NOVICIADO_TK400 Page 1

STORAGE TANK DESIGN CALCULATIONS

1.0 DESIGN CODE & SPECIFICATION

: API 650

1.1 TANK

Service : Oily Base

Item number : -

Type of tank : Self Supported

Cone Roof

1.2 GEOMETRIC DATA

Outside diameter , Do 27,51 ft = 8385 mm

Tank height , H 23,85 ft = 7270 mm

Specific gravity of operating liquid , S.G. = 0,901

Nominal capacity , M = 401,61 m³

Maximum design liquid level, HL = 7270 mm

1.3 PRESSURE & TEMPERATURE

Design pressure : Upper , PU = 6550,27 mm H2O = 642,6 mbar.g.

: Lower , PL = 0 mm H2O = 0,00 mbarg.Vac

Design temperature : Upper , TU = 113 °F = 45,00 °C

1,4 MATERIAL & MECHANICAL PROPERTIES

Tensile Stress Yield Stress Corr. Allow.

Component Material

St (N/mm²) Sy (N/mm²) c.a.(mm)

PLATE

Shell Plate A36 550,00 250,00 250,00 1,0 1,0

Bottom Plate A36 550,00 250,00 250,00 1,0 1,0

Roof Plate A36 550,00 250,00 250,00 1,0 1,0

Stiffener Ring A36 550,00 250,00 250,00 1,0 1,0

STRUCTURE

Top Curb Angle A36 550,00 250,00 250,00 1,0 1,0

19-11-2021

�NOVICIADO_TK400 Page 2

2.0 SHELL DESIGN THICKNESS CALCULATION

2.1 GEOMETRIC DATA

Plate width used 19,69 ft : 6000 mm

Plate height 7,87 ft : 2400 mm

2.2 MATERIAL & MECHANICAL PROPERTIES

Material used : A36

Specified minimum tensile stress, Ss = 550 N/mm²

Specified minimum yield stress, Sy = 250 N/mm²

Yield strength reduction factor, k ( Appendix M ) = 1,00

Joint Efficiency, E = 0,70

Max.allowable design stress,Sd = 166,67 N/mm²

Max.allowable hydro. test stress,St = 187,50 N/mm²

(As per Table 3-2 )

2.3 SPECIFIED MINIMUM SHELL THICKNESS

Specification : API 650 Clause 3.6.1

Minimum thickness 5,00 mm

2,3 TANK SHELL THICKNESS CALCULATION

D = Inside diameter of tank = 27,51 ft

H = Design liquid level = 23,85 ft

Hi = Internal design pressure = 21,49 ft. water

G = Specific gravity of liquid = 0,90

c.a. = corrosion allowance = 0,04 in

Sd = Allow. stress for design condition = 24173 psi

St = Allow. stress for hydrostatic test condition = 27195 psi

(2,6) x (D) X (H - 1) x (G)

Shell Thk at design condition (td) = + C.A.

Sd

(E) x (21000)

(2,6) x (D) X (H - 1) x (G)

Shell Thk at hydrotest condition (tt) = + C.A.

St

(E) x (21000)

2,4 CALCULATION & RESULTS

Course # Liquid Liquid Height of t.design t.hydro. t.used

from bottom height height each (td) (tt) (t) RESULTS

bottom (H) (H) Course

of tank mm ft mm (mm) (mm) (mm)

1 7270 23,85 2400 3,97 2,93 6,00 = O.K.

2 4870 15,98 2400 3,21 2,18 6,00 = O.K.

3 2470 8,10 1235 2,08 1,06 5,00 = O.K.

4 1235 4,05 1235 1,69 0,68 5,00 = O.K.

=

By one foot method. See sec. 3.6.3.2

19-11-2021

�NOVICIADO_TK400 Page 3

By one foot method. See sec. 3.6.3.2

on page 3-7 of API - 650

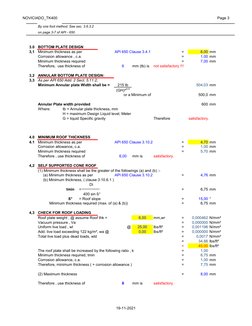

3.0 BOTTOM PLATE DESIGN

3,1 Minimum thickness as per API 650 Clause 3.4.1 = 6,00 mm

Corrosion allowance , c.a. = 1,00 mm

Minimum thickness required = 7,00 mm

Therefore, use thickness of 6 mm (tb) is not satisfactory !!!

3,2 ANNULAR BOTTOM PLATE DESIGN:

3,3 As per API 650 Add. 2 Sect. 5.11.2;

Minimum Annular plate Width shall be = 215 tb 504,03 mm

(GH)^0.5

or a Minimum of 500,0 mm

Annular Plate width provided 600 mm

Where: tb = Annular plate thickness, mm

H = maximum Design Liquid level, Meter

G = liquid Specific gravity Therefore satisfactory.

4.0 MINIMUM ROOF THICKNESS

4.1 Minimum thickness as per API 650 Clause 3.10.2 = 4,70 mm

Corrosion allowance, c.a. = 1,00 mm

Minimum thickness required = 5,70 mm

Therefore , use thickness of 6,00 mm is satisfactory.

4,2 SELF SUPPORTED CONE ROOF

(1) Minimum thickness shall be the greater of the followings (a) and (b) :-

(a) Minimum thickness as per API 650 Clause 3.10.2 = 4,76 mm

(b) Minimum thickness, ( clause 3.10.6.1 )

Di

tmin = = 6,75 mm

400 sin ß°

ß° = Roof slope = 15,00 °

Minimum thickness required (max. of (a) & (b)) = 6,75 mm

4,3 CHECK FOR ROOF LOADING

Roof plate weight , @ assume Roof thk = 6,00 mm,wr = 0,000462 N/mm²

Vacuum pressure , Va = 0,000000 N/mm²

Uniform live load , wl @ 25,00 lbs/ft² = 0,001196 N/mm²

Add. live load exceeding 122 kg/m², wa @ 0,00 lbs/ft² = 0,000000 N/mm²

Total live load plus dead loads, wld = 0,0017 N/mm²

= 34,66 lbs/ft²

< 45,00 lbs/ft²

The roof plate shall be increased by the following ratio , k = 1,00

Minimum thickness required, tmin = 6,75 mm

Corrosion allowance, c.a. = 1,00 mm

Therefore, minimum thickness ( + corrosion allowance ) = 7,75 mm

(2) Maximum thickness = 8,00 mm

Therefore , use thickness of 8 mm is satisfactory.

19-11-2021

�NOVICIADO_TK400 Page 4

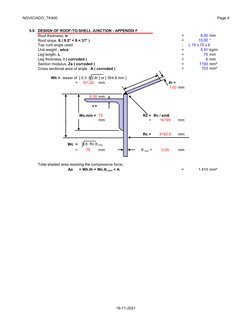

5.0 DESIGN OF ROOF-TO-SHELL JUNCTION - APPENDIX F

Roof thickness, tr = 8,00 mm

Roof slope, ß ( 9.5° < ß < 37° ) = 15,00 °

Top curb angle used : L 75 x 75 x 6

Unit weight , wtca = 5,91 kg/m

Leg length, L = 75 mm

Leg thickness, t ( corroded ) = 6 mm

Section modulus, Za ( corroded ) = 7100 mm³

Cross sectional area of angle , A ( corroded ) = 703 mm²

Wh = lesser of [ 0.3 R2.th ] or [ 304.8 mm ]

= 101,02 mm th =

7,00 mm

6,00 mm

t=

Wc.min = 75 R2 = Rc / sinß

mm = 16199 mm

Rc = 4192,5 mm

Wc = 0.6 Rc.tt.corr

= 75 mm tt.corr = 0,00 mm

Total shaded area resisting the compressive force,

Aa = Wh.th + Wc.tt.corr + A = 1.410 mm²

19-11-2021

�NOVICIADO_TK400 Page 5

5.1 MINIMUM REQUIRED COMPRESSION AREA AT THE ROOF TO SHELL JUNCTION

D²

Ar = = 629 mm²

3000.sin ß°

where

D = Nominal tank diameter = 27,51 ft

Since Ar < Aa, therefore it is satisfactory.

5.2 CHECK FOR MAXIMUM DESIGN PRESSURE

0.245.W 0.735.M

P.max = + 8.th - = 7,71 mbar

D² D³

where

W =Total weight of shell and any framing(not roof plates) = 4692 lbs

supported by the shell & roof

th = Roof plate thickness = 0,20 in

M = Wind moment = 1 lbs.ft

Since Pi > P, therefore it is not satisfactory !!!

6.0 INTERMEDIATE WIND GIRDER DESIGN

6.1 Maximum Height Of The Unstiffened Shell

100tt.corr ³ 100 ²

H1 = 6(100tt.corr) x x k = 0 mm

D V

where

tt.corr = Thickness of the top shell course (corroded) = 0,00 in

D = Nominal tank diameter = 27,51 ft

V = Wind design speed ( @ 44,00 m/s ) = 98,43 miles/hr

k = Yield strength reduction factor ( Appendix M ) = 1,00

6.2 Location Of Intermediate Wind Girder

Course Thickness. Actual Width Transposed Width

t.corr W Wtr =W(tt.corr / t.corr)^2.5

(mm) (mm) (mm)

1 (bottom) 5,00 26353 0

2 5,00 26353 0

3 4,00 26353 0

4 4,00 26353 0

5 0,00 26353 #¡DIV/0!

6 -1,00 26353 0

7 0,00 26353 #¡DIV/0!

8 0,00 26353 #¡DIV/0!

0,00 #¡DIV/0!

0,00 #¡DIV/0!

#¡VALOR! #¡VALOR!

#¡VALOR! #¡VALOR!

0,00 #¡DIV/0!

0,00 #¡DIV/0!

#¡VALOR! #¡VALOR!

Height of transformed shell, H2 = #¡DIV/0!

REMARK : Let all 'Wtr' equal to zero for 'negative' t.corr

19-11-2021

�NOVICIADO_TK400 Page 6

Since H1 #¡DIV/0! H2 , therefore an intermediate wind girder is #¡DIV/0!

No of Wind Girder required = H2 / H1 = #¡DIV/0!

THEREFORE , NO OF WIND GIRDER REQUIRED = #¡DIV/0!

LOCATION EQUA SPACED OF STIFFENER RING = 1212

19-11-2021

�NOVICIADO_TK400 Page 7

7.0 WIND DESIGN CALCULATION

Design code : ASCE -7

7.1 GEOMETRIC DATA

Internal design pressure, Pi @ 642,6 mbar = 0,06426 N/mm²

Diameter of tank, Di = 0 mm

Tank height , Hs = 7270 mm

Roof slope, ß° = 15,00 °

Roof height, Hr = 0 mm

Height from tank bottom to shell centre, Ls = 3635 mm

Height from tank bottom to roof centre,Lr = 7270 mm

Min. depth of product ( always present in tank) , Hw = 50 mm

Weight of tank,Wt (@ 9.461 kg) = 92.813 N

Weight of product ( always present in tank) , Ww = 0 N

7,2 WIND FORCE CALCULATIONS

The wind loading shall be determined as follows : -

H = P.A.C.I N

where

P = Wind dynamic pressure ( N/m² ) = 900

Cr = Shape factor for roof = 0,75

Cs = Shape factor for shell = 0,75

Ar = Projected area of roof ( = 0.5.Di.Hr ) = 0 m²

As = Projected area of shell ( = Di.Hs ) = 0 m²

I = Appurtenances = 1,18

Total wind load exerted on roof, Fr = 0N

Total wind load exerted on shell, Fs = 1N

Total wind moment on tank, Mwind ( = Fr.Lr + Fs.Ls ) = 1,90E+03 Nmm

19-11-2021

�NOVICIADO_TK400 Page 8

7.3 TANK STABILITY AGAINST WIND LOADING

7.3.1 CASE 1 - EMPTY CONDITION

Resistance to overturning moment,

Mres. = 0.5Di.( Wt - 0.25 p Di².Pi ) = 4,19E+03 Nmm

Safety factor, Sa ( = Mres./Mwind ) = 2,20

> 1,50

Since Sa > 1.5, therefore the tank is structurally

stable. Tank anchorage is not required.

7.3.2 CASE 2 - OPERATING CONDITION

Resistance to overturning moment,

Mres. = 0.5Di.( Wt + Ww - 0.25 p Di².Pi ) = 4,19E+03 Nmm

Safety factor, Sa ( = Mres./Mwind ) = 2,20

> 1,50

Since Sa > 1.5, therefore the tank is structurally

stable. Tank anchorage is not required.

7.4 ANCHOR BOLT DESIGN

7.4.1 GEOMETRIC DATA

Number of bolts , N = 35

Diameter of anchor bolt, d = 30 mm

Diameter of anchor bolt, d.corr ( less c.a.@ 0,00 mm) = 30 mm

Bolts circle diameter, Da = 8505 mm

Root area of each hold down bolt, Ab = 707 mm²

Spacing between anchor bolts, Sb = 763 mm

7.4.2 BOLT MECHANICAL PROPERTIES

Allowable stress, St.all = 103,00 N/mm²

7.4.3 ANCHOR BOLTS DESIGN

Tensile force,

1 4.Mwind Pi. pDi²

T= - Wt - = -2.652 N

N Da 4

Tensile stress,

T

sb = = -3,75 N/mm²

Ab

Since sb < St.all, therefore the anchor bolt size is satisfactory.

19-11-2021

�NOVICIADO_TK400 Page 9

8.0 WEIGHT CALCULATION

8.1 General

Design code : API 650

Service : Oily Base

Item number : -

Type of tank : Self Supported

Cone Roof

Inside diameter, Di = 8385 mm

Tank height, H = 7270 mm

Density of steel = 8000 kg/m³

8.2 ERECTION WEIGHT

8.2.1 Weight of bottom plate

Material : A36

Diameter of bottom plate = 8435 mm

Bottom plate thickness = 6 mm

Weight of bottom plate = 2.682 kg

8.2.2 Weight of shell

Course Material Height Length Thickness weight

No. (mm) (mm) (mm) (kg)

1 (bottom) A36 2400 6000 6,00 691

2 A36 2400 6000 6,00 691

3 A36 1235 6000 5,00 296

4 A36 1235 6000 5,00 296

Total weight of shell = 1.975 kg

19-11-2021

�NOVICIADO_TK400 Page 10

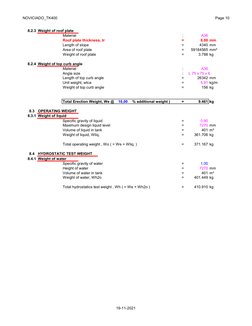

8.2.3 Weight of roof plate

Material : A36

Roof plate thickness, tr = 8,00 mm

Length of slope = 4340 mm

Area of roof plate = 59184565 mm²

Weight of roof plate = 3.788 kg

8.2.4 Weight of top curb angle

Material : A36

Angle size : L 75 x 75 x 6

Length of top curb angle = 26342 mm

Unit weight, wtca = 5,91 kg/m

Weight of top curb angle = 156 kg

Total Erection Weight, We @ ( 10,00 % additional weight ) = 9.461 kg

8.3 OPERATING WEIGHT

8.3.1 Weight of liquid

Specific gravity of liquid = 0,90

Maximum design liquid level = 7270 mm

Volume of liquid in tank = 401 m³

Weight of liquid, Wliq. = 361.706 kg

Total operating weight , Wo ( = We + Wliq. ) = 371.167 kg

8.4 HYDROSTATIC TEST WEIGHT

8.4.1 Weight of water

Specific gravity of water = 1,00

Height of water = 7270 mm

Volume of water in tank = 401 m³

Weight of water, Wh2o = 401.449 kg

Total hydrostatics test weight , Wh ( = We + Wh2o ) = 410.910 kg

19-11-2021