Professional Documents

Culture Documents

GL-Announcing The Ammann AFW 500 June2021

Uploaded by

AkbarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GL-Announcing The Ammann AFW 500 June2021

Uploaded by

AkbarCopyright:

Available Formats

June 2021

To: Ammann Personnel / Ammann Distributors

Introducing the New

Ammann AFW 500 Asphalt Paver

LANGENTHAL, Switzerland – The Ammann Group is pleased to announce the release of the

new Ammann AFW 500 Wheeled Asphalt Paver, available in India and neighbouring countries,

Africa and Southeast Asia (excluding S. Korea, Australia & New Zealand). The wheel-driven

AFW 500 features a standard paving width of 2.55 meter – 4.9 meter – with an ability to pave up

to 6.5 metres with mechanical extensions.

The new AFW 500 is an update of the previous paver of the same name and includes several

enhancements to match the machine to the needs of customers in the local marketplace.

Marketing Strategy

The AFW 500, with its ability to pave up to 6.5 metres, fills a void in the mid-range paver segment

for emerging markets. The machine is well suited to the placement of both binders and surface

(or top) lifts. The machine’s capacity and size make it an ideal fit for larger road projects, such as

highway projects.

The AFW 500 relies on European technology and is a fit for customers who focus on larger road

projects.

© Ammann Group | All rights reserved 1 of 7

Key Features & Benefits

Operator-friendly dashboard

Operation of the machine is kept simple with the new advanced dashboard and screed control

panel, created specifically for the AFW 500. The panel is simple to understand and operate, yet

provides advantages such as lit buttons for optimal visibility when working at night. Individual

control unit parts allow economical replacement.

A central 5” colour display provides the operator with key information regarding the ongoing

paving process. The display also enables simple troubleshooting tips, maintenance schedule &

alarm indications.

A standard CAN bus connection between the individual control units makes replacement easy

and allows for reprogramming as needed.

Excellent visibility

The paver design, sliding seat and dashboard enable the operator to see all phases of the paving

process, which improves productivity, quality and safety.

Leveling system choices

The control unit allows the installation of any common leveling system- the choice is up to the

customer. The installation plug is pre-mounted and allows for quick connection to the leveling

sensors and controls.

Low discharge heights

Lower height reduces material spillage that can cause mat defects. Hopper height also matches

trucks of varied sizes, increasing fleet utilisation and making it easier to find outside haulers with

appropriately sized vehicles.

© Ammann Group | All rights reserved 2 of 7

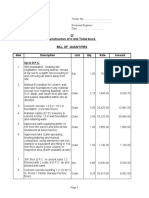

Specifications

Weights & Dimensions

Operating weight (inc. 6.5 m screed) 15 000 kg

A Machine length 6100 mm

B Transport length 5860 mm

C Axle length 1922 mm

D Machine height 3520 mm

E Transport height 3100 mm

F Height without canopy 3000 mm

G Machine width 3240 mm

H Transport width 2550 mm

I Wheel gauge 2076 mm

J Material loading height 600 mm

K Hopper length 2000 mm

Engine

Engine model Cummins QSB 4.5

Rated power @ 2200 rpm

EU Stage IIIA / U.S. EPA Tier 3 119 kW

Engine cooling system Liquid cooling

Electrical system 24 V

© Ammann Group | All rights reserved 3 of 7

Capacity & Performance

Placement thickness 10 - 300 mm

Max. theoretical paving capacity 500 t/h

Paving speed 37 m/min

Transfer speed 10 km/h

Undercarriage

Type Wheel

Hydrostatic through planetary drive

Drive System

gearbox with hydraulic motor

Rear tyres 2 x 17.5 R25

Internal turning radius 3.30 m

Material Feeding System

Hopper capacity 12 t

Conveyor type Two independent & reversible conveyors

Conveyor width 2 x 585 mm

Conveyor speed 29.3 m/min

Auger type Two independent & reversible augers

Auger diameter 360 mm

Auger speed 24.6 m/min

Auger height adjustment 150 mm

Tank Capacities

Fuel tank 220 l

Cooling system (total) 22 l

Engine oil 11.5 l

Hydraulic oil tank 170 l

Emulsion tank 30 l

FST 500 G/E Screed

Standard paving width 2550 mm

Hydr. max. working width 4900 mm

Max. working width with extensions 6500 mm

Min. working width 1500 mm

Standard screed weight 3144 kg

Heating system Gas/Electric

Compaction system, screed Tamper & Vibration

Compaction system, extensions Tamper & Vibration

Crown profile -2.5 % to +4.0 %

Tamper frequency max. 27.5 Hz

Tamper stroke 4.0 mm

Vibration frequency max. 53.3 Hz

© Ammann Group | All rights reserved 4 of 7

Ordering Guide

The machine is manufactured in the Ammann India facility in Ahmedabad. Orders must be

submitted to the Central Order Desk of Ammann India.

Jaspal Zala

Senior Manager

Ammann India Pvt Ltd

Email: Jaspal.zala@ammann.com

Production

The paver is manufactured in the Ammann India facility in Ahmedabad.

Availability

The AFW 500 can be offered in India and neighbouring countries, Africa and Southeast Asia

(excluding S. Korea, Australia & New Zealand).

*Sales Support Materials

Title Media No. Available

Sell Sheet MSS-1028-03-EN Available

Presentation MPR-2728-00-EN Available

Brochure TBA July 2021

*Available from the Dealer Portal on MyAmmann.com

Sales Training

Basic/Special Courses/Advanced/Expert Courses

Sales training courses can be organised at the Ammann India Academy or at the Dealer´s

facility. New Dealers must complete basic training. Courses can be combined with other types of

training programmes.

Contact Information

Prashant Mehta

Training Manager

Ammann India Pvt Ltd

Email: Prashant.Mehta@ammann.com

© Ammann Group | All rights reserved 5 of 7

Product Support Materials

Title Media No. Available

Parts Manual 1587122 Available

OMM 1587131 Available

Service Training / Materials

Basic/Special Courses/Advanced/Expert Courses

Service training courses can be organised at the Ammann India Academy or at the Dealer´s

facility.

New Dealers must complete basic training. Courses can be combined with other types of training

programmes.

Please contact Annamalai Sivakumar for further information.

Service Training Contact Information

A. Sivakumar

Senior Manager

Ammann India Pvt Ltd

Email: A.Sivakumar@ammann.com

Warranty

Standard Ammann warranty for pavers

The Manufacturer represents and warrants that, during the Warranty Period (as defined below),

the Product will (i) be free of defects in material, workmanship and design and (ii) meet the

specifications as agreed in writing at the purchase of such a Product (as defined below), provided

that the Product has been used and maintained in accordance with its specifications and the

Manufacturer’s manuals and instructions (the Warranty). Parts subject to wear, including but not

limited to are excluded from the Warranty:

Batteries will be included in the warranty for 12 months / 1000 hours. Beyond that time frame,

batteries will be categorized as a wear part and therefore excluded from warranty.

For claims related to the engine, the Manufacturer reserves the right to ask for an oil sample.

• Rubber Pads / Wheels • Conveyor Parts

• Belts • Chains

• Scrapers • Soleplates

• Windscreen Wipers • Tamper Bars

• Filters • Auger Elements

• Lubricants • Bearing

• Fluids • Fuels

© Ammann Group | All rights reserved 6 of 7

Warranty Period

The Warranty Period shall mean for:

a) Pavers including engine the time period of 12 months / 1000 working hours

commencing on the Date of First Use, but in no event exceeding 18 months commencing on the

Date of Dispatch;

Contacts

For more information, please contact your Ammann sales manager or local Ammann office.

This information is intended exclusively for Ammann employees and Ammann dealer and broker personnel. Efforts have been made to provide

accurate information regarding Ammann and competitive machines but this document may contain unverified analysis. Providing the latest

available spec sheets and other product information is the goal but these materials also are subject to change without notice. Inclusion of this

disclaimer must be provided if this material is reproduced.

© Ammann Group | All rights reserved 7 of 7

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mid 185 - Sid 254 - Fmi 9Document3 pagesMid 185 - Sid 254 - Fmi 9AkbarNo ratings yet

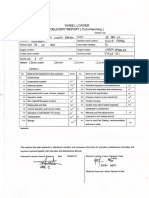

- FORM PDI Wheel LoaderDocument2 pagesFORM PDI Wheel LoaderAkbarNo ratings yet

- ASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishDocument222 pagesASM INTERNATIONAL Carburizing Microstructures and Properties by Geoffrey ParrishAdheith South NgalamNo ratings yet

- Excavator: Inspection Before Engine StartDocument2 pagesExcavator: Inspection Before Engine StartAkbarNo ratings yet

- Two 2 Page Quality ManualDocument2 pagesTwo 2 Page Quality Manualtony sNo ratings yet

- Wo - 43498 Pt. AcaDocument2 pagesWo - 43498 Pt. AcaAkbarNo ratings yet

- Track Inspection MeasureDocument12 pagesTrack Inspection MeasureAkbarNo ratings yet

- Commisioning Report (PT. Lutvindo Wijaya Perkasa)Document1 pageCommisioning Report (PT. Lutvindo Wijaya Perkasa)AkbarNo ratings yet

- Spring Track Campaign-Bulletin - Field - ModificationDocument3 pagesSpring Track Campaign-Bulletin - Field - ModificationAkbarNo ratings yet

- Wo - 43498 Pt. AcaDocument2 pagesWo - 43498 Pt. AcaAkbarNo ratings yet

- DX225 SpesificationDocument25 pagesDX225 SpesificationAkbarNo ratings yet

- Wo - 43498 Pt. AcaDocument2 pagesWo - 43498 Pt. AcaAkbarNo ratings yet

- Wo - 43371 Pt. AcaDocument2 pagesWo - 43371 Pt. AcaAkbarNo ratings yet

- FORM PDI Vibratory RollerDocument2 pagesFORM PDI Vibratory RollerAkbarNo ratings yet

- DX210WA Spec SheetDocument46 pagesDX210WA Spec SheetAkbarNo ratings yet

- Wo - 43371 Pt. AcaDocument2 pagesWo - 43371 Pt. AcaAkbarNo ratings yet

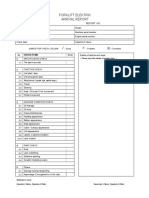

- FORM PDI ForkliftDocument2 pagesFORM PDI ForkliftAkbar100% (1)

- Arrival Report ExcavatorDocument1 pageArrival Report ExcavatorAkbarNo ratings yet

- Delivery Report Form ExcavatorDocument1 pageDelivery Report Form ExcavatorAkbarNo ratings yet

- FORM PDI BreakerDocument1 pageFORM PDI BreakerAkbarNo ratings yet

- Arrival Report Forklift ElektrikDocument1 pageArrival Report Forklift ElektrikAkbarNo ratings yet

- Arrival Report Vibratory RollerDocument1 pageArrival Report Vibratory RollerAkbarNo ratings yet

- Arrival Report Wheel LoaderDocument1 pageArrival Report Wheel LoaderAkbarNo ratings yet

- Arrival Report BreakerDocument1 pageArrival Report BreakerAkbarNo ratings yet

- Article - Technical - Fuel Transfer PumpDocument3 pagesArticle - Technical - Fuel Transfer PumpAkbarNo ratings yet

- Arrival Report Forklift DieselDocument1 pageArrival Report Forklift DieselAkbarNo ratings yet

- Delivery Report Form BreakerDocument1 pageDelivery Report Form BreakerAkbarNo ratings yet

- Mid 185 - Psid 2 - Fmi 7Document3 pagesMid 185 - Psid 2 - Fmi 7AkbarNo ratings yet

- Mid 185 - Psid 2 - Fmi 3Document3 pagesMid 185 - Psid 2 - Fmi 3AkbarNo ratings yet

- Mid 185 - Psid 1 - Fmi 3Document3 pagesMid 185 - Psid 1 - Fmi 3AkbarNo ratings yet

- Mid 185 - Psid 1 - Fmi 5Document3 pagesMid 185 - Psid 1 - Fmi 5AkbarNo ratings yet

- Pradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural CitizensDocument2 pagesPradhan Mantri Gramin Digital Saksharta Abhiyan (PMGDISHA) Digital Literacy Programme For Rural Citizenssairam namakkalNo ratings yet

- Freqinv 3g3fv Ds 01oct2000Document20 pagesFreqinv 3g3fv Ds 01oct2000Mohd Abu AjajNo ratings yet

- Kit 2: Essential COVID-19 WASH in SchoolDocument8 pagesKit 2: Essential COVID-19 WASH in SchooltamanimoNo ratings yet

- Spine Beam - SCHEME 4Document28 pagesSpine Beam - SCHEME 4Edi ObrayanNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityBhavesh PatelNo ratings yet

- Chapter 123 RevisedDocument23 pagesChapter 123 RevisedCristy Ann BallanNo ratings yet

- Drug Study TemplateDocument2 pagesDrug Study TemplateKistlerzane CABALLERONo ratings yet

- Revenue Management Session 1: Introduction To Pricing OptimizationDocument55 pagesRevenue Management Session 1: Introduction To Pricing OptimizationDuc NguyenNo ratings yet

- Installation Manual EnUS 2691840011Document4 pagesInstallation Manual EnUS 2691840011Patts MarcNo ratings yet

- Business-Model Casual Cleaning ServiceDocument1 pageBusiness-Model Casual Cleaning ServiceRudiny FarabyNo ratings yet

- 990-91356A ACRD300 CE-UL TechnicalSpecifications Part2Document25 pages990-91356A ACRD300 CE-UL TechnicalSpecifications Part2Marvin NerioNo ratings yet

- RODECaster Pro II - DataSheet - V01 - 4Document1 pageRODECaster Pro II - DataSheet - V01 - 4lazlosNo ratings yet

- Community-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDocument28 pagesCommunity-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDiane Rose LacenaNo ratings yet

- Flyer Manuale - CON WATERMARK PAGINE SINGOLEDocument6 pagesFlyer Manuale - CON WATERMARK PAGINE SINGOLEjscmtNo ratings yet

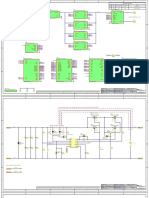

- Rideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardDocument45 pagesRideable Segway Clone - Low Cost and Easy Build: Digital MPU6050 Accelerometer/gyro IMU BoardpaolaNo ratings yet

- 1.2 The Main Components of Computer SystemsDocument11 pages1.2 The Main Components of Computer SystemsAdithya ShettyNo ratings yet

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFDocument68 pagesCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουNo ratings yet

- Scheme Bidirectional DC-DC ConverterDocument16 pagesScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaNo ratings yet

- Coursework For ResumeDocument7 pagesCoursework For Resumeafjwdxrctmsmwf100% (2)

- Auto Report LogDocument3 pagesAuto Report LogDaniel LermaNo ratings yet

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Document6 pagesType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheNo ratings yet

- X HM11 S Manual AUpdfDocument228 pagesX HM11 S Manual AUpdfAntonio José Domínguez CornejoNo ratings yet

- T R I P T I C K E T: CTRL No: Date: Vehicle/s EquipmentDocument1 pageT R I P T I C K E T: CTRL No: Date: Vehicle/s EquipmentJapCon HRNo ratings yet

- Salva v. MakalintalDocument2 pagesSalva v. MakalintalGain DeeNo ratings yet

- Tle 9 Module 1 Final (Genyo)Document7 pagesTle 9 Module 1 Final (Genyo)MrRightNo ratings yet

- Bharat Heavy Electricals LimitedDocument483 pagesBharat Heavy Electricals LimitedRahul NagarNo ratings yet

- TokyoDocument6 pagesTokyoMarcio BonziniNo ratings yet

- Common Base AmplifierDocument6 pagesCommon Base AmplifierMuhammad SohailNo ratings yet