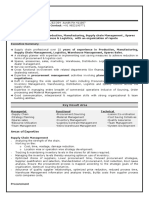

WAREHOUSE

SUPERVISOR

Looking for career enrichment opportunities in Material controller / Warehousing / Store

Management, Logistics, with a frontline organization in EPC, Construction, Production, and

Operation & Maintenance.

INFO SYNOPSIS

A result oriented professional with experience in Project and Execution.

NIAMAT KHAN Proficient in enhancing warehouse/store operations and optimizing resource utilization.

Cell: +966594722401 Adept at supervision, coordination, and team management and capable of group

niamat89@yahoo.com communication direct and co-ordinate the related task.

Jeddah shumaishy To lead and develop staff in warehousing.

deportation complex. An effective communicator with excellent relationship, management skills and strong

analytical, problem solving and organizational abilities.

ACADEMIC QUALIFICATION

Graduate from Hazara University Pakistan

ENGLISH: EXPERT

ARABIC: INTERMIDIATE TECHNICAL QUALIFICATION & CERTIFICATION

HINDI : EXPERT Electrical Domestic and Industrial Wiring and Fitting Certificate

URDU : EXPERT Plumbing Pipe Fitting Course

LINGUISTIC SKILLS

TECHNICAL SKILLS

1) Creating a storage system for inventory that’s orderly and accessible and

includes identifying information.

SKILLS 2) Managing inventory control using various industry software programs and

running daily shipping and receiving reports.

ERP System,ORACLE 3) Reviewing vendor pricing on a consistent basis to ensure the company is

Microsoft Dynamic AX receiving the best available pricing for each item.

2012 4) Creating and maintaining inventory, product cost and logistics data records

Microsoft office 2019/365 that are easily accessible.

Microsoft outlook 5) Ensuring that delivered items match purchase order documentation

6) Preparing detailed lists of items or goods that need purchasing or repairing.

Database management

7) Weighing and measuring products that enter the storage environment.

Material tag

8) Tools of the trade: using a variety of tools in our daily work.

Material History 9) Office Equipment and Software: using computers, scanners, printers and

Purchase order software to help create and maintain important inventory, purchasing and

Material receiving shipping records.

Material issue 10) Weighing and Measuring Equipment: To find the need to weigh and

Hazardous material measure inventory and need to be familiar with measurement tools and

Stock items scales.

11) Operating forklift where heavy items must be moved between

Inventory control departments and to storage locations.

Material control 12) Telephone and Email: Throughout the day, communicating with others

Logistics Inventory user departments by phone and email, which entails leaving and retrieving

levels Production area messages and reading and sending emails.

Mrp 13) Used the Banner Computer System to order and receive packages on-line.

Safety rules 14) Used RF bar-coding computer system for stocking and picking.

Warehouse layout 15) Familiar with mechanical piping materials.

Promotes teamwork 16) Familiar with electrical, hvac, low current and civil items.

Cultivating loyalty &

integrity

Loading & unloading

� TOTAL EXPERIENCE 10 YEARS

DUTIES & RESPONSIBLITY

1. Co-ordinate and monitor the receipt, storage and dispatch of goods. Supervises and monitor receiving and

proper handling/ storing of raw materials and finished goods.

2. Supervises and monitor dispatching of finished goods.

3. Reviews stocks of raw materials regularly and prepare the necessary request for replenishment if needed.

4. Updates daily inventory report of raw materials and finished goods.

5. Coordinates and follows-up all pending deliveries of ordered materials to concerned departments.

6. Leads the team in monthly physical count and prepare monthly inventory reports

7. Monitors the movements of stocks and strictly implements FIFO & FEFO.

8. Enforces good manufacturing practices in any logistics and warehousing activities.

9. Ensures that warehouse provide an adequate space for all stocks to avoid over stacking and damages and

strictly enforces proper housekeeping.

10. Ensure safety of finished goods, raw materials & packaging items from damages by conducting regular

inspection for all the stocks.

11. Maintains necessary records, proper receipts for all stocks movements and renders required reports.

12. Monitors all stocks movements such as non-moving and slow moving, conducts regular cycle inventory and

reconciliation.

13. Responsible for stock inventory.

14. Training people under the departments

15. Maintaining records.

16. Establishes system for keeping of inspection, and monitoring records as well as the occurrence of problem and

corrective action that resolve the problem.

17. Ensure orders are processed efficiently and that the delivery of materials meets customer’s

timescales/requirements.

18. Supervise and control order picking, goods in, goods out operations to ensure accuracy with minimum

handling and stock damage

19. Organize, facilitate and manage stock takes at regular intervals.

20. Ensure that all relevant procedures and processes are followed and adhered to in line with the Company’s

procedures and requirements.

21. Deliver the product to the customer in time, every time using appropriate methods

22. Identify errors and eliminate root cause using robust countermeasures.

23. Sustain the corrective actions to eliminate repeat issues.

24. Implement warehouse and management systems and working practices in line with best practice and

continuous improvement.