Professional Documents

Culture Documents

United States Patent (19) : 11) Patent Number: 45 Date of Patent

Uploaded by

irene septiriana0 ratings0% found this document useful (0 votes)

12 views6 pagesThis patent describes a copper electroplating process that uses a cation-permeable membrane to separate the anode from the cathode. This prevents decomposition of additives in the electroplating bath by oxidation at the anode, increasing bath lifetime and permitting better control of bath chemistry and plating quality. The membrane allows hydrogen ions to pass through but prevents other components of the bath from contacting the anode. This is especially advantageous for nonconsumable electrode processes that consume significant additives.

Original Description:

Original Title

Us 4469564

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis patent describes a copper electroplating process that uses a cation-permeable membrane to separate the anode from the cathode. This prevents decomposition of additives in the electroplating bath by oxidation at the anode, increasing bath lifetime and permitting better control of bath chemistry and plating quality. The membrane allows hydrogen ions to pass through but prevents other components of the bath from contacting the anode. This is especially advantageous for nonconsumable electrode processes that consume significant additives.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views6 pagesUnited States Patent (19) : 11) Patent Number: 45 Date of Patent

Uploaded by

irene septirianaThis patent describes a copper electroplating process that uses a cation-permeable membrane to separate the anode from the cathode. This prevents decomposition of additives in the electroplating bath by oxidation at the anode, increasing bath lifetime and permitting better control of bath chemistry and plating quality. The membrane allows hydrogen ions to pass through but prevents other components of the bath from contacting the anode. This is especially advantageous for nonconsumable electrode processes that consume significant additives.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

United States Patent (19) 11) Patent Number: 4,469,564

Okinaka et al. 45 Date of Patent: Sep. 4, 1984

54 COPPER ELECTROPLATING PROCESS

OTHER PUBLICATIONS

(75) Inventors: Yutaka Okinaka, Madison; Craig G.

Smith, North Plainfield; Lawrence E. Proceedings of the 8th Congress of the International

Smith, Plainfield, all of N.J. Union for Electrodeposition and Surface Finishing,

"Function and Structure of Organic Additives in Elec

(73) Assignee: AT&T Bell Laboratories, Murray troplating", H. Brown, pp. 114-121, 1973.

Hill, N.J. Plating and Surface Finishing, vol. 68, pp. 46-49, 1981,

"Characteristics of Acid Copper Sulfate Deposits for

(21) Appl. No.: 407,151 Printed Wiring Board Applications', L. Mayer and S.

Barbieri.

22 Filed: Aug. 11, 1982 Encyclopedia of Electrochemistry, pp. 726-735, 1964.

51) Int. Cl. .......................... C25D 3/38; C25D 7/00 Primary Examiner-G. L. Kaplan

52 U.S.C. ................................... 204/15; 204/52 R; Attorney, Agent, or Firm-Walter G. Nilsen

204/252

58) Field of Search ................... 204/52 R, 52 Y, 106, 57 ABSTRACT

204/107, 108, 252, 23, 15 A copper electroplating process is described in which

56) References Cited the anode is surrounded by a cation-permeable mem

brane so as to prevent decomposition of additives in the

U.S. PATENT DOCUMENTS electrochemical bath. Such a feature adds to bath life

2,707,166 4/1955 Brown et al. ..................... 204/52 R time and permits better control of bath chemistry and

3,124,520 3/1964 Juda ................... ... 204/52 RX plating quality during the electroplating process. The

3,328,273 6/1967 Creutz et al. ..................... 204/52 R feature is especially advantageous for copper electro

3,537,961 11/1970 White et al. ....... ... 204/52 RX plating processes using nonconsumable electrodes be

4,073,708 2/1978

Hicks .............................. 204/106 X cause of the high consumption of additives and that the

4,269,670 5/1981

Smith .................................... 204/15 copper can be added to the cathode side of the mem

4,310,391 / 1982

Okinaka et al. .................. 204/46 G brane so that acid copper ions need not pass through the

FOREIGN PATENT DOCUMENTS membrane.

591894 2/1960 Canada ............................. 204/52 R 26 Claims, 2 Drawing Figures

U.S. Patent Sep. 4, 1984 4,469,564

4,469,564

1. 2

the bath (e.g., organic additives) from contacting the

COPPER ELECTROPLATING PROCESS anode but permits easy passage of positive ions (gener

ally hydrogen ions) in the electrolyte. Such a process

TECHNICAL FIELD increases bath lifetime because the additives are not

The invention is a process for electroplating copper. 5 affected by the electrochemical processes occurring at

the anode. Such a process using the cation exchange

BACKGROUND OF THE INVENTION membrane permits high speed copper electroplating

Copper electrodeposition is used extensively in a without additive decomposition and allows better con

variety of industrial applications including electroform trol of bath chemistry (e.g., additive concentration).

ing, electrorefining, manufacture of copper powder and O

electroplating. In electrorefining, relatively impure BRIEF DESCRIPTION OF THE DRAWINGS

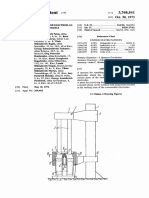

copper is generally dissolved from a consumable copper FIG. 1 shows a diagram of a copper electroplating

electrode and plated out in relatively pure form on a cell with cathode (often a printed wiring board being

cathode. Electroforming is also extensively done in 15 plated with copper), anode and ion exchange membrane

industry to produce various copper articles such as, dividing the cell into two parts; and

electrotypes, phonograph records, band instruments, FIG. 2 shows a diagram of a copper electroplating

heat exchangers, reflectors, etc. cell with membrane immediately surrounding the an

Copper electroplating is used in the production of ode.

many electrical devices and circuits. In many such ap 20 DETAILED DESCRIPTION

plications, particularly in the production of circuit

boards for electronic circuits, a copper electroplating In broad terms, the invention is a copper electroplat

process is used with nonconsumable electrodes. Such ing process in which undesirable oxidation of certain

processes are more versatile than those using consum components of the copper electroplating bath is pre

able electrodes, permit higher plating speeds, better vented by use of a cation-permeable membrane or

control of the bath composition, require smaller appara 25 merely separating the anode from cathode. A large

tus size and generally yield copper layers with excellent variety of copper electroplating processes may be used

physical properties. Particularly advantageous is the (bath composition, temperature, pH, anode structure

fact that the anode does not change size (i.e., cell geom including consumable and non-consumable electrodes,

etry remains fixed) so that more uniform plating results etc.) provided hydrogen ions must pass through the

are obtained. In addition, the copper salts used to pro 30 cation-permeable membrane. Hydrogen ions entering

vide the source of copper are often available as products the cathode compartment should be neutralized in some

of etching procedures associated with the production of way, typically by the addition of an alkaline agent.

copper plated devices. For example, in the production In general terms, the copper electroplating process

of circuit boards, a copper layer is put down over the involves passing current through the anode, electroplat

entire surface of an insulating substrate and part of the 35 ing solution and cathode. The anode may be consum

copper etched off to produce the circuit board of inter able (made of copper which dissolves and replenishes

est.

Copper plating is used extensively in a variety of the solution as plating occurs) or nonconsumable (made

manufacturing procedures. It is used to prevent corro of some inert material such as platinum, platinized tita

sion on various surfaces (i.e., iron surfaces), as a binding 40 nium, lead, etc.) Generally, the invention is more useful

layer for additional metal layers, to increase electrical for nonconsumable anodes where electroplating rates

or thermal conductivity and to provide conducting are greater and the problems associated with additive

paths in many electrical applications. Indeed, such of consumption (usually by oxidation at the anode) are

the recent increase in the activity in copper electroplat greater.

ing is in the manufacture of electrical devices, such as 45 Particularly useful nonconsumable electrodes involve

circuit boards, integrated circuits, electrical contact surfaces with oxides of iridium and tantalum. Typical

surfaces, etc. compositions are 20 to 90 mole percent iridium, remain

Particularly important in any electroplating process der tantalum. Preferred is 60 to 90 mole percent iridium,

is the stability and lifetime of the electroplating bath. remainder tantalum. Generally, these electrodes are

Many electroplating baths contain additives which in 50 made by coating these compounds on a conducting

prove various aspects of the plating process. In particu substrate such as a titanium substrate. There is evidence,

lar, additives are used to improve the brightness of the although not conclusive, that the superior properties of

copper plating, the physical properties of the plated these electrodes, especially as to long lifetimes and sta

copper particularly with respect to ductility and the bility are due to the formation of a double oxide (an

micro-throwing power as well as macro-throwing 55 iridium-tantalum oxide) such as Ir(TaC3)4. Much of this

power of the plating bath. Increased stability of these work is disclosed in U.S. Pat. No. 4,310,391, issued to Y.

additives leads to longer lifetimes for the electroplating Okinaka and C. G. Smith on Jan. 12, 1982.

bath which is economically very important. For exam Other electrodes are also useful in the practice of the

ple, frequent replacement of the bath interrupts the invention. Particularly useful are those described in

copper plating operation which reduces product yield 60 U.S. Pat. No. 4,269,670, issued to C. G. Smith on May

and requires replacement of the chemicals in the new 26, 1981. These electrodes comprise at least 10 mole

bath as well as disposal of the chemicals in the old bath. percent group VIII metal, at least 10 mole percent valve

SUMMARY OF THE INVENTION

metal and at least 5 mole percent binder metal. Group

VIII metals include cobalt, nickel, ruthenium, rhodium,

The invention is a copper electroplating process 65 palladium, iridium and platinum. Valve metals include

using consumable or nonconsumable anode in which titanium, zirconium, hafnium, vanadium, niobium and

the anode is surrounded by a cation exchange mem tantalum. Binder metals include beryllium, calcium,

brane. This membrane prevents certain components of strontium, barium, scandium, yttrium, lanthanum and

3

4,469,564

4.

the rare earth elements with atomic numbers 58 through gms/liter and orthophosphate (HPO4)2 no greater

71. Particularly useful is an oxide composition with than 113 gms/liter.

5-20 mole percent barium, and the ratio of iridium to Typical copper cyanide baths may also be used but

tantalum between and 4. Such a composition is 5 mole considerable caution should be used since the anode

percent barium, 30-40 mole percent iridium, remainder side of the bath may become acidic, and rupture of the

tantalum.

A large variety of cation exchange membranes are membrane may expose cyanide solution to acidic condi

tions, releasing poisonous HCN.

useful in the practice of the invention. Various such The preferred copper electroplating bath comprises

membranes are described in references including the copper sulfate in an acid solution. The concentration of

Encyclopedia of Electrochemistry, C. A. Hampel, ed., 10 copper and acid may vary over large limits. For copper,

Reinhold, 1964, pp. 726-735. compositions generally vary from 0.05 Molar to satura

Both heterogeneous and homogeneous cation-perme tion or, more preferably, from 0.05 Molar to 1.5 Molar.

able membranes may be used in the practice of the in Acid concentration varies from 0.1 to 2 Molar and is

vention. The heterogeneous membrane is made by dis generally added as sulfuric acid.

persing finely ground ion-exchange resin throughout a 15 Special bath compositions are used for special appli

thermoplastic matrix. For cation-permeable membrane, cations. For example, high throwing power, it is pre

the resin is typically of the sulfonated styrene-divinyl

benzene type and the matrix is typically a polymer such ferred that the Molar acid concentration (generally as

as polyethylene, polyvinyl chloride, polyvinylidene sulfuric acid) be at least 5 times the Molar concentration

chloride, natural or synthetic rubber, etc. 20 of copper ions. Plating results are often improved by the

The homogeneous type is made by condensation addition of chloride ions (generally in small amounts

processes using sulfonated phenol and formaldehyde or such as 30-100 mg/liter). The chloride ion is most con

nitrogen-containing compounds and formaldehyde. veniently added as hydrochloric acid.

The condensates are laid out in thin sheets, with or A large variety of additives may be used in the prac

without supports such as paper or plastic screen, before 25 tice of the invention. Usually, more than one additive is

final gelation to an insoluble form. Other homogeneous used, each additive performing a desirable function.

membranes are prepared by the graft polymerization of Among these desirable functions is improved appear

polyethylene and styrene following the soaking of a ance (brightness), improved structure and improved

film of polyethylene in styrene monomer. The film is physical properties (such as electrical conductivity or

then converted to a cation exchange membrane by sul 30 ductility) of the copper desposited. Particular additives

fonation. (usually organic additives) are used for grain refine

The preferred membrane is a copolymer of tetrafluor ment, suppression of dendritic growth (treeing) and

oethylene and perfluoro-3,6-dioxa-4-methyl-7- improved covering and throwing power. Typical addi

octenesulfamic acid. A typical product is marketed by tives used in electroplating are discussed in a number of

Dupont Company under the trade name of Nafion. This 35 references including Modern Electroplating cited above

product is readily available in a number of forms includ and by H. Brown in an article entitled "Function and

ing sheets, tubes, etc., and achieves excellent results Structure of Organic Additives in Electroplating' pub

both as to the rate of exchange and stability toward the lished in The Proceedings of the 8th Congress of the Inter

plating bath. A perfluorinated structure is preferred national Union for Electrodeposition and Surface Finish

because of high chemical stability. High stability is ex 40 ing, Forster-Verlag, A. G., Zurich, 1973, pp. 114-121.

ceedingly important because the membrane is exposed Lists of typical additives are found in these references.

to corrosive chemicals for long periods of time. Additives for acid copper baths are also discussed by L.

The invention may be practiced on a large variety of Mayer and S. Barbieri in an article entitled “Character

copper baths including acid baths and alkaline baths. istics of Acid Copper Sulfate Deposits for Printed Wir

Obviously, the invention is only useful where additives 45 ing Board Applications', published in Plating and Sur

(especially additives subject to anodic oxidation) are face Finishing, 68, (3), pp. 46-49 (1981).

used in the bath. The bath contains a source of copper Generally, there is a variety of additives used in cop

and a supporting electrolyte. per electroplating baths. Aromatic and aliphatic quater

A variety of copper electroplating baths are de nary amines are used to improve the brightness of the

scribed in a book entitled Modern Electroplating, edited 50 deposit. Polysulfide compounds are used to increase the

by F. A. Lowenheim, John Wiley and Sons, Inc., New ductility of the deposited copper and polyethers are

York, especially chapter 7 by A. K. Graham, W. H. used to improve the thickness uniformity of the copper

Safranek and J. W. Dini. plating. Some typical additives are disclosed in U.S.

Copper fluoborate baths are used to electroplate cop Pat. No. 3,328,273 issued to Hans-Gerhard Creutz et al

per. The bath generally contains, in addition to addi 55 on June 27, 1967.

tives discussed below, copper ion often added in the The dyes of the phenazine class (the Safrainine type)

form of copper fluoborate and fluoboric acid. Boric and more especially the phenazine azo dyes (the Janus

acid is also added in many cases. The concentration of Green B type) which make possible the greatly im

the various ingredients is not critical. Typical concen proved leveling and extended bright plating range can

trations are: copper fluoborate 200-500 gms/liter; 60 be represented by the following formula.

fluoboric acid 10-40 gms/liter and boric acid 10-40

gms/liter.

Pyrophosphate baths may also be used. Such baths R 2 R

have a number of advantages. They have high throwing

power, are not corrosive and are not toxic. Typical 65 RN Sa

S N D

concentration of constituents are copper ion (Cu+2) / / N

22-38 gms/liter, pyrophosphate (P2O7)-4 150-250 R A Y

gms/liter, nitrate ion 5-10 gms/liter, ammonia 1-3

4,469,564

6

reasons, the aliphatic quaternary amine should have

between 3 and 10 carbon atoms.

Other types of additives are used to increase ductility

of the deposited copper. Typically, they are polysulfide

compounds disclosed in detail in U.S. Pat. No. 3,328,273

Y is an anion from the group consisting of Cl-, Br, referred to above. The sulfide additives are aliphatic

SO4--, HSO4, CH3SO4-, C2H5SO4, polysulfides of the general formula

C2H5SO3-, C3H7SO3-, -O3SCH2SO3-,

O3SC2H4SO3, HOC2H4SO3, HSC3H6SO3-;

and 10

D is H, CH3, C2H5, OH, NH2, N(CH3)2, N(C2H5)2 in which R1 and R2 are alkylene groups containing 1 to

6 carbon atoms, X is hydrogen or SO3H and n varies

S from 2 to 5. Typical polysulfides are given in Table I.

Concentrations can vary over large limits but are typi

SCOC2H5, 15 cally between 0.0005 and 1.0 gms/liter.

TABLE I

SH, and N-N-Z,

where Z is a coupling group, such as dimethyl aniline, Organic Polysulfide Compounds

aniline, phenylene diamine, and substituted anilines (1) CH3-S-S-CH2-SO3H

and phenylene diamines, naphthols and substituted 20

naphthols, phenols and substituted phenols, thia

zoles, benzothiazoles and aminobenzothiazoles,

coupled to the azo linkage N=N.

The preferred phenazine dyes are the Janus Green B

type (Diethyl Safranine Azo Dimethyl Aniline or Di 25

methyl Safrainine Azo Dimethyl Aniline, C.I. Nos. A polyether is also used as a leveling agent that im

11045, 11050), or the Janus Black R type, also C.I. proves thickness uniformity particularly in circuit

11975 (Colour Index, second edition, Vol. 3, 1956-57), boards with holes. Generally, best results are obtained

as these compounds make possible the highest leveling with polyethers with at least six ether oxygen atoms and

and the widest bright plating range. 30 alkyl chains no larger than six carbon atoms. Typical

Typical structural formulas are as follows: polyeher compounds useful in copper electroplating are

given in Table II of U.S. Pat. No. 3,328,273 cited above.

R3 a N

Particularly good results are obtained with polypro

pylene propanols and glycols with average molecular

R. N ON 1Ol N=N-ON(CH3):

Sa

35 weight of about 360 to about 1,000, i.e., polyethers

which contain the group (C3H6O) where y is an integer

with value from 6 to about 20. Excellent results are also

obtained with polyethers containing the group

(C2H4O) where x is an integer of at least 6. Generally,

x does not exceed 100.

FIG. 1 shows a typical copper electroplating appara

where R, R2 and R3 aliphatic hydrocarbon groups, are tus 10 useful for electroplating various items such as

typically hydrogen, methyl or ethyl groups. For conve circuit boards, etc. The experimental apparatus is also

nience, these compounds are identified as Janus Green useful for demonstrating the advantages of the use of

B type compounds. Many structural formulas for these 45 membranes in copper electroplating. The plating appa

additives are given in U.S. Pat. No. 2,707,166 issued to ratus comprises anode or counterelectrode 11 and cath

H. Brown on Apr. 26, 1955. ode 12 on which the copper is electroplated. Also

Another closely related set of compounds are identi shown is the electroplating bath 13 and container 14 for

fied by the following structure: holding the electroplating bath. The electroplating bath

50 is divided into two parts (anode compartment and cath

R3 a. N

ode compartment) by a cation-permeable membrane 15

which provides easy passage of cations (generally hy

R1Yn Os Ol NN OH - N^ H drogen ions) but prevents passage of anions and neutral

species such as organic additives, etc. Generally, the

/ N- C- N 55 electroplating cell is initially set up so that the organic

R2 C2H5 additives are in the cathode compartment and the ca

CH3 tion-permeable membrane prevents passage of the or

ganic additives to the anode compartment. The anode

may be of the consumable or nonconsumable type. For

where R1,R2 and R3 are aliphatic hydrocarbon groups, 60 nonconsumable anodes, the copper ions are generally

typically hydrogen, methyl or ethyl groups. This type added to the cathode compartment. Also shown in FIG,

of additive may be identified as a phenosafranine-3- 1 is the electric power souce 16 and a current limiting

ethylamino-p-cresol. Janus Black and Janus Blue type device 17 to control plating rate.

dyes are also useful. The structural formula for these FIG. 2 shows another type of electroplating appara

dyes are given in U.S. Pat. No. 2,707,166. 65 tus 20 useful in the practice of the invention. Two an

Aliphatic quaternary amines are also used as bright odes or counterelectrodes 21 and 22 are shown in which

ening agents and to ensure excellent properties of the membrane material 23 and 24 surrounds the electrode,

deposited copper. Generally, for stability and solubility The cation-permeable membrane 23 and 24 is in the

7

4,469,564

8

form of a tube or envelope so as to surround the anode. 9. The process of claim 8 in which the heterogeneous

Generally, it is advantageous that the membrane not membrane comprises resin of the sulfonated styrene

touch the anode over any significant area so that gases divinylbenzene type embedded in matrix comprising

generated at the anode are not trapped. The cathode is polymer selected from the group consisting of polyeth

generally located between the anodes. Additional an ylene, polyvinyl chloride, polyvinylidene chloride, nat

odes and cathodes may be used in the cell. The electro ural rubber and synthetic rubber.

lyte 26 is located in a container 27 and covers at least 10. The process of claim 1 in which the cationic mem

part of the anode and cathode. brane is of the homogeneous type. -

What is claimed is: 11. The process of claim 1 in which the cationic mem

1. A process for electroplating copper onto a circuit 10 brane has a perfluorinated structure.

board, said circuit board comprising an insulating sub 12. The process of claim 11 in which the membrane

strate with a surface at least partially covered with comprises a copolymer of tetrafluoroethylene and per

copper comprising the step of passing current through fluoro 3,6-dioxa-4-methyl-7-octenesulfamic acid.

an anode, copper electroplating bath and cathode, said 13. The process of claim 1 in which the electroplating

electroplating bath comprising a source of copper and 15 bath comprises copper sulfate in aqueous acid solution.

an organic additive, and in which said anode is noncon 14. The process of claim 13 in which the electroplat

sumable characterized in that the anode is surrounded ing bath further comprises chloride ion.

by a cation-permeable membrane so as to prevent or 15. The process of claim 1 in which the organic addi

ganic additives in the bath from reaching the anode. tive comprises aromatic quaternary amine.

2. The process of claim 1 in which at least part of the

20 16. The process of claim 15 in which the aromatic

surface of the nonconsumable anode comprises an ac

quaternary amine is at least one dye of the phenazine

class.

tive oxide, said active oxide comprising oxides of irid 17. The process of claim 16 in which the phenazine

ium and tantalum. dye is the Janus Green B type.

3. The process of claim 2 in which the active oxide 25 18. The process of claim 15 in which the organic

comprises oxidized metals, said oxidized metals consist additive further comprises at least one aliphatic quater

ing essentially of 20 to 90 mole percent iridium, remain nary amine.

der tantalum. 19. The process of claim 18 in which the aliphatic

4. The process of claim 3 in which the oxidized metals quaternary amine contains between 3 and 10 carbon

consists essentially of 60 to 90 mole percent iridium, 30 atOmS.

remainder tantalum. 20. The process of claim 15 in which the organic

5. The process of claim 1 in which at least part of the additive further comprises at least one polysulfide com

surface of the nonconsumable anode comprises active pound.

oxide, said active oxide comprising oxides of metals 21. The process of claim 15 in which the polysulfide

with at least 5 mole percent binder metal, at least 10 35 compound is an aliphatic polysulfide compound with

mole percent group VIII metal and at least 10 mole the general formula

percent valve metal, said binder metal consisting essen

tially of at least one metal selected from the group con

sisting of beryllium, calcium, strontium, barium, scan

dium, yttrium, lanthanum and the rare earth elements in which R1 and R2 are alkylene groups with 1 to 6

with atomic numbers 58 through 71; carbon atoms, X is hydrogen or SO3H and n varies from

2 to 5.

said group VIII metals consisting essentially of at 22. The process of claim 15 in which the organic

least one metal selected from the group consisting additive further comprises at least one polyether com

of cobalt, nickel, ruthenium, palladium, iridium and 45 pound.

platinum;

and said valve metal consisting essentially of at least 23. The process of claim 22 in which the polyether

one metal selected from the group consisting of comprises at least 4 ether oxygen atoms and alkyl chains

of not more than 6 carbon atoms.

titanium, zirconium, hafnium, vanadium, niobium 24. The process of claim 22 in which the polyether is

and tantalum. polypropylene propanols and glycols of average molec

50

6. The process of claim 5 in which the binder metal is ular weight between about 360 and about 1000.

barium, the group VIII metal is iridium and the valve 25. The process of claim 22 in which the polyether

metal is tantalum. comprises the group (C3H6O) where y varies from 6 to

7. The process of claim 6 in which the metal composi 20.

tion is approximately 5-20 mole percent barium, and the 55 26. The process of claim 22 in which the polyether

mole ratio of iridium to tantalum is between and 4. contains the group (C2H4O) where x is between 6 and

8. The process of claim 1 in which the cationic mem 100.

brane is a heterogeneous membrane. as : k

60

65

You might also like

- State Board of PharmacyDocument66 pagesState Board of PharmacyAnonymous hF5zAdvwCC100% (1)

- Essay writing phrases and grammar structuresDocument12 pagesEssay writing phrases and grammar structuresZoeTziavara100% (2)

- ElectroplatingDocument23 pagesElectroplatingJayne Kazandra P. Ortega67% (3)

- Chapter 5: Partial DischargesDocument45 pagesChapter 5: Partial Dischargesain liyanaNo ratings yet

- Plastic Industries MagazinesDocument35 pagesPlastic Industries MagazinesAjayIslaniyaNo ratings yet

- Electroless Nickel Applications in ElectronicsDocument31 pagesElectroless Nickel Applications in ElectronicsVasudevan Narayanan NNo ratings yet

- Corrosive Sulfur Effects in Transformer Oils and Remedial ProceduresDocument9 pagesCorrosive Sulfur Effects in Transformer Oils and Remedial Proceduresandres100% (1)

- Raw Material Handling and Coke Oven ProcessesDocument36 pagesRaw Material Handling and Coke Oven ProcessesJaved AlamNo ratings yet

- Electroplating CopperDocument6 pagesElectroplating CopperLuis EstevesNo ratings yet

- Electrochemistry for Technologists: Electrical Engineering DivisionFrom EverandElectrochemistry for Technologists: Electrical Engineering DivisionRating: 1 out of 5 stars1/5 (1)

- CBSE Class 8 Science Chapter Wise Question BankDocument82 pagesCBSE Class 8 Science Chapter Wise Question BankVersha Rustagi100% (1)

- Asme B36.19M-2004 PDFDocument14 pagesAsme B36.19M-2004 PDFUlises Montao100% (1)

- Atoms bonding forces and interatomic bondsDocument21 pagesAtoms bonding forces and interatomic bondsAlexandre Soares CavalcanteNo ratings yet

- Electroplating Handbook GuideDocument13 pagesElectroplating Handbook GuideAbeerNo ratings yet

- A.2. Noncompetitive InhibitionDocument6 pagesA.2. Noncompetitive InhibitionFlorecita CabañogNo ratings yet

- Water Quality IndicatorsDocument38 pagesWater Quality IndicatorsLa Ode Muhammad ErifNo ratings yet

- Influence of Titanium Oxide Films On Copper Nucleation During ElectrodepositionDocument12 pagesInfluence of Titanium Oxide Films On Copper Nucleation During Electrodepositionapi-19973331No ratings yet

- Fundamental Studies of Copper Anode Passivation During Electrorefining: Part III. The Effect of ThioureaDocument7 pagesFundamental Studies of Copper Anode Passivation During Electrorefining: Part III. The Effect of ThioureaLeandro GuzmánNo ratings yet

- Materials Chemistry and Physics, 14 (1986) 259-261: in The NetherlandsDocument9 pagesMaterials Chemistry and Physics, 14 (1986) 259-261: in The NetherlandsDTMM Anggit DriasadityaNo ratings yet

- 6 3 4 - Platinum Conical Ultramicroelectrode - 2007 - Handbook of ElectrochemistDocument6 pages6 3 4 - Platinum Conical Ultramicroelectrode - 2007 - Handbook of ElectrochemistMahmoud YounesNo ratings yet

- ARC-Slag Remelting of Steel and AlloysDocument323 pagesARC-Slag Remelting of Steel and AlloysAlexiz Alvarado MendozaNo ratings yet

- US4753688Document6 pagesUS4753688dmarandiNo ratings yet

- Based Noble: Electrodes MetalsDocument10 pagesBased Noble: Electrodes MetalsSumedh WaradeNo ratings yet

- Plating Process For ElectrolessDocument5 pagesPlating Process For ElectrolessFrancisco BocanegraNo ratings yet

- View metadata and similar papers for gold plating technologiesDocument11 pagesView metadata and similar papers for gold plating technologiesHiden HidenNo ratings yet

- View metadata and similar papers on CORE for gold plating technologiesDocument11 pagesView metadata and similar papers on CORE for gold plating technologiesHiden HidenNo ratings yet

- Absorption of UV in PlatingDocument11 pagesAbsorption of UV in PlatingHiden HidenNo ratings yet

- Plating DocumentDocument11 pagesPlating DocumentHiden HidenNo ratings yet

- 71 The Effect of Additives On Anode Passivation in Electrorefining of CopperDocument7 pages71 The Effect of Additives On Anode Passivation in Electrorefining of CopperEugenia Araneda HernandezNo ratings yet

- Electrochemical Etching PDFDocument26 pagesElectrochemical Etching PDFMohamed ShaganNo ratings yet

- Selection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessDocument6 pagesSelection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessIbnu AndriNo ratings yet

- NanotecnologiaDocument7 pagesNanotecnologiaviniciushiperNo ratings yet

- Iiihiiihihiiihiiih: United States Patent (19) 11) Patent Number: 5,217,586Document9 pagesIiihiiihihiiihiiih: United States Patent (19) 11) Patent Number: 5,217,586Georgiana-LuizaNo ratings yet

- United States Patent (19) : Findlan Et Al. Patent Number: Date of PatentDocument3 pagesUnited States Patent (19) : Findlan Et Al. Patent Number: Date of PatentJEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- The Study of Corrosion and Wear Resistance of CoppDocument9 pagesThe Study of Corrosion and Wear Resistance of CoppNoura Nour ElshamsNo ratings yet

- Piotrowski1998JECSEPofTi PDFDocument9 pagesPiotrowski1998JECSEPofTi PDFDONGYI ZHOUNo ratings yet

- Electroless Plating28266Document17 pagesElectroless Plating28266fsarfrazNo ratings yet

- Production of Manual Metal Arc Welding Electrodes With Local Raw MaterialsDocument5 pagesProduction of Manual Metal Arc Welding Electrodes With Local Raw MaterialsShubham YadavNo ratings yet

- The Electrolytic Recovery of Copper From BrassDocument2 pagesThe Electrolytic Recovery of Copper From BrassKestrel MgNo ratings yet

- Electrochemistry Prelab 2Document2 pagesElectrochemistry Prelab 2Alexis ChicaizaNo ratings yet

- Electrodeposition of MetalDocument4 pagesElectrodeposition of MetalvkmsNo ratings yet

- Advances and Future Prospects in Copper ElectrowinningDocument17 pagesAdvances and Future Prospects in Copper ElectrowinningBaraa ShalanNo ratings yet

- United States Patent (19) : Lovell (45) Date of Patent: Aug. 15, 2000Document9 pagesUnited States Patent (19) : Lovell (45) Date of Patent: Aug. 15, 2000Thomas KavanaghNo ratings yet

- Report On MaterialsDocument57 pagesReport On MaterialsLucyNo ratings yet

- Moskalyk 1999Document9 pagesMoskalyk 1999Cristian Cornejo AguileraNo ratings yet

- Us 4789439Document6 pagesUs 4789439VatsalNo ratings yet

- US3768541Document5 pagesUS3768541Ronak shahNo ratings yet

- Electrochemical Behaviour of Poly (Pyrrole) Coatings On SteelDocument12 pagesElectrochemical Behaviour of Poly (Pyrrole) Coatings On SteelMarly Blanco VeraNo ratings yet

- A, Krohn, Bohn - 1972 - Electrodeposition and Surface TreatmentDocument13 pagesA, Krohn, Bohn - 1972 - Electrodeposition and Surface TreatmentDhanapal PalNo ratings yet

- 1 Artículo CorrosiónDocument16 pages1 Artículo CorrosiónFabiola CovarrubiasNo ratings yet

- 258 PDFDocument47 pages258 PDFMichelle ArredondoNo ratings yet

- Feb. 25, 1958 R. C. Shutt 2,824,817: Filed July 2, 1954Document5 pagesFeb. 25, 1958 R. C. Shutt 2,824,817: Filed July 2, 1954JEISON ESTEBAN YUCUMA MARTINEZNo ratings yet

- From Editorial DeskDocument2 pagesFrom Editorial DeskRedhot Alastor ThorvaldssonNo ratings yet

- Electrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsDocument7 pagesElectrochemical Behavior of Layered Solid Solution Li Mno 2limo (M 5 Ni, MN, Co) Li-Ion Cathodes With and Without Alumina CoatingsEYERUSALEM TADESSENo ratings yet

- A Review Ofelectroless Gold Deposition Processes: Hassan O. and Ian R.A. ChristieDocument10 pagesA Review Ofelectroless Gold Deposition Processes: Hassan O. and Ian R.A. ChristieLuca BrunoNo ratings yet

- SMAW Basci Concept DoxDocument30 pagesSMAW Basci Concept DoxAmrut KajveNo ratings yet

- Dilute Electrodeposition of TiO2 and ZnO Thin Film MemristorsDocument6 pagesDilute Electrodeposition of TiO2 and ZnO Thin Film Memristorsalagar krishna kumarNo ratings yet

- Natarajan2006 PDFDocument5 pagesNatarajan2006 PDFBasim Al-bhadleNo ratings yet

- And AppliedDocument36 pagesAnd AppliedGeorgiana-LuizaNo ratings yet

- Electroplating: Electroplating Is A General Name For Processes That Create A MetalDocument9 pagesElectroplating: Electroplating Is A General Name For Processes That Create A MetalLollllNo ratings yet

- Materi Pertemuan Ke 4. Pengelasan FCAWDocument31 pagesMateri Pertemuan Ke 4. Pengelasan FCAWRaihan Arrafi10No ratings yet

- Rheology and Metal Forming of Fire-Refined CopperDocument6 pagesRheology and Metal Forming of Fire-Refined CoppervitordeleteNo ratings yet

- Corrosion-Resistant Component For PEM Fuel Cells: Shuo-Jen Lee, Ching-Han Huang, Jian-Jang Lai, Yu-Pang ChenDocument7 pagesCorrosion-Resistant Component For PEM Fuel Cells: Shuo-Jen Lee, Ching-Han Huang, Jian-Jang Lai, Yu-Pang ChenSoh Ming LunNo ratings yet

- Multi-Cathode Cell With Flow-Through Electrodes For The Production of Iron (Ii) - Triethanolamine ComplexesDocument8 pagesMulti-Cathode Cell With Flow-Through Electrodes For The Production of Iron (Ii) - Triethanolamine ComplexestanveerhusseinNo ratings yet

- Effect of Additives on Copper ElectrodepositionDocument9 pagesEffect of Additives on Copper ElectrodepositionNidhiNo ratings yet

- Power Sources: Research and Development in Non-Mechanical Electrical Power SourcesFrom EverandPower Sources: Research and Development in Non-Mechanical Electrical Power SourcesNo ratings yet

- spr06 p32-35 PDFDocument4 pagesspr06 p32-35 PDFJosé ZuñigaNo ratings yet

- 366cocchiaraDocument6 pages366cocchiaraahmed shehataNo ratings yet

- Characterization of NanoMicro Size Copper Powder BDocument8 pagesCharacterization of NanoMicro Size Copper Powder BAndy MaravillaNo ratings yet

- Examination of Copper Electrowinning Smoothing Agents. Part I: A ReviewDocument7 pagesExamination of Copper Electrowinning Smoothing Agents. Part I: A ReviewHelen HuancaNo ratings yet

- Scuba-Related Questions With AnswersDocument12 pagesScuba-Related Questions With AnswersNitesh LaguriNo ratings yet

- LC analysis of impurities in gasesDocument2 pagesLC analysis of impurities in gasesAlex-Bogdan Vișa100% (1)

- Proposal of Activity May 3Document9 pagesProposal of Activity May 3Anne Corrinne BacolodNo ratings yet

- Hydro EfbDocument7 pagesHydro EfbFA MonsterNo ratings yet

- IR-2x2-350-P 2013Document1 pageIR-2x2-350-P 2013AngelNo ratings yet

- SPE 73706 Lessons Learned From Acid Pickle Treatments of Deep/Sour Gas WellsDocument20 pagesSPE 73706 Lessons Learned From Acid Pickle Treatments of Deep/Sour Gas WellsAli mohammadNo ratings yet

- Materials of The Earth Crust: Chemical Composition Rock-Forming MineralsDocument19 pagesMaterials of The Earth Crust: Chemical Composition Rock-Forming MineralsMbiko SabeyoNo ratings yet

- Install Quint 8000 Dental Unit and FD 5100 Dental ChairDocument48 pagesInstall Quint 8000 Dental Unit and FD 5100 Dental ChairØsama ĀlarekeNo ratings yet

- Toggle Structure and ClassificationDocument9 pagesToggle Structure and ClassificationRobin TimkangNo ratings yet

- A Look at The Greenfield Foundries of 2020Document12 pagesA Look at The Greenfield Foundries of 2020skluxNo ratings yet

- Cable Cleats R2Document13 pagesCable Cleats R2Vishal RanjanNo ratings yet

- Tata Chemicals - WikipediaDocument22 pagesTata Chemicals - WikipediaRavi NayakaNo ratings yet

- (RADIANT) WHITE SNOW GelDocument20 pages(RADIANT) WHITE SNOW GelMichaelNo ratings yet

- Geneglace Ice GeneratorsDocument8 pagesGeneglace Ice GeneratorsGia HoàngNo ratings yet

- GP Series: Valve Regulated Lead Acid BatteryDocument1 pageGP Series: Valve Regulated Lead Acid BatteryOscar MorenoNo ratings yet

- Chlorination CEU Registration FormDocument76 pagesChlorination CEU Registration FormGkou DojkuNo ratings yet

- Seepage Controll Measures in Geotechnical EngineeringDocument6 pagesSeepage Controll Measures in Geotechnical EngineeringHaider ShahNo ratings yet

- Newmann Projection ND StrainDocument2 pagesNewmann Projection ND StrainsonujaipratapsinghNo ratings yet

- Sparkwiz Academy: Part TestDocument17 pagesSparkwiz Academy: Part TestSayak SenGuptaNo ratings yet

- Critical Review On The Analytical Methods For The Determination of Sulfur and Trace Elements in Crude OilDocument20 pagesCritical Review On The Analytical Methods For The Determination of Sulfur and Trace Elements in Crude OilLindaNo ratings yet