Professional Documents

Culture Documents

A1blowers Catalog

A1blowers Catalog

Uploaded by

Support aeronom0 ratings0% found this document useful (0 votes)

11 views8 pagesOriginal Title

a1blowers-catalog

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views8 pagesA1blowers Catalog

A1blowers Catalog

Uploaded by

Support aeronomCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

cAMBlowers

Cau)

l

Looking over the upcoming demand of market, we are an able and agile

e n of Mechanical Engineers dedicated to launching their Product with a

2 ene RRe CM Nan ie Ma Remon nee

a — rete ee OER Rom SR en ee a ees

About Us Sere Se eae remeron me

factor, with very competitive price.

Why A1 Our Soul of Work

ly 11. Trust: We believe over our client

At Al we assure you to provide best Quality 2. Quality: Superior Quality

product with higher Reliability factor.

3, Integrity: Believe in working together

4, Solution: Provide you peace of mind in every aspect.

Solid design : Our compact, sturdy design is engineered for continuous service when operated in accordance

with speed and pressure ratings. Timing Gears are secured to the shaft with taper mountings and locknuts. This

eliminates the need for unreliable taper pins, aiding field maintenance. Spherical roller bearings are engineered

for reliable and long service life. All rotating parts like Impellers and Pulleys are dynamically balanced to avoid

Bieler etal rice

Efficiency and reliability: Each Al Compressor has computer calculated impeller profiles and is precision

machined on the latest CNC equipment assuring close tolerance between the impellers, casing and side plates

to minimize,"back slippage" of air, improving efficiency and reliability.

ST ce oC eo ec eRe eR nee Re Recs el eC ee oe eee ae

tuning and accurate timing of the rotating impellers. A controlled lubrication system is provided to ensure

efficient operation without wastage of energy in the gear case,

Snr ua coca eet a geee acu et el cet re UU A aceite anne U eI ey

cel U ue Mtceelfe eM ol RS a ee Reels ace RUC oom eel ole

site. We also offer quality control program, technical documentation, special calculations, or certicates of

eel oleae oP MP) Elie pc) eaere Marte Lt

Perr ee a eco cm ets eee ec ceca ec eon eee ey

frame, safety valve, suction filter, suction silencer, non-retum valve, pressure gauge, anti-vibration pads, v-belts,

v-belt guard, drive and driven pulleys, set of special tools, foundation bolts and interconnecting piping with

flange or alternately with any of the above items, specified as optional equipment.

ROOTS BLOWERS ‘AQUA SERIES

Al TWIN LOBE ROTARY AIR BLOWERS

{AT has introduced its new range of AQUA Series Twin Lobe Rotary Air Blowers (Roots Blowers) to meet (4

the electroplating & aqua culture requirements which essentially demand 100% Oil Free Air. These

blowers are totally dry machines where lubricating chambers are physically isolated from the main gas

chamber ensuring 100 % Oil Free Air delivery. For ease of operation and maintenance, the inlet and

discharge connections are modified with Suction Top and Discharge Horizontal reducing cumbersome

piping. These blowers have a major advantage over centrifugal and regenerative blowers as they are

more power efficient, can handle high flow rates and are insensitive to water depth variations. They

deliver, practically, a constant flow rate irrespective of back pressures thereby maintaining dissolved

oxygen levels, These machines are very versatile and can be run by electric motors or gensets. They have

low maintenance and no internal adjustments resulting in prolonged trouble free operation

Our technology is so STANDARD DESIGN AND CONSTRUCTION FEATURES

flexible, we can custom 100% oll free air delivery.

manufacture Factory engineered, factory guaranteed, superior product.

“Special Air Blowers" Alloy steel hardened and ground timing gears.

by alloying and cross Anti-friction bearings.

linking diverse designs Rotary oil sealings,

Rigid one piece CI casing and side plates.

Easy rotor timing setting,

to suit individual

requirements and import

e

e

e

e

e

e

e

°

a lg cc Cn

roa} oc Cent

i) Ba)

substitutes. Alloy steel toughened shafts ground to close tolerances.

The above chart gives average displacement (FAD Conditions) & Maxon. Pressures for recommended motors.

Actual flow rates may vary marginally depending upon dischange pressures

PRECAUTION :-

‘© Check the quality ofall resources that are used in the farm.

© Quality of water must be checked periodically.

© Disinfection of vehioles accessing the farm,

© Disinfection of equipment used in handling prawn or shrimps.

© Hygiene of employee must be maintained in the plant. Cc

For Fast Growth of Prawn or Shrimps

‘© Proper aeration should be done so that proper BOD is maintained,

© Clean the tank water periodically

© Maintain moderate temperature condition around 20 to 30 degree.

© High quality feeds should be used.

gaol ea Ue OE MU RCC Re he Mc Rud esa oes lore ood

encom RoR um eo eee

Reena a eae aU!

DE eM EA Ma enone See AEE ed

CTE NR eee tae RCs RRS ene Me Ce Sd

building or shed

SPECIFICATION

Design: The sound reduction enclosures are specially

designed to reduce noise pollution to suit the local

environment. These are engineered to take care of air

intake & outlet, resulting in a pleasing & attractive

design.

Air Circulation : Sufficient cooling air inlet acoustic

louvers and exhaust fans are provided in the

enclosure for efficient air circulation avoiding

derating of the machine.

Construction : The robust body work of sound

reduction enclosures is due to its construction from

preformed heavy gauge sheet steel section and its

reinforcement with fabricated superstructure.

Rubber gaskets are provided to all doors and

external joints to resist weathering. The bolted

superstructure provides easy removal of panels for

maintenance or servicing of blowers.

Installation : The sound reduction enclosures are

preassembled on a support frame and can be easily

& quickly assembled at

TWIN LOBE SERIES BLOWERS

m 1 08 8 Ok Ste ke a

© um & of s6 om 8 16 4 17 OD oO

©

we oR te Mimo is @ in & an a

@ 7 ws 9 if @ iw 8 is @ im 2 im «am 3°

© mm Bin mp i 6 Ga me Bae 5

om te wm 1s @ im © a 8 je 7 Gk oman

o mm ie im ie om amo am haw ee

wo i is in te mn we oe aw 2

a) EAS A aS sess ne

om m le m ie is Ge ip Sa im se i tm ewe fb Be

im ot amass) hea a

2 eet ea ae a eee ace

so 32TH 3S MSAD 8D EFS ae

so ie amen % So

wm 69 3) soho 8

mo mm ie so Ge wt ote woe ee Se

mo 8 42 Sal To STD oO

mm 8 in @ i om 7 Me 3 mua wm me mB 2

= SS Gm i 8 an Ge S sh ae

1) 0 4% G7 AMS a SS Sse 2

2 im SS & ie G as mae ae ae oa

soo 9 SAN HTS TM a8 oO

vo lm le Gn ie in een em 5

te te ua ita im ian te dea @

1 ih 6 Gk ae doe Seeker ee e

oom Soko mh BM we em stews

im 2 1 go bo i is Ba lam ims mes Ee e

io is 38 Om iM Al ot Res) ee

1 me ba ioe Ma ME HS aes e

Be Be Bo DR iw uN BO Bo Bo am ry

Ao Soe ee eee ee oe

© i bs diy Me Im sin ie Gm me mmm ea

oe et ao tay omnia) mle stn

30 dm ss OS Maas eR aD aS TOD EIS SOS HSS Co

m8 oar Gm aw) awl uss

oi Gta om Sk Sim eee Sa) sation sn

Note 1. the above ratings at based on ine temperature of 104 OF, ambien pressure 1 e/em2, space ero 010,

2 sformance testing spe 881573, patil 3, All peiieaons are sujet te change without noi.

A1 offers a wide range of positive displacement, three lobe blowers for use in compressions and vacuum

application for air and other natural gases. The al TRI LOBE. series can deliver pressures upto 1 kg/cm2 with

flow rate from 15 m3 /h to 11000 m3/h,

The blower for high section pressure are with mechanical seal and pressurized lubrication and other design

riers

Jana o0

Meee eae No Ueno

Pacemaker ony

Beeson te)

See en ar Cae

Pasar iel Ngel euler Mater ad

+ Cast iron construction with a damper syste

este

Cee Re NC RT RCL)

ret

Co ee]

Performance Data of TRILOBE Series (Alr Cooled Blowers)

M3 149) 120 Me 279 Y 00 | 93

seo 170] tea as | tas 31a ‘er | te

33

‘oo| toa tar] irae | tae ae tae | tae bso

¥2| 283. as) tes 230 | So 351 | Bo ss] ise Si

iol B38 Pa ee ee

Et 148] 229 12.03| 215 1357

3] 388. 1288 2ie ida

350 275) 310 420 a3] 243 1

ao Sot tow) 3a |

ae & e iar| ars 1413

Set St] 356

tors 567] a6 ex 1B.17| so7 2234] 541 2651] 517 30.58

1287 860] 1196 1180 fi24 2181] 1095 2681| 1009 343] 1045 Sea1

200 | 8 i348 1301] t309_teer| iar 24291 eae der

4200| 1351 6.7| 1301 i224] 1263 i761] i231 2298] 1209 28.30| 1177 Sara] 1154 38.10

4440 | 1645 625| 1895 1469] 1457 2is4| t925 27a] tas? S4os| tari aoa

tego | tett_840| trot _ta2| tre 2a4a| vei Snes] tena rer

Be:

Toor] 1805 ISG rz 1836] Tess 2579] iss 3327) Tea8 ages] TATE aBUR| VAST SES | TSBDSrST

200 | 2219 133] 2118 2203] 2040 3095| tons 3980) 1931 aa7| tan) S79] ina oar | 1790 7552

440 | 2620 $830) 2625 2590) 2409 30%0| 2302 4080) 2330 seoi | 2an9 ays] 2248 P77

(000 | 2806 14-83) 2684 76.16] ‘37.45] 2510 4082] 2441 00.15] 2377

‘200 | 3426 1780) 908 315] aot avea| arar snse| soot 7218]

‘Note: 1. The above ratings ao based on het ar omperatwre of 1040 F, ambient pressure 1 hg/em2. soe aravty of 1.0.

2 Pertrmance testing as per 8S 187", pare

3-Al spectfeatons ao subject fo change witout nota.

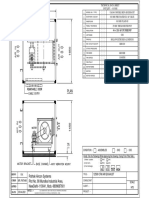

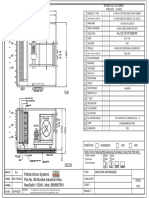

Al DIRECT DRIVE 1HP BLOWER

A1, leading manufacturer of Roots Blowers in India, introduce 1HP Direct Drive Horizontal Twin-Lobe Roots

Blowers. These blowers have been designed keeping the specific demands of the industry of compact & sturdy

machine, reduced noise, minimal space requirements, least vibrations, longer bearing life & minimal

maintenance, in mind,

Complete package units are shipped with all essential accessories & electric motor, ready to install on plug &

play concept. These blowers are designed for continuous duty service & require minimal maintenance. AL

Horizontal Twin-Lobe Blowers come with built-in safety and monitoring equipment such as safety relief valve &

pressure gauge.

These blowers provide 100% Oil Free Air & are extensively used in Sewage Treatment Plants, Effluent Treatment

Plants, Aquaculture, Chemical Plants and Electroplating Plants,

FEATURES

Operation : Al Twin-Lobe rotor enables smooth air output, with less pulsations. This results in a significant

reduction of emitted sound.

A convenient sight glass makes it easy to check oil levels. Drain valve is mounted in the front of the unit, hence

easily accessible

Direct coupled drive resulting in increased drive efficiency, reduced noise and longer service life.

a SPECIFICATIONS

Anti-frication Bearings

Rotary Oil Sealing

Orientation : Vertical Flow

Noise level : 604B(A) From the distance of 1 mtr

Unit Weight :52 Kg, (with 1 HP/1.5 HP, 2 Pole/ 4 Pole motor)

@_ PERFORMANCE TABLE

S© Twin-Lose 1HP DIRECT DRIVE PRESSURE DUTY BLOWER

move. | inyour. sete | rooommivs | 2000mmaws | socommws | sooommvs | sooommwc | sooowmwe | 7000 mmwe

(Gan (am [waynn] euP [ware [one] wayne] onp [warwn [one] ma/ne] one [ mayan] sup] wayne | our

as

twice | 2 90 | 2 ose 2» oso | 2 oe | 9 om | 6 095

asujimo | 2 woo | sos] 6 om | 2 om! 3s roe | 356 as

Conversions: 1 M? /Hr~0.588 CFM~16.67 LPM | 1000 mm WG~1.42 PSI~0.1 Kg/cm?

Note : 1. The above ratings are based on inlet alr temperature of 104 D F, ambient pressure 1 kg/em2, specific gravity of 1.0.

2. Performance testing as per BS 1571, part-ll

3. All specifications are subject to change without notice.

APPLICATIONS

Water Treatment Plants For back washing of flter/mixed beds.

Effluent Treatment Plants For diffused aeration and agitation of effluent.

Cement Plants For Blending, Aeration, Fluiization, Conveying,

‘Aquaculture For maintaining the dissolved Oxygen level

Chemicals Plants For supplying of process air

Electroplating Plants For Oi Fee air agitation of electrolyte

Paper Plants knife edge coating, Drying, Conveying, Vacuum pickup.

Yarn Drying Vacuuny/Pressure Drying of Yarn

Vacuum Moulding For creating quick vacuum,

Polyster Chip Conveying & drying For transfer of polyster Chips and other similar material.

Bag Filters For reverse cleaning of Fite bags.

Pneumatic Conveying Vacuum, Pressure and Combination Conveying of cereals cement, husk, baggage, granules,

powders and other similar materia

© Regeneration of Dryers & Molecular Sieves.

ae!

OUR PRODUCT : elle

Aerie

‘Twin- Lobe Rotary Air Blowers

Tri- Lobe Rotary Air Blowers

‘Twin Lobe Rotary Gas Blowers

‘Twin Lobe Aqua Culture Blowers

Acoustic Hoods

Mechanical Vacuum Boosters

++ et tt

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Company ProfileDocument22 pagesCompany ProfileSupport aeronomNo ratings yet

- Aeap 0645Document2 pagesAeap 0645Support aeronomNo ratings yet

- UAW-200 (20000 CFM) - ModelDocument1 pageUAW-200 (20000 CFM) - ModelSupport aeronomNo ratings yet

- UAE-120 (125000 CFM) - ModelDocument1 pageUAE-120 (125000 CFM) - ModelSupport aeronomNo ratings yet

- Uaw 60 (6000 CFM) ModelDocument1 pageUaw 60 (6000 CFM) ModelSupport aeronomNo ratings yet

- CFM at 120 MMWCDocument1 pageCFM at 120 MMWCSupport aeronomNo ratings yet

- Ahu Detail GFDocument1 pageAhu Detail GFSupport aeronomNo ratings yet

- Technical Data Sheet For Air Washer Unit 10000 CFM AND 25000 CFMDocument3 pagesTechnical Data Sheet For Air Washer Unit 10000 CFM AND 25000 CFMSupport aeronomNo ratings yet

- Grøn Climate Change Presentation Template by SlidecoreDocument15 pagesGrøn Climate Change Presentation Template by SlidecoreSupport aeronomNo ratings yet

- Company Profile AeronomDocument23 pagesCompany Profile AeronomSupport aeronomNo ratings yet

- SS Side Seal: Balance Air Equipment Plot No: 708-709, Sector-2 IMT, Bawal Haryana-123501Document1 pageSS Side Seal: Balance Air Equipment Plot No: 708-709, Sector-2 IMT, Bawal Haryana-123501Support aeronomNo ratings yet

- G.A Drawing Fresh Air Unit 10000 CFMDocument1 pageG.A Drawing Fresh Air Unit 10000 CFMSupport aeronomNo ratings yet