Professional Documents

Culture Documents

114 DM 112016

Uploaded by

Ravindra JeeviOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

114 DM 112016

Uploaded by

Ravindra JeeviCopyright:

Available Formats

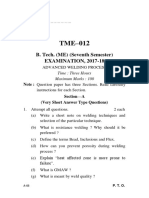

Code No: 114DM R13

JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY HYDERABAD

B.Tech II Year II Semester Examinations, October/November - 2016

PRODUCTION TECHNOLOGY

(Common to ME, MCT, AME, MSNT)

Time: 3 Hours Max. Marks: 75

Note: This question paper contains two parts A and B.

Part A is compulsory which carries 25 marks. Answer all questions in Part A.

Part B consists of 5 Units. Answer any one full question from each unit.

Each question carries 10 marks and may have a, b, c as sub questions.

PART – A (25 Marks)

1.a) Describe repair methods used for casting. [2]

b) Write different types of patterns. [3]

c) Why weld should be penned with a hammer? [2]

d) What are the safety precautions observed in welding? [3]

e) What is soldering process? [2]

f) Write short note on explosive welding. [3]

g) What are wrought products? Define. [2]

h) What is angle bite? What is value of bite angle for various materials in rolling

operations? [3]

i) Define extrusion. [2]

j) What are defects in forged parts. [3]

PART – B (50 Marks)

2.a) What is the purpose of sand conditioning equipment? Name several machines of

this purpose indicating the specific purpose each.

b) Give the steps in sand casting process and explain each briefly. [5+5]

OR

3.a) List several ways to clean casting surfaces, also write advantages and dis-

advantages of each.

b) Describe centrifugal casting process and to what work piece configuration it is

best suited. [5+5]

4.a) Explain the inert-gas metal arc welding. How does it differ from metal arc

welding?

b) What are the advantages and disadvantages of D.C and A.C welding? [5+5]

OR

5.a) Draw diagram showing classification of welding process.

b) Write difference between Arc welding and forge welding. [5+5]

6.a) Explain explosive welding with neat diagram.

b) Explain the mechanism of metal transfer in MIG/MAG welding. [5+5]

OR

7.a) Explain destructive and non- destructive testing of welds.

b) Write difference between friction welding and induction welding. [5+5]

www.ManaResults.co.in

8.a) Explain the principle of stretch forming. What are its advantages and limitations?

b) Describe the process of metal spinning and tools used for spinning. [5+5]

OR

9.a) What are the main characteristics of hot working as compared with cold working

processes?

b) What are different types of drawing? Explain each with a help of neat sketch.

[5+5]

10.a) Explain forging operations and its principles.

b) Explain briefly terms backing and lapping as related to forging practice. [5+5]

OR

11.a) Write the difference between forward extrusion and backward extrusion.

b) Explain the forces in extrusion. [5+5]

--ooOoo--

www.ManaResults.co.in

You might also like

- 114 DM 112016Document2 pages114 DM 112016Ravindra JeeviNo ratings yet

- WWW - Manaresults.co - In: (Mechanical Engineering)Document2 pagesWWW - Manaresults.co - In: (Mechanical Engineering)KKNo ratings yet

- Manufacturing Technology Question Papers of JntuaDocument15 pagesManufacturing Technology Question Papers of JntuaHimadhar SaduNo ratings yet

- R10 JanuaDry - 2014Document4 pagesR10 JanuaDry - 2014sivaenotesNo ratings yet

- B. Tech: 3 Year Pre-University Test (Odd Semester: 2021-22) Semester: 5Th BRANCH: Mechanical Engineering Subject Name Advance WeldingDocument2 pagesB. Tech: 3 Year Pre-University Test (Odd Semester: 2021-22) Semester: 5Th BRANCH: Mechanical Engineering Subject Name Advance Weldingchetan dixitNo ratings yet

- rr322003 Foundry - WeldingDocument5 pagesrr322003 Foundry - WeldingSRINIVASA RAO GANTANo ratings yet

- Jntuworld: R09 Set No. 2Document6 pagesJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNo ratings yet

- 9A14401 Production TechnologyDocument4 pages9A14401 Production TechnologysivabharathamurthyNo ratings yet

- WWW - Manaresults.Co - In: Unconventional Machining ProcessesDocument2 pagesWWW - Manaresults.Co - In: Unconventional Machining ProcessesMohan ReddyNo ratings yet

- Production TechnologyDocument4 pagesProduction TechnologysandchinniNo ratings yet

- rr310301 Production TechnologyDocument6 pagesrr310301 Production TechnologySRINIVASA RAO GANTANo ratings yet

- 127JH052019Document2 pages127JH052019Mohan ReddyNo ratings yet

- Advanced Welding Process PDFDocument3 pagesAdvanced Welding Process PDFbusiness singhNo ratings yet

- Production Technology Jan 2023Document7 pagesProduction Technology Jan 2023530-M-004 AVINASH SAI GANGADANo ratings yet

- PU Paper Manufacturing Science KME-403 - NewDocument2 pagesPU Paper Manufacturing Science KME-403 - Newdaso khagoNo ratings yet

- Question Paper Code:: (10×2 20 Marks)Document3 pagesQuestion Paper Code:: (10×2 20 Marks)Viswanath ViswaNo ratings yet

- JNTU Old Question Papers 2007Document4 pagesJNTU Old Question Papers 2007Srinivasa Rao G100% (1)

- Jntuworld: R09 Set No. 2Document4 pagesJntuworld: R09 Set No. 2saiteja1234No ratings yet

- r05310303 Production TechnologyDocument4 pagesr05310303 Production TechnologySrinivasa Rao GNo ratings yet

- S.E (2008 - 2012 Pattern)Document581 pagesS.E (2008 - 2012 Pattern)sagar shindeNo ratings yet

- Production Technology Sept 2021Document1 pageProduction Technology Sept 2021ithireddiganeshgNo ratings yet

- r05322003 Metal FormingDocument8 pagesr05322003 Metal FormingSRINIVASA RAO GANTANo ratings yet

- M&SE Dec 2011Document4 pagesM&SE Dec 2011simalaraviNo ratings yet

- Code No: 35033Document5 pagesCode No: 35033SRINIVASA RAO GANTANo ratings yet

- Machine Tool Question Paper Jntuh Mt-1-1Document2 pagesMachine Tool Question Paper Jntuh Mt-1-1sudhakarNo ratings yet

- 117JH112017Document2 pages117JH112017Mohan ReddyNo ratings yet

- R7210301 Production TechnologyDocument1 pageR7210301 Production TechnologysivabharathamurthyNo ratings yet

- Advanced Welding Technology Nme055Document2 pagesAdvanced Welding Technology Nme055Pandit Animesh TripathiNo ratings yet

- MP 20Document2 pagesMP 20hkumarchauhan392No ratings yet

- rr311401 Manufacturing TechnologyDocument4 pagesrr311401 Manufacturing TechnologySRINIVASA RAO GANTANo ratings yet

- 117BD112018Document2 pages117BD112018skumarNo ratings yet

- BCCB04 QPDocument2 pagesBCCB04 QPMr V. Phaninder ReddyNo ratings yet

- MT1Document1 pageMT1Afthal AhmedNo ratings yet

- February 2023Document2 pagesFebruary 2023rohitchanakya76No ratings yet

- (WWW - Entrance-Exam - Net) - Kurukshetra University, ME-1st Sem Manufacturing Process Sample Paper 1Document1 page(WWW - Entrance-Exam - Net) - Kurukshetra University, ME-1st Sem Manufacturing Process Sample Paper 1Arun AroraNo ratings yet

- Code No: 35041Document4 pagesCode No: 35041SRINIVASA RAO GANTANo ratings yet

- E D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDocument3 pagesE D1080 Pages: 3: Answer Any Three Questions. Each Question Carries 10 MarksDrRoja A RNo ratings yet

- U93567263bte Study Resources)Document3 pagesU93567263bte Study Resources)Tejas GanganeNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityVraj ShahNo ratings yet

- B.E. (Mechanical Engineering) : Advanced Manufacturing Processes (2012 Pattern) (Semester - I)Document3 pagesB.E. (Mechanical Engineering) : Advanced Manufacturing Processes (2012 Pattern) (Semester - I)N1234mNo ratings yet

- Production Technology-Ii: Part-ADocument3 pagesProduction Technology-Ii: Part-ARkrishna ANo ratings yet

- 1-Casting Jntuh QSDocument4 pages1-Casting Jntuh QSMr. T. Anjaneyulu Mr. T. AnjaneyuluNo ratings yet

- rr322002 Metal FormingDocument8 pagesrr322002 Metal FormingSRINIVASA RAO GANTANo ratings yet

- Set No. 1: C 0 T/RCC C 0 CDocument5 pagesSet No. 1: C 0 T/RCC C 0 CSrinivasa Rao GNo ratings yet

- 2 Nov-Dec 2012Document1 page2 Nov-Dec 2012Game SetupNo ratings yet

- B E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksDocument2 pagesB E1135 Pages: 2: Answer Any Three Full Questions, Each Carries 10marksRahul KorothNo ratings yet

- Workshop Technology C20-Aug-Sept 2021Document3 pagesWorkshop Technology C20-Aug-Sept 2021gopal rao sirNo ratings yet

- Code No: 25056Document8 pagesCode No: 25056SRINIVASA RAO GANTANo ratings yet

- WWW Manaresults Co inDocument2 pagesWWW Manaresults Co inShilpaNanduriNo ratings yet

- Mech3002y 3 2007 2 PDFDocument6 pagesMech3002y 3 2007 2 PDFKeshav GopaulNo ratings yet

- Questionns Primary MFGDocument3 pagesQuestionns Primary MFGRajib MandalNo ratings yet

- Set No. 1Document1 pageSet No. 1Bell P PedNo ratings yet

- PTAM University Question PapersDocument6 pagesPTAM University Question PapersAMRISHRAJNo ratings yet

- University of Mauritius: Special Retake ExaminationsDocument6 pagesUniversity of Mauritius: Special Retake ExaminationsKeshav GopaulNo ratings yet

- Answer: Answer Five Questions From Part BDocument2 pagesAnswer: Answer Five Questions From Part BpalreddyNo ratings yet

- Printed Batteries: Materials, Technologies and ApplicationsFrom EverandPrinted Batteries: Materials, Technologies and ApplicationsSenentxu Lanceros-MéndezNo ratings yet

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Science and Technology of Optical FabricationFrom EverandMaterials Science and Technology of Optical FabricationNo ratings yet

- Swagelok Tubular FittingsDocument8 pagesSwagelok Tubular FittingstotcsabNo ratings yet

- Linux Configuration FilesDocument4 pagesLinux Configuration FilesRaj RajeshNo ratings yet

- McCulloch TM251 SST+ Head SpecDocument1 pageMcCulloch TM251 SST+ Head SpecPriyantha GanegodaNo ratings yet

- MSDS Polyurea CoatingDocument3 pagesMSDS Polyurea CoatingHamzah Sabtian SitorusNo ratings yet

- Hyperautomation: Hyperautomation and AI Security Are Two Technologies That Are Most Likely ToDocument9 pagesHyperautomation: Hyperautomation and AI Security Are Two Technologies That Are Most Likely Torammanohar22No ratings yet

- RasDocument69 pagesRasUsman Madubun100% (1)

- Final - Demo Camera Calib PDFDocument27 pagesFinal - Demo Camera Calib PDFwillingtonvelascoNo ratings yet

- R12 Uploading A Journal Using Web ADI - Step by Step - Oracle Techno & FunctionalDocument18 pagesR12 Uploading A Journal Using Web ADI - Step by Step - Oracle Techno & FunctionalMadhavi SinghNo ratings yet

- Gs Autoclave Mediano SP PDFDocument8 pagesGs Autoclave Mediano SP PDFagh8garciaNo ratings yet

- 5000EH Sell SheetDocument2 pages5000EH Sell SheetHorea CordunianuNo ratings yet

- Bomba Desplazamiento PositivoDocument14 pagesBomba Desplazamiento PositivoAlvaro Jose DíazNo ratings yet

- Guidelines For The Selection and Use of Reference MaterialsDocument16 pagesGuidelines For The Selection and Use of Reference MaterialsPatrick RamotlopiNo ratings yet

- Davidson, Donald - Knowing One's Own MindDocument19 pagesDavidson, Donald - Knowing One's Own Mindgalen_mitchell100% (1)

- Design Spec For TopsideDocument32 pagesDesign Spec For Topsideshadab521100% (2)

- Introduction To The Automatic NodeB and Cell Allocation in The BSC6910 Feature V1.0Document21 pagesIntroduction To The Automatic NodeB and Cell Allocation in The BSC6910 Feature V1.0Ariel MendozaNo ratings yet

- Music From "How To Read Sheet Music": Julian CiancioloDocument2 pagesMusic From "How To Read Sheet Music": Julian CianciolodbirksskribdNo ratings yet

- Mezmeriz Scanning Micro Mirror 1D Oscillator DatasheetDocument2 pagesMezmeriz Scanning Micro Mirror 1D Oscillator DatasheetMichel CombesNo ratings yet

- Ketterer-Hellmann Precipitation RecorderDocument4 pagesKetterer-Hellmann Precipitation RecorderAlif100% (1)

- BlazBlue Continuum Shift Extend Manual en InglesDocument26 pagesBlazBlue Continuum Shift Extend Manual en InglesKenshin Yagami Stark100% (1)

- 1995 Limited Effects Weapons Study - Catalog of Currently Available Weapons and Devices - Edition 1Document402 pages1995 Limited Effects Weapons Study - Catalog of Currently Available Weapons and Devices - Edition 1Firebrand38No ratings yet

- Gorontalo: Journal of Forestry ResearchDocument12 pagesGorontalo: Journal of Forestry ResearchNanda Mustika NNo ratings yet

- Final HBD PresentationDocument24 pagesFinal HBD Presentationccrkota100% (1)

- Prince MRP List 02.07.2022Document17 pagesPrince MRP List 02.07.2022Rachit SharmaNo ratings yet

- Quality Policy Enhanced UnderstandingDocument9 pagesQuality Policy Enhanced UnderstandingReginald MalibiranNo ratings yet

- Zanda Handout Brochure CompressedDocument28 pagesZanda Handout Brochure CompressedHamayet RaselNo ratings yet

- Neuman Interschalt PDFDocument51 pagesNeuman Interschalt PDFCostelNo ratings yet

- Brookfield Operating Manual DV-III UltraDocument122 pagesBrookfield Operating Manual DV-III Ultrageorgiadisg100% (1)

- Manual DPS5005Document12 pagesManual DPS5005Marcos Gomes Missel100% (1)

- Wheel Truing Hand Out Three PagesDocument3 pagesWheel Truing Hand Out Three PagesArgiris MichalisNo ratings yet