Professional Documents

Culture Documents

System PDF Files - 1. UL and cUL Systems - fb2058 - cUL

System PDF Files - 1. UL and cUL Systems - fb2058 - cUL

Uploaded by

Emanuel Almeida PastlOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

System PDF Files - 1. UL and cUL Systems - fb2058 - cUL

System PDF Files - 1. UL and cUL Systems - fb2058 - cUL

Uploaded by

Emanuel Almeida PastlCopyright:

Available Formats

Classified by System No.

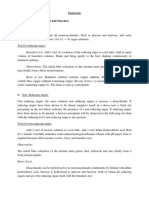

F-B-2058

Underwiters Laboratories, Inc. F Rating - 2 Hr

to CAN/ULC S115 FT Ratings - 0 and 2 Hr (See Item 3)

FH Rating - 2 Hr

FTH Rating - 0 and 2 Hr (See Item 3)

L Rating At Ambient - Less Than 5.1 L/s/m2 (See Items 3, 6 and 7)

L Rating At 400 F - Less Than 5.1 L/s/m2 (See Items 3, 6 and 7)

5 4

A

3

2 2 1

A Section A-A

System tested with a pressure differential of 50 Pa between the exposed and the unexposed surfaces

with the higher pressure on the exposed side.

1. Floor Assembly - Min 152 mm (6 in.) thick reinforced lightweight or normal weight (1600-2400 kg/m3 or

100-150 pcf) concrete floor.

1A. Alternate Floor Assembly - (Not Shown) - The fire rated unprotected concrete and steel deck floor assembly

shall be constructed of the material and in the manner specified in the individual D900 Series designs in the UL

Fire Resistance Directory and as summarized below:

A. Concrete - Min 114 mm (4-1/2 in.) thick reinforced lightweight or normal weight (1600-2400 kg/m3 or

100-150 pcf ) concrete, as measured from the top plane of the steel floor units.

B. Steel Floor and Form Units* - Composite or non-composite max 76 mm (3 in.) deep galv steel fluted units

as specified in the individual Floor-Ceiling Design.

2. Firestop Device* - Cast in place firestop device permanently embedded during the concrete pour or grouted

into the concrete assembly in accordance with the accompanying installation instructions. The devices may be

cut flush or extend above the top surface of the floor.

SPECIFIED TECHNOLOGIES INC - SpecSeal CD200, CD201C, CD300, CD301C, CD400, CD401 or CD402

Cast In Firestop Device

2A. Firestop Device* - (Not Shown) - When Item 1A is used, a steel deck adapter kit consisting of steel plates and

a nonmetallic extension tube is used in conjunction with Item 2. Install the deck adapter in accordance with the

accompanying installation instructions.

SPECIFIED TECHNOLOGIES INC - SpecSeal CD200DK, CD201DK, CD300DK, CD301DK, CD400DK or

CD401DK Cast In Firestop Device Deck Adapter

Specified Technologies Inc. 210 Evans Way Somerville, NJ 08876

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: March 29, 2016 R

STI ® (800)992-1180 · (908)526-8000 · FAX (908)231-8415 · E-Mail:techserv@stifirestop.com · Website:www.stifirestop.com

F-B-2058

PAGE 1 OF 2

2B. Firestop Device* - (Not Shown) - When the concrete thickness exceeds 203 mm (8 in.), a nonmetallic

extension tube is used in conjunction with Item 2. Install the extension tube in accordance with the

accompanying installation instructions.

SPECIFIED TECHNOLOGIES INC - SpecSeal CD200X, CD300X, or CD400X Cast In Firestop Device

Extension

3. Nonmetallic Penetrants - One nonmetallic pipe to be installed within the firestop system. Pipe to extend min

305 mm (12 in.) above top surface of floor. Pipe to be rigidly supported on both sides of the floor assembly. The

following types and sizes of the nonmetallic pipes may be used:

A. Polyvinyl Chloride (PVC) Pipe - Nom 102 mm (4 in.) diam (or smaller) solid or cellular core Schedule 40

polyvinyl chloride (PVC) pipe for use in closed (process or supply) or vented (drain, waste or vent) piping

systems.

B. Chlorinated Polyvinyl Chloride (CPVC) Pipe - Nom 102 mm (4 in.) diam (or smaller) SDR 13.5 chlorinated

polyvinyl chloride (CPVC) pipe for use in closed (process or supply) piping systems.

C. Acrylonitrile Butadiene Styrene (ABS) Pipe - Nom 102 mm (4 in.) diam (or smaller) solid or cellular core

Schedule 40 acrylonitrile butadiene styrene (ABS) pipe for use in closed (process or supply) or vented (drain,

waste or vent) piping systems.

D. Chlorinated Polyvinyl Chloride (CPVC) Pipe - Nom 102 mm (4 in.) diam (or smaller) SDR 11 CPVC pipe

for use in closed (process or supply) piping systems.

IPEX INC - AquaRise

Nom Pipe Diam (a) Firestop Device

38 or 51 mm (1-1/2 or 2 in.) CD200, CD201C

64 or 76 mm (2-1/2 or 3 in.) CD300, CD301C

89 or 102 mm (3-1/2 or 4 in.) CD400, CD401, CD402

(a) When nonmetallic pipe with diam smaller than those shown in the table above is used, packing

material shall be installed in the device as described in Item 6. L Ratings for these penetrants only

apply when the fill material (Item 7) is used. Otherwise, the L Rating for each firestop device is

less than 5.1 L/s/m2 at ambient and at 400F.

When Item 3A, 3B or 3D is used, T Rating is 2 hr. When Item 3C is used T Rating is 0 hr.

4. Compression Coupling - Nonmetallic pipe (Item 3) to be secured to metallic pipe (Item 5) with compression

type high pressure pipe coupling with elastomeric gasket and a stainless steel jacket with stainless steel band

clamps.

5. Metallic Pipe - Nom 102 mm (4 in.) diam (or smaller) Schedule 10 (or heavier) cast or ductile iron pipe. Pipe to

be rigidly supported.

6. Packing Material - (Not Shown) - When required under Item 3, min 102 mm (4 in.) thickness of min 64 kg/m3 (4

pcf) mineral wool firmly packed into device flush with top edge of device (Item 2), and extending a min 25 mm (1

in.) below the top surface of the floor. When L Ratings for penetrants with a diam smaller than those shown in

the table are required, recess mineral wool 6 mm (1/4 in.) from top edge of device to accommodate sealant

(Item 7).

7. Fill, Void, or Cavity Material* - (Optional, Not Shown) - To achieve L Ratings for penetrants with a diam

smaller than those shown in the table in Item 3, apply min 6 mm (1/4 in.) depth of sealant atop packing material

(Item 6) flush with top edge of device (Item 2).

SPECIFIED TECHNOLOGIES INC - SpecSeal Series SIL300 Sealant or SpecSeal Series SIL300 SL Sealant

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL

or cUL Certification (such as Canada), respectively.

+Bearing the UL Listing Mark

Specified Technologies Inc. 210 Evans Way Somerville, NJ 08876

Reproduced courtesy of Underwriters Laboratories, Inc.

Created or Revised: March 29, 2016 R

STI

® (800)992-1180 · (908)526-8000 · FAX (908)231-8415 · E-Mail:techserv@stifirestop.com · Website:www.stifirestop.com

F-B-2058

PAGE 2 OF 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Food Tests 1. Carbohydrates (Sugars and Starches)Document3 pagesFood Tests 1. Carbohydrates (Sugars and Starches)nmrasaNo ratings yet

- Site Analyzer XT Series: SA-3600XT, SA-6000XTDocument2 pagesSite Analyzer XT Series: SA-3600XT, SA-6000XTDorival Junior Ferreira de MelloNo ratings yet

- How I Fucked My NeighborDocument6 pagesHow I Fucked My NeighborgoudtsriNo ratings yet

- Indaten and Arcorox: Self-Protecting Steels With Raw AestheticDocument44 pagesIndaten and Arcorox: Self-Protecting Steels With Raw AestheticJOAO ELOINo ratings yet

- Solution Manual For Principles of Geotechnical Engineering 8th EditionDocument14 pagesSolution Manual For Principles of Geotechnical Engineering 8th EditionBeverly Baker100% (34)

- Set 4Document19 pagesSet 4Dick Morgan FerrerNo ratings yet

- Explaining The Meaning and History of GymnasticsDocument4 pagesExplaining The Meaning and History of GymnasticsJohanna Marie GolinganNo ratings yet

- Section 1.2 - Newtonian GraviationDocument2 pagesSection 1.2 - Newtonian GraviationHoangvu PhamNo ratings yet

- CCARI Goa PDFDocument2 pagesCCARI Goa PDFhari prasadNo ratings yet

- GPS JLR7700Document100 pagesGPS JLR7700Sang Aji Jaya SusenoNo ratings yet

- 9 Desember 2022 SRF22-0413 Volvo D16 SN036063 PDFDocument2 pages9 Desember 2022 SRF22-0413 Volvo D16 SN036063 PDFFajra Nada NadifaNo ratings yet

- Expansion Processes of A Perfect Gas - : TH Series: ThermodynamicsDocument3 pagesExpansion Processes of A Perfect Gas - : TH Series: ThermodynamicsSyamim AsyrafNo ratings yet

- Geologic TimeFossilsDocument1 pageGeologic TimeFossilsGracie ChingNo ratings yet

- Mind Map: Amino Acid MetabolismDocument1 pageMind Map: Amino Acid MetabolismAbbey Ayala100% (1)

- 06 Lister LargeparksDocument12 pages06 Lister LargeparksAluísio MartellNo ratings yet

- Driving and Controlling: Drive Controller Electric Transaxle Drive MotorDocument23 pagesDriving and Controlling: Drive Controller Electric Transaxle Drive Motordgy24wntgcNo ratings yet

- Drill-10 - Engineering MechanicsDocument24 pagesDrill-10 - Engineering MechanicsTine AbellanosaNo ratings yet

- Modeling in Respiratory Movement Using Labview and SimulinkDocument27 pagesModeling in Respiratory Movement Using Labview and SimulinkNashitah AlwazNo ratings yet

- Share Pharmacology Book 1Document101 pagesShare Pharmacology Book 1Jmcle AhmedNo ratings yet

- Exure Determination Determination ChromatographyDocument3 pagesExure Determination Determination ChromatographyDennis Limaymanta YupanquiNo ratings yet

- Adyar Gate Junction PDFDocument1 pageAdyar Gate Junction PDFAnwar ShaikNo ratings yet

- Guidelines SOP For Monitoring and Compliance of All Safety Norms On The HighwaysDocument15 pagesGuidelines SOP For Monitoring and Compliance of All Safety Norms On The HighwaysBilal A BarbhuiyaNo ratings yet

- Wall Finishes PPT (1) (1) Taniya PDFDocument15 pagesWall Finishes PPT (1) (1) Taniya PDFRajaNo ratings yet

- 3rd Meeting Minutes of New Medical ICU ProjectDocument4 pages3rd Meeting Minutes of New Medical ICU Projectsanaishtiaq48No ratings yet

- ABC ClassificationDocument11 pagesABC ClassificationJUan Banquez GarciaNo ratings yet

- Scientific American202009 PDFDocument96 pagesScientific American202009 PDFrenaNo ratings yet

- 2006 2008 Cbf1000 A 1 General InformationDocument44 pages2006 2008 Cbf1000 A 1 General InformationMurariu IonutNo ratings yet

- Clevo m350c m360c m361c m362c SMDocument128 pagesClevo m350c m360c m361c m362c SMОлег КакойтоNo ratings yet

- Tmecc 0410Document7 pagesTmecc 0410Karen BenteoNo ratings yet

- Idoc - Pub Ic4l2t1to8akeyDocument1 pageIdoc - Pub Ic4l2t1to8akeySantiago MadridNo ratings yet