Professional Documents

Culture Documents

Houttuin 249.40

Houttuin 249.40

Uploaded by

Raymond0 ratings0% found this document useful (0 votes)

59 views23 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

59 views23 pagesHouttuin 249.40

Houttuin 249.40

Uploaded by

RaymondCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 23

OPERATING AND MAINTENANCE

INSTRUCTIONS

PUMP TYPE

249.40

To

Pump model

Pump number

Our order

Your order

Order date

Reference

Item number

Destination

Plant

( Batore storing, metalation, operation of mainisnance read iis manual]

ABOUT THIS MANUAL

‘This manual contain deta instructions forte storage, isan, operation and

‘mahtenance ofthe Hout wn sere pump.

‘Toget maximum versa rom the pump ll operators shoud early read an fotow

{henson tis mana

For danting and re-assembly chapter 7 has tobe conse,

Please keep tis manvalin ahandy place nea he purpnt

Warranty

the pumps used fr conditions other than lated nth oder contmation or modified

‘witout wten consent of Hout al guarantee ams boome nai

Dismanting of the screw pump during the pared of guarantee may only be done wth a

‘ror writen consent of Heutun BV, oherse al guarantee clams become nai

‘Acopy of te specie waranty tems applicable to your Houtun product and replacement

pats dan be obtained rom you lal Sales and Service Oca,

Notice

“This document contains propitary ntrmaton, which spotted y copyright. ll ghs

ate reserved. No pat offs document maybe photocopied reprodicod or raneltad 0

‘nother language thou he par writen consort of Houtuin BV.

‘The information contained nts documents ebjeto change witout note.

Service

Forinsalaton, maintenance and pa of he pump you can alway cal the Service

Deparment of Houtuin BV, exparenced sere people ae avalbe on appontment,

Houtun 8.

Service Deparment

Petbue 7

‘500 AB Utecht

‘The Nethetnds

Telephone number: +31 (0)902404611

Fc number #31 (00-241 846

SIGNS :

=

‘Warning for danger

410

an

atta

an

51

82

33

84

TABLE OF CONTENTS

INTRODUCTION

Operating sncile

Shaft sealing afangerents

Rel vale

SAFETY REGULATIONS

Transport

Prepaaton fer istltion

thing

Emergency sop

Pipe accessories

(Check vane

cing of bearings and timing gears

Sarton

Satey valve set pressure

‘TRANSPORT

‘Transport

INSTALLATION

Preparation fo nstalation

Cleaning

Lecaten

Emergency stop

Eating

Foundation

Base plate

‘Algnment of pump and motor

‘Algnment precede fo hrzont mounted pumps

Piping deson

Pipe accessories

Suction eanere

heck vate

(OPERATION

Beto startup

Serip

‘nie the pump sin operation

‘Aor ong te shut Soun

e1

23.

ea

65

92

3

TABLE OF CONTENTS

MAINTENANCE

Scheie

Spare pars

‘breabon table

{breton chart

Bot tohening raves

DISMANTLING AND RE-ASSEMBLY

‘General nsrutons for demanting the srew pump

Dismanting

Re-acembly

‘TROUBLESHOOTING

LONG TERM STORAGE

Prescripton of peservation-intoral

Shaft seal eatment

Prescrpton of preservation - extemal

ENCLOSURES

Drawings

Pars ts

Dociments

1 INTRODUCTION

414 Operating principle see

‘The Houtun gare twin screw pump sa oar postive displacement pure

whieh consis of wo counter rotating ser shat, The cere on tee sats

‘mesh ogetheretaning a ed clearance andotaing ely inside the ner ot

burp cating bores.

‘his creates vacuum (underpressur) that causes the flo flow twa the

up. The pumped ui enters rough the ston. he fw ced ang

fener atthe ends ofthe pump and vares tothe cate ofthe pump and

Ascharge, The cee pat oF te clnders hasan pen canneton towards the

‘decarge

‘The lorque is ranemitod forth diver tyough the ven srew shaft tthe

shot haf by means ofthe timing gears. Boh shal are supped by bearings

‘ad are aly xe a tho non-den end ofthe shat

“The bearings ee net sueced to any oad boca of te hydraulic axial

balance beeen the screws,

. Pb; \ (K\t- =

NN a) :

Fg 1.1 Screws wth timing goa

1.2 Shat sealing arrangements see

‘Due to their specie design, these pumps are executed wth four single

‘mochanial sal. The selon ofthese seal depends on emperture and

Properties ofthe liquid handed 2 wol as on spect opraing condone

1.3 Rit vat ove

“The safety valve connects dlgcharge and sition se of pt ene the

pump aganct over pressive, The vies are leo avalable wh back tank

‘Sesion,

elt va canbe utsas to redice the staring torque Hand whee fate

emits opeing ofthe valve ole the pressure andthe eating org Gurng

Sextp.

2 SAFETY REGULATIONS

24 Transport see

+ Take car when moving he pump. Reugh treatmentor fing nan

Unsuitable way may cause permanent damage. The safe fing methods ae

istatd in chaper Transport.

+The pump shuld nove be ited by tho chaf-ond, Ral valve handuee!

rmayhave tobe removes to aeconmnodatathe ing saps

22 Preparation for Installation +

“After recept each pump should be thoroughly chocked, Damage mus be

reported to the Hout ofc x reprosentatve, athe transportation

‘Company imma. Any clams far damage mst bo known within one

week ater recat ofthe goods.

+ ter eel of the pump, shouldbe stored inary are. The shiping erate

‘Sony suitable fo pote the pump fer amacmurn of80 days afer shoment

tom te factory. This period may be eborter case cl poor atmospheric

‘ondons, Speck poetng far lng tem storage canbe supphed upon

request

2: orthing ove

Ensure that he pumpunt nasa proper ground connection.

24 Emargancy stop oe

outun vies titrate the unit in an emergency sop system,

25 Pipe accossories ove

‘Manmeters shouldbe placed belore and behind th sine fo check when

‘leaning is te card ct,

26 Check valve we

tha dlecharge head i igh andthe viscosity of he ai i ws

Tecommended total a check valve nthe Uscharge ine. This to protect the

prep against reverse rotation nthe event of backflow ven he pump is shut

{down This lz allows parallel operaton of anoter pump Inthe same syst

2 SAFETY REGULATIONS

127.Cooling of bearings and timing gears o

‘+ en the tomperature ofthe lubricating iin tho garsx shuld reach 2

‘maximum oval de tote clon ofthe gears at higher power consumon

tay be necessary to equip Be gearbox with a cooing sytem to cool me

Boaings and ting are

revel contact wih onto. tac amoeratire can ie upto 120°C

ae)

28 Startup oe

“The pump must not be run unless at protective guards supped wth the

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 15 18 128 0R - Catalogue - 12M26.3Document187 pages15 18 128 0R - Catalogue - 12M26.3Raymond100% (1)

- Manual HouttuinDocument31 pagesManual HouttuinRaymondNo ratings yet

- DOOSAN Marine Installation Guide FBHDocument110 pagesDOOSAN Marine Installation Guide FBHRaymond100% (1)

- Damen Stan Tug 1205: General Auxiliary EquipmentDocument2 pagesDamen Stan Tug 1205: General Auxiliary EquipmentRaymondNo ratings yet

- Cargador de Baterias Mastervolt ChargeMasterDocument36 pagesCargador de Baterias Mastervolt ChargeMasterRaymondNo ratings yet

- HVL Electrical Installation (Document File 1)Document431 pagesHVL Electrical Installation (Document File 1)RaymondNo ratings yet

- Impeller Identification Guide: IB-506-Impellerguide-ENDocument16 pagesImpeller Identification Guide: IB-506-Impellerguide-ENRaymondNo ratings yet

- Use With 080 Size 3993 EndcoverDocument67 pagesUse With 080 Size 3993 EndcoverRaymondNo ratings yet

- DBR Gensets DPL120UK Installation, Operation and Maintenance Manual For YN 513510 (MANUAL-I - 2958658 - 1 - A) - 1Document282 pagesDBR Gensets DPL120UK Installation, Operation and Maintenance Manual For YN 513510 (MANUAL-I - 2958658 - 1 - A) - 1RaymondNo ratings yet

- 12 Impeller Replacement: Jabsco - The Original ImpellerDocument10 pages12 Impeller Replacement: Jabsco - The Original ImpellerRaymondNo ratings yet

- Flexible Impeller GuideDocument10 pagesFlexible Impeller GuideRaymondNo ratings yet

- DCU 305 R2 Installation ManualDocument46 pagesDCU 305 R2 Installation ManualRaymondNo ratings yet

- Mx341 Avr SpecsDocument4 pagesMx341 Avr SpecsRaymondNo ratings yet

- Technical Data D7C TA: GeneralDocument2 pagesTechnical Data D7C TA: GeneralRaymondNo ratings yet

- DCU-305-R2 Datos UtilesDocument2 pagesDCU-305-R2 Datos UtilesRaymondNo ratings yet

- Cooling Water Diagram Doosan 4V222TIH KEEL COOLER Bueno para PolargoDocument1 pageCooling Water Diagram Doosan 4V222TIH KEEL COOLER Bueno para PolargoRaymondNo ratings yet

- Catalogo Cylinders For Steering RuddersDocument68 pagesCatalogo Cylinders For Steering RuddersRaymondNo ratings yet

- For Drawing 1695: N-2003 Lillestrøm Sophie Radichs Vei 7 NorwayDocument8 pagesFor Drawing 1695: N-2003 Lillestrøm Sophie Radichs Vei 7 NorwayRaymondNo ratings yet

- DCU 305 R2 Installation ManualDocument46 pagesDCU 305 R2 Installation ManualRaymondNo ratings yet

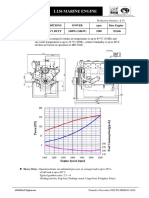

- L136 Marine Engine: Model Conditions Power RPM Base Engine L136 Heavy Duty 160PS (118kW) 2200 D1146Document2 pagesL136 Marine Engine: Model Conditions Power RPM Base Engine L136 Heavy Duty 160PS (118kW) 2200 D1146RaymondNo ratings yet

- QIG Quick Installation Guide DCU 305 A R2Document2 pagesQIG Quick Installation Guide DCU 305 A R2Raymond100% (1)