Professional Documents

Culture Documents

Cladding Curtainwall

Uploaded by

RAJA NADHIRAH BT RAJA IBRAHIM0 ratings0% found this document useful (0 votes)

6 views13 pagesOriginal Title

cladding_curtainwall

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views13 pagesCladding Curtainwall

Uploaded by

RAJA NADHIRAH BT RAJA IBRAHIMCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

Definition :

A system of cladding comprising a frame or

grid of members fixed to the face of a structure,

usually at each floor level and as an infilling of

panels, glazed or solid as may be required to

perform both the functions of window and

wall.

Curtain walls must fulfill certain functional

requirements as other wall systems:

¨ Strength and stability

¨ Movement

¨ Weather resistance

¨ Thermal insulation and condensation

¨ Sound insulation

¨ Materials of construction

Strength and stability

- Must be able to carry its own weight

- Capable of resisting horizontal loadings (the

higher off ground the greater wind speed etc.)

- Fixing must be able to resist wind loading etc.

- Able to transfer all loads to structural frames

- May use energy absorbing connections or

seismic design

Movement

- Allows for differential movements between

parts (between framing & structure, vertical &

horizontal members and framing and infilling

panels)

- Joints and connections must be designed with

to allow for movements etc.

- Movement can also happens due to internal

and external temperature levels

Weather resistance

- Must be waterproof using impervious

materials such as glass, metals and plastics

- Joints must have sufficient tolerances for

movement to avoid leaks (waterproofed strips

etc)

- Joints must be flexible and need to be sealed

Thermal insulation and Condensation

- To reduce heat gains / heat loss, economical

power demand

- Vapour seal at joints between panels and

framing may be difficult to maintain

- Draining of vapour condensate should be

incorporate in design

Sound insulation

- Insulation against airborne sound by providing

walls with adequate mass or discontinuity of

construction (difficult)

- Structure borne sound can be transmitted if

framing system share same elements common

to a number of rooms

Fire resistance

- As in any construction adequate fire protection

must be considered

- Fireproofing of framings and using fire

resisting materials

- Infill panels such as fire resisting glass etc

Material and construction

- Aluminium is favoured because of lightness,

moderate cost and ease of forming

- Steel anchors should be given protective

coatings or insolated by plastic covers or

fibrous washers etc.

- Despite potential corrosion mild steels is

common because of relatively cheap and strong

- Other metals such as bronze may be considered

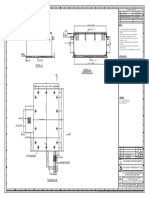

Stick System – assembled piece by piece; low shipping

and handling costs. This system can be adjusted more

readily than the other systems to on-site conditions.

¨ Unit & Mullion System – mullions are installed first. Pre-

assembled units are then lowered into place behind the mullions. The

panel units may be full-story height, pre-glazed or unglazed, or may

be separate vision glass and spandrel units. Shipping bulk is greater

than with Stick System, but less field labour and erection time

required.

¨ Panel System – consist of entirely of large wall units which may

be pre-assembled. The wall units may be more than one storey height

and may be pre-glazed or glazed after installation. Allows for rapid

erection but bulky to handle

You might also like

- Wood Carving Masjid Ar RahmanDocument16 pagesWood Carving Masjid Ar RahmanRAJA NADHIRAH BT RAJA IBRAHIMNo ratings yet

- Group 2 (Panel System)Document29 pagesGroup 2 (Panel System)RAJA NADHIRAH BT RAJA IBRAHIMNo ratings yet

- AAR603 TOPIC 3 - Timber JoistDocument19 pagesAAR603 TOPIC 3 - Timber JoistRAJA NADHIRAH BT RAJA IBRAHIM100% (1)

- AAR603 4A - Axially Loaded ColumnDocument19 pagesAAR603 4A - Axially Loaded ColumnRAJA NADHIRAH BT RAJA IBRAHIMNo ratings yet

- AAR603 4B - Axially Loaded ColumnDocument20 pagesAAR603 4B - Axially Loaded ColumnRAJA NADHIRAH BT RAJA IBRAHIMNo ratings yet

- Green and Black Minimalist ResumeDocument1 pageGreen and Black Minimalist ResumeRAJA NADHIRAH BT RAJA IBRAHIMNo ratings yet

- Green and Black Minimalist ResumeDocument1 pageGreen and Black Minimalist ResumeRAJA NADHIRAH BT RAJA IBRAHIMNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Magnesium: Current and Alternative Production Routes: August 2010Document12 pagesMagnesium: Current and Alternative Production Routes: August 2010Salem GarrabNo ratings yet

- Waller Beam Bracket Calculation SummaryDocument2 pagesWaller Beam Bracket Calculation SummarysolidramenNo ratings yet

- Hydrocarbon ProcessingDocument20 pagesHydrocarbon Processingsanjeevs01No ratings yet

- 10.1111@jerd.12615Document9 pages10.1111@jerd.12615Mairen RamirezNo ratings yet

- Basic Principles of Heat TreatmentDocument26 pagesBasic Principles of Heat TreatmentYaser Mohamed AbasNo ratings yet

- Air Entraining CementDocument14 pagesAir Entraining CementBashairu WaseemNo ratings yet

- Astm b498 b498m 98 Acsr用镀锌钢芯线 英文 AcsrDocument4 pagesAstm b498 b498m 98 Acsr用镀锌钢芯线 英文 AcsrnarinderNo ratings yet

- Ac2xy F Na2xyDocument3 pagesAc2xy F Na2xyLombrea AdrianNo ratings yet

- H5-311E Extracts Newsletter SMS MevacDocument36 pagesH5-311E Extracts Newsletter SMS MevacKetnipha SukwannawitNo ratings yet

- Division SipDocument2 pagesDivision SipXyris Gerard FernandezNo ratings yet

- Potash CrystallizerDocument34 pagesPotash CrystallizerBuddhima SiriweeraNo ratings yet

- BGAS-MCQ-Exam QuestionsDocument11 pagesBGAS-MCQ-Exam QuestionsShanmuga Navaneethan100% (5)

- Compound Wall Toilet Revised (4) - ModelDocument1 pageCompound Wall Toilet Revised (4) - ModelInfra SupportNo ratings yet

- Progress in Additive Manufacturing On New Materials - A ReviewDocument28 pagesProgress in Additive Manufacturing On New Materials - A ReviewRaistlin1No ratings yet

- Utilisation of Waste Derived Out of Mining: V.D. RajagopalDocument37 pagesUtilisation of Waste Derived Out of Mining: V.D. RajagopalSanjay MurthyNo ratings yet

- Five Fluid PDFDocument14 pagesFive Fluid PDFاحمد ابوبكر اشقيفهNo ratings yet

- Mongolian Gold MiningDocument61 pagesMongolian Gold MiningBaasankhuu JrNo ratings yet

- Section - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas LimitedDocument1 pageSection - 1-1 Section - 2-2 (Showing R/F Det.) : Rajasthan State Gas Limitedsumit kumarNo ratings yet

- DT-9 - Lesson 4Document8 pagesDT-9 - Lesson 4Amit Kr GodaraNo ratings yet

- Champion Industrial Spark Plugs - Digipubz PDFDocument56 pagesChampion Industrial Spark Plugs - Digipubz PDFhendntdNo ratings yet

- Can The Anchor Bolts Type ASTM F1554 Grade 36 Be Replaced With ASTM A307 Grade 36?Document2 pagesCan The Anchor Bolts Type ASTM F1554 Grade 36 Be Replaced With ASTM A307 Grade 36?Jovito EdillonNo ratings yet

- Civil Estimate With BoqDocument88 pagesCivil Estimate With Boqsagar pradhanNo ratings yet

- ms1314-2004 - Compress 2Document28 pagesms1314-2004 - Compress 2Robbie LimbiNo ratings yet

- Chapter 3 - Elastic Moduli - 2019 - Engineering Materials 1Document17 pagesChapter 3 - Elastic Moduli - 2019 - Engineering Materials 1Juan Camilo AlarconNo ratings yet

- LP MixproblemDocument10 pagesLP Mixproblemrecettes entréesNo ratings yet

- Summary of Daily Purchase/Service Requisition: Code Penerimaan Barang No. Doc PR - NoDocument33 pagesSummary of Daily Purchase/Service Requisition: Code Penerimaan Barang No. Doc PR - NoTopo AliNo ratings yet

- Unit 2 - Organic BasicsDocument7 pagesUnit 2 - Organic BasicsMalcolmJustMalcolmNo ratings yet

- Comparison of Gas Dehydration Methods Based On Energy Consumption PDFDocument6 pagesComparison of Gas Dehydration Methods Based On Energy Consumption PDFABULARA2K6No ratings yet

- 524r - 93 ACI 524R-93 Guide To Portland Cement Plastering PDFDocument28 pages524r - 93 ACI 524R-93 Guide To Portland Cement Plastering PDFSoe Soe100% (1)

- Arc Welding FundamentalsDocument2 pagesArc Welding FundamentalsSankar NNo ratings yet