0% found this document useful (0 votes)

419 views4 pagesWhat Is A Wear Pad? Functions of Pipe Wear Pads

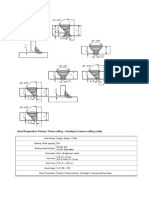

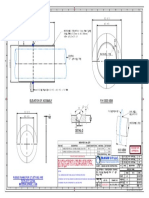

Wear pads are used in piping systems to protect pipes from damage at support locations. They isolate the pipe surface from direct contact with structural supports to avoid metal-on-metal wear and galvanic corrosion. Common wear pad materials include carbon steel, stainless steel, and composite materials. Wear pads serve to eliminate metal-on-metal damage to pipes, prevent crevice corrosion, absorb friction and vibration, and protect pipes from damage during thermal expansion and contraction. They help increase the longevity of piping systems by reducing corrosion and wear over time.

Uploaded by

Sanjeev KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

419 views4 pagesWhat Is A Wear Pad? Functions of Pipe Wear Pads

Wear pads are used in piping systems to protect pipes from damage at support locations. They isolate the pipe surface from direct contact with structural supports to avoid metal-on-metal wear and galvanic corrosion. Common wear pad materials include carbon steel, stainless steel, and composite materials. Wear pads serve to eliminate metal-on-metal damage to pipes, prevent crevice corrosion, absorb friction and vibration, and protect pipes from damage during thermal expansion and contraction. They help increase the longevity of piping systems by reducing corrosion and wear over time.

Uploaded by

Sanjeev KumarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- What is a Wear Pad? Functions of Pipe Wear Pads: Explains the purpose of wear pads in industrial applications and provides a detailed overview of their functions and materials used.

- Difference between RF Pad and Wear Pad: Explains the key differences between reinforcement (RF) pads and wear pads, focusing on their applications and strengths.

- Length of Wear Pads: Details how the lengths of wear pads are calculated and when they should be used, along with discussions on specific types like RF pads and wear pads.