Professional Documents

Culture Documents

L1

Uploaded by

abu faiz0 ratings0% found this document useful (0 votes)

25 views1 pageASNT Question for PT

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASNT Question for PT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views1 pageL1

Uploaded by

abu faizASNT Question for PT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

ee

Revo

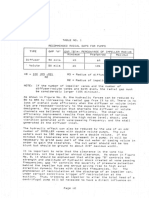

17.

18.

LIQUID PENETRANT METHOD

Lesson 1 Page 8

Quiz 1

Nonmetallic inclusions and porosity in the steel ingot are commonly found

using liquid penetrant inspection techniques.

‘Type II penetrants, according to our test, are those containing a

fluorescent dye.

Because of the capillary action of penetrants, this process of inspection

‘works well on parts with very porous surfaces

When doing a liquid penetrant test. the configuration of the specimen has

lite effect on the effectiveness of the test.

Liquid penetrant inspection can be used only metals such as aluminium

and steel.

The penetrant Inspection method is used only on the finished product

ll and whiting are the names of the two men who invented the penetrant

test method.

The first important step in penetrant testing is surface preparation.

One of the most common contaminants in the penetrant method Is water.

The most common method of surface preparation testing is sandblasting.

Chemical etching is sometimes used to remove smeared metal from a

surface to open discontinuities.

Some subsurface defects can be located with the highly sensitive type II

Penetrants

Blow holes and gas porosity may be detected with the penetrant method.

Solvent cleaning is a common method of surface cleaning parts before

penetrant testing.

The one major limitation to penetrant testing is that the part must be

metallic

Grease and rust would usually be considered a contaminant on the surface

of a test piece.

To locate a defect with penetrant testing, the defect must be open to the

surface.

Tt is considered advantageous for a liquid penetrant material to have low

tension and high capillarity.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Vane Pass FrequencyDocument2 pagesVane Pass Frequencyabu faizNo ratings yet

- Just Right, Just in Time: Condition-Based Maintenance (CBM)Document23 pagesJust Right, Just in Time: Condition-Based Maintenance (CBM)abu faizNo ratings yet

- L5Document1 pageL5abu faizNo ratings yet

- Asme Viii - MT Apendix 6Document2 pagesAsme Viii - MT Apendix 6abu faizNo ratings yet

- ADRE SXP and 408 DatasheetDocument33 pagesADRE SXP and 408 Datasheetabu faizNo ratings yet

- Iris Power TGA B Brochure of PD AnalyzerDocument6 pagesIris Power TGA B Brochure of PD Analyzerabu faizNo ratings yet

- Contoh Perhitungan Maintenance Factor - GER3620Document3 pagesContoh Perhitungan Maintenance Factor - GER3620abu faizNo ratings yet

- Magnetic Particle TestDocument17 pagesMagnetic Particle Testabu faizNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)