Professional Documents

Culture Documents

SW TW502 Op Manual

SW TW502 Op Manual

Uploaded by

Irawan Budi Santosa0 ratings0% found this document useful (0 votes)

63 views101 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views101 pagesSW TW502 Op Manual

SW TW502 Op Manual

Uploaded by

Irawan Budi SantosaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 101

No._s496.35950-2

& Read this handbook thoroughly and understand the whole information

contained before trying to operate, inspect and service your machine!

OPERATING &

MAINTENANCE

INSTRUCTIONS

»

8

8

2

i

s

rT

y

+

Ww

3

3

i

3

3

2

i

SAKAI HEAVY INDUSTRIES, LTD. MODEL

SW352-1TW352.-1

Mond SW502-1TW502s-

From SW352-1 — 18W42 - 20101

TW352-1 — 1TW42 - 20101

SW502-1 1SW43 - 20101

‘TW5028-1 — 18W43 - 20101

SAKAI

PREFACE

This operator's manual serves as a guide for the use of your Sakai SWW/TW352s SW502s

‘TW502S: Vibrating Roller for those who are new to the machine, and also for the people who

have experience in using the machine and want to refresh their knowledge forthe machine.

Fead this manual thoroughly and try to fully understand the information belore operating your

‘machine. Keep this handbook at hand whenever you do your work.

Tho main subjects ofthis manual are:

(1) Basic precautions for safety, (2) Operation, (3} Daily maintenance and (8) Specifications.

For operation and maintanance of the engine, refer to the Engine Instruction Manual fumished

separately. Descriptions in this manual can differ from the machine instructions of your

‘machine due to the results ofthe investigation and improvement in its design. Ifyou have any

inquiry regarding your Machine or this manuel, contact our distributors,

RIGHT FRONT RIGHT

$3521, S502 Tw5e, TW50281

‘CONTENTS

CONTENTS

PREFACE

MACHINE AND ENGINE IDENTIFICATION NUMBERS. 1

SAFETY NOTICES, 2

1. BASIC PRECAUTIONS FOR SAFETY

41 General Precautions. 4

412 Preparation for Safe Operation 6

13 Before Starting the Engin... 7

14 Alor Starting the Engine. 8

15 During Operation 8

46 Loading and Unloading... 10

17 Transportation 11

118 Handling the Battery. 14

19. Towing 2

110. Before Servicing 13

{1 During Servicing 14

142. Safety Decals, as a

2 OPERATION

2c1__Instruments and Controls. 19

21 Operators station 7 19

2.12 Gauges, indator lamps and warning ames oo 20

2.18 Switches. 22

2.14 Operating lovers and pedals 26

2.18 Fuse box. . 27

22° Handling and Adjustments. 28

22.1 Seat adjustment... : 28

22.2 Scraper adjustment and replacement wnssar 28

2.23 _Disengaging the brake when towing 30

23. Operation: 31

2.3.1. Bofore-sarting inspection . 31

2.82 Starting the engine. ee vn

23.3. Afr starting the engine 33

234 Traveling 7 34

235 Stopping! Parking onan 35

2.36 Stopping the Engine. : 36

237 Checc ater Soping ho Engine = 37

24° Vibratory Operation. 37

BE Sprinkler sno : 38

28 Liquid Sprayer (Wass FWGES. 44

2.7 Precautions for Work. 42

2.21 Compaction operation. 42

2.72 When going downhill 42

2.73 Onaslope... 42

- CONTENTS

2.10. Loading and Unioain:

2.10: Use otal equipped with winch

2412 Transportation.

2.13. Operation in Cold Weather.

2.13.1 Fuel ol and grease.

2.13.2 Coolant

2.13.3 Battor...

2.14 When the Cold Season is Over.

2.15. Fora Long Storage Period.

2.18 During the Storage Period

2.17 When the Battery has Discharged.

24171 Connection and disconnection

3 PERIODICAL MAINTENANCE

3.1 Precautions... “

U1 Lifting the machine on @ hoist

3.2. Walk-Around Checking.

‘22.1 Tir inflation pressure chock (TW352.,TW5088.)

$22 Checking for extemal ny ore (TW, THEO

33 Periodioal Maintenance Points.

3.4 Maintenance Procedure.

(() Every 10 hours or daly.

(2) Every 100 hours.

(6) Every 200 hours.

(@) Every 250 hours

(6) Every 450 hours.

(6) Every 500 hours.

(@) Every 1000 hours

(@) As required

35. Consumable Parts :

36 Feeding Wator and Lubricants

37 Elecve Wiring Diagram

4 SPECIFICATIONS..

"MACHINE AND ENGINE IDENTIFICATION NUMBERS

MACHINE AND ENGINE IDENTIFICATION NUMBERS

‘When ordering parts or making inquiries about your machine, the following information is

requested:

(1) Machine model

Indicated on the dashboard in the operators station.

Machine mode

(2) Machine serial number

SW3521 = 18W42—-QOO00

‘Twas2s © 1TWw42—QQO00

SW5021 = 18W43-QOO00

‘Tws028.1© 1TWw43—QOO00

@) Engine serial number

‘sw352.1, W352 Sss02., Tw5025.+

Location

“SAFETY NOTICES

SAFETY NOTICES

For the safe use of your machine, correct handling and periodical maintenance are of utmost

importance. Thoroughly read the safety precautions described in this manwal. Do not attempt

to operate and maintain your machine until you gain a full understanding of these safety

statements.

‘This manual covers the proper and safe method of driving and handling of this machine for its

intended use. When this machine Is used a manner, other than that covered in this manuel,

{you must assume responsibilty for your own personal safety

In this manual and on the machine, you wil find safety notices. Each safety notice starts with

‘a signal word as shown below:

By DANGER —_ Denotes that there is an extreme hazard. If you fal to

take proper precautions, itis highly likely that you could

be killed or Seriously injured (The color of the symbol &

Is red).

A WARNING Denotes that there is a hazard. If you fail to take proper

precautions, you could be killed or seriously injured

(Symbol a is orange).

A CAUTION Calls attention to safety practices. If you fal to take

proper precautions, you could be injured or cause

‘damage to the machine (Symbol A Is yellow).

z “SAFETY NOTICES

Itis almost impossible forthe safety notices in this manual and or the machine to cover all the

potential dangers. Keep alert to possible dangers not mentioned in this manual and on the

decales.

Pron

‘Do not operate your machine before you read its operator's

‘manual thoroughly.

Incorrect operation can kill or cause injury.

is your responsibility to operate the machine safely.

‘4x Non-approved modifications can pose safety-related problems. Before making any

‘modifications, consult your distributor. For an injury or damage to the machine caused by

‘non-approved modifications, Sakai accepts no responsibilty

+f Basie precautions for safe operation of your machine are discussed beginning on page 4.

‘fe To operate and work with your machine, you must be qualified,

A. WARING: Nogigence of thas nstrctons can ead

7 BASIC PRECAUTIONS FOR SAFETY _

1 BASIC PRECAUTIONS FOR SAFETY

11 General Precautions

lM Read thoroughly the operator's manual e@

* Understand the functions of the controls and gauges.

Familiarize yourselt with their location and how to

‘operate them, Understand the meaning ofall the

symbols.

bey the worksite rules

+ Follow the worksite rules such as matters forbidden or to be attended to, and working

procedures,

Wear protective clothing to suit the work

Wear clothing, safety shoes and hard hat to suit your work.

+ Do not wear clothing and accessories that tend to get caught in the controls or protruded

portions of the machine. Do nat wear oly clothing

+ According to the type of jobs, wear safety goggles or mask.

eOdORs

Know the work area in advance

‘= Know the terrain, geology and conditions ofthe road surface atthe worksite. Start working

ator soouring safety such as stationing a guardsman or puting up bartiors where there is a

risk of faling of the machine or collapse of should.

Provide against an accident

* Decide in advance the means of communication in an emergency. Know the location and

use of an extinguisher and first-aid kit

Know the capability of the machine

* Thoroughly understand the performance of your machine and correctly operate the

‘machine to meet the requirements of the jobsite. Operating the machine beyond its

‘capabilities may lead to an accident. Use your machine within its capability.

WARNING: Negigence of thse Istrtons ideo

Cc 1 BASIC PRECAUTIONS FOR SAFETY

Do not use a machine which has not been serviced correctly at regular intervals

* Before working, perform necessary inspections. Start operation only after making

Certain the machine is in good operating condition. I found to be abnormal, report to the

responsible person and have the fault corrected. Operate the machine after making sure

thal itis sale to operate,

Mo not allow anyone to enter the work area except for authorized personnel

* Always conduct the work paying attention to the

‘workers around the machine

Bo careful of hot parts

* After your machine has operated for some time, the

coolant, engine ol and hyctaulc fluid will become hot

and the pressure will build up. If inthis state, you try to

remove the filer caps, drain the ol or replace the fitors,

you can get burned. Perform this work in accordance

With the correct procedures with the machine cooled.

down,

*To remove the radiator cap, slowly loosen the cap to

relieve the pressure with the engine shut down and the

‘coolant cooled down. (For the radiator cap with a lever,

lit the lever to release the trapped pressure.)

+ When removing the filer cap on the hydraulic tank, release the trapped pressure by turning

‘Rout stowly to prevent the oll from gushing out.

+ Do not touch the muffler while the engine is running or immediately ater it has been shut

down. You ean get burned,

Bo careful with fire

* The fuel, oll, and anti-freeze will atch fire if open

flames or ignition sources aro used close to them.

Particularly, the fuel is highly flammable,

* Do not smoke or use match or cigaratte lighter close

to inflammabies (combustibles)

+ When refueling, stop the engine and do not smoke.

+The filer caps ofthe fuel and ol tanks must be kept

tight.

A. WARING: Neigence of hes Instruct

11 BASIC PRECAUTIONS FOR SAFETY

Mi Mount on or dismount from your machine after it has come to a complete stop

* For geting on and of, face the machine and use the handrail and step.

Do not jump on or off @ machine, particularly when itis moving,

To handle the hydraulic fluid

Wear safety goggles to protect your eyes from contact

with hydraulic uid ft can inritate your eyes.

It the flud contacts your eyes, lush with clean water for

15 minutes and get medical aid

‘The fluid can also irate your skin. When handling it,

wear rubber gloves to avoid contact with it In case of

‘kin contact, wash with soap and water.

‘+ Be careful not to swallow the fluid. t can cause

oe s

immodiately.

Do not use worn tires

"Tires may be damaged when they are scratched on curb stones, when the machine runs

over iregular surfaces of roads of projections on roads, and when the machine is operated

suddenly,

+ Continued use of damages tires will cause thom to blow out. Replace them with new ones.

1.2 Preparation for Safe Operation

Clean the step, operator's station and floor board

* Do not place parts, tools or unnecessary articles on the step, operators station and floor

board.

+ Keep the step, floor board, controls and handholds free from muds, oil ice or water, as they

ccan cause slippage. Repair them if found to be damaged. Tighten loose bolts.

+ Keep your boot soles f00 of oll or muds. They can slip, leading to an accident.

inspect your machine before operation

"= Check yout machine for damage such as cracks and deformation If found to be abnormal,

operate the machine alter taking a proper measure to secure safety

+ Check the lava of fluids (tue, engine ol, coolant, antifreeze and hydraulic ol). Add as

necessary.

+ Check the area where the machine has parked fr signs of leakage of oil, fuel and water. If

any leakage is noticeable, determine the cause and make corrections immediatoly.

“A.warma:negisenecftaseiatvctonscanleadinsedienty,

(mast 20g ATION rR SAFETY

Mi Know the stopping distance

‘+ When traveling on a road, bear in mind the stopping

distance. Avoid excessive speed, and abrupt starting

‘and stopping, and moving in a zigzag direction,

1.3 Before Starting the Engine

Mit is confirmed that hood is closed

Please confirm hood has put it auay in the confirmation before it gots on.

I Adjust the operator's seat to your most effective operating position

ton the operator’ seat. Adjust the seat so that your back wil make contact with the seat

back when the brake pedal is depressed tothe full extont. Check tobe sure that the brake

pedal can be fully depressed without difficulty when you twist your body for reverse run.

Secure good visibility (with cabin)

+ Keep the windowpane clean.

* Lock the windows and doors no matter whether they are open or closed.

' Do not leave the doors hatfclosed.

Mi Secure forward and backward visibilities

*= Adjust the rear view mirrors and under mirrors for good visibility If dity, clean them. I

damaged, replace.

Check that the horn, lamps and gauges work correctly

Before starting, make certain that each lever isin the neutral position and the

parking brake Is applied

When starting, sound the horn

*Bofore starting the engine. Make sure there is no one

inthe immediate vicinity and there are no obstructions,

‘around the machine.

Pay attention to ventilation

Exhaust fures are dangorous if breathed in, When

starting the engine in an enclosed area, provide good

Ventilation with windows and doors opened.

AWARDING: Negligence of these instcons can oad to neces

1. BASIC PRECAUTIONS FOR SAFETY

Do not stand close to the exhaust gas pipe opening

Exhaust fumes are noxious if breathed in.

1.4 After Starting the Engine

MSecure safety around the machine

* Ensure thatthe aroa around the machine is clear of or

personnel and obstructions. Pay particular attention to

‘dead spaces. Before starting, sound the hom.

Warm up the Engine

‘Do not put your machine into motion immediately after the engine has started, let it idle for

‘several minutos unt it is at operating temperature,

+ Check the area where the machine has parked for signs of leakage or ol, fuel and water. I

any leakage is noticeable, determine the cause and make corrections immediately.

WiHtave a trial run

* Make a test run in a safe place to check that there are no abnormal signs. I found to be

abnormal, recy the fault before traveling again.

+ Listen for unusual sounds, and check for abnormal temperature rise. abnormal, park the

"machine ina safe location and find the source of trouble belore operating.

4.5 During Operation

|HINo other porson but the operator

* This machine is a one-man roller. Do not allow anyone to get an. Only the operator is

allowed on this machine wile it is running or in operation. Radios are not permited

Sit in the driver's seat before starting operation

* Sit in the divers seat before stating operation. Be sure to wear the seat belt when

provided.

Before mounting, be sure areas around the machine are safe

* Before getting on the machine, make certain tha there are no obstacles around the

machine and no workers under if some workers aro present or close to the machine, tell

them thatthe machine is about to move, warning them to stay away from it

1. BASIC PRECAUTIONS FOR SAFETY

Do not try to get on or off a moving machine

* Get on or off the machine alter making sure it has come to a complete stop.

To go uphill or downhill, run at low speeds. Do not

‘attempt to shift speeds while traveling on a grade

* Shifing speeds on a slope can cause unexpected

running down the slope,

+ Going down hil at speeds other than low range can

‘cause the machine to run down violently

Mi Refrain from inattentive driving

* Inattentive driving or driving relying on quese work can cause an accident. Use extreme

care for workers present in the path ofthe roller or around it. In case of danger, stop and

‘sound the horn, and proceed when the area is clear of personnel or obstructions,

When changing the

direction

ction of travel, secure the safety on the path in the travel

Keep everyone away from the pinch points

* When making turns, donot alow anyone to come close e

to the pinch point.

MEAt night, carefully drive the machine

“+ Nightiime driving tends to frustrate the sense of distance. Caretully dive the machine at

‘a speed suited illumination. Keep the headlamps and flood lamps lighted. It necessary,

provide extra lighting in the work area,

Repair as soon as possible if found to be defective

* Ifthe machine is found to be faulty, stop the machine and repair. Do not operate the

‘machine until the problem is corrected. When any warning lamp indicates faulty operation,

inspect the machine after moving it to the nearest safe location

A.WARWING: Negligence of these

1 BASIC PRECAUTIONS FOR SAFETY

Do not operate the machine except from the operator's seat. Do not drive ina

‘standing posture

While making turns, do not run at abnormally high speed and do not turn the

steering wheel abruptly and sharply

For the traveling on structures such as a bridge, make certain that they can support

‘your machine. Before traveling on the structure, you must know the load capacity

fof the structure and the load weight of the machine you are operating to insure safe

travel across the structure

Do not make turns on a slope and do not travel across sidehil.f necessary to do

80, go down straight along the slope to the flat ground, move sideways and go up

straight to the destination

x, oO ~

<> . S

\ a

a

When parking

"= Select level and hard ground. f necessary to park on a

‘slope, block the front of the drums on the downside of

the slope.

+ When required to park on the public road, provide

necessary markings such as flag, barriers and

ilumination, However, be sure they do not obstruct

traffic. hock

‘When geting of the machine, stop the engine and

remove the key from the ignition switch,

1.6 Loading and Unloading

* Loading and unloading can accompany any

ddangor. Uso extreme care, = ane

+ Select level and hard ground leaving a suficient

distance from the shoulder.

+ Use sturdy ramps with proper width, longth and

thickness which allow safe loading and unloading

If thoy deflect considerably under oad, apply

wooden blocks to reinforce the ramps.

‘A. WARNING: Negligence of thse Instructions can esd to accidents

1 BASIC PRECAUTIONS FOR SAFETY

‘To prevent your machine from crosswise slippage, keep the ramps free from oil, mud,

‘debris, ete. The drum must also be free from extraneous matter that can cause slippage.

+ Do not steer your machine on the ramps. Ifthe machine is facing inthe wrong direction,

allow ito dismount from the ramps, correct the direction and try again.

+ Do not use kinked, twisted or damaged wireropes for crane or winch operation, Use ones

with ample strength

+ When loading is complet, fix the machine with wooden blocks placed under the drums.

and chains fastened to the machine.

1.7 Transportation

+ Follow required regulations.

+ Solect a transporting route according to the overall width, overall height and gross weight

ofthe trallor with the roller loaded.

1.8 Handling the Battery

When handling the battery

' Battory electrolyte contains sulphuric acd. It will destroy

Clothing and skin. It touches your clothing or skin,

flush with large quantities of water.

+ In.case of eye contact, flush with clean water and seek

‘modioal help.

+ if ewallowed, drink large amount of water, milk, beaten

‘099 oF vogetable oil, and get medical help. Q

+ Wear safety goggles when handling the battery. Nod

‘Wear safety goggles, fll face shield, rubber gloves and

rubber apron when adding fluids to the battery

+The battery generates flammable gases that can cause an explosion. Do not smoke close

to the battery. Keep the battery away from flames, sparks and ignition sources.

ASS

A.Wantnic:Negtigence of these instructions can lend o secon

(SIC PRECAUTIONS FOR SAFETY

‘Inspect or handle the battery wth the engine shut down,

and the starter key in the OFF postion.

+ Keep metalic items such as tools away from the battery

terminals.

+ Loose terminals can cause sparks leading to an

‘explosion. Secure the terminals tightly.

ipsa oop

+ Wear safety goggles when jump-starting the machine.

“ich tiara a aor ¥y

net recat ne .

‘+ When connecting the battery cables, start with the 3

re

+ Do not allow a tool to bridge between the positive

terminal and machine body. This can generate Ne

dangerous sparks.

+ Do not connect the booster cable to wrong terminal. Never connect the positive terminal to

the negative.

‘+ Final connection tothe engine block of the disabled machine can cause sparks. The

‘connecting point should be as far as possibe from the battery.

1.9 Towing

‘+ To tow the machine, use wire ropes with ample strength,

+ Do not perform towing on a slope.

‘+ Do not use towing ropes twisted, kinked or damaged,

= Do not stride towing cables.

+ Koop everyone away from the space between the machine and the towing vehicle when

‘connecting the two.

+ Align the connecting portions of the machine and towing vehicle straight when coupling the

machine.

1.10 Before Servicing

Mi Attach warning tags when servicing the machine

* Serious accidents can occur if the machine is unexpectedly stared or controls carelessly

touched by an unauthorized person.

‘Attach a warning tag at a clearly visible location in the operator’ station and insure the Key

has been removed from the ignition switch

ADANGER

Do not operate.

Keep this warning tag, if not used, in tool box.

MUse proper tools

‘tis vory dangerous to use damaged or deteriorated —,

tools oro use tools for other purposes than intended,

Uso correct tools fr their intended use only.

Change safety-related parts at regular intervals

+ Replace fuel hose and high prossure hydraulic hoses regularly to prevent fre, Replace high

pressure hoses ofthe power steering system every two years.

2 Change these parts at regular intervals even if found to be normal, They will deteriorate

as time goes on.

+t Change any hose found to be abnormal even i itis within its recommended service

interval

inspect or service your machine with the engine stopped

+= If required to keep the engine running in such a case

a radiator interior cleaning, perform the work with

two persons. One of thom should sit on the operator's

‘sal gotting ready for shutting down the engine, He

‘must take care not to touch any of controls carelessly.

“Maintenance personnel must exercise extrome caution

‘not to make contact with moving parts.

1. BASIC PRECAUTIONS FOR SAFETY

Hi Supplying fuel and oils

“= Splled fuel oF oil willbe slippery Wipe up immediately. Keep the filer caps tight. Do not use

{uel for flushing ol, Handle fuel and ol in a well ventilated area,

Check the coolant level in the radiator

* To check the coolant level, shut down the engine and allow the engine and radiator to coo!

down,

Mttursination

* For inspecting te level ofthe fue, ol, coolant and

battery ecto, uso bum-poo!luminations.

Fal to use ths type of ilumination can result in an Ls

explosion. ka

4.11. During servicing

Mi Keep unauthorized porsons away

* During service, do not allow persons not concomed

to enter the work area, particulary when grinding or

‘welding operation is performed or heavy hammers are

being used.

Keep your machine clean

* Spilled ol, grease or scattered debris are dangerous. Always keep your machine clean.

‘Moisture that penetrates into the electrical system can cause malfunctions, Do not use

water to clean sensors, connectors and the operator's station.

[When repairing the electrical system

“= For repaling the electrical system or for conducting

welding, disconnect the negative cable from the battery

to shutoff the electricity.

Carefully handle high pressure hoses

**Do not try to bend or hit hoses against a hard object. Do not use hoses or pipes that are

bont or damaged. They will burst.

+ Replace damaged fuel hose and hydraulic hoses. An oll or hydraulic fluid spill can cause a

fire.

‘A. Wanwn: Negligence

1 BASIC PRECAUTIONS FOR SAFETY

Be careful of high pressure hydraulic fluid

* Bear in mind that the working equipment hydraulic

systems are under internal pressure. Do not perform

‘adding, draining, Inspection or servicing ofthe hydraulic

systems until the internal pressure has been relieved.

Hydraulic fluid leaking through a fine hole at high

pressure can penetrate your skin and eyes. Inspect

leakage by holding a hard board close to suspected

leaks wearing goggles. If affected by high pressure oi,

{got medical help immediately.

Bo careful of hot parts

' After the machine has been oporated for some time,

the coolant, engine oll and hydraulic fluid wll become:

hot,

+ Removing the radiator cap or draining the coolant or

‘il can burn you. Perform this work in accordance with

correct procedures after the systems have cooled down.

Use care when inspecting or servicing fan or belts in motion

“= Secure loose clothing and keep articles away that could

‘get caught in moving parts.

‘Do not let your body or tools make contact withthe fan

blades or belts. They can be cut seriously.

Used oll disposal

“= Do not throw used ol into drain or waterway. Drain

the ol from the machine into a proper container. Do not

drain droctly on the ground,

+ Obey all loca, state and federal environment

regulations for the proper disposal of oil, fue, coolant,

battery electrolyte or any other fluids.

Exercise extreme care when replacing and repairing tres

* Disassembly, repair and reassembly of tres require

special facity and knowledge. Have them ropaired at

work shop specialized in handing tires.

improperly fted rim can separate ifthe tre I inflated.

‘When infiating tres, do not work infront ofthe rim. Use

correct inflation pressure,

‘= When gismounting a tire, chock other tres for safety

‘When welding ob is carried out near the tres, use

‘extrome care, as this can cause an explosion of the

tires.

Z ‘A WAnnanG: Negigenc of tees natrutons can en

11 BASIC PRECAUTIONS FOR SAFETY

112 Safety Decals

Keep all decals clean I lost, replace with new one, There are decals other than those

‘shown below: Treat them in the same manner as the one shown here,

Ds00e-185080 @s006.104012 @s0ae-168040

A _WARNING A WARNING B_ DANGER

(@ 309-350020(2 locations)

ponerse ——

A_ DANGER — Z_WARNING

fees | (EEE | oomernme

ae - A WARNING

eoeee

‘A_DANGER

e

awarnne:

ofthese instructions can ad ecient

1 BASIC PRECAUTIONS FOR SAFETY

83524, SW502-1

A.WARWUNG: Neglignnoe ofthese Instructions cn lead to eeldets

1 BASIC PRECAUTIONS FOR SAFETY

7382.1, TW5028-1

— ‘2. OPERATION

2 OPERATION

2.1. Instruments and Controls

2.4.4 Operator's station

@ canti @

OSteering wheel ‘© Combination meter

@Hom switch button Lamp switch

© Fonward-reverse lever (F-R lever) @ Speed shit switch

with vibrator switch (@ Parking brake switch

@Licuid spray switch (TWS521,7W50283) _@ Throtle lover

© Vibration selector switch (SW502s, TW502S1) (8 Starter switch

© Sprinkler switch @ Brake pedal

Vibrator switch © Tum signal over

‘2. OPERATION

2.1.2 Gauges, indicator lamps and warning lamps

For safe execution of your job, fully understand the role and function of the systems

involved.

‘Combination meter

Merit sepiay (Cpt) Tachometer

ue

Oe) : | ee

ual gnuge Temperate gauge Hourmetar

‘Tachometer /Hour meter

Indicates the engine RPM. The hour meter shows total

‘operating hours. The service interval recommendation

in this manual should be based upon the hour meter

readings.

‘Temperature gauge oe

Indicates the coolant temperature. Zone close to symbol a

H indicates overheating. n case of overheating, run the o

{engine at idling for about ten minutes before shutting it

‘down. Then dotermine the cause,

Fuel gauge

Indicates the fuel level in the tank. rt

E: The tank is empty.

F: The tanks ful ®

Replenish fuel appropriately before the fuel runs down.

ACAUTION

[stor a enn SAC er

= ‘2. OPERATION

Monitor display

Hera ot ter

‘ring ao

Somat we ri op

R

ttenan

a Engine oll pressure

Lig sero. sroviene

(ast ease Serta

Sreeinenig eare panes Seas

‘ocean repo,

X Indicator lamps [oo OLB) ‘cn nbn HEA

Light up when corresponding systems have boon operated,

Je Warning lamps [ €3 ft

Go on when the starter switch Is turned to the ON position and go off when the engine has

‘started. I any of them lights up while the engine is running, this indicates a fauty condition,

‘Stop the engine and trace the source of trouble.

= Checking for warning lamp and parking brake indicator lamp =

‘They should tur on light when the starter switch in ON postion.

not, there is some trouble,

(Check and repair the combination meter or wirings hamess,

= The window of the combination motor =

The window of the combination meter may become invisible because of aged deterioration

ccoused by fine sand or dust or ultraviolet. When any flaw or mist is found on the window,

Contact our branch offices or designated factory

[— IMPORTANT =

Hydraulic oil iter warning lamp may go on when the engine rpm is increased before

the engine has been warmed up enough. Keep the engine idling until the lamp goes

off, before starting your work.

In that case, warm up the engine sufficiently, and operate the machine after the

‘warning light has gone out. When the warning light will not go out, the filter may be

clogging up. Check the fiter.

2.13 Switches

‘Starter switch

Starts and stops the engine,

HEAT : When the engine is cold, hold the starter swith in

the HEAT position, the heater indicator lamp will

{99 on. Stay in that postion until the indicator lamp

{9086 of, Reloase the switch key when the indicator

lamp goes oft The key will automaticaly retun

to the OFF postion. Tur the key tothe START

poston to start the engine.

OFF: The key can be removed in this positon. All the

electric systems are snitched off. To shut down,

the engine, move the key to this positon.

(ON: The charging circuit and lamp circuit are charged with electricity. Let the key stay in

this position after the engine has started

START: The engine is eranked and gots started, The moment the engine has started,

‘lease the key, It wll automatically return to the ON position.

Lamp switch

Has three postions.

‘© : Alllamps are sutched of

2D : Each gauge lamp and the headlamps become

bright ©.

BY: Inadstion, th flood lamps become bright.

Atthis time, an icon. on monitor display will go on

"Tum signal lover

“Turn signal lamp flashes when the tur signal lever is operated.

Lettturn: Move the lever forward.

Right tum: Move the lever backward.

NOTE: The lever does not return to the OFF position

‘von ifthe steering wheel is turned back

it

(Parking brake switch

tt owten @ ts prossod down, ho parking brake apples

wih the indicator amp (B) on the monitor display ighted

“.

Winen pressed agin, the brake is released andthe

indeatr lamp goes of

‘AWaRNING

‘+ To disengage the brake, be sure to press the

‘switch again Instead of pulling it.

‘+ When dismounting from the machine, press the

‘switch to apply the brake without fai

caution

‘+ Never pull the switch UP.

parking brake remains applied.

[— Important

Inan emergency, press the parking brake swich.

‘Speed shift switch

Solocts vehicle speed ranges,

Place the switch atthe desired positon

“+ If tho engine is shut down with the parking brake switch pushed down, the

Swaez TWEE

cg | 0~ 8.0mm | 0~9.0 kev

Cw (o~Simieh) | (O~S.émitem)

0~ 12.0 km | 0~ 120 umm

wor | Zemin | O~ Teen

aso TWSDST

o~75kvn | 0~9.0 kmh

tow | OX aTmiem | O~Semitem

o~100kmm | 0~ 12.0 emi

ot Go | Oxia) | amie

(OPERATION

—&

Spead ait nn

‘2. OPERATION

Horn snitch button

Pressing the bution at the center of the steering wheel

‘makes the horn sound.

‘Sprinkler switch a

‘ON : Set the liquid spray switch to ON postion to start ofe ON

spraying, The indication lamp of monitor YN

display lights up.

‘OFF: When spray is stopped, the indication lamp of

‘monitor display is turned of.

Liquid spray switch | crwwgs2-, TW502S-1 only)

Liquidis sprayed wien switch) i prossed

Spraying is shut of the snitch is released

Wil the laud is lng sprayed, the spay indication

lamp oft quid lights up.

[— AcauTion

‘+ Never pull the switch UP.

*+ Driving the liquid spray pump with the liquid

tank empty will damage the pump.

Pay attention to the liquid level in the tank.

Vibrator switch

Selects we choices; FP made and AUTO mode.

Sala ethor mode ooo tj Foqutemont

FF mode: when this modes seeced the vibrator

oes ro ation, Te indeaton tmp WV" of

menior splay igh up atthe same tne

“The vibrator continuous o werk nls the

engine's shutdown or the wbrator sch is

hited to the OFF poston,

OFF: ibratione shat of

‘AZTO modo: vation i ganerated only when the machine is traveling Vibration f shut

down when the Fever moved back the neutral poston

The indication lamp VV of monitor display lights up only for vibration.

(mat control of th vibrators also made by he

pusbtons proved onto lfshand and igithand FR Gqoe

[oor Prose traf hom to work the ibrar. Press

tgnin to eu of bran j

Eneue tal he vbratlon mode selector itch on Tf

the nsturumentpanalis inthe * "postion whon

opoaing the pusuton echo! Vine mi

NOTE: For vibratory compaction, run the engine at 2,200 min" (rpm) or higher.

Incline the throtl lever or forward/backward lever to adjust the vibration pressure

transmission on slope so that the engine rpm may be 2,200 min (rpm) or more.

~ IMPORTANT.

‘+ Do not operate the vibrator on a hard area such as cement concrete pavement

‘surface or the ground covered by thick steel sheets.

‘+ Keep the vibrator stopped when the machine is at rest.

‘+ Shut off the vibrator immediately when the machine has been caught in the mud

‘during vibratory operation.

Vibration selector switch | (SW502-1, TWS02S-* only)

The amplitude of vibration can be changed

Select the amplitude according o the cont

position: Causes vibration to start with low amplitude,

Wi Position: Causes vibration to stat with high amplitude.

2:14 Operating lovers and pedals

Forwardreverse lever (F-A lover) with vibrator switch

‘Moving the F-R lever forward or backward makes the Se

‘machine travel forward or backward respectively. The

voraton ON/OFF

‘neutral position brings the machine toa stop. The vehicle |= Orem

‘speed increases or decreases in proportion to the lever ween

displacement,

“The vibrator ON-OFF controlis easily made by the FR @Revane

lever top vibrator switch (See page 25)

— IMPORTANT —_—____—

‘+ For normal braking, return the F-R lever back to neutral

‘+ Inan emergency, depress the brake pedal.

+ This provides a quick braking with the F-R lever brought to the neutral position (@)

through a mechanical linkage

‘Throttle lever

Shifts the engine RPM.

The engine RPM increases when moved toward the

operator.

[Unioader valve

“The unloader valve disengages the

dive, playing a role lke a clutch. Use

this valve for towing the machine wen

the engine is disabled or when troubles

have developed in the hydraulic dive.

Use the valve only for towing,

For Towing

“Turn the valve counterclockwise to

the fully open position

For normal traveling:

“Turn the valve clockwise to make

sure it reaches tothe fully closed

position,

‘OPERATION

WARNING

+ Ona slope, chock the wheels and use extreme care when handling the unloader

lever and towing the machine.

‘+ Be sure to apply the parking brake when operating the unloader lever.

NOTE: For normal travel, be sure to hold the lever the ONLOAD postion.

Brake pedal

Inn emergency, push down on the pedal tothe full extent, and the machine will come to a

‘sudden stop.

IMPORTANT

Do not use the pedal wherever practicable except for an emergency. If used during

the compacting operation of asphalt pavement, this can cause damage to its

url

NOTE: Depressing the brake pedal brings the F-R lever into neutral ().

2:45 Fuse box

‘A.WARNING

‘When changing a fuse, cut the power supply by turning the starter switch to the

OFF position.

Fuses protect electrical components and witing

from burning. Change any fuse which has become

powder-coated due to deterioration or which has a

play betwoen it and fuse holder. To replace fuses,

take off the cover. Be sure to use fuses of correct

capacity

ota 20K Spare hes)

ling and Adjustments

adjustment

‘Adjust tho seat for your best operating poston. Move tho

lever as shown by arrow. With the lever held in that position,

slide the seat fonvard or backward as desired. When

property adjusted, release the lever.

warning ——____—

‘The adjustment will be necessary when operating the machine first or when

operators are alternated.

2.2.2 Seraper adjustment and replacement

Fol scraper

1) Clearance adjustment of scraper blades ©

‘Loosen set bots @ at2 locations.

® Loosen nuts © at 2 locations. Side blade @ unt

they make contact with the rol

@Tighien nuts © atthe position whee the blade

touches the rol.

@Make adjustment wit set bot © again so thatthe

clearance betwoen the roll and blade wil be 0.5 mm.

2) Replacement of scraper blades

(Remove nuts © at2 locations and bolts @ at 4

locations each

®Replace blades @ with new ones.

@Retit and retighten bolts @

“Tre scraper (Rear wheels of TW352s, TW502S.\)

4) Clearance adjustment of scraper @

Loosen set bots at 2 locations.

®oosen nuts © at 2 locations, Sie blades @ until

‘they make contact with te tre

@Tighten nuts © atthe postion where the blade

touches the tire.

@djust set bot @ to provide a clearance of tmm

(0.038in) between scraper blades @) and ties.

2) Replacement of blades ®

@Remove nuts © and bolts @ at 2 locations.

@Replace blades ® with new ones.

@Roft and retighton bots @

— & caution ——. —

I the blade makes a close contact with the tire, the blade bites the tire in the

rotating direction. |

‘This can cause damage to the tire or blade To avold this, leave a clearance of about

mm.

NOTE: Itis possible to raiso the scraper so that it will not be in contact with the roll during

‘operation.

pe A warning

‘+ Hold blade @ and raise it slowly so that your hand will not be caught between the

roll and blade.

‘+ When returning raised @ to the original position, exercise care so that your hand

will not be caught between the roll and blade.

‘OPERATION

2.2.3 Disengaging the brake when towing

——]

‘AWaRNING

(Ona slope, chock the drums and prepare for towing before disengaging the brake.

1) Front and roar brakes (SW352.1, SW502s)

Front brake (TWS521, TW502S-1)

‘Ramove tho brake release bolls and washers.

(1 location) from the machine frame.

@Rlemove the plug ofthe hydraulic motor.

Pat the bol through the washer into the plug hole

And tighton the bol. The brake willbe released

‘when the bolt is tightened to a certain extent

@When towing is complete, set the bolts and washers:

in the original position and fi the plugs in the motors

securely,

AWaRNING ———

+ For the brake disengagement, wear hard hat

and safety goggles.

*+ Do not try to release the brake immediately

after a hot engine has been stopped. Let the e 6 @

cil cool down. af

2) Rear brake (TW3521, TW502S4)

(@Romove the protection cover of the hose for rear

whoo!

@Pramave the plug ofthe hydraulic motor.

Put the protective cover mounting bolt and washer

into the plug hole and tighten the bot. The brake will

be released when the bot is tightened to a certain,

extent,

@ ter traction, attach the bolt and washer back to

the original position, and tighten the plug to attach it

‘completely to the motor.

NOTE: Perform the work rapidly, as the oil wil gush out

a the plugs are taken of.

Wash clean the brake release bolts and blank

plugs before fiting to the motors,

2.3 Operation

AWaRNING

+ This machine is a one-man roller

+ Operate the machine from th

2.3.1 Before-starting inspection

4) Cheok thatthe steering lock pin isin the carrying

position,

/— AWwaRNinc.

in the carrying position before putting the machine

In motion. Steering is impossible if the pin is in the

steering lock position.

NOTE: Mount the removed lock pin in the innermost

‘section of the step atthe lft ofthe vehicle.

2) Check that the F-F lever Is in the neutral position (@).

NOTE: The engine does not start duo to an interlocking

systom ifthe F-R lover isnot in the neutral

position (@). Ensure that the F-R levers in the

reutral position (@) before starting.

Make sure that the steering lock pin is connected

2. OPERATION

© rorwa

alle

Drovers

(2 openarion ——]

2.82 Starting the engine

4 WARNING ————

‘Check that the F-R lever is in the neutral position, and sound the horn when starting

that there are no one and no objects close to the

41) Set the throttle lever in a position slighty higher than IDLING.

Q~

2) Tum the starter switch to the ON position and chock

‘that the warning lamps and parking brake indicator

lamp on the monitor splay are on,

83) In cold woathor, hold the startor switch in the HEAT

position until the heater indicator lamp @@) goes

‘on. Let the switch key o stay inthis positon til the

indicator lamp goes off. Now the engine is ready to

start

a (OPERATION

44) Turning the key to the START postion makes the

‘engine start, Release the key the moment the engine

thas started. The key will automatically return to the ON

position.

caution ——

‘+ Do not allow the starter key to stay in the START position for more than 15

‘seconds.

‘+ Ifthe engine does not start, wait for about 30 seconds before attempting to

restart it.

‘+ Check that the warning lamps on the monitor display go off immediately after the

‘engine is started. If any of these warning lamps becomes bright while the engine

is running, shut down the machine, determine the cause and rectify the faul

2.8.8 After starting the engine

Try not to move to operation immectately after starting but observe the following:

IMPORTANT 7

‘Avoid increasing the engine speed abruptly before warming-up run is completed.

4) Run the engine at around 1,200 min* (rpm) for about § minutes to warm it up. Warming-

up run allows the lubricating ol to reach the vital parts ofthe engine and hydraulic system,

‘while gradually bringing up the engine oil and hydraulic oll to the working temperature.

2) After the warm-up operation, check that:

‘Temperature gauge Pointer falls near the center zone.

+ Fuel gauge .. PPointr fas between tho E and F marks

+ Charge lamp ‘Has gone of

+ Engine oll pressure warning lamp....Has gone of.

8) Check forthe color of exhaust gas, listen for unusual sounds and vibration. f abnormal,

rome

‘When starting, operate the horn after securing the safety around the

machine. Clear

SWROEL TEST

o~75kmh | 0~8.0 kwh

tow “| omarion | @~S.6mitem)

o~ 100mm | 0~ 12.0 kon

wie foe | (o=c2miem | (0~7 Smien)

;— &cauTion ——

Inert the engine pm when the apeed change

tithe sotto HIGH SPEED ( )

;— @warning ———___________

‘Ona slope, run the machine at low speed. Do not

attempt to shift speed while travelling,

2) Speed up the engine by pulling the throtl lever towards you.

°

)

2)

19g

Fal tte

Ee ‘OPERATION |

5) Press down the parking brake svitch to release the

brake. Check that indicator lamp (B} on the monitor

splay goes of.

4) Move the F-R lever inthe direction to travel, and the

‘machine wil begin traveling

-— caution —

‘Avold abrupt operation of the F-R lever.

NOTE: The travel speed can be controled by the throttle

lever and F-F lover.

Increase the engine RPM when starting ofthe vehicle and when the engine speed

drops drastically while driving.

A.WARNING

Pay extreme attention to the area behind the machine when backing, since the

‘space just behind it tends to be a blind spot.

2.3.5 Stopping / Parking

warning

‘Avoid abrupt braking. Try to leave enough time for braking.

+ Avoid parking on a grad

+ H necessary to park on a grade wheel to prevent unexpected moving down the

grade.

1) Bring the F-A lever tothe neutral position (@), and the

machine wil come to aha 52

— A caution | due”

For normal braking, move the F-R lever back to Teme

Fernermaltrrameremereiembeckie, | ae]

brake pedal Crowne

‘OPERATION

2) Press the parking switch securely, and check that

indicator lamp (9) tluminates.

2.3.6 Stopping the Engine

1) Gradually cool down the engine at low ing for about § minutes.

IMPORTANT

‘+ Do not bring a hot engine to a sudden stop except for an emergency. This will

‘shorten the life ofits component parts.

‘+ Do not also allow an overheated engine to come to a sudden stop, but run it at

middle idling speed for gradual cooling down.

2) Tum the starter key to the OFF postion to stop the

engine.

@cauTiON

Do not turn the starter switch OFF while the

machine is in motion.

3) Remove the starter key.

‘WARNING ——

‘+ When dismounting from the machine, apply the brake by pressing the parking

switch button. If necessary to park on a grade, block the wheels to prevent

unexpected moving down the grade.

+ Never fall to remove the starter key.

z OPERATION.

2.3.7 Check after Stopping the Engine

1) Perform the walk-around checks for oil and water leakage, abnormal signs around the

‘drums.

2) Fil the fuol tank

'8) Remove waste paper if any from the engine compartment, as this will pose a possible fre

hazard,

4) Scrape mud or other materials from and around the drums. For transportation, obey trafic

regulations.

2.4 Vibratory Operation

4} Run the engine at 2,200min* (rpm) or higher by

operating the thot lever.

2) Select AUTO mode or FP mode depending upon ob

eromer

Fe mode: Vibration is generated when the selector

snitch set nthe i" poston. The

indication lamp "St monitor display fA

tights up al the same time. vation ls

shut of ony when the selector sch

is sett the OFF poston or when th

engin ish down,

OF: Vibrations shut of

[AUTO mode: Vibrator works ony when the machines

traveling Vato esto to FR

lever brought back to net

The indication lamp J" of monitor

display lights up only for vibration.

no control ofthe vibrator i also made by the —

pushbuttons provided on the left-hand and right-hand FA ope

levers, Press ethor of them to work the vibrator Press |

again o shut of vibration

Enaure that he vibration mode selector sth on the

insturument panel is inthe "§7°* position when operating :

the pushbuton sutches. Verto eveh

{For sW502., TW5028. ony yaw

“Tho amplitude of vibration can be changed to low or high,

Select the amplitude according to the condtion ofthe

work ste.

8) Proper travel speed for vibratory compaction is 2 ~ 5 kmh (1.2mile /h ~ 3.tmile/h),

however, select speeds depending upon job requirements.

AcauTION

+ Keep the vibrator shut off when the machine is not rolling.

‘+ Stop vibration ifthe machine has encountered a running difficulty, for example,

when it gets stuck in the mud.

2.5 Sprinkler

41) Before spirnkling, check for the water level inthe

sprinkler tank with the sight gauge. Add water as.

necessary.

IMPORTANT

Use clean water wherever practicable.

*Sprinkling on the front roll only (TW352:, TW502S- only)

Before sprinkling, lose the sprinkler valve located at

the flower boad,

2) Tun tho spin switch othe ON poston. Speing

willbe performed. The indication lamp & of monitor R

Silay hghts up athe same te. To sul of spring, of

Sand the indication lamp of mentor dpi is tuned of,

Sate sch to the OFF postion

0108

‘+ Pay attention to the water level inthe sprinkler tank. If the pump operates with the

tank empty, this will cause a pump failure.

+ To avoid freezing, fully drain the sprinkler tank, pump, sprinkler piping, and fiter

in cold weather.

= 2. OPERATION

To drain water:

1) Tum sprinkler tank drain plug @ counter-clockwise and completely drain the tank.

(Be careful so as not to lose the packing ater removal)

2) Fully close sprinkler tank selector valve (), and then open sprinkler filter drain cock @),

sprinker pump drain cock ©), and other drain cocks @)69 Oto completely discharge

water

28) Open sprinkler pipe drain cock @ at the front and rear to completely discharge water

4) Aftor confirming tha the sprinkler tank is empiied completely, ile the sprinkler

pump while al the drain cocks are open inorder to completely discharge water from

the pump

5) Alco drain the hoses, pump and sprinkler nozzles.

2. OPERATION =

AcauTION

+ Open the sprinkler tank cap when draining.

+ Open the respective cocks when itis cold or after work.

+ Open the sprinkler tank selector valve during sprinkling, and close all the cocks

‘except ©) before turning on the sprinkler switch.

{After confirming that water comes out, close cock ©).

Method of antireezing solution circulation in cold weather =

‘Be sure to conduct the operation shown below when there is a fear of freezing.

1) Remove drain cap @ ofthe sprinkle tank to discharge water.

(Exercise care so as not to lose the packing after removal.)

2) Set the selector cock ® under the driver's seat inthe position that permits suction

{rom the antifreszing solution tank.

8) Put antireezing solution into antitreezing solution tank © at lef.

4) Close cock @ of the sprinkler fier.

5) Close drain cock © ofthe sprinkler pump and other cocks 69 (D.

(Open cook 6) .)

6) Close sprinkler pipe cock ® at the front and rear

7) Tura on the sprinkler switch to check that the antireezing solution comes out of the

‘cock @}. After confirming thatthe antifreezing solution comes oul, close cock )

£8) Check thatthe antieezing solution comes out ofthe sprinkler nozzle.

Co rerio”

2.6 Liquid Sprayer (1¥/352s, TW502S- only)

1) Before spraying, check forthe quid level in the tank. 7

Pid a nosey Nai

Look at the tank under the right side ofthe driver seat \.

to check the liquid level

2) Tum the liquid spray quantity

Control valve on the liquid pipe

clockwise tothe utmost extent

3) The tqud is sprayed over he tres Press the uid

spray Sultch to spay, andthe indication lamp & of

montor display ight Up. Spraying is shuts of, andthe

indeation lamp of mentor cpl is tured of when the

‘with i reloased. A vais located the quid spray

Pipe to adjust preying. To increase spraying, tur the

knob clockwise, For reduced spray, rotate counter

clockse.

NOTE: I the liquid isnot sprayed from the nozzle even when pressing the liquid spray switch,

fully open the liquid spray quantity control valve and press the liqud spray switch

again to remove air in the circuit

O __ Adjustment of nozzle extension width

‘When spraying the tires with liquid, adjust the

nozzle extension wicth so that the liquid will not be

“sprayed beyond the tire.

‘Operate the iquid spray quantity control valve on

the liquid pipes of the front and rear tres to adjust

the nozzle extension width.

“Turn the valve counterclockwise

‘The nozzle extension width will increase,

(The spraying quantity increases.)

“Turn the valve clockwise,

‘The nozzle extension width wil decrease.

(The spraying quantity decreases.)

p= ca t90N A

‘+ For spraying, use the smallest amount possible. Excessive spraying can cause

ppromature wear of tires, their deformation and adverse effect on the pavement

surface.

‘+ Driving the liquid spray pump with the liquid tank empty will damage the pump.

Pay attention to the liquid level in the tank.

‘+ For along storage of the machine, drain the liquid through the drain hole.

2.7 Precautions for Work

2.71 Compaction operation

Do not operate the vibrator on hard location

+ Do not work the vibrator on a hard surface such as concrete pavement, as this can cause

‘the machine fo jump and give abnormal shock load, Damage to shock isolators wil result,

Change the direction of travel gently.

‘+ When changing the direction of travel during asphalt mix compaction, slow shift the F-R.

lever.

NOTE: Increase the engine RPM when the engine speed drops drastically during roting

‘compaction.

2.72 When going downhill

Hse the F-R lever.

Run slowly by the operation ofthe F-R lever even ifthe travel distance is short.

Use the engine brake

‘Go downhill by applying the engine brake along with the F-R lever operation

pang

‘When going uphill, run at low speed. Do not attempt to shift speeds during

travelling. The machine can slip down the slope.

ADANGER!

‘Travel downhill with the F-R levers half tited (half stroke) using caution not to allow

the engine to exceed 1,800min" (rpm).

273 Onaslope

Working on a sidebill

Work in an uphil/downhil direction, and avoid working on sidehil withthe machine

Incining sideways:

ee 71)

2.8 Applicable Jobs

‘The machines do a variety of jobs as listed below:

Work

+ Asphalt road paving + Construction of forestry and farm roads

+ Dust removal treatment for road + Foundation building

‘Road improvement * Construction of sidewalk, shoulder

‘+ Embankment construction ‘and gutter foundation

+ Dam construction

‘Material to be compacted

+ Asphalt pavement + Soils

+ Crusher run + Slag

+ Cement concrete + Softrock.

+ Sands

Layers to be compacted

+ Surface course, Binder course + Embankment

+ Base course + Shoulder

+ Subgrade + Sidewalk

2.9 After Operation

Check for tho Goolant tomperature, engine ol prossure and fuel level. Follow the procedures

blow to prevent the machine from falling into an unworkable condition the following morning

caused by muds and other extraneous matter onthe drum, or frozen drums:

1) Remove muds and water from the machine. Muds can get into the seals together with

water drops on the hydraulic cylinder piston od. Damaged seals will result,

2) Park the machine on a hard and dry surface. If such a place is not avilable, cover the

{ground with hard plates.

3) Low temperature will cause a significant reduction of battery efficiency. Cover batteries oF

take them off from the machine and store in a warm place forthe following day's operation

4) To avoid freezing, fully drain the sprinkler tank, pipes, iter and pump in cold weather(See

page 39).

IMPORTANT

‘+ Drain water completely from the sprinkler system, as remai

‘damage to the system.

‘+ Do not wash clean with high pressure water around the instrument panel or

reverse side of the dash board. This can cause instrument failures.

ing water can cause

2. OPERATION =

2.10 Loading and Unloading

warning ___________

+ Use sturdy ramps with proper width, length and thickness which allow safe

loading and unloading.

+ Ifthe ramps deflect considerably under load, apply wooden blocks to reinforce

them.

‘+ Loading should be conducted on a level and hard ground. Leave a sufficient

distance between the machine and the shoulder.

+ To prevent slippage on the ramps, keep the drums free from mud, cils, ete. The

ramps must also be free of grease, oll an

+ Do not steer the machine on the ramps. I the machine is facing in the wrong

direction, allow it to dismount from the ramps and correct the direction.

For loading and unloading, use ramps or a proper loading stand.

2.4101 Use of a trailer equipped with a winch

warning

‘+ Placing the unloader in UNLOAD position disrupts the power for traction. Do not

center the areas ahead of and behind the machine. Its very dangerou

‘+ Do not wash the area around the meter panel and the back of the instrument

panel with pressure, otherwise the instrument and equipment may fa

1) Engage the traler brake and chock its wheels

Fix the ramps so that the machine and trailer are

‘completely aligned.

+4 The angle between the ramps and ground must be

less than 15 degrees.

+ Leave a proper space between the ramps

according tothe width of the rollor drum.

2) Decide the correct direction of run and make the

‘machine run forward tothe ramps.

[aaa eee

8) Draw the wire rope from the trailer winch and put

its hook on the hooking point © or @) of the roller,

4) Place the unioader valve to the UNLOAD poston (Sée

“Unloader vale! on page 26). The unloador valve is

locate inside the engine room

'5) With the engine running at idle, perform loading by

means ofthe trailer winch,

6) When the loading is completed, set the unloader valve

back in the ONLOAD position.

7) Locate the machine correctly on the trailer.

2.10.2 Self-propelling

41) Engage the trailer brake and chook its wheels. Fix the ramps so that the machine and

trailer are completely aligned,

+ The angle between the ramps and ground must be

less than 15 degrees.

+ Leave a proper space between the ramps

‘according tothe width of the roller drum. ean 5°

2) Decide the correct direction of run and conduct loading

or unloading at low speed,

i

For loading, run backward at low spoad.

For unloading, run forward at low speed.

3) Locate the machine correctly onthe tral.

‘2. OPERATION — a]

2.11 After Loading the Machine

\Whon the machine has been located property onthe trae, tie it down as follows:

1) Press the Barking switch button to apply the parking brake. Place wooden blocks under the

drums to prevent movement

2) Fix the machine with ropes ted atthe front and rear towing hook holes. Particularly, pay

attention to sidewise skidding.

2.12 Transportation

warning

‘To decide the transporting route, check the width of the road, height and weight

(including the roller) of the trailer. Obey relevant regulations.

For transportation, obey traffic regulations.

2.13 Operation in Cold Weather

inrcold weather, fake the following moasures to prevent roubles such as stating difeuty and

coolant treezo-up.

2.13.1 Fuel oil and grea:

Use fuel and oll with low viscosity, See “Rating” on page 85.

‘2 OPERATION

213.2 Coolant

FB NG aaa

Do not bring an open flame to the untifroaze or do not smoke when handling it It is

inflammable.

j— caution,

Never use methanol, ethanol- and propanol-base antifreeze.

Use soft water for coolant.

In freezing weather, add antifreeze to the coolant referring tothe table below. Select the most

suitable mix ratio according the lowest temperature in the job location.

sw9521, T5241 (oal)

=e | 2c | re | ec | we

eam | caer | Con | @2n | (22F

‘Amount ot antifreeze | 2.0608) | 262(07) | 280007) | 204006) | 174104)

‘Ambient temperature

“Amount of coolant 2ec(os) | s2ecs)| s5e(os) | aee(i | 414i)

Ratio 50% om 40% 35% 30%

‘sw502, TW5028.

temperature | S86 | 206 8 | 10

Cedaaeelaian a) | 4e'F @27 | c2zF

Amount of antitweoze | 35¢(09) | 324008) | 284007) | 254(07) | 21408)

‘Amount of coolant 35409 | saeito | a2ectn | asec | aoe)

Ratio 60% 45% 40% 35% 30%

‘The SW/TW rolls use a long-life coolant (non-amine type for general location: 36% in

concentration; for cold places: 50%). Chango the coolant a lease every two years.

Use non-amine type long-life coolant when changing coolant.

IMPORTANT ———

Use of machine with a rich coolant in summer time can overheat the engine

depending job conditions.

Use a coolant of 30% solution in the hot season.

“OPERATION

2.13.3 Battery

(— @warnina

+ Battories generate explosive gases. Do not use an open flame close to batteries.

+ The battery electrolyte is corrosive. Keep the electrolyte away from your eyes and

skin. If you are affected by the electrolyte, flush with large quantities of water and

get medical help. >

‘When the temperature decreases, the battery capacity wil ower, possibly freezing the

electrolyte.

Keep the battery in satisfactory condition at all times, and pay attention to heat insulation for

satisfactory start-up on the next morning,

‘The hydrometer atop the battery permits confirmation ofthe condition ofthe battery

Green Satisfactory

Black Charging is necessary.

‘Semitransparent~~- Replacement is necessary.

2.14 When the Cold Season is Over

‘When winter is over and the warm season has come, proceed as follows:

41) Change oil and fuel with those for use in warm season refering o “Rating” on page 85.

2) I{AF-PT antitreezo isin use, drain the coolant completely, wash clean inside the cooling

system, and then fil wth clean water (cy water,

|

2.15 For a Long Storage Period

For leaving the machine unused for longer than one month, proceed as follows:

41) Store the machine ina closed area after cleaning,

2) Conduct oiling, greasing and changing of ol

8) Grease lubricate the exposed portion of hydraulic cylinder piston rods.

4) Cover the battery aftr disconnecting the negative cable or take off the battry from the

‘machine and store in a safe place.

5) Ifthe temperature is expected to go down below 0°C, add antifreeze tothe coolant

6) Completely drain the sprinkler water.

7) Place the F-F lever in the neutral position (@), turn the vibrator and sprinkler switches off

and apply the parking brake.

8) Chock the machine.

9} Fremove the starter switch key.

2.16 During the Storage Period

A waanine

| teceesary to operate the machine for anti-corrosive

purpose in closed area, ensure good ventilation keeping

Windows and doors open to prevent gas poisoning.

+ During storage, operate the machine at least once a month to prevent the ol lms on the

lubricated pars from deteriorating and to charge the batteries

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- RPL - Main Pump PC70-8Document15 pagesRPL - Main Pump PC70-8Irawan Budi SantosaNo ratings yet

- Vibratory Tandem RollerDocument2 pagesVibratory Tandem RollerIrawan Budi SantosaNo ratings yet

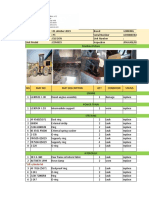

- Surat Pengiriman Barang (Delivery Notes) : PT PP Presisi Doc. No: ... /PD/XI/2021Document3 pagesSurat Pengiriman Barang (Delivery Notes) : PT PP Presisi Doc. No: ... /PD/XI/2021Irawan Budi SantosaNo ratings yet

- Category Fast Moving20211123 - 18160290Document1 pageCategory Fast Moving20211123 - 18160290Irawan Budi SantosaNo ratings yet

- Series: Vibratory Tandem RollerDocument2 pagesSeries: Vibratory Tandem RollerIrawan Budi SantosaNo ratings yet

- PRS Lonking 833 CilegonDocument4 pagesPRS Lonking 833 CilegonIrawan Budi SantosaNo ratings yet