Professional Documents

Culture Documents

Zheng Fei Zhen Guo2003 Article IdentificationOfThePrecipitate

Uploaded by

Praveen CCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zheng Fei Zhen Guo2003 Article IdentificationOfThePrecipitate

Uploaded by

Praveen CCopyright:

Available Formats

JMEPEG (2003) 12:106-111 ©ASM International

Identification of the Precipitates by

TEM and EDS in X20CrMoV12.1 After

Long-Term Service at Elevated Temperature

Hu Zheng-Fei and Yang Zhen-Guo

(Submitted 26 April 2002; in revised form 1 October 2002)

The crystal structures, morphologies, and compositions of carbides in a martensitic pipe steel of type

X20CrMoV12.1 after long-term service at 550 °C have been carefully investigated using transmission

electron microscopy (TEM) and dispersive x-ray spectrometry (EDS). Most of carbides are M23C6. The

M23C6 particles in prior austenite grains and in martensite lath boundaries are extensively coarsened. Most

of the finer carbides within the matrix are also identified as M23C6, and no other type of carbide was found

except for some tiny plate-like V-rich carbides identified as MC. The V and O mass fractions in the M23C6

carbides have variable morphologies and locations, which might be due to their coarsening process. They

are coarsening at different rates even after long-term exposure at elevated temperature. The formation of

V-rich MC during the long-term service contributes to hardness maintenance and is good for microstruc-

tural stability.

Keywords aging, carbide morphology, chromium steel, steel, bides in boundaries; however, the morphologies and character-

X20CrMoV12.1 istics of the carbides in the matrix have not been well reported

and identified.

This article describes detailed results of transmission elec-

tron microscopy (TEM) and dispersive x-ray spectrometer

1. Introduction (EDS) investigation studies of the morphologies and composi-

tional changes of carbides in a main steam pipe of

In the past decades, the 9-12% Cr martensitic steels have X20CrMoV12.1 steel (German grade F12) after 23 years ser-

been widely used as pipework and tubing in the power- vice.

generating industry around the world. To understand the me-

chanical properties of the materials and their behavior in prac-

tical applications, many investigations have undertaken creep 2. Experimental Details

or fatigue tests on materials before and after long-term ser-

vice.[1-3] One of the 12CrMoV steels, standardized for use in The investigated material is a section of 273OD × 26 mm

steam pipes under the German standard DIN17175 designation, thick main steam pipe of X20CrMoV12.1 steel, which had

is X20CrMoV12.1, which has been widely used for steam been in service for 23 years at 550 °C at a pressure of 13.7

pipes in power plants since the 1960s in Europe and other MPa; its chemical composition is given in Table 1.

countries. Some of the steam pipes have been in service more Both the foils and carbon extraction replicas for TEM study

than 20 years, and their mechanical properties and microstruc- were prepared from the material. The foil samples for TEM

tures have degraded. To evaluate or prolong the service time of were cut to about 0.3 mm thick from the sample, and then

those steam pipes, it is important to examine their mechanical normally ground to about 60 m and electropolished in a per-

behavior and microstructural stability. Some of the investiga- chloric acid-alcohol solution at about –20 °C. Carbon extrac-

tions[3,4] for X20CrMoV12.1 steam pipes indicated that severe tion replicas were prepared for carbide identification with TEM

softening did not occur after long-term service exposure at and EDS. A small block of sample was polished and light

elevated temperature. A particularly important aspect of the etched in 5% nital, and then a thin carbon film was evaporated

microstructure is the distribution of carbide particles.[5] Some on it. The film was extracted by floating it in nital and sup-

work on 12CrMoV pipe steels indicated that the carbides of porting it on copper or nylon grids. The extraction replica

M23C6, M7C3, M2X, and MX (M denotes the metal elements, supported on a nylon grid was only for investigation of the

and X denotes non-metallic elements of C and N) were found chemical composition of the carbides. The EDS spectra with

in their as-received heat treatment or after creep exposure test nylon grid samples were obtained without extra peak from the

conditions, which were believed to be decisive factors for pre- grid background, which is convenient for later analysis.

cipitation hardening, as well as high creep strength.[6-8] In the The microstructural investigations were performed by ana-

past, much more attention was paid to the coarsening of car- lytical TEM. The TEM was carried out on both foil samples

and carbon extraction replicas using a PHILIPS (Eindhoven,

Hu Zheng-Fei and Yang Zhen-Guo, Department of Materials Sci- The Netherlands) CM200 TEM operated at 200 kV. Selected

ence, Fudan University, Shanghai 200433, P.R. China. Contact e-mail: area diffraction (SAD) and x-ray microanalysis techniques

zgyang@fudan.edu.cn. were used to identify precipitation phases. As to the examina-

106—Volume 12(1) February 2003 Journal of Materials Engineering and Performance

tion of the very fine precipitates, micro-beam diffraction was 3. Results and Discussion

adopted. In this method, a diffraction pattern is formed by the

finely converged electron beam illuminating only on a very 3.1 The Microstructure of the Examined Material

small area of the specimen. In the present work, an electron

beam of 60 nm was selected to study the very fine precipitates. Figure 1 shows that the microstructure of the examined

An EDAX series DX-4 EDS (EDAX Int. Co., Mahwah, NJ) material is a typical tempered martensite with a high density of

attached to the TEM was used to analyze the compositions of dislocations in the ferrite matrix, and there is no ␦-ferrite ob-

all the carbides. The x-ray spectra were recorded at a sample served. The most distinct microstructure character shown in

tilted 20°, with the converged electron beam illuminating only Fig. 1 is the mass of substructure in the martensite laths, which

the isolated particles. The carbides were classified by mor- developed during the long-term service of the pipe under a

phologies, and more than 10 isolated particles of the same stress. Those substructures are formed by dislocations; a large

appearance were analyzed. The carbon element is not taken number of dislocations gathered together to form subgrain bound-

into account during the measurement of the compositions of the aries and significantly reduced dislocation density in the matrix.

carbides because doing so would introduce a large error. Thus many low dislocation density regions are also seen.

Many of the precipitates can be seen in the examined ma-

Table 1 Chemical Composition of the Examined terial. Figure 1(b) is a TEM image of the corresponding carbon

Material, wt.% extraction replica from the same material. It clearly shows the

distribution of the precipitating carbides; larger carbides are in

C Mn S P Si Cr Mo V Ni Cu prior austenite grain boundaries and in martensite lath bound-

aries, and the smaller carbides are dispersed in the matrix. A

0.23 0.64 0.006 0.02 0.36 11.23 1.00 0.32 0.72 0.08

similar observation has been obtained in 12% Cr heat-resistant

Fig. 1 TEM micrograph of (a) thin foil X20CrMoV12.1 steel service exposed for 23 years at 550 °C and (b) carbon extraction replica from the

same sample; (c) SAD pattern of an interlath particle carbide

Journal of Materials Engineering and Performance Volume 12(1) February 2003—107

Fig. 2 (a) Fine carbides in different morphologies within the matrix; (b) and (c) diffraction patterns for spheroids; (d) diffraction patterns for

rectangle plates (continued on next page)

steels by others.[7,9] The carbides, no matter whether in bound- about 0.35 m on average, and the rest are in the form of an

aries or in matrix, are in various shapes. More detailed inves- irregular spheroid. The intergranular and interlath carbides are

tigations on the morphology and composition are discussed in coarsened distinctly, since their sizes are about twice those

the next section. of the as-received condition measured by Eggeler[11] and Bat-

taini et al.[12]

3.2.2 Carbides Within Matrix. Some much finer carbides

3.2 Identification of Carbide Phases

can be seen within the matrix or in the martensite laths. Those

3.2.1 Carbides in Boundaries. The precipitating carbides fine carbides can be divided roughly into two categories by

in prior austenite boundaries and lath boundaries are well de- morphology; one a rectangular plate and another an irregular

termined by selected area diffraction as M23C6. Figure 1(c) spheroid. Most of the intralath carbides are about 120 nm in

shows a SAD pattern of a particle of carbide in a lath boundary, size, and the smallest is less than 50 nm, which is about 50%

and it is identified as M23C6 in [110] orientation. It is also larger than the statistical values measured by Ennis[13] and by

shown that the M23C6 [110] direction is parallel with the [001] Klimanek et al.[14] It is shown that those carbides are also

of ferrite matrix, which is identical with the relationship of coarsened. Carbides in intralaths are very fine, and in the foil

Singhal and Martin.[10] Most of the carbides in prior austenite sample it is almost impossible to get a clear diffraction spot

grains are in the form of an irregular spheroid with an average pattern of the very small carbides from the thin specimens, due

size in 0.33 m. In contrast, most of the carbides in lath bound- to the interference of the matrix. Therefore, carbon extraction

aries are in a plate-like morphology, with the long dimension replicas were used to determine the structure of the very fine

108—Volume 12(1) February 2003 Journal of Materials Engineering and Performance

Fig. 2 cont. (e) diffraction patterns for rectangle plates; (f) fine V-rich carbides in clustering state, corresponding to diffraction patterns in (g) and (h)

carbides. In the extraction replicas, the carbides lost their origi- bides are in the uniform morphology of rectangular plate within

nal orientation with the matrix. To determine the crystallo- the matrix. They are 100 nm or less; some finer than the M23C6

graphic structure of the fine carbides, micro-beam diffraction particles in varied shapes. In the EDS display they are identi-

studies were performed on the fine carbide particles in the fied as V-rich carbides. They are distributed in an isolated state

matrix, and a diffraction pattern was taken with the very fine as one particle in Fig. 2(a), indicated by letter B, or in cluster

electron beam converged on the fine isolated carbide particles. states shown in Fig. 2(f). Their distinct character is their TEM

Figure 2(b) and (c) shows SAD diffraction patterns of an image, which have much light contrast; this means they are in

isolated spheroidal carbide particle (see Fig. 2a with letter A). a very thin sheet, only several nanometers in thickness. The

They are indexed as face-centered cubic (fcc) structure with a isolated V-rich carbides are much larger, and those in the clus-

lattice constant of 1.08 nm; the axes are [001] and [110], re- ter state are smaller. The isolate V-rich carbides might be rem-

spectively. Another morphology of intralath carbides is a rect- nants from the as-received state, while those in clusters might

angular plate. One particle in such a shape is indicated by letter be formed during long-term service. Figure 2(g) and (h) shows

B in Fig. 2(a ); Fig. 2(d) and (e) gives its micro-beam diffraction the micro-beam diffraction patterns of a V-rich particle in the

patterns, which are also indexed as fcc structure with a lattice cluster state; they are indexed as fcc structure of MX with a

constant of 1.07 nm, and the corresponding axes are [001] and lattice constant of 0.41 nm, and the axes are [001] and [123].

[111]. It was determined that most of the carbides in the matrix Many types of carbides, including M23C6, M7C3, M3C,

in different morphologies are M23C6. The investigations of M2C, and MC, have been reported in 12%Cr steels; which

their compositions below will confirm this conclusion. types of carbides present are strongly dependent on the chemi-

Except for the carbides mentioned above, some tiny car- cal compositions and heat treatment states of the examined

Journal of Materials Engineering and Performance Volume 12(1) February 2003—109

materials.[6,9,11] The microstructure investigation of 12CrMoV

steels in the as-received heat treatment condition[7,15-16]

showed that the finely dispersed M2X and MX were observed

within the matrix; M2X is Cr-rich whereas MX is V-rich. The

carbides in the X20CrMoV12.1 pipe steel after 23 years in

service at 550 °C/13.7 MPa are mostly M23C6 in various mor-

phologies, and no other carbides were found, except for some

tiny V-rich carbides. It is obvious that the potential fine carbide

phases, except M23C6, existing in the as-received heat treat-

ment condition of the examined material mostly dissolved dur-

ing the long-term service exposure at elevated temperature.

This is similar to previous observations[7,9] that minor phases

of M2X and MX would dissolve after long-term creep exposure

at elevated temperature with the coarsening of M23C6 carbides.

Two different observations of the character of the precipitates

in the present work were made: (1) the phenomena present in

a special condition that the material is X20CrMoV12.1 pipe

steel after 23 years in service at 550 °C/13.7 MPa; and (2) all

the potential carbides are classified by morphology and exten-

sively examined. The carbides with the same crystallographic

structure as M23C6 in different appearances might be due to

coarsening. The finding of tiny V-rich MC formed during long-

term exposure at elevated temperature provides a good expla-

nation of the phenomenon that the X20CrMoV12.1 steel did

not soften during long-term service,[4] because V-rich carbides

MX have a good coherent relationship with the matrix and have

a strong hardening effect, both of which are beneficial for

microstructural stability.

3.3 Chemical Composition of Carbides

3.3.1 Carbides in Boundaries. The chemical composi-

tions of carbides in different morphologies were determined by

an EDAX EDS from carbon extraction replicas supported on Fig. 3 Example of carbide EDS spectra from (a) a particle in a grain

nylon grids, and thus the recording spectra contain no extra boundary and (b) a V-rich particle in the cluster state

information. An EDS spectrum from a particle in a grain

boundary is shown in Fig. 3(a). More than 10 spectra are re- attributed to the difference of the compositions of the steels

corded for the same morphology, and the compositions given investigated.

below are average values of the quantitative analysis results. 3.3.3 V-Rich Carbides in Matrix. Several isolated V-rich

The compositions of spheroidal M23C6 carbides at grain bound- carbides were found within the matrix. They contain 65 at.% V,

aries contain 69 at.% Cr, 25 at.% Fe, 5 at.% Mo, and fractional 20 at.% Cr, and factional amounts of Fe, Ni, Mo, and Cu. The

V and Ni; plate particles at lath boundaries contain 65 at.% Cr, V-rich carbides in the cluster state contain 80 at.% V and 20

28 at.% Fe, 2 at.% Mo, 3 at.% V, and fractional others. There at.% Cr, which is obviously different than the isolated precipi-

is a slight difference between them in compositions, with the tates, and an EDS spectrum taken from one of them is shown

carbides at grain boundary containing a little more Mo and Cr, in Fig. 3(b). This confirmed that the two states of V-rich car-

and the interlath carbides containing a little more V. bides nucleated at different times: the isolated precipitates are

3.3.2 Carbides in Matrix. Most of the carbides in the ma- remnants from the as-received state, and the cluster precipitates

trix are also Cr-rich. The analysis EDS results reveal the com- formed during long-term service.

positions of spheroidal carbides with 70 at.% Cr, 20 at.% Fe, An interesting result is the difference in composition of the

8 at.% Mo, and fractional V and Ni. Those in rectangular plates M23C6 carbides, including the intergranular and interlath car-

are 70 at.% Cr, 20 at.% Fe, 3 at.% Mo, 6 at.% V, and fractional bides, as well as the intralath carbides of different morpholo-

others. The spheroidal carbides contain more molybdenum, and gies. In general, the irregular spheroidal carbides contain much

the rectangular plate carbides contain much more vanadium. more Mo and Cr relative to that in the plates, and the plates

It was found that most of the carbides in the material are contain much more V. The most probable explanation is that all

Cr-rich, which confirmed that those carbides are not M6C, but the M23C6 carbides in different states are coarsening, but at

M23C6, because the former is Mo-rich and the latter Cr-rich.[9] different rates; the irregular spheroidal carbides have coarsened

The compositions of M23C6 are in general agreement with more than those in plates. This suggestion is supported by

those of Strang and Vodarek.[7] The compositions of M23C6 previous investigations[6,11] that showed that the amount of Mo

carbides in the boundaries have a slight variance with those and Cr in the carbides increased slightly following aging or

determined by Strang and Vodarek. This difference might be creep, and the intergranular carbides contained much more Cr

110—Volume 12(1) February 2003 Journal of Materials Engineering and Performance

than the interlath carbides. Furthermore, the intergranular car- X20CrMoV12.1 nach einer Bertriebszeit von über 180,000 h,” VGB

bides coarsened faster than those in lath boundaries or within Kraftwerkstechnik, 2000, 11, p. 85 (in German).

4. K. Borggreen and P.B. Mortensen: Long-Term Properties of Fracture

the matrix. It is well known that the carbide coarsening process of X20CrMoV12.1, The Danish Corrosion Center, Nov 1989.

is accompanied by particle coalescence and agglomeration, 5. R.B. Carruthers and M.J. Collins: “Carbide Transformations in Micro-

which markedly causes reduction of carbide particle volume structurally Unstable Low Alloy Ferritic Steel,” Met. Sci., 1983, 17(3),

density and reduces the precipitation strengthening mechanism. p. 107.

6. R.C. Thomson and H.K.D.H. Bhadeshia: “Carbide Precipitation in

Meanwhile, the enrichment of solute in carbides during coars-

12CrMoV Power Plant Steel,” Metall. Trans., 1992, 23A(4), pp. 1171-

ening yields a contribution to depletion of the alloying ele- 79.

ments into the matrix, which weakens the solid solution 7. A. Strang and V. Vodarek: “Microstructural Stability of Creep Resis-

strengthening effect. So material degradation is very tight with tant Martensitic 12%Cr Steels” in Microstructure of High Temperature

the carbide coarsening. Materials, No. 2, A. Strang, J. Cawley, and G.W. Greenwood, ed., The

Institute of Metals, London, UK, 1998, pp. 117-33.

8. P. Bianchi, P. Bontempi, A. Benvenuti, and N. Ricci: “Microstructural

4. Conclusions Evolution of P91 Steel After Long Term Creep Tests” in Microstruc-

ture of High Temperature Materials, No. 2, A. Strang, J. Cawley, and

G.W. Greenwood, ed., The Institute of Metals, London, UK, 1998, pp.

1) In X20CrMoV12.1 pipe steel, which has been in service for 107-16.

23 years at 550 °C at a steam pressure of 13.7 MPa, the 9. V. Vodarek and A. Strang: “Effect of Nickel on the Precipitation

Processes in 12CrMoV Steels During Creep at 550,” Scripta Materi-

carbides are in various morphologies and coarsened during alia, 1998, 38(1), p. 101.

exposure; in addition, the martensite structure undergoes 10. L.K. Singhal and J.W. Martin: “The Nucleation and Growth of

degradation, and a substructure forms by dislocation reor- Widmannstätten M23C6 Precipitation in an Austenitic Stainless

ganization. Steel,” Acta Metall., 1968, 16(9), p. 1159.

11. G. Eggeler: “The Effect of Long-Term Creep on Particle Coarsening in

2) The spheroidal carbides in prior austenite grain boundaries,

Tempered Martensite Ferritic Steels,” Acta Metall., 1989, 37(12), p.

the plate-like carbides in lath boundaries, and the much 3225.

finer carbides within the matrix in different shapes were 12. P. Battaini, D. Dangelo, G. Marino, and J. Hald: “Interparticle Dis-

mostly M23C6. The compositions of those carbides vary tance Evolution on Steam Pipes 12% Cr During Power Plants’ Service

with their morphology because they are coarsening at dif- Time” in Creep and Fracture of Engineering Materials and Struc-

tures, Proc. 4th Inter. Conf., B. Wilshire and R.W. Evans, ed., Apr

ferent rates during the long-term exposure at elevated tem- 1990, The Institute of Metals, London, UK, pp. 1039-54.

perature in service. 13. P.J. Ennis, A.Z. Lipies, and A.C. Filemonowicz: “Quantitative Com-

3) Very fine plate-like V-rich carbides formed after long-term parison of the Microstructures of High Chromium Steels for Advanced

service are identified as MC. These precipitates favor hard- Power Stations” in Microstructure of High Temperature Materials,

ness maintenance and microstructural stability. No. 2, A. Strang, J. Cawley, and G.W. Greenwood, ed., The Institute

of Metals, London, UK, 1998, pp. 135-44.

14. P. Klimanek, K. Cyrener, C. Germain, K. Jenkner, U. Martin, O.

Refererences Oettel, A. Ostwaldt, D. Ostwaldt, and W. Pantleon: “Flow Behaviour

and Microstructure of the Heat-Resistant Steels X20CrMoV12.1 and

1. S. Straub, M. Meier, J. Ostermann, and W. Blum: “Entwicklung der X5NiCrTiAl32.20 (Alloy 800)” in Microstructural and Mechanical

Microstruktur und der Festigkeit des Stahles X20CrMoV12.1 bei Properties of Metallic High-Temperature Materials, H. Mughrabi, ed.,

823K Während Zeitstandbeans pruchung und Gl#369hung,” VGB New York, NY, 1999, pp. 272-89.

Kraitwerkstechnik, 1993, 73(8), p. 744 (in German). 15. A. Hede and B. Aronsson: “Microstructure and Creep Properties of

2. E. El-Magd, G. Nicolini, and M.A. Nasser: “The Influence of Prior Some 12% Chromium Martensitic Steels,” JISI, 1969, 207(9), p. 1641.

Aging on Microstructure, Tensile Properties and Hot Hardness of Al- 16. A. Strang and V. Vodareks: “Precipitation Process in Martensitic

loy 800HT,” Metall., 1996, 50(11), p. 805. 12CrMoVNb Steels During High Temperature Creep” in Microstruc-

3. D.B. Hahn and D.W. Bendick: “Erfahrungen aus der Zustandsbewer- tural Development and Stability in High Chromium Ferritic Power

tung eines FD- und HZÜ-Rohrleitungssystems aus dem Werkstoff Plant Steels, The Institute of Materials, London, UK, 1997, pp. 31-52.

Journal of Materials Engineering and Performance Volume 12(1) February 2003—111

You might also like

- Horing 2010 - Characterization of Reverted Austenite During Prolonged Ageing of Maraging - ORIGINALDocument5 pagesHoring 2010 - Characterization of Reverted Austenite During Prolonged Ageing of Maraging - ORIGINALIAragaoNo ratings yet

- Crystallographic Characterizations of Eutectic and Secondary Carbides in A Fe-12Cr-2.5Mo-1.5W-3V-1.25C AlloyDocument7 pagesCrystallographic Characterizations of Eutectic and Secondary Carbides in A Fe-12Cr-2.5Mo-1.5W-3V-1.25C AlloyCHONKARN CHIABLAMNo ratings yet

- Evolution of Carbide Precipitates in 2.25Cr-1Mo Steel During Long-Term Service in A Power PlantDocument7 pagesEvolution of Carbide Precipitates in 2.25Cr-1Mo Steel During Long-Term Service in A Power PlantRogger Asmat VasquezNo ratings yet

- Effects of The Destabilisation Heat Treatments On The Precipitation of Secondary Carbides and Their Effect On The Corrosion of 27 WT.% Chromium White Cast IronDocument9 pagesEffects of The Destabilisation Heat Treatments On The Precipitation of Secondary Carbides and Their Effect On The Corrosion of 27 WT.% Chromium White Cast IronANA LAURA BRAGA NASCIMENTONo ratings yet

- Characterization of The Carbides in The Steel X20CrMoV12.1 Used in Thermal Power PlantsDocument5 pagesCharacterization of The Carbides in The Steel X20CrMoV12.1 Used in Thermal Power PlantsHilarioPerezNo ratings yet

- Chemical Composition and Morphology of M C Eutectic Carbide in High Chromium White Cast Iron Alloyed With VanadiumDocument5 pagesChemical Composition and Morphology of M C Eutectic Carbide in High Chromium White Cast Iron Alloyed With VanadiumMario SitorusNo ratings yet

- Nanometric Chromium Applications: Ychromium Carbide Multilayers For TribologicalDocument6 pagesNanometric Chromium Applications: Ychromium Carbide Multilayers For Tribologicalrahil7860No ratings yet

- Effect of Niobium On The As-Cast Microstructure of Hypereutectic High Chromium Cast IronDocument4 pagesEffect of Niobium On The As-Cast Microstructure of Hypereutectic High Chromium Cast IronMatheus BoligonNo ratings yet

- Effect of Carbon Concentration On Changing The Morphology of Titanium Carbide Nanoparticles From Cubic To CuboctahedronDocument6 pagesEffect of Carbon Concentration On Changing The Morphology of Titanium Carbide Nanoparticles From Cubic To CuboctahedronRabia Farman 3428No ratings yet

- Nickel Base Reformer TubesDocument8 pagesNickel Base Reformer TubesOwais MalikNo ratings yet

- XRD and Electron Microscope Study of An As-Cast 26.6% Chromium White Iron MicrostructureDocument9 pagesXRD and Electron Microscope Study of An As-Cast 26.6% Chromium White Iron MicrostructureJMarce16No ratings yet

- Ceramics International 2015 Electrical Conductivity and Wear Behavior of Bi-Continuous Cr3C2-Cu CompositesDocument5 pagesCeramics International 2015 Electrical Conductivity and Wear Behavior of Bi-Continuous Cr3C2-Cu Compositesqwerty meNo ratings yet

- Rare MetalsDocument4 pagesRare MetalsmohammadNo ratings yet

- Nondestructive Evaluation of Thermally Degraded SteelDocument5 pagesNondestructive Evaluation of Thermally Degraded SteelPhung Tuan AnhNo ratings yet

- HoCrO3 and HoFeCrO3Document18 pagesHoCrO3 and HoFeCrO3manjeet redduNo ratings yet

- Microstructural and Crystallographical Study of Carbides in 30%Cr Cast IronDocument12 pagesMicrostructural and Crystallographical Study of Carbides in 30%Cr Cast IronVictor Torres SantamariaNo ratings yet

- Characterization of Carbon Nanofibers by SEM, TEM, ESCA and Raman SpectroscopyDocument7 pagesCharacterization of Carbon Nanofibers by SEM, TEM, ESCA and Raman SpectroscopyRavindra RaoNo ratings yet

- 625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFDocument5 pages625 Characterization of Microstructures in Inconel 625 Using X-RAY PDFKara WhiteNo ratings yet

- 1 s2.0 S2352492822000320 MainDocument12 pages1 s2.0 S2352492822000320 MaintarnsonNo ratings yet

- AS 2027 Micro Reference PDFDocument5 pagesAS 2027 Micro Reference PDFdelta lab sangliNo ratings yet

- Synthesis and Characterization of MCM-41 Coatings On Stainless Steel GridsDocument5 pagesSynthesis and Characterization of MCM-41 Coatings On Stainless Steel GridsRiana Okta LestariNo ratings yet

- Skin Daras 2014Document6 pagesSkin Daras 2014CHONKARN CHIABLAMNo ratings yet

- Modification of The Railway Traction ElementsDocument21 pagesModification of The Railway Traction ElementsUHNo ratings yet

- Characteristics of Mould Flux Films for Casting Medium and Low Carbon SteelsDocument13 pagesCharacteristics of Mould Flux Films for Casting Medium and Low Carbon SteelsddantgwynNo ratings yet

- tmp5B32 TMPDocument2 pagestmp5B32 TMPFrontiersNo ratings yet

- Carbide Precipitation in 2.25 Cr-1 Mo Bainitic Steel: Effect of Heating and Isothermal Tempering ConditionsDocument15 pagesCarbide Precipitation in 2.25 Cr-1 Mo Bainitic Steel: Effect of Heating and Isothermal Tempering ConditionsCHONKARN CHIABLAMNo ratings yet

- JustAccepted EML 12 109Document22 pagesJustAccepted EML 12 109Shridhar MathadNo ratings yet

- Bulk Amorphous Magnetic MaterialsDocument10 pagesBulk Amorphous Magnetic MaterialsZdenko PopNo ratings yet

- LIU 16 JMMM Effect of Interface Roughness On Superconducting TransitionDocument6 pagesLIU 16 JMMM Effect of Interface Roughness On Superconducting TransitionElisa Baggio SaitovitchNo ratings yet

- Mno2 Apl 1Document3 pagesMno2 Apl 1CHEMISTRYNo ratings yet

- Microstructure Properties Corrosion Characterization Welded Joint Novel Welding ProcessDocument12 pagesMicrostructure Properties Corrosion Characterization Welded Joint Novel Welding ProcessRami GhorbelNo ratings yet

- Analysis of Precipitation in A Cu-Cr-Zr AlloyDocument4 pagesAnalysis of Precipitation in A Cu-Cr-Zr AlloyNut AssanaiNo ratings yet

- Analysis of Carbides Formed During Accelerated Aging of 2-25Cr-1Mo SteelDocument7 pagesAnalysis of Carbides Formed During Accelerated Aging of 2-25Cr-1Mo SteelLuan CaetanoNo ratings yet

- Paper On Solidification Structures PropertiesDocument8 pagesPaper On Solidification Structures PropertiesRaj BhirudNo ratings yet

- Ductility-Dip Cracking inDocument11 pagesDuctility-Dip Cracking intazzorroNo ratings yet

- In Situ Synthesis of Super-Long Cu Nanowires Inside Carbon NanotubesDocument3 pagesIn Situ Synthesis of Super-Long Cu Nanowires Inside Carbon NanotubesRamon Roman DovalNo ratings yet

- Corrosion % MoDocument13 pagesCorrosion % MoKheiro BzdNo ratings yet

- Synthesis and Characterization of Ba Ca Ti ZR O Ceramics by Hydrothermal MethodDocument7 pagesSynthesis and Characterization of Ba Ca Ti ZR O Ceramics by Hydrothermal MethodSamah SamahNo ratings yet

- 22 PG Koppad Et AlDocument5 pages22 PG Koppad Et Almohamed aliNo ratings yet

- High Strength and Ductility)Document17 pagesHigh Strength and Ductility)ddsiva402No ratings yet

- Structural, Magnetic and Dielectric Analysis of Higher Magnetic MN Doped ZN-CR Oxide NanoparticlesDocument10 pagesStructural, Magnetic and Dielectric Analysis of Higher Magnetic MN Doped ZN-CR Oxide NanoparticlesIJRASETPublicationsNo ratings yet

- InTech-Recrystallization of Dispersion Strengthened Copper AlloysDocument21 pagesInTech-Recrystallization of Dispersion Strengthened Copper AlloysbinkinNo ratings yet

- Kyeongae Nam, Yin-Sheng He, Jungchel Chang, and Keesam ShinDocument7 pagesKyeongae Nam, Yin-Sheng He, Jungchel Chang, and Keesam ShinPranjal SinghNo ratings yet

- Microstructure and Wear Properties of Tic-Vc Reinforced Iron Based Hardfacing LayersDocument6 pagesMicrostructure and Wear Properties of Tic-Vc Reinforced Iron Based Hardfacing LayersLove AllNo ratings yet

- Microstructure Evolution of HP40-Nb Alloys During Aging UnderDocument9 pagesMicrostructure Evolution of HP40-Nb Alloys During Aging UnderOmarNo ratings yet

- Evaluation of Chromium Carbide Coatings On AISI 52100 Steel Obtained by Thermo-Reactive Diffusion TechniqueDocument6 pagesEvaluation of Chromium Carbide Coatings On AISI 52100 Steel Obtained by Thermo-Reactive Diffusion Techniquedaniel leonNo ratings yet

- Characterization of Zro Thin Films Deposited by Mocvd As Ceramic CoatingsDocument10 pagesCharacterization of Zro Thin Films Deposited by Mocvd As Ceramic Coatingsleoplasmo_201469720No ratings yet

- Effect of Titanium Content On Microstructure and Wear Resistance of Fe-Cr-C Hardfacing LayersDocument8 pagesEffect of Titanium Content On Microstructure and Wear Resistance of Fe-Cr-C Hardfacing LayersIsrael RodriguezNo ratings yet

- (Advances in Materials Science) Assessment of Fitness For Service of Cr-Mo Steel Tubes in Catalytic Reforming Charge HeatersDocument10 pages(Advances in Materials Science) Assessment of Fitness For Service of Cr-Mo Steel Tubes in Catalytic Reforming Charge HeatersM ANo ratings yet

- Characterization of An Ex-Service P22 To F91 Ferritic Dissimilar Metal Weld PDFDocument8 pagesCharacterization of An Ex-Service P22 To F91 Ferritic Dissimilar Metal Weld PDFMahsaNo ratings yet

- Menut 2015Document11 pagesMenut 2015Shubhankeet SenapatiNo ratings yet

- Fla Haut 2000Document10 pagesFla Haut 2000jaden flyn riderNo ratings yet

- Materials Characterization: V. Thomas Paul, S. Saroja, S.K. Albert, T. Jayakumar, E. Rajendra KumarDocument12 pagesMaterials Characterization: V. Thomas Paul, S. Saroja, S.K. Albert, T. Jayakumar, E. Rajendra KumargardenergardenerNo ratings yet

- Mechanical properties and microstructure of carbon nanotube reinforced aluminum compositesDocument9 pagesMechanical properties and microstructure of carbon nanotube reinforced aluminum compositesKatari KiranNo ratings yet

- 2009 Discovery of Nanotubes in Ancient Damascus Marianne ReiboldDocument6 pages2009 Discovery of Nanotubes in Ancient Damascus Marianne Reiboldpaula rodriguezNo ratings yet

- Materials Letters: Y.Y. Song, X.Y. Li, L.J. Rong, D.H. Ping, F.X. Yin, Y.Y. LiDocument4 pagesMaterials Letters: Y.Y. Song, X.Y. Li, L.J. Rong, D.H. Ping, F.X. Yin, Y.Y. LiGhazal NanaaNo ratings yet

- Microwave-Assisted Synthesis and Characterization of Cao NanoparticlesDocument7 pagesMicrowave-Assisted Synthesis and Characterization of Cao NanoparticlesBeth JiménezNo ratings yet

- Structural and Magnetic Properties of Co2MnSn FilmsDocument7 pagesStructural and Magnetic Properties of Co2MnSn FilmsΙήήΘςέήτ βόγNo ratings yet

- 11CrMo9-10 Evolution of MicrostructureDocument15 pages11CrMo9-10 Evolution of MicrostructureDaniele CastellaniNo ratings yet

- Persistent Symptoms in Patients After Acute COVID-19: (Reprinted)Document3 pagesPersistent Symptoms in Patients After Acute COVID-19: (Reprinted)Stefano Alvarez MatosNo ratings yet

- Assessment of The Prevalence of Symptoms in Patients Under Institutional Isolation in COVID-19 Pandemic in IndiaDocument9 pagesAssessment of The Prevalence of Symptoms in Patients Under Institutional Isolation in COVID-19 Pandemic in IndiaPraveen CNo ratings yet

- Fatigue Life Prediction of Solder Joints in Electronic Packages With Ansys®Document200 pagesFatigue Life Prediction of Solder Joints in Electronic Packages With Ansys®Praveen CNo ratings yet

- Acta Materialia 54 (2006) 2169 GND in CPFEMDocument11 pagesActa Materialia 54 (2006) 2169 GND in CPFEMPraveen CNo ratings yet

- Low Cycle Fatigue and Cyclic Plasticity Behavior of Indian PHWR Ahwr Primary Piping MaterialDocument8 pagesLow Cycle Fatigue and Cyclic Plasticity Behavior of Indian PHWR Ahwr Primary Piping MaterialPraveen CNo ratings yet

- Torbilo, Vladimir - Zahavi, Eliahu - Fatigue Design - Life Expectancy of Machine parts-CRC Press (2019)Document337 pagesTorbilo, Vladimir - Zahavi, Eliahu - Fatigue Design - Life Expectancy of Machine parts-CRC Press (2019)Praveen C100% (2)

- Energies: Transient Thermal Analysis of NH000 GG 100A Fuse Link Employing Finite Element MethodDocument18 pagesEnergies: Transient Thermal Analysis of NH000 GG 100A Fuse Link Employing Finite Element MethodPraveen CNo ratings yet

- Parameter Refreched Chaboche Model For Midl Steel Cyclic PlasticityDocument17 pagesParameter Refreched Chaboche Model For Midl Steel Cyclic PlasticityFred100% (1)

- Applicability of The One-Internal-Variable Kocks-Mecking Approach For TensileDocument8 pagesApplicability of The One-Internal-Variable Kocks-Mecking Approach For TensilePraveen CNo ratings yet

- 14-Procedia Engineering 55 (2013) 36 - 40Document5 pages14-Procedia Engineering 55 (2013) 36 - 40Praveen CNo ratings yet

- 2016 MSEA Stage-IIhardening-316LNSS BKC-JCDocument5 pages2016 MSEA Stage-IIhardening-316LNSS BKC-JCPraveen CNo ratings yet

- E 606 - 92 R98 RtywngDocument15 pagesE 606 - 92 R98 RtywngAnthony GómezNo ratings yet

- Pandey 2017Document32 pagesPandey 2017Praveen CNo ratings yet

- Metals: A Creep Damage Model For High-Temperature Deformation and Failure of 9Cr-1Mo Steel WeldmentsDocument20 pagesMetals: A Creep Damage Model For High-Temperature Deformation and Failure of 9Cr-1Mo Steel WeldmentsPraveen CNo ratings yet

- Yunpeng Gong, Cristopher Hyde, Wei Sun and Thomas HydeDocument6 pagesYunpeng Gong, Cristopher Hyde, Wei Sun and Thomas HydePraveen CNo ratings yet

- Springerbriefs in Applied Sciences and Technology: Manufacturing and Surface EngineeringDocument120 pagesSpringerbriefs in Applied Sciences and Technology: Manufacturing and Surface EngineeringRhushikeshNo ratings yet

- The Complete Guide to Hot Rolling of SteelDocument13 pagesThe Complete Guide to Hot Rolling of SteelAndréNo ratings yet

- KAXITM Ejector Pins GuideDocument16 pagesKAXITM Ejector Pins GuideAndres Mauricio Villalobos FarelloNo ratings yet

- IJME Volume3 Issue3 Pages13-19Document8 pagesIJME Volume3 Issue3 Pages13-19Alex NoNo ratings yet

- VF HVRBDocument12 pagesVF HVRBNAHRUDIN KOLIĆNo ratings yet

- Metallurgical and metalworking terms glossaryDocument14 pagesMetallurgical and metalworking terms glossaryKasia MazurNo ratings yet

- As 1874-2000 Aluminium and Aluminium Alloys - Ingots and CastingsDocument7 pagesAs 1874-2000 Aluminium and Aluminium Alloys - Ingots and CastingsSAI Global - APACNo ratings yet

- Ammonia Converter FailureDocument15 pagesAmmonia Converter FailureAnonymous UoHUagNo ratings yet

- An Innovative Tin Plating Process: High Performance and Significant SavingsDocument14 pagesAn Innovative Tin Plating Process: High Performance and Significant SavingsNgô TrungNo ratings yet

- Astm A352-A352m 1998Document5 pagesAstm A352-A352m 1998Luis Ricardo OstiNo ratings yet

- Diamond Bit Design HandoutDocument19 pagesDiamond Bit Design Handoutamin peyvand100% (1)

- Dental Porcelain: Composition, Processing, Strengthening and ApplicationsDocument63 pagesDental Porcelain: Composition, Processing, Strengthening and ApplicationsAnonymous LRPHmxh02No ratings yet

- Bramat2011 ProgramDocument25 pagesBramat2011 Programmtierean100% (1)

- A 447 - A447m - 93 R98 Qtq0ny05m1i5oaDocument4 pagesA 447 - A447m - 93 R98 Qtq0ny05m1i5oaMarceloNo ratings yet

- Nedal Alloy Datasheet EN AW 7108ADocument1 pageNedal Alloy Datasheet EN AW 7108ANico VazquezNo ratings yet

- LOVE Rings - CartierDocument1 pageLOVE Rings - CartierenduenaNo ratings yet

- Giới thiệu dây SAWDocument4 pagesGiới thiệu dây SAWNguyen Thanh TrungNo ratings yet

- Datasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1Document3 pagesDatasheet-Sandvik-27-31-4-Lcu-En-V2017-09-19 16 - 34 Version 1laz_kNo ratings yet

- Omega Bright Steel: Test CertificateDocument1 pageOmega Bright Steel: Test CertificateBHUSHANNo ratings yet

- Sterling Lighting Fixture Catalog 99 1972Document60 pagesSterling Lighting Fixture Catalog 99 1972Alan MastersNo ratings yet

- Types of Abrasives for DentistryDocument31 pagesTypes of Abrasives for Dentistryjohn mwambuNo ratings yet

- IGCSE Chemistry Lecture 16 - Group 1 ElementsDocument12 pagesIGCSE Chemistry Lecture 16 - Group 1 Elementsnazzlor08No ratings yet

- Metallurgy of AluminiumDocument9 pagesMetallurgy of Aluminiumhassan materialsNo ratings yet

- Electrode Booklet F Web 105Document1 pageElectrode Booklet F Web 105satnamNo ratings yet

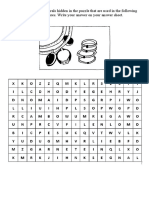

- Objects Shown in The Pictures. Write Your Answer On Your Answer SheetDocument8 pagesObjects Shown in The Pictures. Write Your Answer On Your Answer SheetLoquellano, Paulo R.No ratings yet

- Lightweight Car Body TechnologiesDocument12 pagesLightweight Car Body TechnologiesS P Suganthi GaneshNo ratings yet

- Table 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018Document32 pagesTable 302.3.4 Longitudinal Weld Joint Quality Factor, E: ASME B31.3-2018GabrielNo ratings yet

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Assab 618HH enDocument8 pagesAssab 618HH enSamanthaPereraNo ratings yet

- Definitions and Related Materials: Stahliją or Stakhlijan (Made of Steel), Stahliją (Standing Firm)Document5 pagesDefinitions and Related Materials: Stahliją or Stakhlijan (Made of Steel), Stahliją (Standing Firm)kingNo ratings yet

- RefractoriesDocument6 pagesRefractoriesBHAVINNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionFrom EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionNo ratings yet