Professional Documents

Culture Documents

A245 Toyota

Uploaded by

Ederson BJJOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A245 Toyota

Uploaded by

Ederson BJJCopyright:

Available Formats

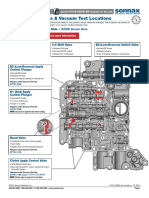

40−1

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

4003Q−01

OVERHAUL

1. REMOVE BREATHER PLUG HOSE

2. REMOVE TRANSAXLE CASE NO.1 PLUG

(a) Remove the transaxle case No. 1 plug and O−ring.

3. REMOVE NEUTRAL START SWITCH ASSY

(a) Remove the nut, washer and manual shift lever.

(b) Pry off the lock washer and remove the manual valve

shaft nut.

(c) Remove the 2 bolts and pull out the neutral start switch

assy.

D25354

4. REMOVE OIL COOLER TUBE UNION

(a) Using an open end wrench, remove the 2 oil cooler tube

unions.

(b) Remove the 2 O−rings from the oil cooler tube unions.

D08574

5. REMOVE AUTOMATIC TRANSAXLE OIL PAN

SUB−ASSY

(a) Remove the 18 bolts.

(b) Remove the automatic transaxle oil pan sub−assy by lift-

ing the transaxle case.

NOTICE:

Do not turn the transaxle over as it will contaminate the

Q02178 valve body with the foreign materials from the bottom of the

pan.

(c) Remove the gasket.

(d) Place the transaxle on wooden blocks to prevent damage

to the pipes.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−2

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

6. INSPECT AUTOMATIC TRANSAXLE OIL PAN

SUB−ASSY

(a) Remove the magnets and use them to collect any steel

chips. Carefully examine the chips and particles in the

pan and on the magnet to determine what type of wear

has occurred in the transaxle:

Steel (magnetic)..... bearing, gear and plate wear

AT0103 Brass (non−magnetic).....bushing wear

7. FIX AUTOMATIC TRANSAXLE ASSY

(a) Place automatic transaxle assy on wooden blocks.

8. REMOVE VALVE BODY OIL STRAINER ASSY

(a) Remove the 3 bolts and valve body oil strainer assy.

D25328

9. REMOVE MANUAL DETENT SPRING SUB−ASSY

D25333

10. REMOVE TRANSMISSION VALVE BODY ASSY

(a) Disconnect the solenoid connectors.

D25329

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−3

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(b) Remove the 17 bolts.

D25330

(c) While disconnecting the manual valve connecting rod

from the manual valve lever, remove the valve body.

(d) Remove the manual valve from the transmission valve

body assy.

D25334

11. REMOVE TRANSMISSION WIRE

(a) Remove the bolt.

D08575

(b) Remove the transmission wire.

Q02184

12. REMOVE CHECK BALL BODY

(a) Remove the check ball body and spring.

Q02240

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−4

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

13. REMOVE GOVERNOR APPLY GASKET NO.1

Q02187

14. REMOVE BRAKE DRUM GASKET

(a) Using needle−nose pliers, pull out the brake drum gasket.

Q02333

15. REMOVE B−2 ACCUMULATOR PISTON

(a) Using low−pressure compressed air (98 kPa, 1 kgf/cm2,

14 psi), pop out the B−2 accumulator piston into a rag and

remove the spring.

(b) Remove the 2 O−rings from the B−2 accumulator piston.

Q02241

16. REMOVE C−2 ACCUMULATOR PISTON

(a) Using low−pressure compressed air (98 kPa, 1 kgf/cm2,

14 psi), pop out the C−2 accumulator piston into a rag and

remove the spring.

(b) Remove the 2 O−rings from the C−2 accumulator piston.

Q02242

17. REMOVE C−1 ACCUMULATOR PISTON

(a) Using low−pressure compressed air (98 kPa, 1 kgf/cm2,

14 psi), pop out the C−1 accumulator piston into a rag and

remove the spring.

(b) Remove the 2 O−rings from the C−1 accumulator piston.

Q02243

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−5

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

18. REMOVE C−3 ACCUMULATOR PISTON

(a) Using low−pressure compressed air (98 kPa, 1 kgf/cm2,

14 psi), pop out the C−3 accumulator piston into a rag and

remove the spring.

(b) Remove the 2 O−rings from the C−3 accumulator piston.

Q03875

19. REMOVE MANUAL VALVE LEVER SHAFT

(a) Using a screwdriver and hammer, unstake the spacer and

remove it.

D25335

(b) Using a pin punch and hammer, drive out the pin.

HINT:

Drive out the spring pin slowly so that it will not fall into the trans-

axle case.

D25336

(c) Remove the spring retainer.

AT0547

(d) Slide out the manual valve lever shaft and remove the

manual valve lever and plate washer.

AT0548

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−6

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(e) Using a screwdriver, remove the manual lever shaft oil

seal.

Q02291

20. REMOVE TRANSAXLE HOUSING

(a) Remove the 17 bolts and transaxle housing.

Q02189

21. REMOVE FRONNT DIFFERENTIAL ASSY

AT0525

22. REMOVE FRONT DRIVE PINION FRONT TAPERED

SST

ROLLER BEARING

(a) Setting SST to the cut−out portion on the speedometer

drive gear, remove the bearing from the differential case.

SST 09950−40011, 09950−60010 (09951−00340)

(b) Remove the speedometer drive gear.

SST

D02361

SST 23. REMOVE FRONT DRIVE PINION REAR TAPERED

ROLLER BEARING

(a) Setting SST to the cut−out portion on the differential case,

remove the bearing.

SST 09950−40011, 09950−60010 (09951−00410)

SST

D02358

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−7

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

24. REMOVE TRANSMISSION CASE PLATE NO.1

(a) Remove the bolt and transmission case plate No. 1.

25. REMOVE GOVERNOR APPLY GASKET NO.2

Q02204

26. REMOVE OIL PUMP ASSEMBLY

(a) Remove the 6 bolts and holding the oil pump assembly to

the transaxle case.

D08612

(b) Pull out the oil pump assembly from the transaxle case.

D08613

(c) Remove the race from the oil pump assembly.

AT8648

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−8

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(d) Using a screwdriver, remove the O−ring from the oil pump

assembly.

AT3035

27. REMOVE TRANSAXLE APPLY TUBE CLAMP NO.3

(a) Remove the bolt and transaxle apply tube clamp No. 3.

Q02334

28. REMOVE GOVERNOR PRESSURE TUBE

(a) Using a screwdriver, remove the governor pressure tube.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Be careful not to bend or damage the tube.

Q02335

29. INSPECT PISTON STROKE OF 2ND COAST BRAKE

(a) Apply a small amount of paint to the piston rod at the point

where it meets the case.

Q02336

(b) Using SST, measure the piston stroke while applying and

SST releasing compressed air (392 − 785 kPa, 4 − 8 kgf/cm2,

57 − 114 psi).

SST 09240−00020

Piston stroke: 1.5 − 3.0 mm (0.059 − 0.118 in)

If the piston stroke exceeds the limit, inspect the brake band.

Q02337

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−9

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

30. REMOVE 2ND COAST BRAKE PISTON

SST

(a) Using SST, remove the snap ring.

SST 09350−32014 (09351−32050)

Q02295

(b) Using low−pressure compressed air (98 kPa, 1 kgf/cm2,

14 psi), pop out the cover into a rag.

Q03874

(c) Remove the cover, 2nd coast brake piston and spring.

(d) Remove the 2 O−rings from the cover.

(e) Remove the oil seal ring.

Q02244

31. REMOVE INPUT SHAFT ASSY

(a) Remove the direct clutch with the forward clutch from the

case.

Q02338

(b) Remove the direct clutch from the forward clutch.

AT8650

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−10

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Remove the thrust washer and 2 assembled bearings

and races from the forward clutch.

Q02245

32. REMOVE 2ND COAST BRAKE BAND ASSY

(a) Pull out the pin.

(b) Remove the 2nd coast brake band assy.

Q02192

33. INSPECT 2ND COAST BRAKE BAND ASSY

If the lining of the 2nd coast brake band assy is peeling off or

discolored, or even if a part of the printed numbers are defaced,

Printed

replace the 2nd coast brake band assy.

Number

AT5205

34. REMOVE FRONT PLANETARY RING GEAR

(a) Remove the front planetary ring gear.

Q02246

(b) Remove the assembled bearing and race and race from

the front planetary ring gear.

Q02193

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−11

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

35. REMOVE FRONT PLANETARY GEAR ASSY

(a) Remove the front planetary gear assy with the bearing

and race.

D25337

(b) Remove the assembled bearing and race and race from

the front planetary gear assy.

D25338

36. INSPECT FRONT PLANETARY GEAR ASSY

(a) Using a feeler gauge, measure the planetary pinion gear

thrust clearance.

Standard clearance:

0.2 − 0.5 mm (0.008 − 0.020 in.)

Maximum clearance: 0.5 mm (0.020 in.)

If the clearance is greater than the maximum, replace the front

D25339 planetary gear assembly.

37. REMOVE PLANETARY SUN GEAR SUB−ASSY

(a) Remove the planetary sun gear sub−assy with the sun

gear input drum and thrust washer.

Q02248

38. REMOVE 1 WAY CLUTCH ASSY

Q02249

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−12

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

Lock 39. INSPECT 1 WAY CLUTCH ASSY

Free

Hold

(a) Hold the sun gear and turn the hub. The hub should turn

Turn freely clockwise and should lock if turned counterclock-

wise.

AT0185

40. INSPECT 2ND BRAKE PISTON

(a) Using compressed air, check that the 2nd brake piston

moves smoothly.

AT8652

41. REMOVE 2ND BRAKE PISTON RETURN SPRING

SUB−ASSY

(a) Remove the bolt and 2nd coast brake band guide.

Q02688

(b) Using a screwdriver, remove the snap ring.

HINT:

Tape the screwdriver tip before use.

Q02250

(c) Remove the 2nd brake drum.

HINT:

If the brake drum is difficult to remove, lightly tap it with a wood-

en block.

Q02251

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−13

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(d) Remove the 2nd brake piston return spring sub−assy.

Q02339

(e) Remove the plates, discs and flange.

Q02252

42. INSPECT 2ND BRAKE CLUTCH DISC

(a) Check if the sliding surfaces of the discs, plates and

flanges are worn or burnt. If necessary, replace them.

Printed HINT:

Number S If the lining of the disc is peeling off or discolored, even if

a part of the printed numbers are defaced, replace all

discs.

Q02607 S Before assembling new discs, soak them in ATF for at

least 15 minutes.

43. REMOVE REAR PLANETARY GEAR ASSY

(a) Using 2 screwdrivers, remove the snap ring.

HINT:

Tape the screwdriver tip before use.

Q02296

(b) Remove the No. 2 1 way clutch and rear planetary gear

assy with the 2 thrust washers.

Q02253

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−14

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Remove the 2 thrust washers from the rear planetary gear

assy.

(d) Remove the No. 2 1 way clutch from the rear planetary

gear assy.

D25342

(e) Remove the assembled bearing and race and race from

the planetary ring gear.

Q02254

44. INSPECT REAR PLANETARY GEAR ASSY

(a) Using a feeler gauge, measure the planetary pinion gear

thrust clearance.

Standard clearance: 0.2 − 0.5 mm (0.008 − 0.020 in.)

Maximum clearance: 0.5 mm (0.020 in.)

If the clearance is greater than maximum, replace the rear plan-

etary gear assembly.

D25343

45. INSPECT PACK CLEARANCE OF FIRST & REVERSE

BRAKE

(a) Using a feeler gauge, measure the first and reverse brake

pack clearance.

Pack clearance:

A245E: 1.00 − 2.00 mm (0.0393 − 0.0787 in.)

A246E: 1.19 − 2.25 mm (0.0469 − 0.0886 in.)

If the pack clearance is non−standard, check the disc.

Q02390

46. REMOVE 1ST & REVERSE BRAKE CLUTCH DISC

(a) Using a screwdriver, remove the snap ring.

HINT:

Tape the screwdriver tip before use.

Q02297

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−15

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(b) Remove the flange, plates and discs.

D08580

47. INSPECT 1ST & REVERSE BRAKE CLUTCH DISC

(a) Check if the sliding surfaces of the discs, plates and

flanges are worn or burnt. If necessary, replace them.

Printed HINT:

Number S If the lining of the disc is peeling off or discolored, even if

a part of the printed numbers are defaced, replace all

discs.

Q02610 S Before assembling new discs, soak them in ATF for at

least 15 minutes.

48. REMOVE 1ST & REVERSE BRAKE RETURN SPRING

SUB−ASSY

SST

(a) Using SST and a press, in the return spring until the snap

ring is free from the return spring.

SST 09350−32014 (09351−32040)

(b) Using snap ring pliers, remove the snap ring.

Q02990

(c) Remove the 1st and reverse brake return spring sub−

assy.

AT2889

49. REMOVE 1ST & REVERSE BRAKE PISTON

(a) Apply compressed air into the oil passage of the case to

remove the 1st and reverse piston.

HINT:

Hold the 1st and reverse piston so it is not slant and blow with

the gun slightly away from the oil hole.

(b) If the 1st and reverse piston does not pop out with com-

AT8662 pressed air, use needle−nose pliers to remove it.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−16

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Using a screwdriver, remove the 2 O−rings from the 1st

and reverse piston.

AT2891

50. REMOVE TRANSMISSION CASE COVER REAR

(a) Remove the 13 bolts.

Q02195

(b) Tap off the circumference of the transmission case cover

rear with a plastic hammer to remove the rear case from

the transaxle case, and remove the transmission case

cover rear.

Q02196

51. REMOVE INTERMEDIATE SHAFT SUB−ASSY

(a) Using a chisel and hammer, unstake the counter driven

gear nut.

Q02340

(b) Using SST, remove the counter driven gear nut.

SST SST 09330−00021, 09350−32014 (09351−32032)

Q02197

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−17

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Remove the intermediate shaft sub−assy.

Q02255

52. REMOVE COUNTER DRIVE GEAR

SST

(a) Using SST and a press, remove the counter drive gear.

SST 09950−60010 (09951−00380), 09950−70010

(09951−07100)

(b) Remove the spacer from the counter drive gear assem-

bly.

Q02341

53. REMOVE COUNTER DRIVEN GEAR

(a) Using a chisel and hammer, unstake the counter driven

gear nut on both sides.

AT2894 AT2895 D02423

(b) Using SST to hold the counter shaft assy, remove the lock

SST nut on the counter driven gear side.

SST 09350−32014 (09351−32170), 09330−00021

(09351−32032, 09351−32061)

Q02198

SST (c) Using SST to hold the counter driven gear, remove the

counter driven gear nut of the other side.

SST 09350−32014 (09351−32170), 09330−00021

(09351−32032, 09351−32061)

SST Q02343

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−18

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(d) Using SST, remove the counter driven gear.

SST SST 09350−32014 (09351−32170), 09330−00021

(09351−32032, 09351−32061)

Q02199

(e) Remove the thrust needle bearing.

D08614

54. REMOVE COUNTER SHAFT ASSY

(a) Pull out the counter shaft assembly.

AT2896

(b) Remove the thrust bearing with race from the counter

shaft assembly.

C81859

55. INSPECT PISTON STROKE OF UNDERDRIVE

SST

CLUTCH

(a) Set a dial indicator (long type pick or SST)

SST 09350−32014 (09351−32190)

AT8072

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−19

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(b) While applying and releasing compressed air (392 − 785

kPa, 4 − 8 kgf/cm2, 57 − 114 psi), measure the underdrive

clutch piston stroke.

Piston stroke: 1.5 − 1.9 mm (0.059 − 0.075 in.)

If the piston stroke is non−standard, select another flange.

HINT:

There are 4 different flange thickness.

Flange thickness: mm (in.)

AT7999 Thickness Thickness

2.04 (0.0803) 2.40 (0.0945)

2.20 (0.0866) 2.50 (0.0984)

56. REMOVE UNDERDRIVE CLUTCH DRUM SUB−ASSY

(a) Remove the underdrive clutch drum sub−assy.

57. REMOVE UNDERDRIVE 1 WAY CLUTCH RETAINER

Q04379

58. INSPECT UNDERDRIVE 1 WAY CLUTCH ASSY

Free

Lock

(a) Hold the 1 way clutch drum and turn the 1 way clutch.

Hold Turn Check that the 1 way clutch must be able to turn free

counterclockwise and will lock if turned clockwise.

AT8001

59. REMOVE UNDERDRIVE 1 WAY CLUTCH ASSY

Thrust Washer

(a) Remove the 1 way clutch and thrust washer from the un-

derdrive clutch drum.

AT2942

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−20

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

60. INSPECT PACK CLEARANCE OF UNDERDRIVE

BRAKE

(a) Using a dial indicator, measure the underdrive brake pack

clearance.

Pack clearance:

1.15 − 1.97 mm (0.0453 − 0.0786 in.)

If clearance is non−standard, check the disc.

Q02392

61. REMOVE OVERDRIVE CLUTCH DRUM OIL SEAL

RING

(a) Remove the 2 overdrive clutch drum oil seal rings.

AT2898

62. REMOVE UNDERDRIVE CLUTCH FLANGE NO.2

HOLE SNAP RING

(a) Using SST and a press, press in the flange until the snap

ring is free from the flange.

SST 09350−32014 (09351−32070)

(b) Using a screwdriver, remove the underdrive clutch flange

No. 2 hole snap ring.

C81860

63. REMOVE UNDERDRIVE CLUTCH DISC NO.2

(a) Remove the flange, plates and discs.

Q02588

64. INSPECT UNDERDRIVE CLUTCH DISC NO.2

(a) Check if the sliding surfaces of the discs, plates and

flanges are worn or burnt. If necessary, replace them.

HINT:

S If the lining of the disc is peeling off or discolored, even if

Printed a part of the printed numbers are defaced, replace all

Numbers

discs.

AT5823 S Before assembling new discs, soak them in ATF for at

least 15 minutes.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−21

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

65. REMOVE UNDERDRIVE BRAKE RETURN SPRING

SUB−ASSY

Q02593

66. REMOVE UNDERDRIVE BRAKE PISTON

(a) Using low−pressure compressed air (98 kPa, 1 kgf/cm2,

14 psi), pop out the underdrive brake piston into a rag.

AT8661

(b) Using a screwdriver, remove the 2 O−rings from the un-

derdrive blake piston.

O−ring

AT2903

67. REMOVE PARKING LOCK PAWL

(a) Remove the 2 bolts, parking lock pawl stopper plate, tor-

sion spring and spring guide.

AT0541

(b) Remove the bolt and pawl shaft clamp.

AT8663

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−22

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Remove the parking lock pawl shaft and lock pawl.

AT8664

68. REMOVE PARKING LOCK SLEEVE

AT8665

69. REMOVE CAM GUIDE SLEEVE

(a) Remove the cam guide sleeve.

AT8666

70. REMOVE B−4 ACCUMULATOR PISTON

(a) Remove the 2 bolts.

(b) Using a torx wrench, remove the 7 screws.

Remove the oil gallery cover and gasket.

D25349

(c) Remove the B−4 accumulator piston and spring.

AT2910

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−23

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

71. REMOVE TRANSMISSION CASE PLATE NO.3

(a) Remove the bolt and transmission case plate No. 3.

72. REMOVE COUNTER DRIVEN GEAR CYLINDRICAL

ROLLER BEARING

SST (a) Using SST, remove the counter driven gear cylindrical

roller bearing.

SST 09308−00010

AT0555

73. REMOVE TRANSAXLE APPLY TUBE CLAMP NO.1

(a) Remove the 2 bolts and transaxle apply tube clamps

No. 1.

74. REMOVE TRANSAXLE APPLY TUBE CLAMP NO.2

(a) Remove the bolt and transaxle apply tube clamp No. 2.

Q02202

75. REMOVE TRANSMISSION LUBE APPLY TUBE

(a) Using a screwdriver, remove the transmission lube apply

tube.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Be careful not to bend or damage the tube.

Q02203 76. REMOVE DIFFERENTIAL GEAR LUBE APPLY TUBE

(a) Using a screwdriver, remove the differential gear lube ap-

ply tube.

HINT:

Tape the screwdriver tip before use.

NOTICE:

Be careful not to bend or damage the tube.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−24

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

77. REMOVE UNDERDRIVE CYLINDRICAL ROLLER

BEARING

(a) Remove the bolt and retainer.

Q04381

(b) Using SST, remove the underdrive cylindrical roller bear-

ing.

SST 09308−00010

Q05196

78. REMOVE TRANSAXLE HOUSING OIL SEAL

(a) Using a screwdriver, remove the transaxle housing oil

seal.

Q02358

79. REMOVE TRANSAXLE CASE OIL SEAL

(a) Using a screwdriver, remove the transaxle case oil seal.

Q02359

80. REMOVE SIDE BEARING OUTER RACE

(a) TRANSAXKLE CASE:

Using SST and a hammer, drive out the side bearing outer

race and adjusting shim.

SST 09350−32014 (09351−32090, 09351−32130,

09351−32150)

SST

AT8479

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−25

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

NOTICE:

S The automatic transaxle is composed of highly precision−finished parts, necessitating careful

inspection before reassembly because even a small nick could cause fluid leakage or affect

performance. The instructions here are organized so that you work on only one component

group at a time. This will help avoid confusion from similar−looking parts of different sub−as-

semblies being on your workbench at the same time. The component groups are inspected and

repaired from the converter housing side. As much as possible, complete the inspection, repair

and reassembly before proceeding to the next component group. If a defect is found in a certain

component group during reassembly, inspect and repair this group immediately. If a compo-

nent group cannot be assembled because parts are being ordered, be sure to keep all parts of

that group in a separate container while proceeding with disassembly, inspection, repair and

reassembly of other component groups.

Recommended ATF: T−IV

S All disassembled parts should be washed clean and any fluid passages and holes should be

blown through with compressed air.

S Dry all parts with compressed air−never use shop rags.

S When using compressed air, always aim away from yourself to prevent accidentally spraying

ATF or kerosene on your face.

S The recommended automatic transaxle fluid or kerosene should be used for cleaning.

S After cleaning, the parts should be arranged in the correct order to allow efficient inspection,

repairs, and reassembly.

S When disassembling a valve body, be sure to keep each valve together with the corresponding

spring.

S New discs for the brakes and clutches that are to be used for replacement must be soaked in

ATF for at least 15 minutes before reassembly.

S All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be

coated with ATF prior to reassembly.

S All gaskets and rubber O−rings should be replaced.

S Do not use adhesive cements on gaskets and similar parts.

S Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed

in the groove correctly.

S If a worn bushing is to be replaced, the sub−assembly containing that bushing must also be

replaced.

S Check thrust bearings and races for wear or damage. Replace if necessary.

S Use petroleum jelly to keep parts in place.

S When working with FIPG material, you must observe the following.

Using a razor blade and gasket scraper, remove all the old packing (FIPG) material from the gas-

ket surface.

Thoroughly clean all components to remove all the loose material.

Clean both sealing surfaces with a non−residue solvent.

Parts must be reassembled within 10 minutes often application. Otherwise, the packing (FIPG)

material must be removed and reapplied.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−26

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

81. BEARING POSITION

H

G

D

Q02419

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−27

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

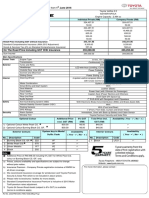

Front Race Diameter Thrust Bearing Diameter Rear Race Diameter

Mark

Inside / Outside mm (in.) Inside / Outside mm (in.) Inside / Outside mm (in.)

A 30.0 (1.181) / 41.8 (1.646) 31.0 (1.220) / 43.9 (1.728) −

B − 31.0 (1.220) / 43.9 (1.728) −

C − 41.0 (1.614) / 58.0 (2.283) −

D − 30.7 (1.209) / 46.0 (1.811) −

E − 25.8 (1.016) / 42.0 (1.654) 26.0 (1.024) / 39.5 (1.555)

F − 22.0 (0.866) / 38.0 (1.496) 19.0 (0.748) / 35.0 (1.378)

G − 28.1 (1.106) / 45.0 (1.772) −

H 24.1 (0.949) / 37.6 (1.480) 22.1 (0.870) / 37.6 (1.480) −

82. INSTALL SIDE BEARING OUTER RACE

SST (a) Using SST and a press, press a new side bearing outer

race into the transaxle housing.

SST 09350−32014 (09351−32111, 09351−32130)

D25347

(b) Place the adjusting shim onto the transaxle case.

SST

(c) Using SST and a press, press a new side bearing outer

race into the transaxle case.

SST 09350−32014 (09351−32111, 09351−32130)

AT8003

83. INSTALL TRANSAXLE CASE OIL SEAL

(a) Using SST and a hummer, drive in a new transaxle case

SST

oil seal.

SST 09350−32014 (09351−32111, 09351−32130)

(b) Coat the lip of oil seal with MP grease.

AT8005

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−28

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

84. INSTALL TRANSAXLE HOUSING OIL SEAL

SST

(a) Using SST and a hummer, drive in a new transaxle hous-

ing oil seal.

SST 09350−32014 (09351−32130, 09351−32150)

(b) Coat the lip of oil seal with MP grease.

D25346

85. INSTALL UNDERDRIVE CYLINDRICAL ROLLER

SST BEARING

(a) Using SST and a press, install the underdrive cylindrical

roller bearing into the transaxle housing.

SST 09350−32014 (09351−32140)

Q02361

(b) Install the bearing stopper with the bolt.

Torque: 17 N×m (173 kgf×cm, 13 ft×lbf)

Q02589

86. INSTALL DIFFERENTIAL GEAR LUBE APPLY TUBE

(a) Using a plastic hammer, install the differential gear lube

apply tube.

NOTICE:

Be careful not to bend or damage the tube.

87. INSTALL TRANSMISSION LUBE APPLY TUBE

Q02362 (a) Using a plastic hammer, install the transmission lube ap-

ply tube.

NOTICE:

Be careful not to bend or damage the tube.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−29

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

88. INSTALL TRANSAXLE APPLY TUBE CLAMP NO.2

(a) Install the transaxle apply tube clamps No.2 with the bolt.

Torque: 5.4 N×m (55 kgf×cm, 48 in.×lbf)

89. INSTALL TRANSAXLE APPLY TUBE CLAMP NO.1

(a) Install the transaxle apply tube clamps No. 1 with the 2

bolts.

Q02202 Torque: 5.4 N×m (55 kgf×cm, 48 in.×lbf)

90. INSTALL COUNTER DRIVEN GEAR CYLINDRICAL

SST ROLLER BEARING

(a) Using SST and a press, install the counter driven gear cy-

lindrical roller bearing into the transaxle case.

SST 09350−32014 (09351−32090)

AT0593

91. INSTALL TRANSMISSION CASE PLATE NO.3

(a) Install the transmission case plate No. 3 with the bolt.

Torque: 10 N×m (102 kgf×cm, 7 ft×lbf)

92. INSTALL B−4 ACCUMULATOR PISTON

(a) Coat new O−ring with ATF, and install them to the B−4 ac-

cumulator piston.

(b) Install the B−4 accumulator piston and spring to the case.

AT2910

(c) Clean the threads of the screws and case with white gaso-

line.

(d) Install a new gasket and oil gallery cover in place.

(e) Install and tighten the 2 bolts.

Torque: 10 N×m (102 kgf×cm, 7 ft×lbf)

D25348

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−30

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(f) Apply seal packing or equivalent to the 7 screws.

Seal packing:

Part No. 08833 − 00070, THREE BOND 1324 or equiva-

lent

(g) Using a torx wrench, install the 7 screws.

Torque: 7.0 N·m (71 kgf·cm, 62 in.·lbf)

D25349

93. INSTALL MANUAL VALVE LEVER SHAFT

(a) Using a 14 mm socket wrench and hammer, drive in a new

manual valve lever shaft oil seal.

(b) Apply MP grease to the seal lip.

Q02292

(c) Install the parking lock rod to the manual valve lever.

(d) Slide in the manual valve lever shaft and install the plate

washer, a new spacer and manual lever.

AT0548

(e) Install the retaining spring retainer.

HINT:

Make sure there is a washer between the retaining spring and

case.

AT0547

(f) Using a pin punch and hammer, drive in the pin.

(g) Position the spacer and stake it.

D25336

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−31

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

94. INSTALL PARKING LOCK PAWL

(a) Install the cam guide bracket and then insert the parking

lock rod into the guide bracket.

AT8666

(b) Install the parking lock sleeve with the protruding portion

facing up.

AT8665

(c) Place the stopper plate on the protruding portion of the

lock sleeve.

AT0700

(d) Install the guide sleeve and spring with the 2 bolts.

Torque: 13 N·m (130 kgf·cm, 9 ft·lbf)

AT0701

(e) Install the parking lock pawl.

AT7931

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−32

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(f) Install the parking lock pawl shaft and install the shaft

Clamp Groove clamp with the 2 bolts.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

AT7890

95. INSTALL COUNTER DRIVE GEAR

(a) Using SST and a press, install the counter drive gear,

front bearing, and a new spacer.

SST 09350−32014 (09351−32150, 09351−32130)

SST

Q02401

96. INSTALL INTERMEDIATE SHAFT SUB−ASSY

(a) Install the intermediate shaft sub−assy.

Q02255

(b) Using SST, install the counter driven gear nut.

SST 09960−10010 (09962−01000, 09963−01000)

SST

Q02725

97. INSPECT DRIVE GEAR PRELOAD

(a) Using a torque wrench, measure the starting torque of the

counter drive gear.

Starting torque:

New bearing:

0.3 − 0.7 N·m (3.1 − 7.1 kgf·cm, 2.6 − 6.1 in.·lbf)

Reused bearing:

0.2 − 0.4 N·m (2.0 − 4.1 kgf·cm, 1.7 − 3.5 in.·lbf)

Q02556 If the torque exceeds the limit, replace the spacer.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−33

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

98. TIGHTEN COUNTER DRIVEN GEAR NUT

(a) Using a pin punch and hammer, stake the counter driven

gear nut.

Q04377

99. INSTALL UNDERDRIVE BRAKE PISTON

(a) Coast 2 new rings with ATF.

(b) Install the 2 O−rings to the underdrive brake piston.

AT2960

(c) Place the piston into the case with the cup side up, being

careful not to damage the O−rings.

Q02592

100. INSTALL UNDERDRIVE BRAKE RETURN SPRING

SUB−ASSY

Q02593

101. INSTALL UNDERDRIVE CLUTCH DISC NO.2

(a) Install the plates, discs and flange in order.

Install in order: D = Disc P = Plate F = Flange

P−D−P−D−P−D−F

HINT:

Install the flange with the flat side facing downward.

Q02588

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−34

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

102. INSTALL UNDERDRIVE CLUTCH FLANGE NO.2

HOLE SNAP RING

SST

(a) Place SST on the flange, and compress the flange with

a press.

SST 09350−32014 (09351−32070)

(b) Using a screwdriver, install the underdrive clutch flange

No. 2 hole snap ring.

Q02594 HINT:

Be sure the end gap of the snap ring is not aligned with one of

the cutouts.

103. INSPECT PACK CLEARANCE OF UNDERDRIVE

BRAKE

(a) Using a dial indicator, measure the underdrive brake pack

clearance.

Pack clearance:

1.15 − 1.97 mm (0.0453 − 0.0776 in.)

If the pack clearance in non−standard, parts have been misas-

sembled. Check them.

Q02392

104. INSTALL OVERDRIVE CLUTCH DRUM OIL SEAL

RING

(a) Install the 2 overdrive clutch drum oil seal rings to the

transaxle case.

AT2898

105. INSTALL UNDERDRIVE 1 WAY CLUTCH ASSY

Thrust Washer

(a) Remove the underdrive 1 way clutch assy and thrust

washer from the underdrive clutch drum.

AT2942

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−35

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(b) Install the underdrive 1 way clutch assy.

Q02595

106. INSTALL UNDERDRIVE 1 WAY CLUTCH RETAINER

(a) In the place shown in the illustration (the space between

the 1 way clutch outer race and case), push the under-

drive 1 way clutch retainer in until you hear a ”click”.

107. INSTALL UNDERDRIVE CLUTCH DRUM SUB−ASSY

(a) Coat the thrust washer with petroleum jelly and install it

AT1289 onto the No. 3 1 way clutch.

(b) Align the flukes of discs in the underdrive brake.

(c) Install the underdrive clutch assy.

(d) Turn the underdrive clutch assy. The clutch assembly

Lock should turn freely counterclockwise and should lock

Free clockwise.

Q02596

(e) Install the assembled bearing and race, with the bearing

facing upward.

Assembled bearing and race:

Outer diameter Inner diameter

Assembled bearing

43.9 mm (1.728 in.) 31.0 mm (1.220 in.)

and race

Q02599

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−36

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

108. INSPECT HEIGHT OF CLUTCH ASSY

(a) Using vernier calipers, check the height from the sleeve

to the inner race.

Height: 17.3 − 18.2 mm (0.681 − 0.717 in.)

Q02597

109. INSPECT PISTON STROKE OF UNDERDRIVE

SST CLUTCH

(a) Set a dial indicator and measuring terminal (SST) togeth-

er.

SST 09350−32014 (09351−32190)

Q02598

(b) While applying and releasing compressed air (392 − 785

Cps, 4 − 8 kgf/cm2, 57 − 114 psi), measure the underdrive

clutch piston stroke.

Piston stroke:

1.5 − 1.9 mm (0.059 − 0.075 in.)

If the piston stroke is less than the limit, parts may have been

misassembled. Check them.

If the piston stroke is non−standard, select another flange.

AT7999 HINT:

There are 4 different thickness for the flange.

Flange thickness:

Thickness Thickness

2.04 (0.0803) 2.40 (0.0945)

2.20 (0.0866) 2.50 (0.0984)

110. INSTALL UNDERDRIVE PLANETARY SUN GEAR

SUB−ASSY

(a) Remove the underdrive planetary sun gear from the

counter shaft.

(b) Remove the thrust bearing and race.

Q04376

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−37

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Install the underdrive planetary sun gear sub−assy of the

counter shaft to the case.

111. INSTALL COUNTER SHAFT ASSY

(a) Align the flukes of the discs in the underdrive clutch.

(b) Install the thrust bearing with the race, with the bearing

facing upward.

Bearing and race:

Outer diameter Inner diameter

Q02600

Bearing 43.9 mm (1.728 in.) 31.0 mm (1.220 in.)

Race 41.8 mm (1.646 in.) 30.0 mm (1.181 in.)

(c) Install the counter shaft assy.

Q02601

112. INSPECT HEIGHT OF COUNTER SHAFT

(a) Using vernier calipers, measure the distance between the

tip of the counter shaft and bolt seat of the clutch support.

Height: 33.3 − 35.5 mm (1.311 − 1.398 in.)

Q02402

113. INSTALL COUNTER DRIVEN GEAR THRUST NEEDLE

ROLLER BEARING

Bearing:

Outer diameter Inner diameter

Bearing 58.0 mm (2.283 in.) 41.0 mm (1.614 in.)

Q02200

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−38

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

114. INSTALL COUNTER DRIVEN GEAR

Using SST and a press, press in the counter driven gear.

SST

SST 09350−32014 (09351−32100, 09351−32140)

Q02552

115. INSTALL COUNTER DRIVEN GEAR NUT

(a) Using SST to hold the driven gear, tighten a new counter

driven gear nut.

SST 09350−32014 (09351−32032)

Torque: 180 N·m (1,835 kgf·cm, 133 ft·lbf)

(b) Remove the SST.

SST

Q02369

116. INSPECT END PLAY OF COUNTER SHAFT

(a) Using a dial indicator, measure the end play of the counter

shaft.

End play: 0.2 − 0.9 mm (0.008 − 0.035 in.)

AT0076

117. TIGHTEN COUNTER DRIVEN GEAR NUT

(a) Using a pin punch and hammer, stake the counter driven

gear nut.

Q02403

118. INSTALL TRANSMISSION CASE COVER REAR

FIPG

(a) Remove any packing material and be careful not to get oil

on the contacting surfaces of the transmission case cover

rear or transaxle case.

(b) Apply FIPG sealant to the transmission case cover rear.

FIPG:

Part No. 08826 − 00090, THREE BOND 1281 or equiva-

Q02365 lent

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−39

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Install and tighten the 13 bolts.

A

Torque: 10 N·m (102 kgf·cm, 7 ft·lbf)

A

HINT:

Each bolt length is indicated in the illustration.

A

Bolt length:

B Bolt A: 25 mm (0.98 in.)

Bolt B: 32 mm (1.26 in.)

AT8039

119. INSPECT INTERMEDIATE SHAFT SUB−ASSY

(a) Make sure that the intermediate shaft sub−assy turns

smoothly.

Q02405

120. INSTALL 1ST & REVERSE BRAKE PISTON

(a) Install 2 new O−rings to the 1st and reverse brake piston.

(b) Coat the O−rings with ATF.

AT2962

(c) Place the piston into the bore of the case, facing the

spring seats upward.

NOTICE:

Be careful not to damage the O−rings.

Q02999

121. INSTALL 1ST & REVERSE BRAKE RETURN SPRING

SUB−ASSY

SST

(a) Install the 1st and reverse brake return spring sub−assy

and snap ring in place.

(b) Place SST on the 1st and reverse brake return spring

sub−assy, and compress the 1st and reverse brake return

spring sub−assy with a press.

Q02990 SST 09350−32014 (09351−32040)

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−40

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(c) Using snap ring pliers, install the snap ring.

HINT:

Visually check to make sure it is fully seated and centered by

the 3 lugs on the spring retainer. Be sure the end gap of snap

ring is aligned with the spring retainer claw.

122. INSTALL 1ST & REVERSE BRAKE CLUTCH DISC

(a) Install the discs and plates in order.

HINT:

245E: 5 plates and 5 discs

246E: 6 plates and 6 discs

Install in order: D = Disc P = Plate

245E: P − D − P − D − P − D − P − D − P − D

D08580 246E: P − D − P − D − P − D − P − D − P − D − P − D

(b) Install the outer flange with the flat side facing downward.

D08608

(c) Using a screwdriver, install the snap ring.

HINT:

Be sure the snap ring end gap is not aligned with one of the cut-

outs.

Q02408

(d) Coat the races and bearing with petroleum jelly, and

install them onto the ring gear.

Bearing and race:

Outer diameter Inner diameter

Race 37.6 mm (1.480 in.) 24.1 mm (0.949 in.)

Bearing 37.6 mm (1.480 in.) 22.1 mm (0.870 in.)

Q02254

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−41

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

123. INSPECT PACK CLEARANCE OF FIRST & REVERSE

BRAKE

(a) Using a feeler gauge, measure the first and reverse brake

pack clearance.

Pack clearance:

A245E: 1.00 − 2.00 mm (0.0393 − 0.0787 in.)

A246E: 1.19 − 2.25 mm (0.0469 − 0.0886 in.)

If the pack clearance is non−standard, parts have been misas-

Q02390 sembled. Check them.

Thrust Washer 124. INSTALL REAR PLANETARY GEAR ASSY

(a) Coat the thrust washer with petroleum jelly and install it

onto the rear planetary gear assy.

HINT:

Make sure that the different lug shapes match the correspond-

ing openings on the gear.

D25345

(b) Align the spline of the planetary gear with the flukes of the

discs and install the planetary gear into the first and re-

verse brake discs.

AT0614

(c) Check the part ”A” of the rear planetary gear is below the

A upper surface of the flange.

Rear

Planetary

Flange Gear

C81862

125. INSTALL 1 WAY CLUTCH NO.2

Lock

Free (a) Place the 1 way clutch No. 2 into the case, with the shiny

side facing upward.

(b) Install the 1 way clutch onto the inner race while turning

the planetary gear clockwise with SST.

SST 09350−32014 (09351−32050)

(c) Check that the planetary gear turns freely clockwise and

SST

AT2965 locks if turned counterclockwise.

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−42

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(d) Coat the thrust washer with petroleum jelly and install it

Thrust Washer

onto the planetary gear.

AT2966

(e) Be sure the end gap of the snap ring is not aligned with

one of the cutouts.

AT7989

126. INSTALL 2ND BRAKE CLUTCH DISC

(a) Install the flange with the flat side facing upward.

Q02602

(b) Install the discs and plates in order.

Install in order: D = Disc P = Plate

D−P−D−P−D−P

Q02603

(c) Install each of the springs over the protrusions in the

case.

AT0620

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−43

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(d) Install the 2nd coast brake band guide so that its tip

touches the case.

(e) Install the bolt.

Torque: 5.4 N·m (55 kgf·cm, 48 in.·lbf)

Q02689

(f) Align the groove of the drum with the bolt and place the

drum into the case.

AT0621

(g) Place both ends of the snap ring in the groove, and then

set the snap ring into the case.

(h) While compressing the piston return springs over the

drum with hammer handles, install the snap ring.

HINT:

Be sure the end gap of the snap ring is not aligned with one of

the cutouts.

AT0622

127. INSTALL BRAKE DRUM GASKET

(a) Install a new brake drum gasket until it makes contact with

the 2nd brake drum.

AT8696

128. INSPECT 2ND BRAKE PISTON

(a) Using compressed air, check that the 2nd brake piston

moves smoothly.

AT7891

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−44

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

129. INSTALL 1 WAY CLUTCH ASSY

(a) Using a screwdriver, align the flukes of the discs in the 2nd

brake.

AT0626

(b) Align the spline of the 1 way clutch with the flukes of the

discs and install the 1 way clutch to the 2nd brake discs.

AT8697

130. INSPECT 2ND BRAKE HUB INSTALLATION

DISTANCE

(a) Check the distance between the surface of the 2nd brake

hub and rear planetary gear.

Distance: Approx. 5 mm (0.20 in.)

AT8088

131. INSTALL PLANETARY SUN GEAR SUB−ASSY

(a) Coat the thrust washer with petroleum jelly and install it

on the sun gear input drum.

AT8056

(b) By turning the planetary sun gear sub− assy clockwise,

install it into the No. 1 one−way clutch.

AT0628

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−45

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

132. INSTALL FRONT PLANETARY GEAR ASSY

(a) Coat the race and bearing with petroleum jelly and install

them onto the front planetary gear assy.

Bearing:

Outer diameter Inner diameter

Bearing 45.0 mm (1.772 in.) 28.1 mm (1.106 in.)

D25340

(b) Install the front planetary gear assy.

133. INSTALL FRONT PLANETARY RING GEAR

(a) Coat the races and bearing with petroleum jelly and install

them onto the front planetary ring gear.

Bearing and races:

Outer diameter Inner diameter

Race 35.0 mm (1.378 in.) 19.0 mm (0.748 in.)

D25341

Bearing 38.0 mm (1.496 in.) 22.0 mm (0.866 in.)

(b) Install the front planetary ring gear.

AT2968

HINT:

If the front planetary ring gear and the other parts are installed

correctly into the case, the end of the bushing with the ring gear

flange will be flush with or under the shoulder of the intermedi-

ate shaft.

C81863

(c) Coat the races and bearing with petroleum jelly and install

them onto the tip of ring gear flange.

Bearing and races:

Outer diameter Inner diameter

Race 39.5 mm (1.555 in.) 26.0 mm (1.024 in.)

Bearing 42.0 mm (1.654 in.) 25.8 mm (1.016 in.)

Q02410

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−46

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

134. INSTALL 2ND COAST BRAKE BAND ASSY

(a) Place the 2nd coast brake band assy into the case.

(b) Install the pin.

Q02192

135. INSTALL INPUT SHAFT SUB−ASSY

(a) Coat the assembled bearing and race with petroleum jel-

ly, and install it onto the forward clutch drum.

Assembled bearing and race:

Outer diameter Inner diameter

Assembled bearing

46.0 mm (1.811 in.) 30.7 mm (1.209 in.)

and race

Q02411

(b) Coat the clutch drum thrust washer with petroleum jelly,

and install it onto the direct clutch drum with the oil groove

facing upward.

AT0349

(c) Using a screwdriver, align the flukes of the discs in the di-

rect clutch.

AT0350

(d) Mesh the hub with the flukes of the direct clutch while turn-

ing the clutch drum or forward clutch.

HINT:

If the flukes of the discs are meshed correctly, the end of the

bushing with the direct clutch will be flush with the surfaces of

the forward clutch.

Q04382

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−47

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(e) Place the direct clutch and forward clutch into the case.

(f) While rotating the forward clutch to mesh the front plane-

tary ring gear and discs, install them.

AT2971

(g) Check the distance between A and B.

Distance: Approx. 3 mm (0.118 in.)

Q02693

O−ring 136. INSTALL 2ND COAST BRAKE PISTON

(a) Install 2 new O−rings to the cover.

HINT:

Coat the O−rings with ATF before the installation.

AT2870

(b) Install the spring, 2nd coast brake piston and cover into

the bore.

Q02244

(c) Using SST, install the snap ring.

SST

SST 09350−32014 (09351−32050)

Q02295

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−48

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

137. INSPECT PISTON STROKE OF 2ND COAST BRAKE

(a) Apply a small amount of paint to the piston rod at the point

where it meets the case.

Q02336

(b) Using SST, measure the piston stroke while applying and

SST releasing compressed air (392 − 785 kPa, 4 − 8 kgf/cm2,

57 − 114 psi).

SST 09240−00020

Piston stroke: 1.5 − 3.0 mm (0.059 − 0.138 in.)

If the piston stroke exceeds the limit, select a new piston rod.

Q02337

138. INSTALL GOVERNOR APPLY GASKET NO.2

Q02204

139. INSTALL TRANSMISSION CASE PLATE NO.1

(a) Install the transmission case plate No. 1 with the bolt.

10 N·m (102 kgf·cm, 7 ft·lbf)

140. INSTALL GOVERNOR PRESSURE TUBE

(a) Using a plastic hammer, install the governor pressure

tube.

NOTICE:

Be careful not to bend or damage the tube.

Q02413

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−49

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

141. INSTALL TRANSAXLE APPLY TUBE CLAMP NO.3

(a) Install the transaxle apply tube clamp No. 3 with the bolt.

Torque: 5.4 N·m (55 kgf·cm, 48 in.×lbf)

Q02334

142. INSTALL FRONT DRIVE PINION REAR TAPERED

SST ROLLER BEARING

(a) Using SST and a press, install the side bearing into the

differential case.

SST 09710−30031 (09710−03161)

AT5833

143. INSTALL FRONT DRIVE PINION FRONT TAPERED

ROLLER BEARING

(a) Install the speedometer drive gear to the differential case.

AT2982

(b) Using SST and a press, install the side bearing into the

differential case.

SST SST 09350−32014 (09351−32090, 09351−32120)

AT8044

144. INSTALL FRONNT DIFFERENTIAL ASSY

AT0525

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−50

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

145. INSTALL TRANSAXLE HOUSING

(a) Remove any packing material and be careful not to get oil

on the contacting surfaces of the transaxle housing or

FIPG transaxle case.

(b) Apply FIPG to the transaxle housing.

FIPG:

Part No.08826 − 00090, THREE BOND 1281 or equiva-

Q02360 lent

A (c) Apply sealant to the bolt B threads.

A

Sealant:

Part No.08833 − 00090, adhesive 1131, or equivalent

A (d) Install the bolts.

Torque: 30 N·m (306 kgf·cm, 22 ft·lbf)

HINT:

Each bolt length is indicated in the illustration.

A Bolt length:

A B Q04360 Bolt A: 30 mm (1.18 in.)

Bolt B: 35 mm (1.38 in.)

146. ADJUST DIFFERENTIAL SIDE BEARING RRELOAD

(a) Using SST, rotate the differential in both directions to

snug the bearing down.

SST 09564−32011

(b) Using SST and a torque wrench, measure the preload of

the side bearing.

SST 09564−32011

Preload (at starting):

Q05199 New bearing:

0.8 − 1.4 N×m (8 − 14 kgf×cm, 6.9 − 12.2 in.×lbf)

Used bearing:

0.4 − 0.7 N×m (4 − 7 kgf×cm, 3.5 − 6.1 in.×lbf)

If the preload is not within the specified range, remove the differ-

ential from the transaxle case. Re−select the transaxle case

side adjusting shim according to the following table.

Adjusting shim thickness.

2.00 mm (0.0787 in.) 2.05 mm (0.0807 in.) 2.10 mm (0.0827 in.)

2.15 mm (0.0846 in.) 2.20 mm (0.0866 in.) 2.25 mm (0.0886 in.)

2.30 mm (0.0906 in.) 2.35 mm (0.0925 in.) 2.40 mm (0.0945 in.)

2.45 mm (0.0965 in.) 2.50 mm (0.0984 in.) 2.55 mm (0.1004 in.)

2.60 mm (0.1024 in.) 2.65 mm (0.1043 in.) 2.70 mm (0.1063 in.)

2.75 mm (0.1083 in.) 2.80 mm (0.1102 in.) 2.85 mm (0.1122 in.)

2.90 mm (0.1142 in.) − −

HINT:

The preload will change about 0.3 − 0.4 N×m (3 − 4 kgf×cm, 2.6

− 2.9 in.×lbf) according to a change in shim thickness of 0.05 mm

(0.0020 in.)

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−51

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

147. INSTALL OIL PUMP ASSEMBLY

(a) Coat a new O−ring with ATF, and install it to the pump

body.

AT2972

(b) Place the oil pump through the input shaft, and align the

bolt holes of the pump body with those of the transaxle

case.

(c) Hold the input shaft, and lightly press the oil pump body

to slide the oil seal rings on the input shaft through the di-

rect clutch drum.

NOTICE:

Do not push on the oil pump strongly, or the oil seal ring will

Q05182 stick to the direct clutch drum.

(d) Install the 6 bolts.

Torque: 25 N·m (255 kgf·cm, 18 ft·lbf)

Q05181

148. INSPECT INPUT SHAFT ASSY

(a) Measure the thrust play in the axial direction.

Thrust play: 0.3 − 0.9 mm (0.012 − 0.035 in.)

If the play is not as specified, select and replace the race for the

end of the input shaft assy.

HINT:

There are 3 different thickness for races, if necessary, select

one of them.

Q05180 Race thickness: mm (in.)

thickness thickness

0.8 (0.031) 1.0 (0.039)

1.4 (0.055) −

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−52

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

149. INSPECT INPUT SHAFT ENDPLAY

(a) Make sure that the input shaft rotates smoothly.

Q05178

150. INSTALL ACCUMULATOR PISTON AND SPRING

C3 B2 C2

(a) Coat new O−rings with ATF, and install them to the pis-

C1

tons.

(b) Install the pistons and springs to the case.

A245E:

Spring Free length Color

(1) (1) C3 (Outer) 68.4 mm (2.815 in.) Yellow

(3) (4) (5)

(2) C3 (Inner) 50 mm (1.968 in.) Yellow

(3) B2 64.68 mm (2.685 in.) Light blue

(4) C2 64.68 mm (2.547 in.) Green

(2)

(5) C1 (Outer) 60.39 mm (2.780 in.) Pink

A246E:

Spring Free length Color

C3 (1) C3 (Outer) 68.4 mm (2.815 in.) Yellow

B2 (2) C3 (Inner) 50 mm (1.968 in.) Yellow

C2 C1

(3) B2 64.68 mm (2.685 in.) Light blue

(4) C2 70.45 mm (2.773 in.) Purple

D25350

(5) C1 (Outer) 60.39 mm (2.780 in.) Pink

151. INSTALL GOVERNOR APPLY GASKET NO.1

Q02187

152. INSTALL CHECK BALL BODY

(a) Install the check ball body and spring.

Q02240

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−53

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

153. INSTALL TRANSMISSION WIRE

(a) Install the transmission wire.

Q02184

(b) Install the bolt.

Torque: 5.5 N·m (56 kgf·cm, 49 in.·lbf)

D08575

154. INSTALL TRANSMISSION VALVE BODY ASSY

(a) Install the connecting rod to the manual valve.

(b) Using needle−pliers, install the E−ring to the connecting

rod.

C81864

(c) Install the manual valve to the valve body assy.

D25351

(d) Connect the connecting rod to the manual valve lever.

D25352

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−54

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

(e) Install the 17 bolts.

B B

HINT:

Each bolt length is indicated in the illustration.

Torque: 10 N·m (102 kgf·cm, 7 ft·lbf)

A A Bolt length:

Bolt A: 20 mm (0.79 in.)

Bolt B: 28 mm (1.10 in.)

C C

A

Bolt C: 50 mm (1.97 in.)

D25330

155. INSTALL MANUAL DETENT SPRING SUB−ASSY

Torque: 10 N·m (102 kgf·cm, 7 ft·lbf)

D25333

A 156. INSTALL VALVE BODY OIL STRAINER ASSY

Install the valve body oil strainer assy with the 3 bolts.

HINT:

Each bolt length is indicated in the illustration.

Torque: 10 N·m (102 kgf·cm, 7 ft·lbf)

Bolt length:

Bolt A: 12 mm (0.47 in.)

B D25328 Bolt B: 20 mm (0.79 in.)

157. INSTALL TRANSMISSION OIL CLEANER MAGNET

(a) Install the 2 transmission oil cleaner magnets to the oil

pan.

D25353

158. INSTALL AUTOMATIC TRANSAXLE OIL PAN

SUB−ASSY

(a) Install a new gasket to the automatic transaxle oil pan

sub−assy and install them to the transaxle.

(b) Tighten the 18 bolts.

Torque: 5.2 N·m (54 kgf·cm, 47 in.·lbf)

C81865

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−55

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

159. INSTALL OIL COOLER TUBE UNION

(a) Install new O−rings to each oil cooler tube unions.

(b) Install the oil cooler tube unions to the transaxle case.

Torque: 30 N·m (306 kgf·cm, 22 ft·lbf)

D08574

160. INSTALL NEUTRAL START SWITCH ASSY

(a) Install the neutral start switch assy to the manual valve

shaft.

(b) Place a new lock washer and tighten the nut.

Torque: 7.0 N·m (71 kgf·cm, 62 in.·lbf)

(c) Temporarily install the 2 bolts.

D25354

(d) Temporarily install the manual shift lever.

(e) Turn the lever counterclockwise until it stops, then turn it

clockwise 2 notches.

(f) Remove the manual shift lever.

N

R

P

D25126

(g) Align the groove with neutral basic line.

(h) Install and tighten the 2 bolts.

Torque: 5.3 N·m (54 kgf·cm, 49 ft·lbf)

Neutral

Basic

Line

Groove

D08584

(i) Using a screwdriver, stake the nut with the lock washer.

D08585

A245E,A246E A/T REPAIR MANUAL (RM847E)

40−56

AUTOMATIC TRANSMISSION / TRANS − AUTOMATIC TRANSAXLE ASSY (A245E/A246E)

161. INSTALL MANUAL VALVE LEVER SUB−ASSY

162. INSTALL BREATHER PLUG HOSE

163. INSTALL TRANSAXLE CASE NO.1 PLUG

(a) Install the transaxle case No. 1 plug and O−ring.

A245E,A246E A/T REPAIR MANUAL (RM847E)

You might also like

- A245e PDFDocument21 pagesA245e PDFluizjunior501100% (2)

- TRANSMISSION VALVE BODY ASSY REMOVALDocument1 pageTRANSMISSION VALVE BODY ASSY REMOVALLuis Velazquez75% (4)

- A 240Document89 pagesA 240Mario Diaz Lopez100% (1)

- Toyota A245eDocument18 pagesToyota A245etambache6969% (16)

- A6gf1 Corpo 2Document2 pagesA6gf1 Corpo 2Alex Maceira Graterol100% (1)

- Transmission Valve Body ReplacementDocument5 pagesTransmission Valve Body ReplacementPablo MontesNo ratings yet

- Valve Body A246e PDFDocument1 pageValve Body A246e PDFLuis Velazquez67% (9)

- Automatic A245E, A246EDocument17 pagesAutomatic A245E, A246EAntonio Carlos Santos79% (14)

- 變速箱 A245E,A246E ZZE121Document136 pages變速箱 A245E,A246E ZZE121esquisof67% (9)

- Transmission Valve Body Assy (A245E/A246E) : OverhaulDocument2 pagesTransmission Valve Body Assy (A245E/A246E) : OverhaulGearauto Power100% (2)

- Overhaul A240e PDFDocument140 pagesOverhaul A240e PDFMuslihnofal50% (2)

- U440e PDFDocument2 pagesU440e PDFMaxisys Autel75% (4)

- A4cf0 - HyundaiDocument29 pagesA4cf0 - Hyundaijair75% (4)

- U-340 Valve BodyDocument19 pagesU-340 Valve BodyAle100% (4)

- Shop Manual U-341FDocument115 pagesShop Manual U-341FDavid100% (3)

- A340 VB ID PDFDocument5 pagesA340 VB ID PDFleeroy381No ratings yet

- Overhaul A240eDocument140 pagesOverhaul A240eSamuel83% (6)

- U341e PDFDocument18 pagesU341e PDFmaq8048100% (2)

- A4cf1 A4cf2 SCHEMEDocument2 pagesA4cf1 A4cf2 SCHEMEIvan Escalona100% (8)

- Automatic Transaxle Components and OperationDocument140 pagesAutomatic Transaxle Components and OperationRadu Xnx100% (6)

- A4cf SolenoidDocument9 pagesA4cf Solenoidhaddadi100% (13)

- A6lf1 PDFDocument4 pagesA6lf1 PDFAlan Mitt Costa50% (2)

- Dokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFDocument5 pagesDokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFAleksandr Kuznichenko0% (1)

- A750Document2 pagesA750ReydeEspa1100% (2)

- Auto Trans U241e PDFDocument396 pagesAuto Trans U241e PDFmasakp94% (16)

- Previous MenuDocument88 pagesPrevious MenuFSR1407100% (1)

- A-240L-A241E-A243 ManualDocument278 pagesA-240L-A241E-A243 Manualilloatayde100% (3)

- Honda Accord, Acura RSX, TSX, CR-V Transmission SpecsDocument8 pagesHonda Accord, Acura RSX, TSX, CR-V Transmission Specshidraulic100% (5)

- U151E ComponentsDocument203 pagesU151E ComponentsAndres Chavez Barrios100% (3)

- A245EDocument21 pagesA245EDavid Chalker93% (46)

- k313 (CVT) - Fluid AdjustmentDocument15 pagesk313 (CVT) - Fluid AdjustmentTeddy Frederick100% (3)

- U340 441E DescriptionDocument25 pagesU340 441E Descriptionruslan1580No ratings yet

- Aw 0370Document5 pagesAw 0370Alex Maceira GraterolNo ratings yet

- 4CF1-4CF2 - I30 - Transtec PDFDocument25 pages4CF1-4CF2 - I30 - Transtec PDFJorge Abreu78% (9)

- F4A4x at Manual PDFDocument135 pagesF4A4x at Manual PDFDener Rogerio Dos SantosNo ratings yet

- Gearbox k310 PDFDocument3 pagesGearbox k310 PDFmaq804850% (10)

- AUTOMATIC TRANSAXLE COMPONENTSDocument19 pagesAUTOMATIC TRANSAXLE COMPONENTSWissem RatelNo ratings yet

- Specification and function of U340E and U441E automatic transaxlesDocument25 pagesSpecification and function of U340E and U441E automatic transaxlesOliverFrancoCruzAranibar100% (2)

- Toyota A340FDocument1 pageToyota A340FReydeEspa171% (7)

- A340E and A343E automatic transmission specifications and operationDocument8 pagesA340E and A343E automatic transmission specifications and operationcalixtoruas75% (4)

- Import A6mf1 RebuildDocument43 pagesImport A6mf1 RebuildJordy Ram75% (4)

- K111 Continuously Variable Transaxle: DescriptionDocument35 pagesK111 Continuously Variable Transaxle: Descriptionhungchagia1100% (2)

- F4ael PDFDocument120 pagesF4ael PDFPablo Cansas100% (2)

- U341E GearDocument18 pagesU341E Gearpalaboy88875% (12)

- At A5hf1Document175 pagesAt A5hf1Jeffree Alexander Ramirez67% (3)

- U140e U241e Zip PDFDocument8 pagesU140e U241e Zip PDFossoski100% (1)

- A4CF2Document65 pagesA4CF2Alex Maceira Graterol100% (2)

- Location Valve Body U151EDocument5 pagesLocation Valve Body U151EgabotoyoNo ratings yet

- TBR at Aw03-72leDocument19 pagesTBR at Aw03-72lehayyeuanh_duchimotla83% (18)

- Overhaul: 1. Remove Transmission Control Shaft Lever RHDocument43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever RHBắc HoàngNo ratings yet

- Alt Is MaticDocument25 pagesAlt Is MaticminaryNo ratings yet

- Automatic transaxle disassembly guideDocument20 pagesAutomatic transaxle disassembly guidelucas harleyNo ratings yet

- Transmission Valve Body Assy (A246E) : ReplacementDocument4 pagesTransmission Valve Body Assy (A246E) : ReplacementJesusNo ratings yet

- Automatic Transaxle Replacement GuideDocument11 pagesAutomatic Transaxle Replacement GuideluisNo ratings yet

- Transmission Valve Body Assy (Hilux (Tasa Made For Argentina) )Document5 pagesTransmission Valve Body Assy (Hilux (Tasa Made For Argentina) )Michael MarshallNo ratings yet

- Automatic Transaxle Assy (U34#E Series) : OverhaulDocument46 pagesAutomatic Transaxle Assy (U34#E Series) : Overhaulvipper king2012No ratings yet

- Automatic Transaxle Assy (U34#E Series) : OverhaulDocument46 pagesAutomatic Transaxle Assy (U34#E Series) : Overhaulvipper king2012No ratings yet

- Engine Mechanical PDFDocument193 pagesEngine Mechanical PDFDean BNo ratings yet

- Overhaul: 1. Remove Transmission Control Shaft Lever LH (A750F Except 4runner, Gx470)Document43 pagesOverhaul: 1. Remove Transmission Control Shaft Lever LH (A750F Except 4runner, Gx470)joe nathanNo ratings yet

- Transmission Valve BodyDocument4 pagesTransmission Valve Bodyjeremih alhegnNo ratings yet

- Workshop Manual Checking Fluid Level PDKDocument11 pagesWorkshop Manual Checking Fluid Level PDKEderson BJJNo ratings yet

- PDK Valve Body and Temp SensorDocument13 pagesPDK Valve Body and Temp SensorKrzysztof Kjb100% (1)

- PDK Repair Aftersales TrainingDocument22 pagesPDK Repair Aftersales TrainingEderson BJJNo ratings yet

- SSP385 6-Speed Automatic Gearbox 09L 0AT 0B6 0BQ 09EDocument96 pagesSSP385 6-Speed Automatic Gearbox 09L 0AT 0B6 0BQ 09EdeklokkieNo ratings yet

- 01V 01L Automatic Transmissions PDFDocument80 pages01V 01L Automatic Transmissions PDFJOHNNY537767% (3)

- 01V 01L Automatic Transmissions PDFDocument80 pages01V 01L Automatic Transmissions PDFJOHNNY537767% (3)

- Multitronic 01j A8 2003 EngDocument113 pagesMultitronic 01j A8 2003 EngEderson BJJNo ratings yet

- Transmission Fluid Drain and Refill - 10R80Document10 pagesTransmission Fluid Drain and Refill - 10R80Ederson BJJ100% (1)

- PDK Factory T-Shoot DocumentDocument17 pagesPDK Factory T-Shoot DocumentEderson BJJNo ratings yet

- Transmission Fluid Drain and Refill - 10R80Document10 pagesTransmission Fluid Drain and Refill - 10R80Ederson BJJ100% (1)

- GM 8 Speed Shudder Flyer All Sizes 2Document2 pagesGM 8 Speed Shudder Flyer All Sizes 2Ederson BJJNo ratings yet

- Workshop Manual Checking Fluid Level PDKDocument11 pagesWorkshop Manual Checking Fluid Level PDKEderson BJJNo ratings yet

- SsangyongDocument1,991 pagesSsangyongmichaeltiboche100% (2)

- Kyron 201001Document1,108 pagesKyron 201001Ederson BJJNo ratings yet

- Actyon 200603Document1,103 pagesActyon 200603Ederson BJJNo ratings yet

- Kyron PDFDocument1,105 pagesKyron PDFDamir MilisaNo ratings yet

- Audi TB 37-06-13Document5 pagesAudi TB 37-06-13Victor GabrielNo ratings yet

- Korando 2013 PDFDocument1,320 pagesKorando 2013 PDFاليكترونيك اوتوNo ratings yet

- Transmission Fluid Drain and Refill - 10R80Document10 pagesTransmission Fluid Drain and Refill - 10R80Ederson BJJ100% (1)

- Engine Service Manual OverviewDocument702 pagesEngine Service Manual OverviewEderson BJJNo ratings yet

- Curso Electrohidraulicos Electronica Hidraulica Maquinaria PesadaDocument16 pagesCurso Electrohidraulicos Electronica Hidraulica Maquinaria PesadaCamille Araujo100% (3)

- Workshop Manual Checking Fluid Level PDKDocument11 pagesWorkshop Manual Checking Fluid Level PDKEderson BJJNo ratings yet

- Transmission Fluid Drain and Refill - 10R80Document10 pagesTransmission Fluid Drain and Refill - 10R80Ederson BJJ100% (1)

- DSI 6 A/T GuideDocument106 pagesDSI 6 A/T GuideEderson BJJ93% (15)

- Comparison Between Icf and Fiat BogieDocument76 pagesComparison Between Icf and Fiat BogieIvica BudrovacNo ratings yet

- Explore new grounds with the SZ15RR v2.0Document1 pageExplore new grounds with the SZ15RR v2.0JimJiangNo ratings yet

- Lamborghini Gallardo Paper Model InstructionsDocument3 pagesLamborghini Gallardo Paper Model InstructionsFelixz Giatama100% (1)

- Clockspring Removal and Installation PDFDocument6 pagesClockspring Removal and Installation PDFMichael HernandezNo ratings yet

- Date Statistice APIA 2010-2011Document3 pagesDate Statistice APIA 2010-2011Razvan GanglerNo ratings yet

- Vellfire PM Ipte PDFDocument1 pageVellfire PM Ipte PDFTrader Teknik SqdNo ratings yet

- TL 20 ToyDocument4 pagesTL 20 ToyElectroventica ElectroventicaNo ratings yet

- Engine and Engine Peripherals Sump: Mot. 1233-01 Threaded Rods For Lowering The Sub-FrameDocument1 pageEngine and Engine Peripherals Sump: Mot. 1233-01 Threaded Rods For Lowering The Sub-FramesimpluokNo ratings yet

- 67 Nissan 2c Rl4f03a Re4f03aDocument16 pages67 Nissan 2c Rl4f03a Re4f03aMarcioMartinhoFerreira0% (1)

- Tabela FIPE SP 2015Document181 pagesTabela FIPE SP 2015Roger RicciNo ratings yet

- Hyundai i30 Compact Hatchback ReviewDocument3 pagesHyundai i30 Compact Hatchback ReviewDruppy MarkNo ratings yet

- BMW C 400 XDocument4 pagesBMW C 400 Xextremefocus122No ratings yet

- Saab 900 1991 GBDocument50 pagesSaab 900 1991 GBDejan JovanovicNo ratings yet

- Electric Cargo Cycle Range and FeaturesDocument14 pagesElectric Cargo Cycle Range and FeaturesJasNo ratings yet

- Wiper and Washer: DescriptionDocument2 pagesWiper and Washer: DescriptionRoma KuzmychNo ratings yet

- 2010 Tech Inspect SheetDocument6 pages2010 Tech Inspect SheetDaniel PassagliaNo ratings yet

- 4R44E 5R55E Vac LocationsDocument2 pages4R44E 5R55E Vac LocationsPedroMecanico100% (1)

- Bsa S8135Document2 pagesBsa S8135supatNo ratings yet

- ABS 580 - Datasheet 2019Document2 pagesABS 580 - Datasheet 2019Amiet ChatterpalNo ratings yet

- Check: 840-Emirates Auctions 13 Jul 2022, 17:25:35 93079925 (CC10006) 312309Document2 pagesCheck: 840-Emirates Auctions 13 Jul 2022, 17:25:35 93079925 (CC10006) 312309Muhammad Usman AnwerNo ratings yet

- Trakker E4Document74 pagesTrakker E4EVCYNo ratings yet

- BMW 3 Series Brochure 2022.pdf - Asset.1649317076427Document23 pagesBMW 3 Series Brochure 2022.pdf - Asset.1649317076427Muskrati ShaamNo ratings yet

- C1310-11 - Open or Short in Active Brake Booster Circuit (2007 Tundra)Document3 pagesC1310-11 - Open or Short in Active Brake Booster Circuit (2007 Tundra)AirmanNo ratings yet

- Study, dismantling and assembly of rear axle componentsDocument3 pagesStudy, dismantling and assembly of rear axle componentsAnkit G SinghNo ratings yet

- 2017 - VW Passat b8 Arteon Brake System Eng PDFDocument160 pages2017 - VW Passat b8 Arteon Brake System Eng PDFRadoslav Rebrinsky100% (1)

- Porsche 959 - The legendary 1980s supercarDocument6 pagesPorsche 959 - The legendary 1980s supercarDiego López CarúsNo ratings yet

- BMW 3 Series - Pdf.asset.1618556602279Document23 pagesBMW 3 Series - Pdf.asset.1618556602279belleNo ratings yet

- 3N71B - 4N71B (N4a-El)Document4 pages3N71B - 4N71B (N4a-El)Daniel leon Leon RamosNo ratings yet

- HondaRevo110NEW PDFDocument13 pagesHondaRevo110NEW PDFmahendrachmandaNo ratings yet

- Suzuki Jimny 2015 UKDocument20 pagesSuzuki Jimny 2015 UKJhonathan BaptistaNo ratings yet