Professional Documents

Culture Documents

IoT Smart Manufacturing

Uploaded by

HendroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IoT Smart Manufacturing

Uploaded by

HendroCopyright:

Available Formats

Telkomsel provides a one-stop solution for Smart

Manufacturing.

So, end-customers don’t have to worry about connecting different

parts of a complex system.

Device + System Cyber Account After Sales

Consultation Designing Software Integration Connectivity Management Billing

Analytics Security Service

Stage and Key Factor of Industry 4.0

Connectivity

Processes, Peoples and Machines

are connected to improve efficiency

UNDERSTAND

FIND IT FIX IT IT AUTOMATE IT

Optimization

Step 1 : Step 3: Step 4:

Prescriptive Step 2:

High levels of automation to

increase uptime and productivity

What is Why is it What will Autonomous

happening? happening? happen? Action?

Predictive

Agility • Data acquisition • Patterns and

• From knowledge to • Autonomous action

Diagnostic • Implementing MES transparency forecast and machines

Configurable factory layout and • KPI : Advance OEE • Data analysis • Preparation • Self-optimizing

implementation of product change Descriptive scoring (provide • From information to • Predictive system

in real-time symptom & root knowledge/insight capability • From forecast to

cause to prepare • Diagnostic Capability pro-action

Transparency for maintenance) • Advance maintenance • Prescriptive

based on OEE insight:

• Descriptive scheduled maintenance,

Capability

Visibility across all operation to Capability preventive maintenance,

allow real-time decision making continuous base

monitoring (based on

formula algorithm)

Proactive

Starting with data acquisition phase:

Automated restocking, fault

detection, and safety monitoring from paper to paperless, manual to automation Telkomsel Internet of Things 1

Benefits of Implementing Smart

Manufacturing

30% Inventory material cost

21 % Factory Logistic Cost

Parameter Monitored 15% Overall equipment effectiveness

25% Labor Efficiency

Cost Reduction EFFICIENCY

OEE without Software

action will (Software after OEE

be Zero Implementation)

Ensure OEE Implementation

impacts in cost reduction

Parameters : Features:

1. Auto OEE Scoring 1. Alarm & Notifications SMART

2. Info Detail Downtime 2. Real-time Dashboard MANUFACTURING

3. Multi SKU Configuration 3. Machine Learning Algorithm

4. ID Operator, ID Supervisor 4. Multi Flow Process

5. Batch Number 5. Problem / Root cause identification

6. Lot Production

7. Material ID PRODUCTIVITY SAFETY

8. Weighing data acquisition

20% Production Output 25% Hazardous

20% Machine Utilization Operations Injuries

10% Equipment Repair Time 18% Transport

30% Unanticipated breakdowns Accidents

Telkomsel Internet of Things 2

You might also like

- Software Reliability: State of the Art Report 14:2From EverandSoftware Reliability: State of the Art Report 14:2A. BendellNo ratings yet

- Ahead Remotemonitoring: Permanently Monitored For A Personal ServiceDocument2 pagesAhead Remotemonitoring: Permanently Monitored For A Personal ServiceMerouane AmraouiNo ratings yet

- Smart Environments - Cis Professional Services - Devops: - July 2016Document15 pagesSmart Environments - Cis Professional Services - Devops: - July 2016jack_deth100% (1)

- Introduction MachineVision Deck Maret 2021Document42 pagesIntroduction MachineVision Deck Maret 2021andini eldanantyNo ratings yet

- Digital Now - PresentationDocument210 pagesDigital Now - PresentationAgustanto100% (1)

- Optimizing The Total FactoryDocument25 pagesOptimizing The Total FactoryElaine R RiveraNo ratings yet

- ABB Digital Substations - Introduction, Benefits, Solutions, References - ABB 2019Document30 pagesABB Digital Substations - Introduction, Benefits, Solutions, References - ABB 2019MohamedNo ratings yet

- IR4 Productivity & ProfitabilityDocument17 pagesIR4 Productivity & ProfitabilityZamir RashidNo ratings yet

- Focus On Reliability To Improve Availability, Profitability and SafetyDocument9 pagesFocus On Reliability To Improve Availability, Profitability and SafetykEWQ 865kNo ratings yet

- Dynatrace Training BRI Sessi 2Document129 pagesDynatrace Training BRI Sessi 2Muhammad NasrudinNo ratings yet

- Zenoss Solution Overview BrochureDocument8 pagesZenoss Solution Overview BrochurenkibmNo ratings yet

- Pitch - INTERACT Software - July 2022Document10 pagesPitch - INTERACT Software - July 2022Selima BEN MAHMOUDNo ratings yet

- NovelIRS MIRAT PresentationDocument18 pagesNovelIRS MIRAT PresentationPt sinergi teknologi BersatuNo ratings yet

- INS Intro 2021Document65 pagesINS Intro 2021forhometvactNo ratings yet

- Intelligent Automation HealthcareDocument12 pagesIntelligent Automation HealthcarehealthcarelifeproNo ratings yet

- 3 & 8. AVEVA Predictive Asset AnalyticsDocument8 pages3 & 8. AVEVA Predictive Asset AnalyticsTeguh YuliantoNo ratings yet

- Unit 1: Introduction To The Technical ToolingDocument7 pagesUnit 1: Introduction To The Technical ToolingLuciano GlauberNo ratings yet

- openSAP s4h14 Week 1 All Slides PDFDocument79 pagesopenSAP s4h14 Week 1 All Slides PDFSivaramakrishna MandapatiNo ratings yet

- Production Performance Manager: The Industry 4.0 Software Solution For Systematic Improvements To ProductionDocument7 pagesProduction Performance Manager: The Industry 4.0 Software Solution For Systematic Improvements To ProductionValdemar AristaNo ratings yet

- Epicor Informance: Enterprise Manufacturing Intelligence OverviewDocument12 pagesEpicor Informance: Enterprise Manufacturing Intelligence OverviewnkooNo ratings yet

- Robotic Process Automation RPA Bootcamp: Munich, March 7, 2016Document45 pagesRobotic Process Automation RPA Bootcamp: Munich, March 7, 2016shadowantNo ratings yet

- IsenzR PresentationDocument16 pagesIsenzR PresentationdheepmaxNo ratings yet

- IoT Manufacturing Sharing - YogyakartaDocument12 pagesIoT Manufacturing Sharing - YogyakartaBambang Heru PNo ratings yet

- Industry 4.0Document27 pagesIndustry 4.0willy wigia sofyanNo ratings yet

- OMC-Security and ComplianceDocument27 pagesOMC-Security and Complianceanoop666rNo ratings yet

- Introduction To Intelligent Systems and Soft ComputingDocument11 pagesIntroduction To Intelligent Systems and Soft ComputingJoganna JesvanNo ratings yet

- Kaseya Product Presentation Final v2.0Document24 pagesKaseya Product Presentation Final v2.0Kunal PradhanNo ratings yet

- Pr06 - Factorytalk Innovationsuite For Process Control in Plantpax 5.0Document26 pagesPr06 - Factorytalk Innovationsuite For Process Control in Plantpax 5.0mika cabello100% (1)

- Acceldata Pulse SlidesDocument23 pagesAcceldata Pulse SlidesgmalikinNo ratings yet

- Performance: Automated Operations: Ron ColemanDocument11 pagesPerformance: Automated Operations: Ron ColemanAnonymous TnmRw4OAmXNo ratings yet

- Smart Grid Kumud WadhwaDocument52 pagesSmart Grid Kumud WadhwaPMG Bhuswal ProjectNo ratings yet

- Cantier Profile With MES - Industry 4.0 (Partners)Document28 pagesCantier Profile With MES - Industry 4.0 (Partners)lampfievNo ratings yet

- IBM X Celonis For BIAL: Production PlanningDocument9 pagesIBM X Celonis For BIAL: Production Planningmaggi14No ratings yet

- The Digital Mine:: How To Implement Predictive MaintenanceDocument6 pagesThe Digital Mine:: How To Implement Predictive MaintenanceM A GallegosNo ratings yet

- Operational Excellence in IT Service Management: Mehmet Özgür Depren Technical Sales Manager - IBM MiddlewareDocument27 pagesOperational Excellence in IT Service Management: Mehmet Özgür Depren Technical Sales Manager - IBM MiddlewareRiya StephenNo ratings yet

- PentanaBrochure2017 V2 WebDocument3 pagesPentanaBrochure2017 V2 WebamasiddayNo ratings yet

- Brochure - AVEVA InsightDocument8 pagesBrochure - AVEVA InsightEmilio .H.S.No ratings yet

- NSE Insider - Learn How FortiSIEM's New Security Analytics Can Extend Threat Visibility August 11, 2020Document35 pagesNSE Insider - Learn How FortiSIEM's New Security Analytics Can Extend Threat Visibility August 11, 2020fathanNo ratings yet

- Connectivity & Industry 4.0: Claudio Makarovsky - Siemens Oil &gasDocument20 pagesConnectivity & Industry 4.0: Claudio Makarovsky - Siemens Oil &gasnttaiNo ratings yet

- Brochure Accurate Actionable Data Renishaw Central GenDocument5 pagesBrochure Accurate Actionable Data Renishaw Central Genjonny johnNo ratings yet

- IIOTManufacturingDocument17 pagesIIOTManufacturingkedar majethiyaNo ratings yet

- Revolusi Industri 4.0Document7 pagesRevolusi Industri 4.0Jhon WahlaNo ratings yet

- Brochure SE-LIO PredictiveAssetAnalytics 01-18Document8 pagesBrochure SE-LIO PredictiveAssetAnalytics 01-18Karin RodriguezNo ratings yet

- A Four-Step Approach To Predictive Maintenance 4.0Document11 pagesA Four-Step Approach To Predictive Maintenance 4.0Breno ValinhasNo ratings yet

- OPS239006 NCE-T Basic NE Configuration ISSUE19Document72 pagesOPS239006 NCE-T Basic NE Configuration ISSUE19randydooks100% (2)

- When AI Meets Network-New Business With AI, New Era of Standards and IndustryDocument20 pagesWhen AI Meets Network-New Business With AI, New Era of Standards and IndustryM javidNo ratings yet

- Ethernet OverviewDocument50 pagesEthernet OverviewEvando PereiraNo ratings yet

- 340803_SCM – IoT Intelligent Apps Product Development Updates (2022)Document30 pages340803_SCM – IoT Intelligent Apps Product Development Updates (2022)davidjqNo ratings yet

- Remote Admin TrainingDocument196 pagesRemote Admin TrainingRadu DraganNo ratings yet

- Industry4 PKTDocument29 pagesIndustry4 PKTM Humaam AlNo ratings yet

- Weaknesses: Key ChallengesDocument1 pageWeaknesses: Key ChallengesTempNo ratings yet

- Weaknesses: Key ChallengesDocument1 pageWeaknesses: Key ChallengesRishabh PantNo ratings yet

- Industry Solutions Presentation - ISS v1Document40 pagesIndustry Solutions Presentation - ISS v1Abbas HammoudNo ratings yet

- Tenable Slides For PresentationDocument23 pagesTenable Slides For PresentationTofan Dwi ArtaNo ratings yet

- Ir Adv6075 6055 6065 eDocument12 pagesIr Adv6075 6055 6065 evijaiNo ratings yet

- 04 WonderwareDocument19 pages04 WonderwaregpuzoneNo ratings yet

- 02 - Campus Network Intelligent O&M and CampusInsightDocument59 pages02 - Campus Network Intelligent O&M and CampusInsighttran quan hongNo ratings yet

- Basics of MVision PDFDocument3 pagesBasics of MVision PDFkehindeloNo ratings yet

- The Design and Implementation of Geographic Information SystemsFrom EverandThe Design and Implementation of Geographic Information SystemsNo ratings yet

- Hindon Forge V State of UP (Pgs 2, 20 - 21 & 23)Document33 pagesHindon Forge V State of UP (Pgs 2, 20 - 21 & 23)Ekansh AroraNo ratings yet

- Fin358 Chap 4 BondDocument5 pagesFin358 Chap 4 Bondsyaiera aqilahNo ratings yet

- Nur Amaliyah - 041811333032 AKLDocument5 pagesNur Amaliyah - 041811333032 AKLNur AmaliyahNo ratings yet

- 5 - Spa To Transfer TitleDocument2 pages5 - Spa To Transfer TitleAntonio AlfelorNo ratings yet

- Pratik JadhavDocument64 pagesPratik JadhavSandip ChavanNo ratings yet

- InventoryDocument8 pagesInventoryDianna DayawonNo ratings yet

- Minutes of The Meeting Chaired by Secretary MoP On 18th Aug 2015Document65 pagesMinutes of The Meeting Chaired by Secretary MoP On 18th Aug 2015Anshu SinghNo ratings yet

- Brandywine by LawsDocument16 pagesBrandywine by Lawsapi-681087199No ratings yet

- Executive Summary:: The Bank of PunjabDocument40 pagesExecutive Summary:: The Bank of PunjabLucifer Morning starNo ratings yet

- Assignmeliptopnt of LiptonDocument13 pagesAssignmeliptopnt of LiptonKomal Goklani100% (2)

- City of Cleveland Shaker Square Housing ComplaintDocument99 pagesCity of Cleveland Shaker Square Housing ComplaintWKYC.comNo ratings yet

- Addition/Modification/Replacement (Amr) SchemeDocument1 pageAddition/Modification/Replacement (Amr) SchemeDebasis BasaNo ratings yet

- Group 5 BSBA Major in Marketing Block 3 1 Del Monte PhilippinesDocument117 pagesGroup 5 BSBA Major in Marketing Block 3 1 Del Monte PhilippinesChristine Joy MauroNo ratings yet

- Certificate of Motor Insurance: Signedonbehalfof Aviva Insura Nce Limite D (Authorise D Insure RS)Document3 pagesCertificate of Motor Insurance: Signedonbehalfof Aviva Insura Nce Limite D (Authorise D Insure RS)paulNo ratings yet

- Alumni Fee Voucher UpdatedDocument1 pageAlumni Fee Voucher UpdatedHassan KhalidNo ratings yet

- Process Costing Example for Lakeland ChemicalDocument233 pagesProcess Costing Example for Lakeland ChemicalAishwarya Raju0% (1)

- AsterDM Annual Report FY 2019-20Document280 pagesAsterDM Annual Report FY 2019-20Jayaprakash MuthuvatNo ratings yet

- To Prosperity: From DEBTDocument112 pagesTo Prosperity: From DEBTمحمد عبدﷲNo ratings yet

- Commercial RevolutionDocument6 pagesCommercial Revolutionadarsh aryanNo ratings yet

- EXXONMOBIL Strategic Marketing PlanDocument19 pagesEXXONMOBIL Strategic Marketing PlanSaad MalikNo ratings yet

- Section 3 (Other Definition)Document26 pagesSection 3 (Other Definition)jinNo ratings yet

- Sex Toys Market - NewDocument9 pagesSex Toys Market - NewPrasun RaiNo ratings yet

- Due Diligence For IPOsDocument14 pagesDue Diligence For IPOsNishant AnandNo ratings yet

- Valores de Referencia Tumorales Bio RadDocument3 pagesValores de Referencia Tumorales Bio RadorthincoatzaNo ratings yet

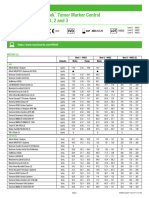

- TXVNM 2019 Dec ADocument8 pagesTXVNM 2019 Dec AMinh AnhNo ratings yet

- Managerial Skills and Roles at Bashundhara GroupDocument31 pagesManagerial Skills and Roles at Bashundhara Grouprythm QUraishiNo ratings yet

- ACCOUNTING 1: KEY DIFFERENCES BETWEEN PERPETUAL AND PERIODIC INVENTORY SYSTEMSDocument45 pagesACCOUNTING 1: KEY DIFFERENCES BETWEEN PERPETUAL AND PERIODIC INVENTORY SYSTEMSKathleen SantiagoNo ratings yet

- An Overview of Support For Women Entrepreneurs in Indonesia and Canada: Focus On Smes and Start-UpsDocument24 pagesAn Overview of Support For Women Entrepreneurs in Indonesia and Canada: Focus On Smes and Start-UpsbuNo ratings yet

- Chapter 22 Homework R. CochranDocument3 pagesChapter 22 Homework R. Cochrancochran123No ratings yet

- Meryl Manalo Minutes of The MeetingDocument3 pagesMeryl Manalo Minutes of The MeetingBoogie San JuanNo ratings yet