Professional Documents

Culture Documents

Alivio Front Drive System

Uploaded by

MarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alivio Front Drive System

Uploaded by

MarCopyright:

Available Formats

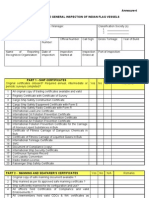

General Safety Information Technical Service Instructions SI-6BLFA-001 Installation of the Front Derailleur, Chain length

Cut off the excess length of inner cable and then install the inner

end cap.

Bottom Bracket and Front Chainwheel Add 2 links (with the chain on Largest sprocket Largest chainring

WARNING both the largest sprocket and Note:

<FD-M330-E>

• Use neutral detergent to clean the chain. Do not use alkali-based or acid based

detergent such as rust cleaners as it may result in damage and/or failure of the chain. Front Drive System Use the special tools (TL-UN74-S and TL-UN66) to install the bottom

bracket (1) and the front derailleur so that they face as shown in the

the largest chainring) Pass the cable

through as shown

in the illustration.

• Use the reinforced connecting pin only for connecting the narrow type of chain. illustration. If the bottom bracket shell width is 68 mm, insert a spacer

• There are two different types of reinforced connecting pins available. Be sure to check (2.5 mm) as shown in the illustration when installing the front derailleur.

the table below before selecting which pin to use. If connecting pins other than Chain

Install the adapter (2), and then use an 8 mm Allen key to install the

reinforced connecting pins are used, or if a reinforced connecting pin or tool which is

front chainwheel.

not suitable for the type of chain is used, sufficient connection force may not be

obtained, which could cause the chain to break or fall off. Front Derailleur

5 mm allen key

In order to realize the best performance, we recommend that the following combination be

Reinforced

Chain

connecting pin

Chain tool used. Mounting the shifting lever Wire fixing bolt

Series Altus Top route type Normal type

9-speed super narrow chain

such as Silver TL-CN32 / TL-CN23 Rapidfire Plus SL-MC40 Use a handlebar grip with a maximum

CN-7701 / CN-HG93 6.5mm outer diameter of 32 mm. Tightening torque:

8- / 7- / 6-speed narrow Outer casing SP40 5 - 7 N·m {44 - 60 in. lbs.}

chain such as Black TL-CN32 / TL-CN23 Front derailleur FD-M411 / FD-M410 / FD-M330-E

CN-HG50 / CN-IG51 7.1mm Tightening torque:

Front chainwheel FC-M341 / FC-M341-8 6 - 8 N·m {53 - 69 in. lbs.} After taking up the initial slack in the cable, re-secure to the front

• If it is necessary to adjust the length of the chain due to Reinforced Connecting Pin ➁ Adapter ➀ Bottom Bracket derailleur as shown in the illustration.

a change in the number of sprocket teeth, make the cut Bottom bracket BB-UN26 / BB-UN26-E / BB-ES25

Spacer (2.5mm) Normal type Top route type

at some other place than the place where the chain Chain CN-HG50 / CN-HG40

has been joined using a reinforced connecting pin or

Bottom bracket cable guide SM-SP17 / SM-BT17 / SM-SP18 / SM-BT18

an end pin. The chain will be damaged if it is cut at a End Pin Link Pin 5 mm Allen key

➂ Front Chainwheel Pull

place where it has been joined with a reinforced

connecting pin or an end pin. • Install the shifting lever in a position where it will not obstruct Pull

• Be careful not to let the cuffs of your clothes get caught in the chain while riding, brake operation and gear shifting operation.

otherwise you may fall off the bicycle. Specifications • Do not use in a combination which causes brake operation to

• Check that the tension of the chain is correct and that the chain is not damaged. If the Adapter / bottom bracket tightening torque: be obstructed.

tension is too weak or the chain is damaged, the chain should be replaced. If this is Front Derailleur 50 - 70 N·m {435 - 608 in. lbs.}

X = Available

not done, the chain may break and cause serious injury. Front chainwheel tightening torque:

Model number FD-M410 / FD-M411 FD-M330-E 35 - 50 N·m {305 - 435 in. lbs.} 3. Top adjustment

• Check that there are no cracks in the crank arms before riding the bicycle. If there are

Set so that the clearance between the chain guide outer plate and

any cracks, the crank arm may break and you may fall off the bicycle. Normal type X X

the chain is 0-0.5 mm.

• Obtain and read the service instructions carefully prior to installing the parts.

Top route type X X

Loose, worn, or damaged parts may cause injury to the rider. We strongly recommend <FD-M410 / FD-M411>

only using genuine Shimano replacement parts. Front chainwheel tooth difference 20T 20T SIS adjustment

Install using the special tool TL-UN74-

• Obtain and read the service instructions carefully prior to installing the parts. Min. difference between top and intermediate 10T 10T S / TL-UN66. Be sure to follow the sequence described below.

If adjustments are not carried out correctly, the chain may come off and this may cause First install the main body, then the

Front derailleur installation band diameter S, M, L – 1. Low adjustment

you to fall off the bicycle which could result in serious injury. adapter.

First remove the Pro-Set alignment block. Top adjustment

• Read these Technical Service Instructions carefully, and keep them in a safe place for Chainstay angle (a) 63°- 66°, 66°- 69° 66°- 69° screw

later reference. Next, set so that the clearance between the chain guide Chain position

Applicable chain line 50.0mm inner plate and the chain is 0-0.5 mm. Smallest sprocket Largest chainring

Installation band diameters: Chainstay angle

Note S (28,6 mm), M (31,8 mm), L (34,9 mm) Adapter Main body

Pro-Set

alignment block

• In addition, if pedaling performance does not feel normal, check this once more. Chain guide outer

Chain plate

• Check that there is no looseness in any joints or connections before riding the bicycle.

(BB-FC, FC-PD) Chainwheel Adapter / bottom bracket tightening torque:

• Do not wash the bottom bracket with high-pressure jets of water. 50 - 70 N·m {435 - 608 in. lbs.}

• If you feel any looseness in the bottom bracket axle, the bottom bracket should be Model number FC-M341-8 FC-M341 FC-M341 Low adjustment 4. Adjustment of the intermediate chainring

replaced. Chainwheel tooth

screw When carrying out adjustment, set the chain to the largest sprocket,

• If gear shifting operations do not feel smooth, wash the derailleur and lubricate all 42-32-24T 48-38-28T Use an 8 mm Allen key to install the front chainwheel. Chain position and at the front, set the chain to the intermediate chainring. Adjust

combination

moving parts. using the outer casing adjustment barrel so that the clearance

Bolt circle diameter 104mm / 64mm 104mm / 64mm Largest sprocket Smallest chainring

• If the amount of looseness in the links is so great that adjustment is not possible, you between the chain guide inner plate and the chain is 0-0.5 mm.

Chain guide

should replace the derailleur. Crank arm length 170 mm, 175 mm 170 mm, 175 mm

inner plate

• Apply grease to the bottom bracket before installing it.

• For smooth operation, use the specified outer casing and the bottom bracket cable Applicable bottom bracket BB-ES25 BB-UN26 BB-UN26 (-K) Chain Chain position

guide. Intermediate

Largest sprocket

• You should periodically wash the chainrings in a neutral detergent and then lubricate Applicable front derailleur FD-M411 / FD-M410 / FD-M330-E FD-M410 / FD-M411 chainring

them again. In addition, cleaning the chain with neutral detergent and lubricating it can 8 mm Allen key

(TL-WR38)

be a effective way of extending the useful life of the chainrings and the chain. Pedal thread dimensions BC 9/16" X 20 T.P.I. (English thread) BC 9/16" X 20 T.P.I. (English thread) 2. Connecting and securing the inner cable

• If the chain keeps coming off the chainrings during use, replace the chainrings and the Operate lever (B) 2 or more times, check on the indicator

chain. that the low position is correct, and then secure the inner

• This front derailleur is for triple front chainwheel use only. It cannot be used with the Bottom Bracket

cable.

double front chainwheel, as the shifting points do not match. Chain guide

Model number BB-UN26-E BB-UN26 While firmly pulling the inner cable, secure by tightening the inner plate

• When installing the top route type, choose a frame that has three Outer casing holders Securely tighten fixing bolt with a 5 mm Allen key.

outer casing holders as shown in the illustration at right. Stamped marking LL123 LL113 LL123 LL113 Chain

• Use an outer casing which still has some length to spare even Spindle length 123 mm 113 mm 123 mm 113 mm

when the handlebars are turned all the way to both sides. Front chainwheel tightening torque:

Furthermore, check that the shifting lever does not touch the Chain line 50.0 mm 50.0 mm 50.0 mm 50.0 mm 35 - 50 N·m {305 - 435 in. lbs.}

Outer casing adjustment barrel

bicycle frame when the handlebars are turned all the way. Applicable front

FC-M411 FC-M410 FC-M411 FC-M410

• Grease the inner cable and the inside of the outer casing before chainwheel

use to ensure that they slide properly. BC 1.37" X 24 T.P.I. BC 1.37" X 24 T.P.I. (73m) BC 1.37" X 24 T.P.I. (68, 73 mm) Adjust and then install the front derailleur as shown in the illustration.

• Operation of the levers related to gear shifting should be made only when the front Thread dimensions Do not remove the Pro-Set alignment block at this time.

(68, 73mm) M 36 X 24 T.P.I. (70mm) M 36 X 24 T.P.I. (70mm) 3

Lever (B) 2

chainwheel is turning. 5. Troubleshooting chart

Pro-Set alignment block 1

• Parts are not guaranteed against natural wear or deterioration resulting from normal Model number BB-ES25 BB-ES25-E BB-UN26 (-K) After completion of steps 1 - 4, move the shifting lever to check the

use. Gear teeth should shifting. (This also applies if shifting becomes difficult during use.)

Stamped marking 118 118 LL123 Tightening torque :

• For maximum performance we highly recommend Shimano lubricants and come within this 5 - 7 N·m {44 - 60 in. lbs.}

maintenance products Spindle length 118 mm 118 mm 123 mm range If the chain falls to the crank side. Tighten the top adjustment screw

• For any questions regarding methods of installation, adjustment, maintenance or Chain line 50.0 mm 50.0 mm 50.0 mm clockwise (about 1/4 turn).

Pro-Set gauge

operation, please contact a professional bicycle dealer. Inserting the inner cable

Applicable front If shifting is difficult from the Loosen the top adjustment screw

FC-M410-8 FC-M410-8 FC-M411 Insert the inner cable into the outer casing from the end intermediate chainring to the counterclockwise (about 1/8 turn).

chainwheel

1 mm

with the marking on it. Apply grease from the end with the largest chainring.

BC 1.37" X 24 T.P.I. BC 1.37" X 24 T.P.I. BC 1.37" X 24 T.P.I. marking in order to

Thread dimensions If shifting is difficult from the Loosen the low adjustment screw

(68, 73mm) (68, 73mm) (68mm) 3 mm maintain cable operating intermediate chainring to the counterclockwise (about 1/4 turn).

efficiency. smallest chainring.

Marking

If there is interference between the Tighten the top adjustment screw

Gear shifting operation chain and the front derailleur inner clockwise (about 1/8 turn).

Cutting the outer casing plate at the largest chainring.

Both lever (A) and lever (B) always return to the initial position when they are released after shifting. The level section of the chain guide outer When cutting the outer casing, cut the opposite end to the If there is interference between the Loosen the top adjustment screw

When operating one of the levers, always be sure to turn the crank arm at the same time. plate should be directly above and parallel Chainwheel

end with the marking. After cutting the outer casing, make chain and the front derailleur outer counterclockwise (about 1/8 turn).

to the largest chainring. Secure using a 5 (largest chainring) the end round so that the inside of the plate at the largest chainring.

Lever (A) initial position mm Allen key. hole has a uniform diameter. If the intermediate chainring is Loosen the outer casing adjustment

To shift from a small chainring to a larger chainring

(Lever A) skipped when shifting from the barrel counterclockwise

Chain guide largest chainring. (1 or 2 turns).

When lever (A) is pressed once, there is a shift of one step

from a small chainring to a larger chainring. If there is interference between the Tighten the outer casing adjustment

Tightening torque :

Attach the same outer end cap to the cut end of the outer chain and front derailleur inner barrel clockwise (1 or 2 turns).

Example: 5 - 7 N·m {44 - 60 in. lbs.}

plate when the rear sprocket is

casing.

from intermediate chainring to largest chainring. shifted to the largest sprocket when

the chainwheel is at the

Outer end cap intermediate chainring position.

If the chain falls to the bottom Tighten the low adjustment screw

bracket side. clockwise (about 1/2 turn).

To shift from a large chainring to a smaller chainring

(Lever B)

When lever (B) is pressed once, there is a shift of one step

from a large chainring to a smaller chainring. This service instruction explains how to use and

maintain the Shimano bicycle parts which have been

Example: used on your new bicycle. For any questions One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

from largest chainring to intermediate chainring. regarding your bicycle or other matters which are not

related to Shimano parts, please contact the place of Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan

Lever (B)

purchase or the bicycle manufacturer. Please note: specifications are subject to change for improvement without notice. (English)

© Jan. 2007 by Shimano Inc. XBC IZM Printed in Singapore.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hatz Diesel - Diagnostic Trouble Codes SPN/FMI C81 - V6XX - 05653402Document28 pagesHatz Diesel - Diagnostic Trouble Codes SPN/FMI C81 - V6XX - 05653402MARINE DIESELNo ratings yet

- XT FD & Crank InstallationDocument1 pageXT FD & Crank InstallationMarNo ratings yet

- XT 2012 Brake SystemDocument1 pageXT 2012 Brake SystemMarNo ratings yet

- XT 2012 Brake Adding Mineral OilDocument1 pageXT 2012 Brake Adding Mineral OilMarNo ratings yet

- Alivio Front Drive SystemDocument1 pageAlivio Front Drive SystemMarNo ratings yet

- Suspension SystemDocument10 pagesSuspension SystemMécanique et Diagnostic automobileNo ratings yet

- BRIDGE ENGINEERING DefinitionDocument3 pagesBRIDGE ENGINEERING DefinitionFor TwitterNo ratings yet

- FSI Checklist (May 2011)Document13 pagesFSI Checklist (May 2011)Arun Mishra67% (3)

- Spare Part - ERGOS 15 TA 4AC - CatalogueDocument94 pagesSpare Part - ERGOS 15 TA 4AC - CatalogueВладимир ШыловNo ratings yet

- 2.0L EA888 TSI EngineDocument6 pages2.0L EA888 TSI EngineeliotroyanoNo ratings yet

- RCKHDocument39 pagesRCKH蔡雨澄No ratings yet

- NR 529 Safety Gas Fuelled EngineDocument36 pagesNR 529 Safety Gas Fuelled EngineSoren KjaerNo ratings yet

- Write The Clipped FormDocument4 pagesWrite The Clipped FormjenNo ratings yet

- 3 Months PDFDocument6 pages3 Months PDFMarkyNo ratings yet

- Research Paper Marine TransportationDocument6 pagesResearch Paper Marine Transportationafnjobmwsvoamu100% (3)

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- PMP-47-06 Tyres JRC-VTI Study and Next StepsDocument22 pagesPMP-47-06 Tyres JRC-VTI Study and Next StepsTahzeeb AttariNo ratings yet

- UR Z10-2 Rev23 Feb 2007Document99 pagesUR Z10-2 Rev23 Feb 2007Katsaras SotirisNo ratings yet

- Technical Volume PDFDocument14 pagesTechnical Volume PDFindramaniNo ratings yet

- History of Press in KeralaDocument10 pagesHistory of Press in KeralaDeepu Jose100% (1)

- Section F - Axles, Wheels and TransmissionDocument186 pagesSection F - Axles, Wheels and TransmissionAndré Targino100% (1)

- Employment Contract of Commercial Vessel's FishermanDocument6 pagesEmployment Contract of Commercial Vessel's FishermanCarlota TejeroNo ratings yet

- Lines PlanDocument1 pageLines PlanRachel Archie PangloliNo ratings yet

- Handover Report MasterDocument1 pageHandover Report MastercatalinNo ratings yet

- Shipyard PlanningStrategy + Case StudyDocument27 pagesShipyard PlanningStrategy + Case StudyAlgha PratiwaNo ratings yet

- Number: Group: Date:: America, EMEA and LATAMDocument7 pagesNumber: Group: Date:: America, EMEA and LATAMKleber OrdóñezNo ratings yet

- Cygnus Energy LNG News Weekly 04th June 2021Document20 pagesCygnus Energy LNG News Weekly 04th June 2021Sandesh Tukaram GhandatNo ratings yet

- ECU List 7 0 0 New Features ListDocument37 pagesECU List 7 0 0 New Features ListLUATNo ratings yet

- Clark Inflight Issue No 2Document24 pagesClark Inflight Issue No 2Eugene Ignaxius Reymond OrejasNo ratings yet

- Ship To Ship LNG Transfer GuidelinesDocument70 pagesShip To Ship LNG Transfer GuidelinesRobert WatersNo ratings yet

- NuclearDocument3 pagesNuclearjuliano.santosNo ratings yet

- Sublevel CavingDocument58 pagesSublevel Cavingchutiya1No ratings yet

- BTC Sweep 02Document6 pagesBTC Sweep 02paradoja_hiperbolicaNo ratings yet

- A Secretive Family Landing A 4 Billion Haul Has Everyone Guessing 52437Document3 pagesA Secretive Family Landing A 4 Billion Haul Has Everyone Guessing 52437siewyukNo ratings yet