Professional Documents

Culture Documents

Upravuvanje SoČADvo Objekti

Uploaded by

Erica Morrison0 ratings0% found this document useful (0 votes)

17 views13 pagesOriginal Title

UpravuvanjeSoČADvoObjekti

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views13 pagesUpravuvanje SoČADvo Objekti

Uploaded by

Erica MorrisonCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 13

SMOKE MOVEMENT IN BUILDINGS

by

John H. Klote

Building and Fire Research Laboratory

National Institute of Standards and Technology

Gaithersburg, MD 20899

and

Harold E. Nelson

Hughes Associates, Inc.

3610 Commerce Drive

Baltimore, MD 21227

Fire Protection Handbook, 18 Edition, NFPA FPH1897, Section 7, Chapter 6. Cote, A.E.,

Linville, J.L., Appy, M.K., Benedetti, R.P., Cote, RM., Curtis, M.H., Grant, C.C., Hall,

4R., Jr, Moore, W.D., Powell, P.A., Solomon, RE., Tokle, G.O., and Vondrasek, RJ.,

Editors. National Fire Protection Association, One Batterymarch Park, Quincy, MA, 1997.

NOTES: ‘This paper is a contribution of the National Institute of Standards and

Technology and is not subject to copyright.

Section 7/Chapter 6

SMOKE

MOVEMENT

IN BUILDINGS

Sake and fre gaeee, inherent in all unwanted fre, sre dangeraie

prvdvts of combustion that have critical influences on life safety,

property protection, and fire suppression practices in buildings. fn

Some fies, the volume of smoke is so great that it may fill an entice

building and obscure visibility a the street level to such an extent

that it in difficult to identify the Bre-involved building. In ether inc

dont, the volume of smoke generated may be considerably less, a:

though the danger to Tife is not necessarily diminished because of

the presence of ether airborne producis of combustion,

This chapter gives information onthe techniques used 1 eva

uate the physical charactristies of smoke movement through both

short and tall buildings as a basis for designing smoks-conteol sys-

tems, Italso covers the approaches that can be used to test the effec

tiveness of designed smoke-control systems inthe absence of actual

performance tests involving tet tes,

For more information on controlling the hazards of smoke, see

the following chapters in this section: Chapter 7, “Venting Prac

ties" and Chapter 14, “Airconditioning and Ventilating Systems”

Also see Seaton 1, Chapter 10, “Simplified Fine Guawth Caller

This chapter provides general background, a discussion of re

lutonships, and selected equations useful in understanding smoke

‘movement and smoke management in builings. OF necessity, the

information i not suficient for detailed design analysis, but design

{information is available from a number of sources. The 1992 book

by Klote and Mike! Design af Smoke Managemens Systems, pro-

‘ides a consolidation and systematic presentation of data and caleu-

lions necessary for the design of systems to manage smoke

‘movement, Specific design information is provided in that publica

‘ing Tor presurized stairwell, precsurizedelovatore, zoned smoke

contra, and smoke management in large spaces including alia and

shopping malls. The smoke-control chapter of the 1995 SFPE,

Handbook of Fire Protection Engineering? summarizes much of

‘he general information from Klote and Milke. NFPA 92A. Recom:

mended Practise fon Sine-Cinral Systems lercinaier hei

Jot FL Kt, D.Se, PE it reearch engnovr tthe Building and Fite

Research Laboratory NIST He isa member ofthe SFPE, the NEDA Aie

Condtining Comite ane NEPA Sre Manapome Syme

Cone, Dr. Klote sala a member of the ASHIRAE Fire and Smoke

Consol Commits, Harold E Nelson, PE, v3 soni research ire protec

Yionengineer with gles Avocisen, le, altro, MD es om pres

“the SPE, ad chara ofthe NEPA She Mast Ses

7-93

——— Revised by Jobn H. Klote and Harold E. “Bud” Nelson

ss NFPA Q7A), was frst published in 1988 and provides additional

recommendations for stairwell pressurization systems and zoned

‘smoke-control systems, including suggested levels of pressurization

for such systems in sprinklered and Unsprinklered busldings. NFPA

92B, Guide for Smoke Management Systems in Malls, Aria, and

Lange Areas (heseinaferreferied to a5 NFPA 92D), vas fis pub

lished in 1991, and isa technical guide forthe design of smoke man

agement systems in shopping malls. atria. and other large-volume

spaces,

CLASSIFICATION OF SMOKE ZONES:

As a fire burns it

1. Generates he,

‘Changes major portions of the burning material or fuel from its

‘original chemical composition toonc or more other compounds,

such as carbon dioxide, earhon monoxide, water, and/or other

compounds.

Often, duc to les than 100 percent combustion efficiency, trans

ports & portion ofthe fuel as soot or other material that may or

‘may not have undergone a chemical change.

‘A major portion ofthe heat generated aso fuel burns reanains

inthe mass of produets liberated by the fre. This mass expands, is

Tighter than the surrounding air. and rises as a plume. The rising

plume is turbulent and, because ofthis, entrains large quaaties of

air from the surtounding atmosphere into the rising gases. This en-

1 Tereages the total mass and vom af the pam

2. Cools the plume by mixing the cool entrained air withthe rising

hot gases. Normally, the rising plume is hover at its center and

cooler toward the edges where cooler air is entrained

Dilutes the concentration offre products in the plume

Smoke, as discussed in this chapter, is therefore defined as a

ninture of hot vapors and gases produced by the combustion pro

cess along with unbumed decomposition and condensation matter

And the quantity of air that is enrsined o otherwise mixed into the

For the purposes of describing emake movement in buildings,

the treiment of smoke movement is divided into two general areas

(1) the hat smoke zone and (2) the coo! smoke 20ne

7-94 CONFINING FIRES

Hot Smoke Zone

This zone includes those areas in a building where the temperature

ofthe smoke ishigh enough so that the natural Buoyancy ofthe body

‘of smoke tends 10 lift the smoke toward the ceiling while clean, or

at leas Tes polluted, air is drawn in through the lower portion ofthe

space, Normall, this condition exiss ia abe room) of Are exigin. De

pending upon the level of energy produced by the fre and the size

ff consecting openings, sich a8 open doors, hot smoke zones can

readily exist in adjacent rooms oF corridors. Industrial and ware

house smoke and hea venting, aria smoke removal, and the move-

‘ment of smoke ta conndors open to spaces that have hashed over, ll

involve a hot smoke zone where the smoke is lifted and driven by

‘the buoyant forces produced by the fire.

Cool Smoke Zone

‘This zone includes those areas in a building where mixing and other

forms of heat transfer have reduced the effect of the diving force of

the fire tothe point at which buoyant lift in the smoke body is mi-

nor factor. In these areas, the movement of smoke is primarily cor

trolled by other forces, such as wind and stack effect, and the

mechanical heat, ventilating, sir conditioning, or ether aie-meve.

‘ment systems. In these areas, the movement of smoke is essentially

the same as the movement of any other pollutant

SMOKE. MOVEMENT IN THE

HOT SMOKE ZONE.

“The volume of combustion products entrained in arising plume in

the hot smoke zone is eatvely small, compared with the volume of

arin the total mixture. Consequently, the smoke produced by a fire

Will approximate the Volume of ai drawn into the rising plume. Fig

te 7-6 llastetes te press

In situations in which the height of the plume, as measured

from the top ofthe fie othe level ofthe srmoke layer, is more than

about tice the heigh of the solid body of flame, itis reasonable to

estimate the amount of sucke using developed formlas.™

In general the equations given in tis chapter for conditions in

the ot smoke zone should be used where the fire i small compared

to the beight ofthe space involved. For locations where this fs not

tive, approaches such as those contained in Section 7, Chapter 7,

fenting Practices"; Section 11, Chapter 5, "Deterministic Com

puter Fire Models”: and Section 11, Chapter 10, “Simplified Fire

‘Growth Calculations” are more appropriate

‘The following equation is based on research conducted at Fae

tory Mutual Research Corporation (FMRC) ands the equation used

ayer

Height ot |

cea ayer

Flammable vapors Burning

Sol fl decomposing,

‘9ving of ammabe vapors

FIG. 7-64. The production of smoke from a fre.

for smoke production in NFPA 92B. The amount of smoke gener

sted can be estimated as

i= 0.071K°7Q"2"” +0.00180,

where

>it = mas flow in plume at height, kes;

Q. = convective heat release rate of fire, kW;

Insight above tap of fel, mn: and

wal factor (see Figure 7-68),

“The above equation Is the same as the corresponding equation

in NFPA 928 forthe value of

‘Ie expression aso inludes a seres of assumptions, the most

important of which are

1. The tip of the Name isa significant distance below the bottom of

the smoke layer. The formula, while useful, is much less accu

fate in spaces with alow eciling relative tothe eight of the fi

involved

2, The fire bed itself covers an area whose length and width are

reasonably approximate o each other. The original formula is

based onthe assumption ofa circular fire. The degree of eo in

‘he formula increases as the relationship of length wo sd

2. The ceiling ie suficently high sothat acorretion forthe vit

“origin ofthe fire is unnecessary. This is true where the fre

small compared tothe height ofthe space involved, as isthe cse

for smal tres m rooms or tor design applications ahvolving ats

or other large-volume spaces.

Flame Height

‘A reasonable estimate of the visible lame height? can be obtains!

‘rom the expression:

166(Q7%)"*

where

sp = mean lame height. m

= heat release ofthe fire, KW; and

k= wall factor (see Figure 7-08),

NN

a uct package

Fuel package

warn fen walls vot ae ie

yyy \

a ruetpacaye” |

Fuel packas

Fuel package ust package

ear wa near nte e

my wet

FIG. 7-68, Wall factors for fuel package locations

SMOKE MOVEMENT IN BUIL

“The above equations the same asthe corresponding equation

NFPA 92B for the value of k= The convective portion of the

eat oleae, rate, Q.,can be expressed as

a=

store & isthe convective fraction of heat release. The convective

faction depends on the heat conduction through the fuel nd then

sitive heat transfer of the lames, but a value of 0.7 is often used For

5 The results of this equation for a convective fraction of 0.7 are

Thuwa graphically in Figure 7-6C.

Average Plume Temperature

Denied engineering equations for fre plumes have been present

cg However he average lempenatare of fv pe

2

TAC,

hee

AT = average temperature increase above room temperature,

1 = mass flow in plume at height, keh

0, = convective heat rel

se rate of fie, KW: and

Gy = tpeciic heat of plume gare, 1.00 kk °C

‘The average temperature difference should ot be confused

with the centerline plume temperature, which is houter. The mass

fow can be estimated by the plume equations already presented.

These plume equations ae for strongly buoyant plumes. For small

inceases over Foom temperature, errors de to Tow uoyaney could

te significant. This topic needs furter study, and, in the absence of

ever daa, itis recommended thatthe pluie equations wt be sed

the average temperature increase is small less than 2°F

Ch. The average temperature rise of a plume fora fuel package

ssh no nearby walls is shown in Figue 7-D.

Volumeuie Plume Flow

The volumetric ow rate of «plume is

yt +273)

a

whee

V = volumetric flow rate of plume at heights, ms;

128s flow in plume at height, ks: and

verage temperature of plume gases at height 2. °C

1,

T+ room temperature

Incustom units, his equation is

v=.Sbi(r, +460)

where

lumetre Now rate of plume at height, cu fin;

‘mass flow in plume at height =, bys and

“= svcrage temperature of plume gases at height °F

1,

T+ room temperature

Total heat ease ate, (Btls)

wp eee ;

: a oe

Bot Reseemrst- i

ie _ : ae

°

rota est eat 9

FIG. 7-6C. Flame height vs. fire heat release rate,

Ange oan, a7

rhzo.071 ad al+0.0018.,

]

- Ab, o

E where k= and 0,07 @ z

5 Taegan, 1

z /,40000 (9500) z

| jis 8 '

: JB ven

ee J {7500 880) 4

5 L///,;5004470) 2

==

° °

ee

‘Average temperature rise, ATC)

FIG. 7-6D. Average plume temperature rts.

SMOKE MOVEMENT IN THE

COLD SMOKE ZONES

[As smoke is transmitted roa the area of fie origi, itis cooled by

entrainment of air; by the transfer of heat from the smoke body t0

building materia, primarily thove inthe wall and eelingzs and, 9

‘the smoke cools, by radiant energy losses. When smoke from a fire

ows through aretatively small crack, the entrainment of cool zi on

‘the unexposed side tends to cool the smoke very quickly. When the

leakage is through larger openings, there may be less entrainment

relative to the mass of smoke movement at such junctures and

therefore, cooling will be slower. Once the smoke fas cooled 0 3

significant degre, however, itis transported in the same manner as

any other pollotart, andthe primary moving forees are those pre-

‘onted bythe stack effect, the wind effet, and mechanical air mave

‘When hot smoke is transported from one area of a building to

another through a confined pareagewray, such on @ duct, shaft, or

stairwell, there will be litle or no cooling due to entrainment. In

such cases, cooting willbe limited to heat lost by conduction from,

7-96 CONFINING FIRES

te moving smoke tothe shaft material. Often, this lous is modest,

land hot smoke can be transported significam distances with only

minor cooling by such confined passageways

PRINCIPLES OF SMOKE MOVEMENT

Smoke can behave very dferey in tll uildings than in low

buildings. th lower blige the infsences of the fe sich ne

feat convective movement and re pressures, ean be the major fe

tosh cae smoke movement Ske removal and vain prac:

tes reflet ts behavior Ini Buldings, these same facto.

Complicated by the sack cffet, which the vera natural ait

tmovement hugh bing coud the difconcae in tempor.

Eres and denies baween the inside and ouside at. This stack

effec can become an imprint factor i smoke movement an i

Bailing design fers ted o combat hat movement

“The predominant factors that cause smoke movement in ll

beings rete sack ees le nfiene of etal wind res,

nthe forced airmoverent within the bling. The llowing text

pres he theoreta natural eit movement, which fected by

theft two facts. Forced sie movement eased by the Ding

hihanding equipment is presented in Section 7, Chapter 7, and

Seaton 7, Chapter 13,of hs handbook, batt shouldbe noted hat

airmoverent canbe nluenced significantly by the mechanical sys

te ofthe ulin. Many desig sluts ote problem of tena

bility Use emergency operon ofthe mechani stems

Flow Through Openings

Tora crack, gap, o ther opening wit pressure difference arose

ita flow will result from the higher pressure tothe lower pressure.

The ovfce equation is commonly used to describe such How

where

V_ = volumetric flow rate through the path, m/s;

C= dimensionless ow coeficient,

A = flow area also called leakage area),

AP = pressure difference aross path, Pa; and

(= density gas in path, kg/m

Inthe context of flows through gaps around doors and through

constuction cracks, the coefficient is generally in the ange of 0.6

9. For standard air density of p= 1.20 kg/m? (0.075 lbfeu ft) and

for C= 0.65, the flow equation above can be expressed as

v= 0.839AYaP-

where

V_ = volumetric flow rate through the pat, mss

A. = flow area (also called leakage area, m?; and

AP = pressure difference aeross path, Pa

Incustom units, this equation is

6 10AYaP

where

= volumetric low rate through the path, cu fumin

A. = flow area (also called leakage ara), sqft; and

AP = pressure difference across path, in, of water.

Stack Effect

‘Under normal conditions, the stack effect ean account fora major

part ofthe natural aie movement in buildings. During fit, the stack

effect is often responsible forthe wide distribution of stoke and

toxic gases in high-rise buildings.

The stack effect is characterized by a strong draft from the

round floor to the soof of a tall building. The magnitude of din

Stack effet isa fanction ofthe building height, the airtightness of

theexterior walls, the air leakage between floors ofthe building and

the temperature difference between the inside and outside of the

building.

‘To illustrate the principle of stack effect, consider the she

matic of « box with a single opening near the bottom and another

thom the top, as shown in Figure 7-6E- The theoretical natural ut

between the wo openings is caused by the difference in weigh of

the column of air within the box and that of a corresponding column

‘of air of equal dimensions outside the box. The magnitude ofthe

theoretical natural draft may be computed using the Following fr

ute

a

15,

20th 7)

where

AP = theoretical pressure difference in, of water:

H_ = vertical distance between the inlet and the outlet,

8, = baronies pressut, in. of mercury:

T, = temperature of ouside air; and

= density of air at 'F and | atmosphere pressure, Ico!

29.9 in, and p = 0.0862 Ibeu fi, thse

pe

Assuming values of B,

pression reduces to

)

ap=763H| 4-2

7

7,

Vertical air movement in a building is caused by this mats!

ude ofthe stack effect depends

the difference between the inside and outside temperatures an!

the vertical distance between openings. Ifthe inside and outst

= i

“

Neural

Pine

Lio

om

FIG 7-68 Air mavemente caused by preesure (4) and loc

‘of neutral pressure plane (B) ina structure without sect!

Barriers and with the two openings shown.

SMOKE MOVEMENT IN BUILDINGS 7-97

EE eee eee

snperataes are equal (7; = T,), no natura alr movement takes

Shee When T, 5 The airmoves vertically upward, with the lower

ing Ate ac the nr and the upper opening ax the outlet A ee

Re sack effect occurs when 7,2 7, In this case, the upper open

ng iste inlet and the lower opening becomes the outlet.

Part (B) of Figure 7-6E. illustrates the pressures that eause

these movements. If tis assumed inthis figure that T, <7, the ex

Tnx presture wll De greater tnan the interior pressure at the lower

gen, This is a positive pressure which forces ouside air into the

[Weting at that loetion ‘The utside preseure at the upper opening

‘tower than the inside pressure, which ctestes a negative pressure

iihat location which forces the inside air outside, The pressure dis

irbution between these two locations is assumed to be linea,

Ian opening were present inthe exterior wall ina region of

positive pressure, air would flow into the building. An opening ia a

fepion of negative pressure would cause ar to flow out ofthe build

ing. The neutral precture plane indicates whore inside and outside

pressures are equal. If there were an opening at this level, at Would

fhoveaeitherinvard nor outward, The location of the neutral pres-

Sore plane ina structure without horizontal barriers and with the two

‘penings shown in Figure 7-6E can be determined from the follow

ity eclationsips

A AST,

A, AT,

where

and fy represent the distances from the neutral pressure plane to

the lower and upper openings, respectively

and A; ropresent the cross-sectional areas of the lower and upper

openings, respectively; and

and 7, represent the absolute temperatures ofthe ai inside and

outside the Building, respectively

“The magnitude of the pressures created by the stack effet are

escrbed by the equation

/

«76314 4 +)

(nt)

Examination of Figure 7-6F illustrates the significant differ

ences between tall and short buildings with regaed to air movement

Height (im)

30s st o 122

‘P=7BHIT,-UTn wher

Hoge

Jp =o ong

connote

Pressure had (of wt

CC )

Height

FIG.7-6F. Stack effectdue to heightand temperature difference

[C=(F-32)x50,

by sack effect For example, assume that a ite develops a pressure

‘of 006 in, of water (25 Pa) in a compartment, Assume further that

The tse temperatire 50°F (10°C) ower than hence temper

tue and thatthe fie occurs at the same level a the lower opening.

‘The curve 7, + 50°F (10°C) indicates that, if the upper outlet were

approximately aU tt (12 m) above the fie, the amet stack pressure

‘would balance the pressure caused by the fre. building taller that

40 1(17m) would eveatea greater stack pressure and, theoretically,

the outside air would move int the building

Influence of Floors and Partitions

‘The theoretical draft described by Fignee 7-6F andthe final reduced

‘equation are modified in real buildings by the presence of floors and

partitions. These batries impede the free movement of ar although

"significant flow can take place through openings in the assemblies

The magnitude and location of the leakage areas ina building

naturally vary wih the bullding’s tuction and type of construction.

‘The National Research Council of Canada conducted studies ofa

Highness for majar sepeations on four Hiltinge ranging fem 9 ta

44 stories high. The measurements were used for computer mode!

ing of the air movemeat for a simulated 20-story building with a

oor plan dimension ot 120 by 120 tt (46 by 86 m) and a Hor to

floor height of 12 f (3.6 m).? The data from the National Research

CCouneil of Canada has been established as a table of eaevlation?

Te data are given in Table 7-64,

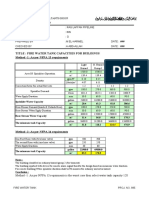

TABLE 7-6A, Typical Leakage Areas for Walls and Floors of

Commercial Buidinge

Construction Element _WallTighiness Area Rallo VA,”

Exteroe building was Tight 070% 10+

(includes corsitucion Average 023x103

Grauks, crac atound Lanse 082107

windows and doors) Very Loose 013% 10?

‘Stairwel walle Tiong 01x10

(includes construction Averages O10

fracke but not oracke —_Loceog 0.5102

‘round windows or

doors)

Elevator shat was Tons 018x109

Cincies constmction —— AveeagaS Daa 109

cracks but not cracks 00806 018x102

‘around doors) Ae

Floors Avoragot 052x104

(includes construction

‘racks and cracks

around penetrations)

‘Ax wakoge wea, Ay =

{oma na Shaw 1976

Hamu and Wisen 1966

Tamura ana Shaw 1376

‘These leakage areas are sufficient to allow a substantial air

movement throughout the building. Most of the air will flow into

vertical shafts, such as stairwells and elevator shafts. Some will low

ertially fom Moor to Moor uy dhe vai openings ie the

Aoor-ceiling assembly. This floor to-floor movement is always

caused by a pressure diferential between the Roors.

Pare (A) of Figure 7-6G illustrates the pressure difference cha

acteristics of a building in which stack action causes air movement

7-98 CONFINING FIRES

‘The slopes of the pressure lines represent citerences between any

two regions a he stme height. Airflow from one region to another

‘rll aliways be in the direction of the region whose pressure curve i

Tore tothe left. This is ilusteated by the aelow directions repre-

‘sented by the arrows in Part (B) of Figure 7-66.

‘Wind Effects

‘Wind ation is another important feature in the movement of smoke

Again, tll and short hnilings behave somewhat differently inthis

‘epard, Figure 7-6H illustrates the air pressure distribution along the

four sides and the roof of a building. The plan view ofthe pressures,

shows that the windward wall § subjected to an inward pressure,

‘while the leeward wall and the to side walls have an outward pres

tre, o setion, The flat roof his an pwr preccre, with the max

‘mum amount occurring atthe windward edge.

“These pressures are caused by the movement of a macs of ait

around and over the sircture. A shor, wide building will cause the

major volume of air to move over the roof, with correspondingly

Jess eit movement around the sides. tal, narrow building, on the

other hand, will cause the major volume of air to follow the path of

feast resistance aroun the bulking, with Tess movement over the

haf pressure

Fer preoure

use pressure

Neutal pressure

Plane

between foor and

shal

Pressure diterence

between for and

“ ®

FIG. 7 6G. The pressure difference characteristics fa hil

ing in which stack action causes air movement.

ovation

Plan

FIG, 76H. The air pressure distribution along the four sides

‘and the raf af a building

top. Te velocities ofthese movenents ats the primary cause ofthe

amount and directions of the pressures on the building

Wind velocities and direction vary over any face of a buiking

‘The mos important effects are:

1. Win velocity. ‘The higher the wind velocity.

Feets of the following two influences,

2. Ground effect. Unless influenced by unusual arrangements of

structures or terrain, the fiction and turbolence that occur as air

tures aver the ground cesults in the Lowest velocity at ground

Jevel and inereases with increases in height

greater the

3, Structures, Buildings and other man-made er mtural fat

such as tees, can produce localized effect that ean increas,

crease, or alter the direction of wind forces

‘The effect of wind pressures and suctions modifies the natural

sirmovement within huiling. For example, the negative pressure

‘on the roof ofa tall building can have an aspirating effect ona ver.

tical shaft opened atthe roof level. This ean cause the observed draft

toexceed the theoretical dralt shown mn Figure 7-1

Horizontal pressures and suctions cause the neutral planes in

exterior walls to move. Positive wind pressure would tend (0 raise

the neutral pressure plane, while negative pressure will lower i

Figure 7-6 luna the influence of wind ation on air movement

ina building

Neutral

plane

: Starwol levater, of

‘etteal sonnce shalt

Wins

Sterol. levator of

Sgrifcant wind

761. Influcnce of wind action on air movement it

building. Note how the neutral pressure plane changes!"

throughout the building in the presence of significant wit

SMOKE MOVEMENT IN BUILDINGS 7-99

SMOKE MANAGEMENT.

Te term “smoke management." as used inthis section, includes all

methods that can be sed alone or in combination to modify smoke

‘movement for the benefit of accupants or firefighters oto reduce

Property damage. The mechanism of comparmentaion, dilution,

inflow, pressurization, and buoyancy are used by themselves or in

combination to manage smoke conditions in fires. These mecha

nisms are discussed below.

Compartmentation

Rarriers with sufficient fre endurance to remain effective through=

fut & fire exposure have a long history of providing protection

azains fire spread. In such fire compartmentation, the walls, parti-

ions, Noors, doors, and other barriers provide some level of smoke

protection to spaces remote from the te. This section discusses the

the af passive campartmentaion, while the use of compartment

tion in conjunction with pressurization is discussed later. Many

odes, such as NFPA 10/®, Life Safety Code®. provide specific cr-

tena forthe constriction of smoke barners, including doors and

smoke dampers in these batiers. The extent to which smoke leaks

through such barrere depends on the rize and shape ofthe leakage

pats in the barriers and onthe pressure dferences across the paths

“There is no formalized analytical method for detrmining the

rate of smoke leakage through barriers and the resulting levels of

hazard in areas to be protected, However, emerging fre and smoke

transport models can addres the smoke leakage through barriers. A

ficstorder approximation of the leakage can be made using the

equation for low through an opening, typical leakage aces listed in

‘Tle 7-6A, estimates of the dimensions of paths such as gaps

around doo, and the procedures for estimating effective low ar

fs. More accurate caleulations await better data and improved cal

ulation procedures. Full appraisal of the impact of such leakage

fequtes hivwledge of the stoke toxicity or an assumed design

‘le of acceptable smoke concentration in protected spaces. for.

malized approach to smoke compartmentaion should include de-

‘elopment of appropriate methods of acceptance testing and routine

testing. More effort is needed to increase understanding of the pas-

sive capabllides of bariers inorder to maximize the usefulness of

this oldest and most fundamental method of smoke management.

Dilution

Dituion of smoke Is sometimes referred 1 as smoke purging,

smoke removal, smoke exhaust, or smoke extraction, Dilution can

be used to maintain an acceptable smoke concentration in a com-

artment subject to smoke ifilraton from an adjacent space. This

an be effective if the rate of smoke leakage is small compared 10

‘ier the total volume of te safeguarded space or the rate of purg-

ing ar supplied to and removed from the space. Dilution also can be

beneficial tothe fre service for removing smoke after ie has heen

extinguished. Sometimes, when doors ate opened, smoke will ow

imo areas intended tobe protected, Ideally, doors will only be open

‘or short periods during evacuation, Smoke that has entered spaces

‘ero he fe cn be purged by supplying outside art dite

the smoke,

Some people have unrealistic expectations about what dilution

can accomplish in the fie space, There tno theoretical or exp

"ental evidence tat using a building's heating, ventilation, and ait

conditioning (HVAC) system for smoke dilation will result in any

“igntcant improvement in tenable conditions within the fir space.

HVAC systems promote a considerable degree of ai mixing within

the spacer thay seve Besson ofthis and theft that bling Bex

‘anproduce very large quantities of smoke, clin of smoke by an

HVAC system in th fie space will not eesult in any practical im

provement in the tenable conditions of that space. Thus, smoke-

urging systems intended to improve hazard conditions within fire

space oF in spaces connected to a fre space by lange openings

should not be used.

The following isa simple analysis of smoke dilution for spaces

in which there is no ire. At time zero (r= 0), compartment i con-

taminated wit some concentration of smoke, and no further smoke

flows into or is generated within the compariment. In addition, d

contaminant is considered uniformly distributed throughout the

space, The concentration of contaminant in the snace can he ex

pressed as:

where

CC, = initial concentration of contaminant

© = concentration of contaminant at timer:

2 = dilution rate in number of air changes per min

f= time after smoke stops entering space or time after

hich smoke production has stopped, in min; and

‘© = constant, approximately 2.178

‘The concentrations C, and C must be expressed in the same

units, and they can be any units appropriate Fr the particular con

‘aminant being considered, McGuire, Tamura, and Wilson’ evalu

ated the maximum levels of smoke obscuration from a number of ire

tests and a number of proposed criteria for tolerable levels of smoke

‘bacuration, Dased on this evaluation, they sate thatthe maxima

levels of smoke obscuration are greater by a factor of 100 than those

relating tothe limit of tolerance, Thus, they indicate that an area c

be considered “reasonably safe™ with respect to smoke obscuration

ifs atmosphere will not be contaminated to an extent eater than |

percent by the stmosplire prevailing inte innediate ve wea, Kis

‘obvious that such dilution would also reduce the concentrations of

toxie smoke components. Toxicity is a more complicated problem,

tnd no parallel statement has been made regarding dilution needed

te obtain a safe atmosphere with respect to toxic gases

In reality, it is impossible to ensure thatthe concentration of

the contaminant i uniform chroughout the compartment. Because

fof the buoyancy, tis kely that higher concentrations would tend to

bbe near the ceiling. Therefore, an exhaust inlet located near the ceil-

ing and a supply outlet laeated nenr the Raor weld penbably ite

smoke even faster than indicated by the above equations. Caution

shouldbe exercised in locating the supply and exhaust points to pre=

vent the supply air from blowing into the exhaust inlet and thus

short circuiting the dilution operation.

EXAMPLE: Smoke purging after th fr is extinguished

|. After the fire department puts out a fie. the smoke must be

cleared quickly so that an inspection ean be made to determine

ifthe fire is completely out. I the smoke HVAC system is eapa-

bie of aaiiuton rate of sx alr changes perf, haw Jong will i

take to reduce the smoke concentration to I percent ofthe initial

value?

‘The dilution rate, a is 0.1 changes per min, and C, ICs 100.

300)

46 min to purge smoke

to | percent of inital value

7-100 CONFINING FIRES

ae

Considering the fre department's desire to inspect the area

‘quickly, such along purging Gime wil probably be excessive,

Ifthe fire department wants tho cpace to be purged in 10 min,

what dilation rate is needed?

2 10 min, and C, JC ie 100

‘The dilation time,

tog, (100)

(0.46 changes per min

(28 changes per hx)

0

Pressurization

‘Systems using pressurization produced by mechanical fans are re

ferred to as smoke-control systems in NFPA 92A. Pressurization re-

sulin aiflows of high velocity ia the smell gaps around closed

‘doors and in constuction cracks, thereby preventing smoke back-

flows throush these openings. The pressurization systems most

‘commonly used are pressurized stairwells and zoned smoke contro.

Elevator smoke control is less common. Klote and Milke! present

the public Uonsin vompater program ASCOS for analysis of

smoke-contzol systems that use pressurization. Another public do-

‘main program. called CONTAMS, has extended capabilites for

smoke-contgol analysis and runs more eiciently

Many pressurized stairwells are designed and built with the

goal of providing a tenable environment within the escape route in

the event ofa building fire. Is obvious that a pressurized stairwell

‘ean meet ts objectives, even Ifa small amount of smoke infiluates

the stairwell, The three major design concemns with pressurized

1. Nonuniform pressure differences that occur over the stairwell

hehe

2. Large pressure uctuations caused by doors being opened and

closed

3, The location of supply air inlets and fans.

A first, it might appear that the pressure differences from the

stairwell to the building would be essentially the same over the

height of the staitwell. Unfortunately, tis isnot the case. For a

building without vertical leakage through floors or shaft other than

the stairwell, the pressure profile is linea. OF course, this leakage

Characteristic is not eepresenttive of many buildings. However, this

tease i useful because it has been analytically solved, and it repre

sents a worst case, The analysis has been adéressed. It is a worst

‘ease scenario in that its minimum pressure difference is less than

that for other, more realistic leakage configurations and its maxi

fun pressure diffeeie is greater than that for othorIeskage com

figurations. Computer analysis can be performed to include the

effets of more complicated building leakage arrangements

‘When a door is opened in a pressurized stairwel, the pressure

difference across the remaining closed doors can drop dramatically.

‘The lwo clases of design concepts that have been sed to deal with

this problem are overpressure relief and feedback contol. An over

pressure rele system tha has gained auction xs Ueing simple ad

cost-effective is the “Canadian System.” The essential features of

thie system are that air is supplied by one or more fans at relatively

constant flow rates, and the ground-floor exterior stairwell door

‘opens automatically when the system activates. Tis sytem elimi

ites the source of the most severe pressure Nucuations—she open

ing and closing ofthe exterior door

mere 1s concer about cating supply a nlers near de exe

sior ground-floor doors of the stairwell. Ha supply inet is located

roar thie ane ti pele tha much ofthe supply aie will ow di

rectly dough the exterior doorway when itis opened, thus effec

tively eedicing stairwell pressurization, It is believed that locating

inlets nly ane Aor away from exteriar doors eliminates this poten

tial

Im the Tate 19606, the concept of the “pressure sandwich”

‘evolved, This consisted of exhausting the fire oor and pressurizing

surrounding floors to limit smoke movement to the fre floor. The

pressure sanawicn concept has evolved ino today's zoned smoke

‘contol systems. According to the concept of zoned smoke contol,

4 building can be divide into a numberof emake rones, each sep.

arated from the others by panitions and floors. A smoke-contol

zone ean consis of one floor or more than one floor, oF aloor ean

Consist of more than one smoke zone. In the event ote, pressure

differences and airflows produced by mechanical fans can be used

te restrict smoke spread to the 2one in which the re began, or the

smoke zone. The concentration of smoke inthis zone may render it

‘untenable. Accordingly, in zoned smoke-control systems, building

‘occupants should evacuate the zone in which the fire occurs as soon

fas possible ater the fire has been detected,

Airflow

Airflow has been used extensively to manage smoke trom tres in

subway, railroad, and highway tunnels. Large flow rates of air are

needed to control moke flow, and these Now rates can supply addi-

tional oxygen tothe fire. Beeause ofthe need for complex controls

flow isnot used as extensively in buildings. The contol problem

consists of having very smal flows when a door is closed, and then

having those flows increase significantly when that door Opens.

“Thomas! determined that airflow in a corridor in which there

is fire can almost totally prevent smoke from flowing upstream of

{he fire. As illstated in Figure 7 6H, the smoke forms a surface

that slopes into the direction of the oncoming airflow. Molecular

difusion is believed to result in the transfer of trace amounts of

smoke, producing no hazard upstream, just the odor of smoke

‘There is a minimum velocity below which smoke will low up.

stecan, and Thomas! developed the following empirical relation

for this critical velocity. Ths relation, evaluated at air density of

(0.081 Ihfeu ft and temperature of 81°F (27°C) is:

easel

V; = critical aie velocity to prevent smoke backflow, fui,

whoce

1b = energy release rate into corridor, Bur; and

W = comsidor wid

‘This relation can be used when the fire i located inthe comidor

‘or when the smoke enters the corridor through an open doors

ale transfer grille, oF some other opening, Te eritical velocities eal

‘ulated are approximate, because only an approximate value of

‘was used. However, the critical velocities from this relation ar it

ticative ofthe kind of at velocities required to prevent smoke back

Flow from fees of different sizes

EXAMPLE: Rough estimates of airflow fora doorway.

1. Thomna.®indiested thst hi rltionship for eiteal velocity cat

be used to obtain a rough estimate for doorways. A room fil)

involved in fire could have an energy release rat onthe order

8x 10" Blulhr. What estimate of crseal Velocity 1 obtaie

from the Thomas! equation fora daor 3 ft (0.9 m) wide?

y,

.69(8>10"/3)"" = 800 iin

If the door hasan area of 20 3 this would amount too

of 1600 cu f/min

2. Consideration of a smaller fire, such as 3 wasicaske fire, may

be appropriate for many situations. What flow rate does the

‘Tomas relation indieate is needed wo prevent backNIOW Tor he

shove door? A wastebasket fire has an energy release rate neat

153 10 Rate

5.68(0.5x 10°73} = 300 fvmin

Fora door area of 20 ft, this would amount to. flow of 6000

cu fin

Buoyancy in Large Spaces

Buoyancy of hot combustion gases is employed in both fan-pow:

«red and nonpowered smoke management sysiems for large-volume

spaces. The spaces where such systems are employed include ata,

sycodes, covered chopping malls, sport arenas and exhibition hal

in goneral, these buoyancy systems are used for spaces with floor 10

seiling heights of at least 33 £ (10m). The following are approaches,

that cam be used to manage smoke in large spaces.

1, Smoke filing: This approach consists of allowing smoke t fill

the large-volume space while occupants evacuate the atrium,

‘This approach applies only to spaces where the smoke filling

lime is sufficient for both decision making, ial evacuations

Evacuation time can be estimated by people movement analy

is. Smoke filing time can be estimated by either computer

Fie models or by the filling time equations in NFPA 92B.

2. Unsieady clear height with upper layer exhaust: This ap

proach consists of exhausting smoke from the atrium top at a

rate such that occupants will have sufficient time for decision

raking and evacuation. This approach requicer an analysis of

‘people mavement and a fire model analysis of smoke filling

3. Steady clear height with upper layer exhaust: This approach

‘consists of exhausting smoke from the top of the atrium in order

to achieve a steady clear height fora steady fire, (See Figure 7-

{51 Design analysis of this system is bared on the fac that the

mass flow of smoke entering the upper smoke layer equals that

‘ofthe exhaust, Fora fuel package away from walls. the exhaust,

Airflow rates are shown in Figure -6K.

Computer fie models include the Harvard Code!” ASET!

ASET-B,"* the BRI Model,"® FIREFORM,"” CCFM,"" and

CEAST.” The University of Maryland has made modifications to

CCEM, specially for aurium smoke management Uesign2® De-

FUG 7-4) Atrium emake exhaust ta maintain a emokecfore

lear height

SMOKE MOVEMENT IN BUILDINGS 7-101.

‘Atrium exaust, V(108 cu fin)

o 2 4 6 8 0 2

maoor Holz 00080, 600

its 279)

180 s00

| seem sto ere) Ae 1,20 a.+07 9 z

5 s00

B &

7” ZO 200

3 3

3 Totathestratese aia, @: 299 &

25000 1 (240 Btls)

ie

"S000 {4700} x

aes 0

2 1000 2000

‘Aum exhaust, VPs),

3000 4000 000 6000

FIG 7.6K Atrium vhauet needed to maintain a clear height

for various heat release rates.

sctiptions of zone models are provided by Bukowski?" Friedman

Jones." Miller and Rocket." Miler2® and Quintere® Kiots”

provides an overview of atrium smoke management and a public

Hlomain computer program, eniled “Atcinm Smoke Management

Engincering Tools” (ASMET).

BIBLIOGRAPHY

References Cite

1. Rio, J. Haid Mlle JM, Design of Smoke Atanagemen Systems,

“American Society of Heating, Refigraing, and Aie- Conditioning Ea-

siners, Alana, GA, 1992

lot, "Smoke Conta” The SEPE Handbook of Fre Protection

Engineering, 2nd ed, DiNeneo, 3, ed. National Fe Proetion A

sociation, Quinsy. MA, 1998.

3. Thomas, PH, ral, "vestigations into the Flow of Hot Gases in Roof

‘emting” Fie Research Technical Paper No.7, Jia Fie Research

Option, London, Enand, 1963,

4. Butcher, E.G. and Pare. A.C., Smoke Control in Five Safety Design,

‘Ceand F 8. Spon, London. Eagland, 1979.

5. Hestesta, G., "Fie Plumes." The SFPE Handbook of Fire Protection

Enginering, 2nd ed, DiNenno, PJ. National Pre Protection A

station, Quincy, MA, 195.

6. Hestesta,G.,"Enginering Relations for Fie Plumes” SFPE Tent

‘ogy Rep 62-8, Sxiely of Fe Pract Engine, Boston MA,

1982,

17. Tamura, G.T. “Computer Analysis of Smoke Movement ia Tall Build

‘ings Annus] Meeting, American Society of Hesing, Retigeating,

st Air Condtoning Engineers, Jone 1969,

4B. McQuit, JH, Tata 0.7, ad Wien, AC, “Fas i Come

{ing Smoke in High Busines." Ssmposin on Fire Waza in Bui

ings, ASHRAF Semiannual Meeting in San Fanisco, CA, 1970, p.

a5)

9, Walton, WD., "CONTAMO3 User Mapua" NISTIR $385, 1994, Ne

‘oral inatitateof Standards and Technology Guitersbrg, MD.

10. Thomas, PH. "Movement f Smoke in Horizontal Corridor Against

an Aion hsinte of Five Engineers Quarers, Vol. 30,No. 7,

1970 pp 48-53

11. Nelson, H.Eand MacLennan, H.A.. "Emergency Movement” The

‘SEPE Handbool of Fire Prvsction Bxginvaring, 3nd, DN

3a, National ie Protection Assocation, Quincy, MA, 1995

You might also like

- ECG - Deluge System CalculationDocument22 pagesECG - Deluge System CalculationzshehadehNo ratings yet

- Elegantry: Water Storage Tank Hydraulic Calculations: 1Document3 pagesElegantry: Water Storage Tank Hydraulic Calculations: 1zshehadehNo ratings yet

- Pump HeadDocument14 pagesPump Headzshehadeh100% (1)

- Chiller RC SS 3 BDDocument34 pagesChiller RC SS 3 BDzshehadehNo ratings yet

- FM200Document6 pagesFM200zshehadehNo ratings yet

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsFrom EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNo ratings yet

- ECG-Foam CalculationDocument22 pagesECG-Foam CalculationzshehadehNo ratings yet

- Pavement Materials for Heat Island Mitigation: Design and Management StrategiesFrom EverandPavement Materials for Heat Island Mitigation: Design and Management StrategiesNo ratings yet

- ECG-SUMP PUMP CalculationDocument83 pagesECG-SUMP PUMP Calculationzshehadeh100% (3)

- Chiller OptimizationDocument91 pagesChiller Optimizationavbsky100% (1)

- The Control of Indoor Climate: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandThe Control of Indoor Climate: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionFrom EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionNo ratings yet

- BS 5422-2009Document82 pagesBS 5422-2009zshehadeh100% (1)

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995From EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Rating: 5 out of 5 stars5/5 (1)

- Expansion Calculations and Loop SizingDocument2 pagesExpansion Calculations and Loop Sizingzshehadeh0% (1)

- Dust Control and Air Cleaning: International Series of Monographs in Heating, Ventilation and RefrigerationFrom EverandDust Control and Air Cleaning: International Series of Monographs in Heating, Ventilation and RefrigerationNo ratings yet

- Combined Cooling, Heating and Power: Decision-Making, Design and OptimizationFrom EverandCombined Cooling, Heating and Power: Decision-Making, Design and OptimizationNo ratings yet

- Heat Pumps: Solving Energy and Environmental ChallengesFrom EverandHeat Pumps: Solving Energy and Environmental ChallengesTakamoto SaitoNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- A Method of Reaching Extreme Altitudes: The seminal text on rocket science that foretold the Space AgeFrom EverandA Method of Reaching Extreme Altitudes: The seminal text on rocket science that foretold the Space AgeNo ratings yet

- Chemical Thermodynamics: Principles and Applications: Principles and ApplicationsFrom EverandChemical Thermodynamics: Principles and Applications: Principles and ApplicationsRating: 4.5 out of 5 stars4.5/5 (4)

- Industrial and Process Furnaces: Principles, Design and OperationFrom EverandIndustrial and Process Furnaces: Principles, Design and OperationNo ratings yet

- Natural Gas: Economics and Environment: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Economics and Environment: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsFrom EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNo ratings yet

- Theory and Calculation of Heat Transfer in FurnacesFrom EverandTheory and Calculation of Heat Transfer in FurnacesRating: 3 out of 5 stars3/5 (4)

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesFrom EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- The Steam Engine and Turbine - A Text Book for Engineering CollegesFrom EverandThe Steam Engine and Turbine - A Text Book for Engineering CollegesNo ratings yet

- Natural Gas: Consumers and Consuming Industry: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Consumers and Consuming Industry: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringFrom EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNo ratings yet

- Finite Physical Dimensions Optimal Thermodynamics 1: FundamentalsFrom EverandFinite Physical Dimensions Optimal Thermodynamics 1: FundamentalsNo ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

- Temperature and Humidity Independent Control (THIC) of Air-conditioning SystemFrom EverandTemperature and Humidity Independent Control (THIC) of Air-conditioning SystemNo ratings yet

- Finite Physical Dimensions Optimal Thermodynamics 2: Complex SystemsFrom EverandFinite Physical Dimensions Optimal Thermodynamics 2: Complex SystemsNo ratings yet

- Advances in Air Conditioning Technologies: Improving Energy EfficiencyFrom EverandAdvances in Air Conditioning Technologies: Improving Energy EfficiencyNo ratings yet

- Solar Energy Engineering: Processes and SystemsFrom EverandSolar Energy Engineering: Processes and SystemsRating: 3 out of 5 stars3/5 (1)

- Chimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemFrom EverandChimneys & Fireplaces: They Contribute to the Health Comfort and Happiness of the Farm Family - How to Build ThemNo ratings yet

- Description of the Process of Manufacturing Coal Gas: For the Lighting of Streets Houses, and Public BuildingsFrom EverandDescription of the Process of Manufacturing Coal Gas: For the Lighting of Streets Houses, and Public BuildingsNo ratings yet

- Hydraulic Calculation of Water Pump Item 14-2 Plumbing WorksDocument2 pagesHydraulic Calculation of Water Pump Item 14-2 Plumbing WorkszshehadehNo ratings yet

- THERMAL STANDARD FOR BUILDINGS IN LEBANON For New Residential and Non-Residential Buildings PDFDocument45 pagesTHERMAL STANDARD FOR BUILDINGS IN LEBANON For New Residential and Non-Residential Buildings PDFzshehadehNo ratings yet

- GRP PipeDocument6 pagesGRP Pipezshehadeh0% (1)

- The Junction District Centre Treendale: Boiler F&R SchematicDocument1 pageThe Junction District Centre Treendale: Boiler F&R SchematiczshehadehNo ratings yet