Professional Documents

Culture Documents

Eurowater 103000

Uploaded by

born2dive 9702Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eurowater 103000

Uploaded by

born2dive 9702Copyright:

Available Formats

REFERENCE 103000

INDUSTRY Food industry |

APPLICATION Process water |

Water treatment for PepsiCo dairy

Construction of the new food production facilities in the city of Vyshneve, close to Kiev, is one of PepsiCo’s

largest investments in the Ukrainian dairy industry since the acquisition of Wimm-Bill-Dann. PepsiCo has

converted an existing dairy in accordance with typical PepsiCo standards. EUROWATER has supplied the water

treatment plant ensuring the highest possible standards. The project included the following parts:

Modernization of the existing pre-treatment system of the inlet water in order to prevent clogging of the

membranes. The filters can now be backwashed with air and water. Results: Better backwash efficiency of filter

media, less backwash cycles, less water consumption, and better quality of filtered water.Three new RO-units,

each with a flow rate of 35 m³/h, meaning high redundancy and reliable supply of demineralized water.Fully

automatic CIP unit in order to perform regular cleaning of the membranes to remove precipitations caused by

calcium salts or bio-fouling.Reuse of the existing UV disinfection system to ensure a consistently high water

quality with no bacteriological activity.Central PLC control cabinet to monitor and control the complete water

treatment plant – existing as well as new units. The central PLC control cabinet serves as the motor control

centre and includes programmable controllers (SIEMENS S7), a touch screen operator interface, variable

frequency converters and metering and includes communication through Profibus and GSM/SMS.Installation;

instruments and pipes in stainless steel AISI 316.Start-up and commissioning.

TECHNICAL DATA UNITS IN PLANT

Flow: 3 x 35 m³/h Antiscalant dosing pumps 2 x DDC 9-7

Reverse osmosis units 3 x RO C3-30

Dosing of NaOH NaClO and sodium metabisulfit 7 x

DDC 9-7

Fully automatic CIP unit

Central PLC control cabinet

See more references at www.eurowater.com

You might also like

- Demineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsFrom EverandDemineralization by Ion Exchange: In Water Treatment and Chemical Processing of Other LiquidsRating: 4 out of 5 stars4/5 (2)

- GE Osmonics SWRO 200C O&M Manual L PDFDocument38 pagesGE Osmonics SWRO 200C O&M Manual L PDFtonbaldinNo ratings yet

- SWRO Chemical CalculationsDocument38 pagesSWRO Chemical CalculationsBenjamin MillerNo ratings yet

- GE Osmonics SWRO 200C O&M Manual LDocument38 pagesGE Osmonics SWRO 200C O&M Manual LIsaac Deusdedit Salazar Ehuan100% (1)

- 1 s2.0 S0011916400900018 MainDocument16 pages1 s2.0 S0011916400900018 MainAnita YunusNo ratings yet

- Innovations For S3 (Sanitation, SeptageDocument34 pagesInnovations For S3 (Sanitation, SeptageLITO ESTABLECIDANo ratings yet

- Grundfos WWTPDocument34 pagesGrundfos WWTPNguyen Phuc PhamNo ratings yet

- GVT-ODIS-SWRO For PBMC PDFDocument35 pagesGVT-ODIS-SWRO For PBMC PDFSwati BhattacharyyaNo ratings yet

- Hydromagx 1Document19 pagesHydromagx 1Jeya KumarNo ratings yet

- User Manual: Milli-Q IX 7003/7005/7010/7015Document48 pagesUser Manual: Milli-Q IX 7003/7005/7010/7015Khanh TranNo ratings yet

- Method Statement - Chilled Water Chemical Flushing - HEAT & POWER GEMS SCHOOLDocument19 pagesMethod Statement - Chilled Water Chemical Flushing - HEAT & POWER GEMS SCHOOLAnash RajanNo ratings yet

- Membrane Pre TreatmentDocument10 pagesMembrane Pre Treatmentadalcayde2514No ratings yet

- Reverse Osmosis Model #R44 Installation InstructionsDocument40 pagesReverse Osmosis Model #R44 Installation InstructionsWatts100% (1)

- Technical Aspects of Desalination PlantDocument12 pagesTechnical Aspects of Desalination PlantMonica UrbietaNo ratings yet

- Wattreat1 12Document9 pagesWattreat1 12p samantNo ratings yet

- User Manual Milli Q Iq MKDocument50 pagesUser Manual Milli Q Iq MKJuan Jesús Cruz MaldonadoNo ratings yet

- New Controller Eliminates Manual Filter Leak Inspections: Online Cost of Grit Calculator To Predict Efficiency SavingsDocument1 pageNew Controller Eliminates Manual Filter Leak Inspections: Online Cost of Grit Calculator To Predict Efficiency SavingsNadiar IswanNo ratings yet

- Veolia Water 2573, Biosep - Pack3 - EN Membrane BioreactorDocument2 pagesVeolia Water 2573, Biosep - Pack3 - EN Membrane BioreactorhenbauNo ratings yet

- Water Treatment 2Document4 pagesWater Treatment 2Lisbeth Roos RoosNo ratings yet

- 17 - Section-12 Seawater Systems PDFDocument31 pages17 - Section-12 Seawater Systems PDFShamsiNo ratings yet

- The Universal Traveler Don Koberg Jim Bagnall PDFDocument12 pagesThe Universal Traveler Don Koberg Jim Bagnall PDFRevathi Hariharan0% (1)

- Reverse Osmosis R12-Wall Mount Installation InstructionsDocument15 pagesReverse Osmosis R12-Wall Mount Installation InstructionsWattsNo ratings yet

- Seawater Heat RejectionDocument48 pagesSeawater Heat RejectionNiong DavidNo ratings yet

- AFS 8D / 16D Degassed: Water Purification SystemsDocument8 pagesAFS 8D / 16D Degassed: Water Purification SystemsMohammed Al BeabaiNo ratings yet

- British Waste Water TreatmentDocument22 pagesBritish Waste Water Treatmentraudelmoreno83No ratings yet

- DCW Type SewageDocument13 pagesDCW Type SewageDara FinaldaNo ratings yet

- Reverse Osmosis R14-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R14-SERIES Installation InstructionsWattsNo ratings yet

- Reverse Osmosis R24-SERIES Installation InstructionsDocument44 pagesReverse Osmosis R24-SERIES Installation InstructionsWattsNo ratings yet

- Guidelines: For Efficient Water UseDocument28 pagesGuidelines: For Efficient Water UseAnonymous Rn3gBriINo ratings yet

- 2015 Johnson Screens Passive Intake ScreensDocument12 pages2015 Johnson Screens Passive Intake Screensrogervieira1979No ratings yet

- Vepl 1956 1211Document13 pagesVepl 1956 1211Jeevan HingneNo ratings yet

- Gujarat Technological University: Chandkheda, Ahmedabad Affiliated Government Engineering College, Dahod A Report OnDocument20 pagesGujarat Technological University: Chandkheda, Ahmedabad Affiliated Government Engineering College, Dahod A Report OnindrajeetsinhNo ratings yet

- MBBR SystemDocument7 pagesMBBR SystemThanneeru Naga Raju100% (1)

- 5260, Rwo WWT LC 4 2012 WebDocument4 pages5260, Rwo WWT LC 4 2012 Webnguyenvanhai19031981No ratings yet

- Virtual Visit Report ABIDALI MANER 21Document11 pagesVirtual Visit Report ABIDALI MANER 21Abid Maner0% (1)

- Milli-Q Direct BrochureDocument8 pagesMilli-Q Direct BrochurevaglohrdNo ratings yet

- Chemical InjectionDocument7 pagesChemical InjectionAga Sanity SainsNo ratings yet

- Fontis 15 30 UKDocument2 pagesFontis 15 30 UKPep VasilevaNo ratings yet

- CWP 121Document23 pagesCWP 121mistytewestNo ratings yet

- J910-DD02-P0GDF-125134 - A - Design Criteria For WTPDocument14 pagesJ910-DD02-P0GDF-125134 - A - Design Criteria For WTPAdrianus Hindradjaja100% (1)

- Bi-Osmoseur GAMBRODocument4 pagesBi-Osmoseur GAMBROHassan EladliNo ratings yet

- BS Water Treatment Presentation 1 1Document44 pagesBS Water Treatment Presentation 1 1wan yeeNo ratings yet

- ASML - Techincal Proposal For Grey Water TreatmentDocument7 pagesASML - Techincal Proposal For Grey Water TreatmentChachi TerijanNo ratings yet

- Pure Water Production - An Overview ScienceDirecDocument14 pagesPure Water Production - An Overview ScienceDirecoffyNo ratings yet

- EN23560 Seal Tank Systems Guide EMEDocument16 pagesEN23560 Seal Tank Systems Guide EMEDomingo DíazNo ratings yet

- Reverse Osmosis Model # R48 Installation InstructionsDocument30 pagesReverse Osmosis Model # R48 Installation InstructionsWatts0% (1)

- With Membrane Technolgy For Oil Sands and Power Generation ApplicationsDocument8 pagesWith Membrane Technolgy For Oil Sands and Power Generation ApplicationsMarcelo Varejão CasarinNo ratings yet

- Zero BDocument1 pageZero Bmaksudur4No ratings yet

- Modern Water - AquaPak-B - BrochureDocument4 pagesModern Water - AquaPak-B - BrochureYoo BoyyooNo ratings yet

- Aquatec VFL en PDFDocument36 pagesAquatec VFL en PDFeremeevionNo ratings yet

- Clean-iX® Pilot Plant For Recycling Water From Woodman Point WWTPDocument12 pagesClean-iX® Pilot Plant For Recycling Water From Woodman Point WWTPنيرمين احمدNo ratings yet

- Sedron Services Sumner Washington - ST 6267 - Draft O&M Manual - Emailed 1-26-21Document31 pagesSedron Services Sumner Washington - ST 6267 - Draft O&M Manual - Emailed 1-26-21Vishal shuklaNo ratings yet

- Automatic Tank Cleaning PsDocument1 pageAutomatic Tank Cleaning PsSami ArebiNo ratings yet

- Ucc - H2OIL Water in Oil MonitorDocument5 pagesUcc - H2OIL Water in Oil MonitorShannon WigginsNo ratings yet

- Reverse Osmosis Model R4X40 Installation InstructionsDocument16 pagesReverse Osmosis Model R4X40 Installation InstructionsWattsNo ratings yet

- A Cost Effective Design of Water Purific PDFDocument5 pagesA Cost Effective Design of Water Purific PDFRejith K MNo ratings yet

- Wick Irrigation System: Presented By: Guided byDocument27 pagesWick Irrigation System: Presented By: Guided byAparna PNo ratings yet

- Experiment 12 Study of Dairy Effluent Plant: StructureDocument5 pagesExperiment 12 Study of Dairy Effluent Plant: StructureSrinivasa BandaloreNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Medicinal and Aromatic Crops (HPM 100) 3 (2+1)Document200 pagesMedicinal and Aromatic Crops (HPM 100) 3 (2+1)born2dive 9702No ratings yet

- GRAS Substances (4024-4068)Document11 pagesGRAS Substances (4024-4068)born2dive 9702No ratings yet

- Flavourist Training Course: Food and NutritionalsciencesDocument2 pagesFlavourist Training Course: Food and Nutritionalsciencesborn2dive 9702No ratings yet

- The Quantification of Cocaine From The Erythroxylum Coca Plant AnDocument28 pagesThe Quantification of Cocaine From The Erythroxylum Coca Plant Anborn2dive 9702No ratings yet

- Fat MetabolismDocument30 pagesFat Metabolismborn2dive 9702No ratings yet

- GRAS Substances (3755-3774)Document6 pagesGRAS Substances (3755-3774)born2dive 9702No ratings yet

- Svpaj 1Document265 pagesSvpaj 1born2dive 9702No ratings yet

- GRAS Substances (3597-3650)Document9 pagesGRAS Substances (3597-3650)born2dive 9702No ratings yet

- GRAS Substances (3797-3815)Document9 pagesGRAS Substances (3797-3815)born2dive 9702No ratings yet

- GRAS Substances (3326-3390)Document4 pagesGRAS Substances (3326-3390)born2dive 9702No ratings yet

- Prune Juice ConcentrateDocument1 pagePrune Juice Concentrateborn2dive 9702No ratings yet

- Us 3867262Document5 pagesUs 3867262born2dive 9702No ratings yet

- SCPC375 1Document1 pageSCPC375 1born2dive 9702No ratings yet

- P1025 CodeRevision AppR Attach ADocument556 pagesP1025 CodeRevision AppR Attach Aborn2dive 9702No ratings yet

- Us 4956429Document5 pagesUs 4956429born2dive 9702No ratings yet

- Food and Agricultural Import Regulations and Standards - Canberra - Australia - 07!28!1999Document38 pagesFood and Agricultural Import Regulations and Standards - Canberra - Australia - 07!28!1999born2dive 9702No ratings yet

- IOFI Global Reference List NCS 8 November 2021Document23 pagesIOFI Global Reference List NCS 8 November 2021born2dive 9702No ratings yet

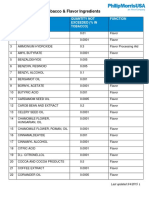

- Pmusa Tobacco and Flavor IngredientsDocument6 pagesPmusa Tobacco and Flavor Ingredientsborn2dive 9702No ratings yet

- Bradley, We'Ve Received Your Income-Based Repayment (Ibr) Plan Application From Studentaid - GovDocument2 pagesBradley, We'Ve Received Your Income-Based Repayment (Ibr) Plan Application From Studentaid - Govborn2dive 9702No ratings yet

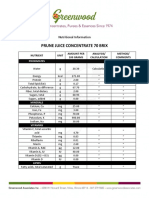

- Prune Juice Concentrate 70 Brix Nutritional InformationDocument2 pagesPrune Juice Concentrate 70 Brix Nutritional Informationborn2dive 9702No ratings yet

- Lorillard IngredientList March-2012Document1 pageLorillard IngredientList March-2012born2dive 9702No ratings yet

- Prune Juice Concentrate Technical Data SheetDocument1 pagePrune Juice Concentrate Technical Data Sheetborn2dive 9702No ratings yet

- Earlmerwin Flavor History-1Document150 pagesEarlmerwin Flavor History-1born2dive 9702No ratings yet

- Prune Juice Concentrate 70 Brix Nutritional Information 1Document2 pagesPrune Juice Concentrate 70 Brix Nutritional Information 1born2dive 9702No ratings yet

- Federal Register / Vol. 83, No. 195 / Tuesday, October 9, 2018 / Rules and RegulationsDocument14 pagesFederal Register / Vol. 83, No. 195 / Tuesday, October 9, 2018 / Rules and Regulationsborn2dive 9702No ratings yet

- CFR 2019 Title21 Vol1Document594 pagesCFR 2019 Title21 Vol1born2dive 9702No ratings yet

- A Manufacturer'S Guide To Clean Label Formulations Using Whey ProteinDocument7 pagesA Manufacturer'S Guide To Clean Label Formulations Using Whey Proteinborn2dive 9702No ratings yet