement. For example, annex “K” 6.8), providing they are “suitably docu-

verification inspection – just the code- mented by the proposer and approved

mandated visual inspection performed contains alternate techniques for UT of

welds, but the use of the annex proce- by the engineer.” The proposer could

by (typically) an employee of the con- be the engineer, and this can be speci-

tractor. dures is subject to approval by the en-

gineer. Annex “K” allows for fied in the contract documents. As will

Should the engineer subsequently be discussed later, the proposer could

elect to perform some nondestructive inspection of welds beyond the condi-

tions stated in part “F” of Section 6, and be the contractor, in which case the en-

testing when it was not originally spec- gineer would be called upon to evalu-

ified in the contract documents, then includes variations such as other weld

geometries, transducer sizes, frequen- ated and approve the suitability of the

the owner “shall be responsible for all alternate criteria.

the associated costs including han- cies, couplants, painted surfaces, and

testing techniques, but such variations The alternate criteria can be either

dling, surface preparation, nondestruc- more or less demanding than the stan-

tive testing, and repair of the must be approved of in the contract

documents, according to 6.20.2. dard criteria in the code. More

discontinuities at rates mutually agree- demanding criteria may be important

able between the owner and the con- For T-, K-, and Y- tubular connec-

tions, and when such joints are to be ul- for new and unproven designs, higher

tractor,” according to provision 6.6.5. strength materials, extremely thick

The only relief afforded the owner is trasonically inspected, provision 6.27.1

requires that, “Prior to use on produc- material, very rigid structures, extreme

that, “If such testing should disclose an operating temperatures, high loading

attempt to defraud or gross nonconfor- tion welds, the procedure and accept-

ance criteria shall be approved by the conditions, applications involving little

mance to this code, repair work shall be redundancy, and other factors.

done at the contractor’s expense.” A engineer . . . ” The acceptance criteria

for all tubular connections is to be iden- Conversely, well understood applica-

much better situation exists if the engi- tions with a long history of satisfactory

neer considers inspection issues where tified in the contract documents, ac-

cording to provision 6.13.3. performance may be instances where

the contract documents are being cre- the engineer would use the option of

ated. Part G of Section 6 deals with “other

examination methods,” permitting the 6.8 to permit less rigorous acceptance

In provision 6.1.1, the code requires criteria, providing their use can be

that nondestructive testing (NDT) use of less conventional nondestructive

testing methodologies. Subsection 6.34 justified.

requirements be stated in the bid docu-

ments, including the types of welds to requires that all NDT methods in part

G have “specific written approval of Impact Testing

be examined, the extent of examina- Provision 4.1.1.3 states: “When re-

tion, and the method or methods of the engineer.” The code recognizes ra-

diation imaging systems, including quired by contract documents or speci-

testing. The code automatically fications, impact tests shall be included

requires fabrication/erection inspec- real-time imaging, and such NDT may

be used when so approved by the engi- in the WPS qualification. The impact

tion, which are the responsibilities of tests, requirements, and procedures

the contractor unless the contract docu- neer, in conformance with provision

6.35.1. Provision 6.35.2 outlines twelve shall be in conformance with the provi-

ments indicate otherwise. The engineer sions of Annex III, or as specified in the

is obligated in 6.1.2.2 to determine specific essential variables that are to

be addressed in the written procedures. contract documents.” Annex III con-

whether verification inspection is tains a variety of details regarding the

required – the type of inspection that is The specifics of many of the nonde-

structive testing techniques may be location of the Charpy impact testing

independent of the contractor, and the specimen, the number of required

results of which are reported to the quite foreign to the typical Structural

engineer, but the independent testing specimens, the procedures of retests

engineer. Provision 6.1.2.2 permits the and other details. What is not con-

engineer to waive verification inspec- laboratories that commonly are

charged with executing these assign- tained therein, however, is the testing

tion, perform all inspection functions temperature or the minimum average

with the verification inspector, or use ments are usually highly cognizant of

these details and can provide the nec- energy level. Annex III 1.3 makes this

both fabrication/erection and verifica- the responsibility of the engineer. Also,

tion inspection. essary help for such situations. Re-

liance on these other experts, however, the engineer is to “consider the effects

of welding position as it may relate to Visual inspection is required for the

heat input on the heat-affected zone work performed to strengthen or repair

(HAZ) test results….” a structure, in accordance with provi-

The role of impact properties, frac- sion 8.6.1. However, such visual in-

ture toughness, and the requirements spection is also subject to conforming

for minimum specification of proper- with the “engineer’s comprehensive

ties as they relate to these issues is be- plan.” Nondestructive testing criteria

yond the scope of this paper. Excellent are required to be specified in contract

references are available that address documents as well (8.6.2).

the complex issues involved. (2.) How- Strengthening existing structures is

ever, the engineer must understand a challenge. Repairing damaged struc-

that, when no impact requirements are tures is an even greater challenge. Per- Figure 1

specified in contract documents, there forming such procedures on structures lows: “for cyclically-loaded non-tubu-

is no minimum level of notch tough- with materials that were not welded in lar connections, there shall be no tem-

ness that can be assumed for the weld the first place compounds the problem porary welds in tension zones or

metal, heat-affected zone, or the base further. Under such circumstances, the members made of quenched-and-tem-

metal. engineer should seek out the experts pered steels except at locations more

with experience in this particular field. than 1/6 of the depth of the web from

Welding on Existing Structures These unique situations are prime ex- tension flanges of beams or girders…”

When one is strengthening and re- amples of circumstances that codes For architecturally exposed steel, or for

pairing an existing structure, the num- cannot be expected to address suffi- other conditions of dynamic loading,

ber of situations that conceivably could ciently. Job-specific specifications need such temporary welds may be unac-

be encountered is practically endless. to be developed by the engineer in ceptable. In such circumstances, the en-

Thus, it is impossible for any code to order to address these unique circum- gineer can specify their removal.

provide specific requirements applica- stances. Tack welds are to be incorporated

ble to every situation that could arise. into the final welds. Provision 5.18.2.3

D1.1 Section 8 is devoted to the subject requires that tack welds not incorpo-

OPTIONS TO BE ORDERED rated into the final welds be removed.

of welding on existing structures, and

so issues requiring the engineer’s in- BY THE ENGINEER This provision, however, does not

volvement are concentrated in this sec- The code tries to provide general re- apply to statically loaded structures,

tion for this topic. The specific plans quirements that are applicable to most unless required by the engineer. With-

drawn up by the engineer constitute situations. There are other conditions out the engineer’s involvement, there-

the means by which the code writers that are made available as “options” to fore, tack welds need not be

have addressed these situations. the engineer, fully described, but not incorporated, and they need not be re-

D1.1 Section 8 obligates the engi- made universally applicable. Rather, moved from statically loaded struc-

neer to prepare “a comprehensive plan the code relies upon the engineer to de- tures. This may be undesirable for

for the work”, with plans that include termine when these options should be architecturally exposed steel, and may

“but are not limited to, design, work- specified for a specific application. not be considered a conservative ap-

manship, inspection, and documenta- Such specification is typically done in proach for higher-strength steels.

tion” (8.1). The base metal type used in the contract documents. There are no secondary members in

the original structure is to be deter- 1) Options that the engineer may spec- welded design, and therefore, attach-

mined before drawings and specifica- ify fit into four categories: ments such as steel backing may affect

tions are developed (8.2.1), and the 2) Structural details the performance of the overall struc-

suitability of welding of the base metal 3) Certifications for welding materials ture. Provision 5.10.4 requires the re-

is to be established (8.2.2). For base 4) Qualification of weld details moval of backing from joints that are

metals other than those that are pre- 5) Stud welding activities transverse to the direction of computed

qualified and listed in Table 3.1, “Spe- stress, but permits steel backing of

cial consideration by the engineer must Structural Details welds that are parallel to the direction

be given to the selection of filler metal There are a variety of structural de- of stress to stay in place, unless their re-

and WPSs” (8.2.3). tails that the engineer may elect to re- moval is specified by the engineer

Provision 8.3.5 requires that, “The quire for a specific project. What is an (5.10.4). Additionally, the longitudinal

engineer shall determine the extent to acceptable detail for one type of struc- welds that attach backing are required

which a member will be permitted to ture may not be acceptable for another. to be welded full length for cyclically-

carry loads while heating, welding, or The type of loading may be a major fac- loaded structures, but for statically-

thermal cutting is performed.” tor in determining such acceptability. loaded structures, provision 5.10.5

If fatigue life enhancement is re- The engineer must evaluate these de- permits intermittent welds, and allows

quired, provision 8.4.1 identifies meth- tails and the structural requirements all the backing to stay in place, regard-

ods that can be used, when approved and order the optional details appro- less of the direction of loading, unless

by the engineer. The engineer is obli- priate for the specific application. required to be removed by the engi-

gated to determine appropriate in- Provision 5.18.1 requires that tem- neer.

creases in the allowable stress range, porary welds be made to the same Weld tabs permit groove welds to be

according to 8.4.2. When members are quality criteria as final welds. Even made in a manner that will ensure

to be “heat straightened”, the provi- though the quality should be the same weld soundness to the end of the joint.

sions of 8.5.5 apply; and, additionally, as a final weld, when the engineer so

requires, the temporary welds are to be

Visit InfoExpress No. 48

8.5.2 requires the engineer to determine

whether unacceptable discontinuities removed. Conversely, when the engi- at www.modernsteel.com

are to be repaired prior to heat straight- neer does not require their removal, Provision 5.31.2 permits weld tabs to

ening or welding. they may remain in place except as fol- remain in place (and this is typical

May 2001 / Modern Steel Construction

practice) unless the engineer requires will permit the structure to perform in New Materials and Processes

them to be removed. Aesthetics may its intended manner. The code provides for methods of

dictate their removal, and AISC re- Approval or denial of these alterna- allowing new welding and cutting

quires the removal of weld tabs from tives may significantly affect the con- processes, new base metals and new

jumbo section splices (AISC LRFD J15). tractor’s cost. Not knowing whether an filler metals. New developments will

When removal is required as in these alternative will be approved or not always precede code changes that re-

examples, D1.1 stipulates that the engi- places a contractor in a difficult posi- flect such advances. If such provisions

neer must specify it. tion during the bidding process. To did not exist, progress would be im-

eliminate this risk, some contractors peded as innovations are put “on-

Certification of Materials will submit bids contingent upon ap-

If the engineer desires certification hold,” waiting for incorporation into

proval of certain code-permitted alter- the governing specifications.

of certain welding materials, these natives that are subject to the

must be requested. This would include The code lists welding processes

engineer’s approval. In accepting the that may be used for prequalified

welding filler materials (5.3.1.1), weld- bid, the engineer agrees to also ap-

ing shielding gas (5.3.1.3), and welding WPSs, as well as welding processes

prove such alternatives. If the contract that may be used for construction

stud certification (7.3.3). is modified later, the contractor is then under the code. The code further ex-

in a position to renegotiate the financial tends the opportunity for the use of

Qualification of Welding Joints aspects of the project. other welding processes, when the en-

The weld throat in a flair groove Sometimes, after the contract is let, gineer (3.2.3, 4.15.2) approves these

weld is dependent upon the actual cost-saving alternatives are identified other methods. Alternate processes

groove geometry and the welding pro- which still require the engineer’s ap- could involve a variety of new or dif-

cedures employed. As such, provision proval. In order to make the situation ferent controls that need to be moni-

4.10.5 permits the engineer to order into a ‘win-win’ proposition, “value- tored, and the evaluation of such

tests that are used to verify that the re- engineering” can be applied, and the variables is part of the alternate process

quired weld throat is consistently ob- savings divided between the contractor approval activity.

tained. The engineer must specify the and the owner. Regardless of any pos- The code approves specific thermal

extent of testing, the sizes of members sible financial incentives, the integrity cutting processes including electric arc

involved, etc. of the project cannot be sacrificed. cutting and gouging, and oxyfuel cut-

In most situations, the contractor ting. Provision 5.15.4.1 permits other

Stud Welding Operations makes the request to the engineer to thermal processes to be used for cut-

The engineer has a variety of op- approve an alternative. When the op- ting, provided the engineer approves

tions with regard to stud welding. Pro- tion is not granted, a default position the method.

vision 7.3.5 allows the engineer to exists and the project can progress ac- The code lists various base metals

select the studs that will be used for cordingly, utilizing the standard prac- that can be used for construction, but

testing. The studs are supplied at the tice identified in the code. materials that are not listed in Table 3.1

contractor’s expense, although the test- There is one known exception to the or Annex M can be used if the WPSs

ing is done at the owner’s expense. Re- general pattern where the default posi- are qualified by test, and are approved

garding stud bases, 7.2.4 permits the tion exists: provision 4.1.1 requires the by the engineer (4.7.3).

engineer to request descriptive infor- engineer to approve WPSs that have

mation on the stud and arc shield, cer- been qualified by test, and if the WPSs

tification from the stud manufacturer are not approved, there is no default Routine Items

regarding the stud base qualification, status presented in the code. Provision While nothing should be viewed as

and qualification test data. In all of 4.1.1 clearly states that this is applicable truly routine, the code contains some

these situations, the engineer must to WPSs that are qualified by test, and a provisions that are generally accepted

evaluate the option’s significance and similar, clear-cut statement cannot be by engineers for most projects, and

relative applicability to a specific proj- found in Section 3 regarding welding these have been placed into this cate-

ect. There is generally some degree of procedures that are prequalified. This gory.

cost associated with these activities, topic has been previously discussed All welders, welding operators, and

and therefore, the Committee has not (see Funderburk & Miller, 1998) and tack welders who perform work gov-

chosen to make them universally appli- further details are beyond the scope of erned by the code must be qualified by

cable. It is the engineer’s obligation to this paper. In this situation, the engi- test as prescribed in the code. In most

determine when and where such op- neer must approve the WPS qualified situations, contractors will have previ-

tions should be applied. by test in order for welding to begin. ously qualified their work force in

When the engineer is called upon to other projects, and the code extends to

APPROVALS approve a request made by the contrac- the engineer the option of approving

The engineer is required to make a tor, it typically fits into one of the fol- the use of previous personnel qualifica-

significant number of evaluations of al- lowing general categories: tion tests, eliminating the need for re-

ternatives that the code permits. These 1) New materials and processes not testing (4.1.2.1).

are generally in response to requests by covered by the code. The engineer’s involvement in ap-

the contractor. Issues that require the 2) Routine items that are generally ap- proving the qualifications of personnel

engineer’s approval are concentrated proved but should be critiqued for goes beyond welders, and includes in-

in D1.1 Section 5, although such items anomalies. spectors (6.1.4.5).

are dispersed throughout the code. The 3) Practices that need careful review to Stud welding is covered in Section 7

relative suitability of these various al- make certain they are appropriate of the code, and there are a number of

ternatives must be considered by the for the application. situations where the engineer may be-

engineer, always with an eye to 4) Practices that may or may not be ac- come involved. Provision 7.2.1 permits

whether the alternatives being sought ceptable, depending on the specific alternate stud head configurations,

application. when approved by the engineer. Provi-

Modern Steel Construction / May 2001

sion 7.3.4 permits the use of studs that “agreed upon by the engineer and the dures that have been previously quali-

do not have quality control tests pro- fabricator.” fied, and can also approve the use of

vided the manufacturer of the studs standard welding procedures as pub-

performs mechanical tests. The engi- Practices Requiring lished in AWS B2.1.XXX-XX. In most

neer is to determine the number of tests Careful Review cases, the acceptance of previously

to be performed. To prove the suitabil- The following options need careful qualified welding procedures is a rou-

ity of stud welding procedures, “bend review since the test data that is re- tine practice, providing that these

tests” are performed and often can be quired to support these alternatives WPSs have the proper documentation,

used in the bent condition. When may not be applicable to the specific and are applicable to the proposed

straightening is required, provision project involved. In other words, the work. The use of standard welding

7.8.3 requires that it be done without tests may accurately demonstrate the procedures, a new provision in D1.1-

heating, except as otherwise provided capability of a concept to work under 2000, can be reviewed with the same

in the contract, and as approved by the test conditions, and yet it may not per- scrutiny, except that the supporting

engineer. form under actual fabrication condi- PQRs would not be available to the en-

When performing reduced section tions. This warning should not cause gineer for review. However, the AWS

tension tests, and when the steels in- the engineer to automatically reject B2 Committee has performed this task

volved are high strength, some tensile such options. Rather, they need to be already, simplifying the process, and

testing machines may be incapable of carefully reviewed, with the assistance perhaps adding another level of assur-

pulling the high strength specimen to of a consulting expert if necessary, to ance to the sequence.

destruction. Under these conditions, ensure the expected results will be Preheat for welding is an essential

Figure 4.14, Note 8, permits changes to achieved. variable of a WPS, and the code pro-

the specimen dimensions when According to provision 4.1.1.2, the vides minimum levels of preheat for

engineer can accept welding proce- prequalified WPSs. The code extends

the option of reduced preheats, based

upon the use of Annex XI; or, for SAW

welding,when hardness checks are

made in the HAZ. Also, WPSs could be

qualified by test with a reduced pre-

heat. In all three of these cases, the en-

gineer must approve the reduced

preheat before it can be used in pro-

duction (3.5.2, 3.5.3, 4.1.1).

The required level of preheat for a

project is a function of many variables,

including the actual composition of the

steel being used, the degree of restraint,

and the hydrogen content of the de-

posited weld metal. These conditions

may not be replicated under testing

conditions. Restraint is almost never

replicated with small test specimens,

and the engineer should carefully re-

view supporting data for the reduced

preheats in order to make certain that

the tests adequately represent the con-

ditions that will be encountered in pro-

duction.

Alternate acceptance criteria, previ-

ously discussed above under “Contract

Documents,” may also fit into the ap-

proval category when someone other

than the engineer proposes the alter-

nate criteria. Such options are ad-

dressed in subsection 6.8, and

provision 6.5.5. The code makes such

alternate criteria acceptable, providing

that certain stipulations are met, and

that the engineer approves of the alter-

native.

Practices That May or

May Not Be Acceptable

The acceptability of application-spe-

cific provisions may depend on the

structure, loading, specific location

within the structure, or other factors. It

is not a matter of “good practice” or

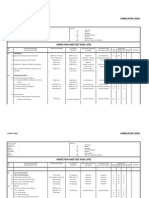

Table 6.1. Reprinted with permission of the American Welding Society, from AWS

D1.1: 2000, Structural Welding Code-Steel.

“bad practice,” but rather, what is right quires that the inspector check to make Provision 5.15.1 permits removal

for the particular conditions involved. certain “that no unspecified welds and repair of mill-induced discontinu-

Specific roughness requirements for have been added without approval.” ities on the surface of the material. The

various thermal cuts are outlined in While a citation to the engineer is not discontinuity is required to be removed

5.15.4.3, and gouges that exceed those made, 1.2 states that “the need for ap- and all welded repairs are required to

limits can be repaired under the provi- proval shall be interpreted to mean ap- be done in accordance to the code. The

sions of 5.15.4.4, which ends by stating proval by the building commissioner total length of repair welding may not

“In thermal-cut surfaces, occasional or the engineer.” exceed 20% of the length of the plate

notches or gouges may, with approval Weld tabs are required by 6.17.3.1 to surface being repaired, except with the

of the engineer, be repaired by weld- be removed prior to radiographic in- approval of the engineer. For edge dis-

ing.” The commentary applied to these spection unless otherwise specified by continuities that are discovered on cut

provisions specifically addresses the the engineer. material, provision 5.15.1.1 provides

topic of “occasional notches and For cyclically loaded structures, specific levels of acceptability and re-

gouges” by stating that the Committee thermal cutting is to be done in a mech- pair practices. If these limits are ex-

“refrained from assigning any numeri- anized or automatic manner unless the ceeded, the part “shall be rejected and

cal values on the assumption that the engineer approves of free-hand thermal replaced, or repaired at the discretion

engineer, being the one most familiar cutting 5.15.4.2). of the engineer.”

with the specific conditions of this During weld inspection, discontinu-

structure – will be a better judge of UNEXPECTED CIRCUMSTANCES ities in the base material may be ob-

what is acceptable. The engineer may Irregularities that may occur during served. Provision 6.20.4 deals with UT

choose to establish the acceptance crite- a project often present undesirable cir- inspection and requires that base metal

ria for occasional notches and gouges.” cumstances for both the contractor and discontinuities such as cracking, lamel-

Caulking involves the mechanical, the engineer, but they must be resolved lar tearing and delaminations that are

plastic deformation of weld metal and in order for the project to move ahead. discovered adjacent to the weld be re-

base metal and historically has been Time is of the essence, since while the ported to the engineer for disposition.

prohibited by the code since it can be engineer is evaluating such situations, For UT inspection of T-, Y-, and K- con-

used to fraudulently mask weld dis- projects are typically put on hold, re- nections in tubular steel, base metal

continuities. D1.1:2000 was changed to sulting in delays. Unlike situations in discontinuities detected are required to

permit caulking under certain condi- which the code has provided a default be “brought to the attention of the en-

tions because it may prevent failure of alternative, these circumstances require gineer or inspector.”

various coatings that are subsequently the engineer to act. Efforts at mutual

applied. Weld inspection must be com- cooperation on the part of the contrac-

pleted prior to the caulking treatment, Fit-up and Alignment Problems

tor and the engineer will facilitate When steel is assembled, fit-up be-

and “the technique and limitations on progress in difficult circumstances.

caulking are [to be] approved by the tween adjacent members may not be

When unexpected construction dif- what was expected on the drawings.

engineer” (5.28). ficulties arise, and when such difficul-

s various base metals that can be Such misalignment may be the result of

ties are potentially significant to the poor workmanship. It can also result

used for construction, but materials project and the performance of the

that are not listed in Table 3.1 or Annex from the accumulation of acceptable

structure, it is important for the engi- tolerance variations, whether in the as

M can be used if the WPSs are qualified neer to obtain the necessary technical

by test, and are approved by the engi- received materials, or in the fabricated

guidance in order to perform the code- pieces, resulting in dimensions that ex-

neer (4.7.3). mandated obligations. This expertise

Provision 6.5.6 requires the inspec- ceed code limits. Such variations may

frequently comes from consultants have no effect on the final structures

tor to identify parts that have been in- who have unique expertise in dealing

spected and accepted, but the method behavior, but in other situations, such

with such problems. differences may be critical. The engi-

of identification is not defined. How- Unexpected issues requiring the en-

ever, “die stamping” cannot be used on neer must make this evaluation.

gineer’s involvement fit into these cat- Provision 5.22.3.1 provides specific

cyclically loaded members, unless ap- egories:

proved by the engineer. girth weld alignment requirements for

1) Base metal discontinuities tubular members; additional tolerance

Provision 5.21.3 requires a distor- 2) Fit-up and alignment problems

tion control plan where “excessive relief is available for this alignment,

3) Welding problems when approved by the engineer.

shrinkage or distortion can be ex- 4) Post-welding corrections

pected.” The plan is to be submitted to Specific acceptable tolerances for

the engineer “. . . for information and groove weld root openings are given in

Base Metal Problems provision 5.22.4.3. If these tolerances

comment” before welding is per- During fabrication and erection, dis-

formed on the member in which the ex- are exceeded, they may be corrected by

continuities in base metals may be de- welding, but only when approved by

cessive shrinkage or distortion is tected. The shrinkage stresses induced

expected. The code provides no “de- the engineer (5.22.4.4).

by welding are significant, and crack-

fault” position for the condition when ing or lamellar tearing may result. Cut-

the engineer does not supply com- ting of plates or shapes may expose Welding Problems

ments, nor is there a code-defined time- internal discontinuities within the base A crack in a weld, or in the adjacent

frame, or method for communication metals. Such discontinuities may or base metal, is a very serious issue that

of such comments. may not affect the performance of the needs to be addressed. The causes or

In addition to ascertaining that all final structure, and as such, the code re- implications of such cracking need to

required welds have been placed in the quires the engineer to evaluate any be understood, and the potential im-

proper location and are of the required non-routine imperfections in the base pact on the structure evaluated. When

size and length, provision 6.5.1 re- metal. major cracking occurs, the engineer is

to be notified so such an evaluation can applied in order to correct for camber Funderburk, R.S., and Miller, Duane

take place. variations. Provision 5.19.1 permits K., “Reviewing and Approving Weld-

When base metal is damaged be- such adjustments, but 5.19.2 requires ing Procedure Specifications,” AISC

cause of faulty welding, or when the that any corrections in the camber of National Steel Construction Confer-

base material is damaged by removal quenched-and-tempered steel mem- ence Proceedings, April 1-3, 1998, New

Orleans, pages 24-1—24-25.

of faulty welds for re-welding, and the bers be done only with the approval of

base metal is no longer “in accordance the engineer.

with the intent of the contract docu- Provision 5.26.2 prescribes the tem-

ments, the contractor shall remove and perature limits for heat straightening,

replace the damaged base metal or and quenched-and-tempered steels

shall compensate for the deficiency in have a lower approved temperature

a manner approved by the engineer” limit (1100ºF) than other steels (1200°F).

(6.6.3). This requires more careful monitoring

Provision 5.26.3 requires the engi- of the steel and thus requires the engi-

neer’s approval for “repairs to base neer’s involvement.

metal . . . repairs of major or delayed

cracks, repairs to electroslag and elec- Conclusion

trogas welds with internal defects, or As the preceding has demonstrated,

for a revised design to compensate for there are a host of situations that may

deficiencies.” This provision is in place require the engineer to become in-

because such defects can have a major volved with the construction process as

impact on the performance of the struc- it relates to welding. This involvement

ture and the repair techniques to deal can range from nearly routine events to

with such problems may be complex in major unexpected occurrences with po-

and of themselves. tentially monumental consequences.

When electroslag welding is per- The Structural Welding Code relies

formed, and if the welding is inadver- upon the engineer to use engineering

tently stopped, and then restarted, judgment in determining how specific

such restarts are required by Provision issues are to be addressed for individ-

5.4.4 to be reported to the engineer. ual applications. Particularly challeng-

Other criteria apply to these conditions ing circumstances may dictate that the

as well, including radiographic inspec- engineer consult with experts in the

tion. field in order to properly evaluate the

When unacceptable welds are situation and determine the correct

made, and further work is performed course of action to follow.

which makes access to the original de-

fective weld impossible, a plan must be DISCLAIMER

established to address the problems. If An attempt was made to compre-

the members are not cut apart in order hensively identify circumstances cited

to gain access to the original weld, the within AWS D1.1-2000 where the engi-

deficiency in the original weld “shall neer is required to interact in the fabri-

be compensated for by additional work cation and erection processes that

performed according to an approved, relate to welding. It is possible and

revised design” (5.26.4). The engineer even probable that provisions have

is responsible for this approval, consis- been missed. The author welcomes

tent with subsection 1.2. feedback regarding items that may

have been missed, and also strongly

Post-Welding Corrections encourages the user of this information

Before steel is cut apart for any rea- to perform his/her own independent

son, 5.26.3 requires that the engineer be review of the entire code to address all

notified. This is particularly important the issues that may be applicable to a

for structures during the erection stage, specific project. While the author is a

since the member being cut may be member of the AWS D1 Committee,

performing critical load-bearing func- opinions and views expressed in this

tions at that time. article are his alone, and not those of

When holes are mislocated, provi- the AWS D1 Structural Welding Com-

sion 5.26.5 provides a detailed se- mittee.

quence that must be followed. The

engineer must approve such proce-

dures when the base metal is subject to References

cyclic loading. In many cases, it is pre- American Welding Society. Struc-

ferred to leave the mislocated hole in tural Welding Code—Steel: AWS

place since welding under these condi- D1.1:2000, 17th ed., Miami, FL, 2000.

tions frequently introduces weld de- John M. Barsom and Stanley T.

Rolfe, Fracture and Fatigue Control in

fects that may be more harmful than Structures: Applications of Fracture Me-

the hole itself. chanics, 3rd ed., West Conshohocken,

When camber is incorrect on a built- PA: American Society for Testing and

up member, heat straightening can be Materials, 1999.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bridge Inspection Manual V4.2 (REVISE As of MAR 15 - 05)Document159 pagesBridge Inspection Manual V4.2 (REVISE As of MAR 15 - 05)Vincent Montrix O. Calapre100% (1)

- Iso 9002 International StandardDocument6 pagesIso 9002 International Standardjojumathew100% (1)

- Painting System Guide: SSPC: The Society For Protective CoatingsDocument2 pagesPainting System Guide: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- NYX Ndustries ZC: Welder Performance Qualification RecordDocument1 pageNYX Ndustries ZC: Welder Performance Qualification RecordanoopkumarNo ratings yet

- 20210430023301-Technical Delivery Conditions - 2021 - enDocument1 page20210430023301-Technical Delivery Conditions - 2021 - enanoopkumarNo ratings yet

- BS 5276-3-1979Document10 pagesBS 5276-3-1979anoopkumarNo ratings yet

- Anoop Kumar.V: UAE: +971547574919 IND: +918606579679Document5 pagesAnoop Kumar.V: UAE: +971547574919 IND: +918606579679anoopkumarNo ratings yet

- BS 5276-4-1977Document18 pagesBS 5276-4-1977anoopkumarNo ratings yet

- BS 709-1983Document38 pagesBS 709-1983anoopkumarNo ratings yet

- BS 709-1983Document38 pagesBS 709-1983anoopkumarNo ratings yet

- Paint Specification No.: SSPC: The Society For Protective CoatingsDocument6 pagesPaint Specification No.: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- SSPC Paint 25 BCSDocument6 pagesSSPC Paint 25 BCSanoopkumarNo ratings yet

- Paint Specification No.: Steel Structures Painting CouncilDocument6 pagesPaint Specification No.: Steel Structures Painting CouncilanoopkumarNo ratings yet

- Qualification Procedure No. 2: SSPC: The Society For Protective CoatingsDocument11 pagesQualification Procedure No. 2: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- SSPC How To UseDocument7 pagesSSPC How To UseanoopkumarNo ratings yet

- SSPC Tu 8Document7 pagesSSPC Tu 8anoopkumarNo ratings yet

- SSPC PS Guide 3.00Document3 pagesSSPC PS Guide 3.00anoopkumarNo ratings yet

- Qualification Procedure No. 4: SSPC: The Society For Protective CoatingsDocument6 pagesQualification Procedure No. 4: SSPC: The Society For Protective CoatingsanoopkumarNo ratings yet

- SSPC PS Guide 4.00Document5 pagesSSPC PS Guide 4.00anoopkumarNo ratings yet

- SSPC QP 3Document6 pagesSSPC QP 3anoopkumarNo ratings yet

- HandbookOnRailwayConstruction PDFDocument756 pagesHandbookOnRailwayConstruction PDFrajesh kannan100% (1)

- Electrical MS &check ListDocument17 pagesElectrical MS &check Listjiguparmar20094903No ratings yet

- Kan - TN LP 07Document13 pagesKan - TN LP 07suwantyNo ratings yet

- Sample Itp For VesselDocument10 pagesSample Itp For VesselWijayanto BekasiNo ratings yet

- Test Procedure For PTS - Latest EditionDocument24 pagesTest Procedure For PTS - Latest EditionFirstface LastbookNo ratings yet

- Electrical Permit ApplicationDocument28 pagesElectrical Permit Applicationteodoro,jr. quintanaNo ratings yet

- ELS Lift User Manual VM10-JDocument36 pagesELS Lift User Manual VM10-JPiero CaprettiNo ratings yet

- Food Contact Packaging HandbookDocument93 pagesFood Contact Packaging HandbookJose Luis Castillo100% (1)

- DNV HSC RulesDocument20 pagesDNV HSC RulesRachit SharmaNo ratings yet

- 07412.May2017.Exam PaperDocument13 pages07412.May2017.Exam PaperSasidharan RajendranNo ratings yet

- 9201 Spec Barred TeeDocument23 pages9201 Spec Barred TeeSoumya KumarNo ratings yet

- Storage Tank Test & Inspection Report enDocument10 pagesStorage Tank Test & Inspection Report enMarketing CTNNo ratings yet

- Jethro S. Cariaga: - 09663473605 (Globe) 09516350192 (Talk and text) Philippines· e-mailDocument7 pagesJethro S. Cariaga: - 09663473605 (Globe) 09516350192 (Talk and text) Philippines· e-mailAlexander RaposasNo ratings yet

- IAB 337r3 17 January 2017 Interpretation Implementation ISO 3834Document17 pagesIAB 337r3 17 January 2017 Interpretation Implementation ISO 3834Luice Carol0% (1)

- BS 5750Pt1Document13 pagesBS 5750Pt1Maher BmdNo ratings yet

- Receipt Inspection NS2A4Document11 pagesReceipt Inspection NS2A4islam atifNo ratings yet

- Ism CODE RemovedDocument95 pagesIsm CODE Removedo.atikNo ratings yet

- Cópia de 10Document318 pagesCópia de 10Manoela RodriguesNo ratings yet

- Info Sheet Iris Inspection of TubesDocument2 pagesInfo Sheet Iris Inspection of TubesCepi Sindang KamulanNo ratings yet

- SP 2387Document30 pagesSP 2387Anoop GokhaleNo ratings yet

- SB3.15 Guideline ICA PDFDocument259 pagesSB3.15 Guideline ICA PDFBianca ZahariaNo ratings yet

- CSSBI 61 2021 e v1 1 1 Cold Formed Steel Framing Members CISC 2021Document28 pagesCSSBI 61 2021 e v1 1 1 Cold Formed Steel Framing Members CISC 2021rincivil2ry1232244No ratings yet

- API Moderate Drill Inspection 1607425178Document1 pageAPI Moderate Drill Inspection 1607425178Islam M. RedaNo ratings yet

- SPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS (Singapore Generic - Siphonic) 13092019Document5 pagesSPECIFICATION FOR SIPHONIC RAINWATER DRAINAGE OF ROOFS (Singapore Generic - Siphonic) 13092019Asoka Kumarasiri JayawardanaNo ratings yet

- Round SlingsDocument9 pagesRound Slingswalkerproductions20009116100% (1)

- Printed Circuit Heat Exchangers - Design and FabricationDocument26 pagesPrinted Circuit Heat Exchangers - Design and FabricationJacob Philip100% (1)

- Es 1Document42 pagesEs 1xharpreetxNo ratings yet

- Operating Instruction ROTOCEM - ENDocument81 pagesOperating Instruction ROTOCEM - ENLuis MecNo ratings yet