Professional Documents

Culture Documents

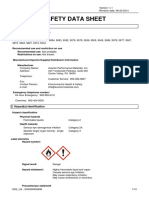

08-Polyguard Bs Me Msds

Uploaded by

shamroz khanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

08-Polyguard Bs Me Msds

Uploaded by

shamroz khanCopyright:

Available Formats

Conforms to ANSI Z400.

5-2004 Standard (United States, Canada)

Material Safety Data Sheet

1. Product and company identification

Produce Name: Polyguard BS ME Liquid Membrane Part B

Material uses: Product initiator

Supplier/Manufacturer: Polyguard Products

3801 South Interstate 45

Ennis, TX 75119

Tel (800) 541-4994

In case of emergency: CHEMTREC, US: +1-800-424-9300 International: +1-703-527-3887

2. Hazards identification

Physical state: Liquid

Odor: Slightly musty

OSHA/HCS status: This material is considered hazardous by the OSHA Hazardous Communication Standard. (

29CFR 1910.1200)

Potential acute health effects

Inhalation: Hazardous in case of inhalation (lung irritant, lung sensitizer).

Ingestion: Slightly hazardous in case of ingestion.

Skin: Hazardous in case of skin contact (irritant, sensitizer). Skin inflammation is characterized by

itching, scaling or reddening.

Eyes: Hazardous in case of eye contact ( irritant)

Potential chronic health effects

Chronic effects: Repeated inhalation of vapor or aerosol above the occupational exposure limits could cause

respiratory sensitization. A hyper- reactive response to even minimal concentrations of MDI

may develop in sensitized persons. Repeated and/or prolonged contact may cause skin

sensitization.

Carcinogenicity: Not listed as a carcinogen.

Mutagenicity: No known significant effects or critical hazards.

Teratogenicity: No birth defects were seen in two independent animal (rat) studies. Fetotoxicity was observed

at doses that were extremely toxic (including lethal) to the mother. Fetotoxicity was not

observed at doses that were not maternally toxic. The doses used in these studies were

maximal respirable concentrations well in excess of the defined occupational limits.

Fertility effects: No adverse reproductive effects are anticipated.

Over-exposure signs/symptoms

Inhalation: This product is a respiratory irritant and potential respiratory sensitizer. Repeated inhalation

of vapor or aerosol above the occupational exposure limits could cause respiratory

sensitization. Symptoms include irritation to the eyes, nose, throat and lungs, possibly

combined with dryness of the throat, tightness of the chest and difficulty breathing. The onset

of respiratory symptoms may be delayed for several hours after exposure. A hyper- reactive

response to even minimal concentrations of MDI may develop in sensitized persons.

Ingestion: Ingestion may cause irritation of the gastrointestinal tract.

Skin: Moderate irritant. Repeated and/or prolonged contact may cause skin sensitization.

Eyes: Adverse symptoms may include the following: pain and irritation, redness, watering.

Date of issue 5/4/11 85 liquid membrane- Part B 1 of 8

2. Hazards identification

Medical conditions aggravated by May cause or aggravate dermatitis and asthma.

over-exposure:

See toxicological information ( section 11)

3. Composition/information on ingredients

United States

Name CAS number %

Polymeric Diphenylmethane 101-68-8 100

Diisocyanate

There are no additional ingredients present which within the current knowledge if the supplier and in the concentrations

applicable, are classified as hazardous to health or the environment and hence require reporting in this section.

4. First aid measures

Eye contact: Check for and remove any contact lenses. In case of contact with eyes, rinse immediately

with plenty of water for at least 15 minutes. Get immediate medical attention.

Skin contact: Remove contaminated clothing. After contact with skin, wash immediately with plenty of

warm soapy water. If symptoms develop, obtain medical attention. Contaminated clothing

should be cleaned thoroughly cleaned. An MDI study has demonstrated that polyglycol-

based skin cleanser or corn oil may be more effective than soap and water.

Inhalation: Remove patient from exposure, keep warm and at rest. Obtain immediate medical attention.

Treatment is symptomatic for primary irritation and bronchospasm. If breathing is labored,

oxygen should be given by administered by qualified personal. Apply artificial respiration if

breathing has ceased or shows signs of failing.

Ingestion: Do not induce vomiting. Never give anything by mouth to an unconscious person. Provided

that patient is conscious, wash mouth out with water. Seek medical attention immediately.

Protection of first-aiders: No action shall be taken involving any personal risk or without suitable training. It may be

dangerous to the person providing aid to give mouth to mouth resuscitation.

Notes to physician: Symptomatic and supportive therapy as needed. Following severe exposure medical follow

up should be monitored for at least 48 hrs.

5. Fire-fighting measures

Flammability of the product: Not considered flammable.

Extinguishing media

Suitable: SMALL FIRE- Use dry chemical.

SMALL FIRE- Use Water spray, Fog or Foam.

Not suitable: Do not use water jet

Hazardous thermal Decomposition products may include the following materials: Carbon Dioxide, Carbon

decomposition products: Monoxide, Nitrous Oxide and HCN.

Special protective equipment: Fire-fighters should wear appropriate protective equipment and self-contained breathing

apparatus (SCBA) with a full-piece face mask operating in a positive pressure mode. Splash

goggles, full suit boots and gloves.

Date of issue 5/4/11 85 liquid membrane- Part B 2 of 8

5. Fire-fighting measures

Special Remarks on Fire Hazards Reacts slowly with water to produce carbon dioxide which may rupture closed containers.

This reaction accelerates at higher temperatures.

6. Accidental release measures

Personal precautions: No actions shall be taken involving any personal risk or without suitable training. Evacuate

surrounding areas. Keep unnecessary and unprotected personal from entering. Do not touch

or walk through spilled material. Test area for MDI .Avoid breathing vapor or mist. Provide

adequate ventilation. Wear respirator when ventilation is inadequate. Put on appropriate

personal protective equipment (see section 8).

Environmental Precautions: Avoid dispersal of spilled material and runoff and contact with soil, waterways, drains and

sewers. Inform the relevant authorities if the product has caused environmental pollution

(sewers, waterways, soil or air). Notify applicable governmental authorities if release is

reportable. The CERCLA RQ for 4,4- MDI is 5,000 lbs.

Method for clean up

Small spill: Clean up should only be performed by trained personnel. People dealing with major spillages

should wear full protective clothing including appropriate respiratory protection. Evacuate

the area. Neutralize small spillages with decontaminate. Remove and dispose of residue.

Prevent further leakage, spillage or entry into drains. Dispose of via a licensed waste disposal

contractor.

Large spill: Contain and absorb large spillages onto an inert, non-flammable absorbent carrier (such as

earth or sand). Shovel into open-top drums or plastic bags for further decontamination, if

necessary. Wash the spillage area clean with liquid decontaminant.

Decontaminant Preparation of Decontaminate Solution: Prepare a decontaminate solution of 0.2-0.5 % liquid

detergent and 3-8 % concentrated ammonium hydroxide in water (5-10 % sodium carbonate

may be substituted for the ammonium hydroxide). Follow the precautions on the supplier’s

material safety data sheets when preparing and using the solution. Use of Decontaminate

Solution: Allow deactivated material to stand for at least 30 minutes before shoveling into

drums. Do not tighten the bungs. Mixing with wet earth is also effective, but slower.

7. Handling and storage

Handling: Avoid personal contact with the product or reaction mixture. Put on appropriate personal

protective equipment (see section 8). Do not get in eyes or on skin or clothing. Do not breathe

vapor, aerosols or mist. Do not ingest. Use only adequate ventilation. Wear appropriate

respirator when ventilation is inadequate. Do not enter storage areas and confined spaces

unless adequately ventilated. Keep in the original container or an approved alternative made

from compatible material, kept tightly closed when not in use. Empty containers retain

product residue and can be hazardous. Do not reuse container.

Storage: Store in accordance with local regulations. Keep containers properly sealed and when stored

indoors, in a well ventilated area. Keep contents away from moisture. Due to reaction with

water, producing CO2 gas, a hazardous build up of pressure could result if contaminated

containers are resealed. Do not reseal contaminated containers. Uncontaminated containers,

free of moisture, may be resealed only after placing under a nitrogen blanket. Do not store in

containers made of copper, copper alloys or galvanized surfaces. An ideal storage

temperature is 16-38 C (660-100 F).

Date of issue 5/4/11 85 liquid membrane- Part B 3 of 8

8. Exposure controls/personal protection

United States

Product name Exposure limits

Polymeric Diphenylmethane Diisocyanate NIOSH REL

CEIL: 0.2 mg/m3 10 minute(s)

TWA: 0.5 mg/m3 10 hour(s)

OSHA PEL

CEIL: 0.2 mg/m3

ACGIH TLV

TWA: 0.5 mg/m3 10 hour(s)

Consult local authorities for acceptable exposure limits.

Recommended monitoring Conditions of use, adequacy of engineering or other control measure, and actual exposures will

procedure: dictate the need for specific protective devices at your workplace.

Engineering measures: Use local exhaust ventilation to maintain airborne concentrations below the TLV. Suitable

respiratory equipment should be used in cases of insufficient ventilation or where operational

procedures demand it. For guidance on engineering control measures refer to publications such

as ACGIH current edition of “Industrial Ventilation, a manual of Recommended Practice.

Exposure controls: Medical supervision of all employees who handle or come in contact with respiratory

sensitizers is recommended. Persons with respiratory problems including asthmatic type

conditions, chronic bronchitis, other chronic respiratory diseases or recurrent skin eczema or

skin allergies should be evaluated for their suitability of working with this product. Once a

person is diagnosed as sensitized, no further exposure to the material that caused the

sensitization should be permitted. The Occupational Exposure limits do not apply to previously

sensitized individuals.

Hygiene measures: Wash hands, forearms and face thoroughly after handling chemical products, before eating,

smoking and using the lavatory and at the end of the working period. Appropriate techniques

should be used to remove potentially contaminated clothing. Wash contaminated clothing

before reusing. Ensure that eyewash stations and safety showers are close to the workstation

location.

Personal protection

Eyes Chemical safety goggles. If potential for splashing, use a full face shield.

Skin Overalls button at the wrist & neck

Respiratory When the product is sprayed or heated without adequate ventilation, an approved

MSHA/NIOSH positive pressure, supplied air respirator may be required. Air purifying

respirators equipped with organic vapor cartridges and a HEPA ( P100) particulate filter maybe

used under certain conditions when a cartridge change-out schedule has been developed in

accordance with OSHA respiratory protection standard ( 29 CFR 1910.134)

Hands Gloves- neoprene, nitrile rubber, butyl rubber. Thin latex disposable gloves should be avoided

for repeated or long term use.

Protective equipment

Environmental exposure controls Emissions from ventilation or work process equipment should be checked to ensure they

comply with the requirements of environmental protection legislation. In some cases, fume

scrubbers, filters or engineering modifications to the process equipment will be necessary to

reduce emissions to acceptable levels.

Date of issue 5/4/11 85 liquid membrane- Part B 4 of 8

9. Physical and chemical properties

Physical state: Liquid

Flash point Closed cup: > 110 C (230 F) ( Set-a-Flash)

Auto ignition temperature > 600 C ( 1112 F)

Flammable limits Not available

Color Brown

Odor Slightly musty

Boiling /Condensation Point > 300 C ( 572 F) decomposes

Specific Gravity: 1.2 ( water=1)

Vapor Pressure: 1 E -5 mmHg

Vapor Density 8.5 [Air=1]

Evaporation rate Not available

NCO Content % 32.5 %

10. Stability and reactivity

Stability: The product is stable at room temperature.

Hazardous polymerization: Polymerization may occur at elevated temperatures in the presence of alkalis, tertiary amines

and metal compounds.

Conditions to avoid: Avoid high temperatures and freezing.

Materials to avoid: Strong alkalis, acids and alcohols.

Hazardous decomposition: Carbon Monoxide, carbon Dioxide, Nitrous Oxide and HCN.

11. Toxicological information

Acute Toxicity

Product/ingredient name Species Dose Result Exposure

Polymeric Diphenylmethane Diisocyanate Rabbit > 5000 mg/kg LD50 Dermal -

Rat > 5000 mg/kg LD50 oral -

Rat 2240mg/m3 LC 50 Respirable 1 hr

aerosol

Rat 0.49 mg/m3 LC 50 Respirable 4 hr

aerosol

Inhalation: This product is a respiratory irritant and potential respiratory sensitizer. Repeated

inhalation of vapor or aerosol above the occupational exposure limits could cause

respiratory sensitization. Symptoms include irritation to the eyes, nose, throat and

lungs, possibly combined with dryness of the throat, tightness of the chest and

difficulty breathing. The onset of respiratory symptoms may be delayed for several

hours after exposure. A hyper- reactive response to even minimal concentrations of

MDI may develop in sensitized persons.

Ingestion: Ingestion may cause irritation of the gastrointestinal tract. Based on the acute oral

LD50 this product is considered practically non-toxic by ingestion.

Skin: Moderate irritant. Repeated and/or prolonged contact may cause skin sensitization.

There is limited evidence from animal studies that skin contact may play a role in

respiratory sensitization. These results emphasis the need for protective clothing

including gloves to be worn at all times when handling these chemicals or in

maintenance work.

Eyes: The vapor, aerosol, and liquid are irritants.

Date of issue 5/4/11 85 liquid membrane- Part B 5 of 8

11. Toxicological information

Carcinogenicity

classification

Product/ingredient name ACGIH IARC EPA NIOSH NTP OSHA

Polymeric - 3 - - - -

Diphenylmethane

Diisocyanate

12. Ecological information

Environmental effects: No known significant or critical hazards.

Aquatic ecotoxicity:

Product/ingredient name Test Species Exposures Results

Polymeric Diphenylmethane - Zebra Fish - LC 50 > 1000 mg/L

Diisocyanate

- Daphnia 24 hours EC50 > 1000 mg/L

magna

- E Coli - EC 50 > 100 mg/L

13. Disposal considerations

Waste disposal : The generation of waste should be avoided or minimized wherever possible. Empty

containers or liners may retain some product residues. This material and its container must

be disposed of in a safe way. Dispose of surplus and non-recyclable products via a licensed

waste disposal contractor. Disposal of this product, solutions and any by-products should at

all times comply with the requirements of environmental protection and waste disposal

legislation and any regional local authority requirements. Avoid dispersal of spilled

material and runoff and contact with soil, waterways, drains and sewers.

Disposal should be in accordance with applicable regional, national and local laws and regulations.

Refer to section 7: HANDLING AND STORAGE and section 8: EXPOSURE CONTROL/PERSONAL PROTECTION for

additional handling information and protection of employees.

14. Transportation information

DOT Classification * Single containers less than 5,000 lbs are not regulated. Single containers with 5,000 lbs or more of 4,

4, - Methyl diisocyanate are regulated. See information listed below.

AERG: 171

Regulatory Un Number Proper Shipping Classes PG Label Additional

Information Name Information

Other regulated

substances liquid Misc.

DOT Classification NA 3082 N.O.S. ( Methyl 9 III Hazardous RQ

Diphenyl materials

Diisocyanate)

TDG Classification Not regulated

IMDG Class Not regulated

IATA-DGR Class Not regulated

Date of issue 5/4/11 85 liquid membrane- Part B 6 of 8

15. Regulatory information

United States

HCS Classification: Toxic material

Irritating material

Sensitizing material

U.S. Federal regulations: TSCA 4(a) final test rules: None

United States Inventory (TSCA 8b): All components are listed or exempted.

TSCA 12(d) Unpublished health/safety studies

TSCA 12(e) Risk notification: 8EHQ-0892-9111

SARA 302/304 Emergency Planning and Notification: No products were found.

SARA 302/304/311/312 hazardous chemicals: No products found

SARA 311/312 MSDS Distribution- Chemical inventory –hazard identification

No products listed.

Clean Water Act (CWA) 307: No products found

Clean Water Act (CWA) 311: No products found

Clean Air Act (CAA) 112 accidental release prevention No products were found.

Clean Air Act (CAA) 112 regulated flammable substances No products were found.

Clean Air Act (CAA) 112 regulated toxic No products were found.

SARA 313

Form R- Reporting Product name CAS number Concentration

Requirements

Diisocyanate compounds 9016-87-9 100 %

Category code N 120

Supplier notification Diisocyanate compounds 9016-87-9 100 %

Category code N 120

EPCRA section 313 (40 CFR 372) CERCLA (Comprehensive Environmental Response, Compensation and liability Act) 4, 4- Methyl

diphenyl diisocyanate (CAS 101-68-8) has been a 5,000 lb RQ (reportable quantity). Any spill or release above the RQ must be

reported to the National response Center. (800-424-8802).

SARA 313 notifications must not be detached from the MSDS and any copying and redistribution of the MSDS shall include copying

and redistribution of the notice attached to copies of the MSDS subsequently redistributed.

California Prop. 65 No chemicals listed

Canada

WHMIS (Canada): Class D-1A: Material causing immediate and serious toxic effects ( VERY TOXIC)

Class D-2A: Material causing other toxic effects ( VERY TOXIC)

Class D-2B: Material causing other toxic effects ( toxic)

16. Other information

Causes damage to the following organs: Lungs, respiratory tract, skin, eyes. May be harmful is

inhaled. May cause respiratory tract, eye and skin irritation. May cause allergic respiratory and skin

reaction.

Date of issue 5/4/11 85 liquid membrane- Part B 7 of 8

16. Other information

Hazardous Material

Information System (USA) Health - *2 HAZARD RATING

Fire Hazard- 1 4- Extreme

Physical Hazard 1 3-Serious

Personal Protection 2- Moderate

1- Slight

0- Minimal

See section 8 for more detailed information on

personal protection.

The customer is responsible for determining the PPE code for this material.

National Fire Protection

Association (USA) Health 2

Flammability 1

Instability 1

Special

References: ANSI Z400.5, MSDS standard, 2004.-Manufacturer’s Material Safety Data Sheet- 29CFR

Part1910.1200 OSHA MSDS Requirements.-49 CFR Table List of Hazardous Materials, UN #, Proper

Shipping Names, PG. – NIOSH Pocket Guide.

Date of Issue: 5/4/11

Version: 2

Notice to reader: To the best of our knowledge, the information contained herein is accurate. However, neither the above named

supplier nor any of its subsidiaries assumes any liability whatsoever for the accuracy or completeness of the information

contained herein. Final determination of suitability of any material is the sole responsibility of the user. All materials may

present unknown hazards and should be used with caution. Although certain hazards are described herein, we cannot guarantee

that these are the only hazards that exist.

Date of issue 5/4/11 85 liquid membrane- Part B 8 of 8

You might also like

- SAEP-13 - 09 - 19 - 22 - NTC.1 (Fina)Document91 pagesSAEP-13 - 09 - 19 - 22 - NTC.1 (Fina)shamroz khan100% (1)

- Fire Officer Interview Question & AnswersDocument14 pagesFire Officer Interview Question & Answersshamroz khanNo ratings yet

- Naib Tehsildar Previous Year Paper VINOD PUBLICATIONS PDFDocument8 pagesNaib Tehsildar Previous Year Paper VINOD PUBLICATIONS PDFShahnawaz Mustafa100% (1)

- Safety Data Sheet: Section 1. IdentificationDocument9 pagesSafety Data Sheet: Section 1. IdentificationJosePPMolinaNo ratings yet

- DOPO-Me Bisphenol - UN Form SDS PDFDocument9 pagesDOPO-Me Bisphenol - UN Form SDS PDFAl RammohanNo ratings yet

- Material Safety Data Sheet: Pilot IIDocument7 pagesMaterial Safety Data Sheet: Pilot IIBeyar. ShNo ratings yet

- Epibond 1534 ABDocument26 pagesEpibond 1534 ABNikolayNo ratings yet

- Safety Data SheetDocument5 pagesSafety Data SheetRafael FrançaNo ratings yet

- Hepa-S200 English Us 3.00Document10 pagesHepa-S200 English Us 3.00Edy WijayaNo ratings yet

- SAFETY DATA SHEET FOR SODIUM CHLORIDEDocument10 pagesSAFETY DATA SHEET FOR SODIUM CHLORIDEjhohurry RojoNo ratings yet

- PPD 2 - Champion X Para19304aDocument9 pagesPPD 2 - Champion X Para19304aJeevanNo ratings yet

- Bhi SCW203Document10 pagesBhi SCW203Seoudi AbdelhafidNo ratings yet

- Safety Data Sheet for CamphorDocument7 pagesSafety Data Sheet for CamphorNur HasanahNo ratings yet

- Safety Data Sheet: Multitherm Pg-1 Heat Transfer FluidDocument8 pagesSafety Data Sheet: Multitherm Pg-1 Heat Transfer FluidRoberto ZevallosNo ratings yet

- MSDS Desoximetasone Ointment 0.25 TeligentDocument4 pagesMSDS Desoximetasone Ointment 0.25 TeligentIntan AisyahNo ratings yet

- SDS Epi 1909 en 220923Document9 pagesSDS Epi 1909 en 220923juprykaNo ratings yet

- Data ShhetDocument12 pagesData ShhetDiego MarquinaNo ratings yet

- Sds Poly Guard FDA 32 Us EngDocument10 pagesSds Poly Guard FDA 32 Us EngÆ José TonatiuNo ratings yet

- Q05693 - Quadra - Canada (CA) SDS HPR 2015 - EngDocument10 pagesQ05693 - Quadra - Canada (CA) SDS HPR 2015 - EngJean GrégoireNo ratings yet

- Castrol Brayco Micronic LV3Document10 pagesCastrol Brayco Micronic LV3Khoon Fen KBNo ratings yet

- Snoop Soap SolutionDocument11 pagesSnoop Soap SolutionskandagroupsblrNo ratings yet

- Make Up V 705-DDocument10 pagesMake Up V 705-DRowi ArifudinNo ratings yet

- Lewatit Monoplus S 108 KRDocument8 pagesLewatit Monoplus S 108 KRcabooseNo ratings yet

- SDS Epi 1970 en 220923Document10 pagesSDS Epi 1970 en 220923juprykaNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. IdentificationAliciaNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document6 pagesMaterial Safety Data Sheet: Product and Company Identification 1zubair1950No ratings yet

- SAFETY DATADocument10 pagesSAFETY DATAahmedalgaloNo ratings yet

- BUNDocument10 pagesBUNJermain BarbadosNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. IdentificationBalaji SNo ratings yet

- Material Safety Data SheetDocument7 pagesMaterial Safety Data SheetBryan Ramírez CaicheNo ratings yet

- Blb8002f Sds SGP Eng WT ActDocument7 pagesBlb8002f Sds SGP Eng WT ActKhizar NaqviNo ratings yet

- Cumene DatasheetDocument12 pagesCumene DatasheetDiana BanuNo ratings yet

- Mortein FKD Fly & Mosquito Killer Aerosol, All Scents-V6.2-D0067111 PDFDocument11 pagesMortein FKD Fly & Mosquito Killer Aerosol, All Scents-V6.2-D0067111 PDFAbbas AlzydiNo ratings yet

- Mpa-1 Usa PDFDocument7 pagesMpa-1 Usa PDFAquiles CarreraNo ratings yet

- SAFETY DATADocument9 pagesSAFETY DATAJohn SabestianNo ratings yet

- Hypo-Chlor 5.25%: Safety Data SheetDocument6 pagesHypo-Chlor 5.25%: Safety Data SheetAincad HunterNo ratings yet

- Warm Yellow MsdsDocument3 pagesWarm Yellow Msdsapi-373957590No ratings yet

- Isopropyl-Alcohol Cleaner SdsDocument12 pagesIsopropyl-Alcohol Cleaner Sdswalha kamelNo ratings yet

- h8874 en 20170802Document12 pagesh8874 en 20170802r vasudevNo ratings yet

- Material Safety Data Sheet: Cetrimonium ChlorideDocument2 pagesMaterial Safety Data Sheet: Cetrimonium ChlorideRoberto IturraldeNo ratings yet

- Adblue Material SafetyDocument8 pagesAdblue Material SafetyMadalin DaniliucNo ratings yet

- Jotashield Tex Medium SDSDocument9 pagesJotashield Tex Medium SDSARUN PRASANTHNo ratings yet

- OM-IB542000H MSDS - Apcoflor TC 510 HardenerDocument8 pagesOM-IB542000H MSDS - Apcoflor TC 510 HardenerdeekshithNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. Identificationfitrisya luckiNo ratings yet

- SYLOBEAD Molecular Sieve 512Document5 pagesSYLOBEAD Molecular Sieve 512Ian MannNo ratings yet

- Anti Foaming Liquid-MSDSDocument11 pagesAnti Foaming Liquid-MSDSsandeep HSENo ratings yet

- M-I LLC Duo-Vis SdsDocument6 pagesM-I LLC Duo-Vis Sdsmazen mahrousNo ratings yet

- 131-msds 2014Document11 pages131-msds 2014ivan_kenzo1290No ratings yet

- GuaiacolDocument4 pagesGuaiacolMiranti PuspitasariNo ratings yet

- Apcomin Ind Enl RAL 7040 - MSDSDocument8 pagesApcomin Ind Enl RAL 7040 - MSDSArun RajaNo ratings yet

- Sds - Efflux C-Y Cas (Ghs4e)Document5 pagesSds - Efflux C-Y Cas (Ghs4e)Sophie TranNo ratings yet

- Oil Block Primer Part b Sds 010116Document5 pagesOil Block Primer Part b Sds 010116陈辉No ratings yet

- Sds Dulux Ambiance Metallic CopperDocument11 pagesSds Dulux Ambiance Metallic CopperMeliany SariNo ratings yet

- Ulvac Ulvoil r7Document5 pagesUlvac Ulvoil r7Hiskia Benindo PurbaNo ratings yet

- Gunites (7000, 7001, 7100, 7101, 7500) : Dry/Wet Sprayable Mortar/ ConcreteDocument8 pagesGunites (7000, 7001, 7100, 7101, 7500) : Dry/Wet Sprayable Mortar/ ConcreteRavi SinghNo ratings yet

- Fipronil Sds UsDocument8 pagesFipronil Sds UsAhmedNo ratings yet

- MSDS (16) Foamaxx QS PlusDocument4 pagesMSDS (16) Foamaxx QS PlusKhadar SetiawanNo ratings yet

- Methylen Chloride MSDS 00029431Document10 pagesMethylen Chloride MSDS 00029431Ibad MuhammedNo ratings yet

- Pengard Comp B - Jotun - SDSDocument13 pagesPengard Comp B - Jotun - SDSmani nadarNo ratings yet

- Safety Data Sheet for 2-PropanolDocument10 pagesSafety Data Sheet for 2-PropanolPurwito SigitNo ratings yet

- Material Safety Data Sheet: Elan Chemical Company, IncDocument5 pagesMaterial Safety Data Sheet: Elan Chemical Company, IncVanesh NezhNo ratings yet

- Nutraphos Calzinc 2.0 20230131Document15 pagesNutraphos Calzinc 2.0 20230131azhaniNo ratings yet

- Survival Skills: How to Survive Anything and Anywhere in the World (A Comprehensive Guide to Preparing for and Overcoming Challenges of Earthquakes)From EverandSurvival Skills: How to Survive Anything and Anywhere in the World (A Comprehensive Guide to Preparing for and Overcoming Challenges of Earthquakes)No ratings yet

- 06 Grease MSDSDocument11 pages06 Grease MSDSshamroz khanNo ratings yet

- Clorox Original Bleach PDFDocument10 pagesClorox Original Bleach PDFPubcrawlNo ratings yet

- MSDS Gasoline by HollyFront (2017)Document13 pagesMSDS Gasoline by HollyFront (2017)Torero02No ratings yet

- MSDS Fast - Acrylic - Lacquer - ThinnerDocument9 pagesMSDS Fast - Acrylic - Lacquer - ThinnerM.FAIZAN ARSHADNo ratings yet

- California CARB Compliant: Safety Data SheetDocument5 pagesCalifornia CARB Compliant: Safety Data SheetFriddyNo ratings yet

- Sds Fuel Diesel Vgo Cas 68334Document14 pagesSds Fuel Diesel Vgo Cas 68334TestNo ratings yet

- Extracted - Hydrology, Soil and Water Quality Control PlanDocument8 pagesExtracted - Hydrology, Soil and Water Quality Control Planshamroz khanNo ratings yet

- 03-Hand Soap MSDSDocument8 pages03-Hand Soap MSDSshamroz khanNo ratings yet

- Vehicle Inspection Check ListDocument1 pageVehicle Inspection Check Listshamroz khanNo ratings yet

- AlQattan-Sand Storm Drill Ss-in-KuwaitDocument212 pagesAlQattan-Sand Storm Drill Ss-in-Kuwaitshamroz khanNo ratings yet

- Weekly HSE Management Site Walkthrough Plan-BI 243-AL GIHAZDocument1 pageWeekly HSE Management Site Walkthrough Plan-BI 243-AL GIHAZshamroz khanNo ratings yet

- 38#weekly Environmental Highlights BI 243 Al-Gihaz - 21-09-2022Document6 pages38#weekly Environmental Highlights BI 243 Al-Gihaz - 21-09-2022shamroz khanNo ratings yet

- Hafeez Ur RehmanDocument6 pagesHafeez Ur Rehmanshamroz khanNo ratings yet

- 39#weekly Environmental Highlights BI 243 Al-Gihaz - 21-09-2022Document6 pages39#weekly Environmental Highlights BI 243 Al-Gihaz - 21-09-2022shamroz khanNo ratings yet

- 37#weekly Environmental HighlightsDocument6 pages37#weekly Environmental Highlightsshamroz khanNo ratings yet

- Ijerph 19 07382Document17 pagesIjerph 19 07382shamroz khanNo ratings yet

- Safety Officer Interview QuestionsDocument2 pagesSafety Officer Interview Questionskishan KKNo ratings yet

- 36-#Weekly Environmental Highlights BI 243 Al-Gihaz 10-09-2022Document5 pages36-#Weekly Environmental Highlights BI 243 Al-Gihaz 10-09-2022shamroz khanNo ratings yet

- 38#weekly Environmental Highlights BI 243 Al-Gihaz - 21-09-2022Document6 pages38#weekly Environmental Highlights BI 243 Al-Gihaz - 21-09-2022shamroz khanNo ratings yet

- Section 4-1 SOPDocument31 pagesSection 4-1 SOPshamroz khan100% (1)

- Whole-Body VibrationDocument1 pageWhole-Body Vibrationshamroz khanNo ratings yet

- D-9 EPD Approved EIA Consultants (September 2017)Document1 pageD-9 EPD Approved EIA Consultants (September 2017)shamroz khanNo ratings yet

- SOP 16 Management of FuellingDocument7 pagesSOP 16 Management of Fuellingshamroz khanNo ratings yet

- Section 5-2 HACCP PLANDocument3 pagesSection 5-2 HACCP PLANshamroz khanNo ratings yet

- Iphone 14 Plus PER Sept2022Document9 pagesIphone 14 Plus PER Sept2022shamroz khanNo ratings yet

- Food Safety Management SystemDocument28 pagesFood Safety Management SystemVeny Wijayanti Candra MariaNo ratings yet

- Trans Environmental Awareness Signs 2015 01Document3 pagesTrans Environmental Awareness Signs 2015 01shamroz khanNo ratings yet

- Summary of The Competition Commission of India Order No. 022023 Dt. 190723Document2 pagesSummary of The Competition Commission of India Order No. 022023 Dt. 190723Siddheesh YadavNo ratings yet

- G.R. No. L-17739 December 24, 1964 ITOGON-SUYOC MINES, INC., Petitioner, Jose Baldo, Sangilo-Itogon Workers Union and Court of Industrial RELATIONS, RespondentsDocument4 pagesG.R. No. L-17739 December 24, 1964 ITOGON-SUYOC MINES, INC., Petitioner, Jose Baldo, Sangilo-Itogon Workers Union and Court of Industrial RELATIONS, RespondentsAddAllNo ratings yet

- Pictorials During The Launching of School Reading Program Project "ABAKADA KA" (Anolingan Basa Alang Sa Kahibalo Ug Dakong Kalambuan Nimo)Document5 pagesPictorials During The Launching of School Reading Program Project "ABAKADA KA" (Anolingan Basa Alang Sa Kahibalo Ug Dakong Kalambuan Nimo)Rose Mae Cagampang PawayNo ratings yet

- Preference SharesDocument7 pagesPreference Sharesmayuresh bariNo ratings yet

- HazingDocument29 pagesHazingJulius ManaloNo ratings yet

- Technological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityDocument10 pagesTechnological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityJheo TorresNo ratings yet

- Dl-54b Photo ID Card ChangeDocument2 pagesDl-54b Photo ID Card ChangePA Work LicenseNo ratings yet

- Forklift ChecklistDocument5 pagesForklift ChecklistCJ BoeyNo ratings yet

- Analyzing The Firm's Cash FlowDocument12 pagesAnalyzing The Firm's Cash FlowJohn Joseph CambaNo ratings yet

- Property Management ManualDocument44 pagesProperty Management ManualChosnyid UmmaNo ratings yet

- 7 ElevenDocument4 pages7 Elevenangel_angiNo ratings yet

- HyperMesh 12.0 Tutorials-ANSYSDocument60 pagesHyperMesh 12.0 Tutorials-ANSYSĐỗ Minh ĐứcNo ratings yet

- SumTotal Talent Acquisition 19.2 Onboarding Administrator GuideDocument75 pagesSumTotal Talent Acquisition 19.2 Onboarding Administrator GuideVincent John RigorNo ratings yet

- Regulation S DisclaimerDocument2 pagesRegulation S DisclaimerDouglas SlainNo ratings yet

- Social Issues Brainstorming and SpeakingDocument7 pagesSocial Issues Brainstorming and SpeakingNatasa BudisinNo ratings yet

- Distinguishing The Types of Historical SourcesDocument3 pagesDistinguishing The Types of Historical SourcesCassandraNo ratings yet

- Faculty of Social Sciences Banaras Hindu University VaranasiDocument7 pagesFaculty of Social Sciences Banaras Hindu University VaranasiSNo ratings yet

- Legal Basis of ARRESTS - LECTUREDocument34 pagesLegal Basis of ARRESTS - LECTUREBielle BlissNo ratings yet

- Accounting For Managers-Unit-1Document21 pagesAccounting For Managers-Unit-1VenkateshNo ratings yet

- Bad Debts and Provision For Doubtful DebtDocument22 pagesBad Debts and Provision For Doubtful DebtNauman HashmiNo ratings yet

- Analysis About OPLANDocument3 pagesAnalysis About OPLANMsy SarsonasNo ratings yet

- Chapter 2 Basic LawsDocument15 pagesChapter 2 Basic LawsChristian Muli0% (1)

- Assessing The Department of Homeland Security Yousuf Aboutaam HM 101 - Homeland Security December 9, 2014 Schoolcraft Community CollegeDocument18 pagesAssessing The Department of Homeland Security Yousuf Aboutaam HM 101 - Homeland Security December 9, 2014 Schoolcraft Community Collegeaboutaam3No ratings yet

- Fulgado v. Court of AppealsDocument8 pagesFulgado v. Court of AppealsSei KawamotoNo ratings yet

- Summary of ArgumentsDocument12 pagesSummary of ArgumentsArchana MuraliNo ratings yet

- MCCP LeafDocument2 pagesMCCP LeafManish GoelNo ratings yet

- ROSADO - MSDS - 8374 - SDS - GB - en - Interflon - Food - Lube - AerosolDocument14 pagesROSADO - MSDS - 8374 - SDS - GB - en - Interflon - Food - Lube - AerosolNyriamNo ratings yet

- Level 3 CPNI Certification 2016 For 2015 Final (2.26.2016) PDFDocument3 pagesLevel 3 CPNI Certification 2016 For 2015 Final (2.26.2016) PDFFederal Communications Commission (FCC)No ratings yet

- Pakistan Donor ProfileDocument47 pagesPakistan Donor ProfileAtif Ahmad KhanNo ratings yet