Professional Documents

Culture Documents

CH 10

Uploaded by

Vedagya Saraswat0 ratings0% found this document useful (0 votes)

9 views31 pagesThe document discusses supply chain coordination and the bullwhip effect. A lack of coordination can result in the bullwhip effect, where demand fluctuations increase as orders move up the supply chain. This harms supply chain performance by increasing costs. Obstacles to coordination include misaligned incentives, information processing issues, and behavioral factors. Managerial levers to improve coordination are aligning goals, improving information sharing, optimizing operations, and building collaborative relationships through methods like CPFR.

Original Description:

you

Original Title

ch10

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses supply chain coordination and the bullwhip effect. A lack of coordination can result in the bullwhip effect, where demand fluctuations increase as orders move up the supply chain. This harms supply chain performance by increasing costs. Obstacles to coordination include misaligned incentives, information processing issues, and behavioral factors. Managerial levers to improve coordination are aligning goals, improving information sharing, optimizing operations, and building collaborative relationships through methods like CPFR.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views31 pagesCH 10

Uploaded by

Vedagya SaraswatThe document discusses supply chain coordination and the bullwhip effect. A lack of coordination can result in the bullwhip effect, where demand fluctuations increase as orders move up the supply chain. This harms supply chain performance by increasing costs. Obstacles to coordination include misaligned incentives, information processing issues, and behavioral factors. Managerial levers to improve coordination are aligning goals, improving information sharing, optimizing operations, and building collaborative relationships through methods like CPFR.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 31

Supply Chain Management

Dr. C.Phaneendra Kiran

Ph.D

BITS Pilani Department of Mechanical Engineering

Hyderabad Campus BITS Pilani Hyderabad Campus

BITS Pilani

Hyderabad Campus

Coordination in a Supply Chain

Content taken from Pearson material

Learning Objectives

1. Describe supply chain coordination and the bullwhip effect,

and their impact on supply chain performance.

2. Identify obstacles to coordination in a supply chain.

3. Discuss managerial levers that help achieve coordination in a

supply chain.

4. Understand the different forms of collaborative planning,

forecasting, and replenishment that are possible in a supply

chain.

BITS Pilani, Hyderabad Campus

Lack of Supply Chain Coordination

and the Bullwhip Effect

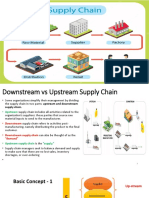

• Supply chain coordination – all stages of the chain take

actions that are aligned and increase total supply chain

surplus

• Requires that each stage share information and take into

account the effects of its actions on the other stages

• Lack of coordination results when:

– Objectives of different stages conflict

– Information moving between stages is delayed or distorted

BITS Pilani, Hyderabad Campus

Bullwhip Effect

• Fluctuations in orders increase as they move up the supply

chain from retailers to wholesalers to manufacturers to

suppliers

• Distorts demand information within the supply chain

• Results from a loss of supply chain coordination

BITS Pilani, Hyderabad Campus

Demand at Different Stages

BITS Pilani, Hyderabad Campus

The Effect on Performance

• Lack of coordination increases variability and hurts supply

chain surplus

• Impact on costs

– Manufacturing cost

– Inventory cost

– Replenishment lead time

– Transportation cost

– Labor cost for shipping and receiving

– Level of product availability

– Relationships across the supply chain

BITS Pilani, Hyderabad Campus

The Effect on Performance

BITS Pilani, Hyderabad Campus

Key Point

• The lack of coordination hurts both responsiveness and cost in

a supply chain by making it more expensive to provide a given

level of product availability.

BITS Pilani, Hyderabad Campus

Obstacles to Coordination

in a Supply Chain

• Incentive Obstacles

• Information Processing Obstacles

• Operational Obstacles

• Pricing Obstacles

• Behavioral Obstacles

BITS Pilani, Hyderabad Campus

Incentive Obstacles

• Occur when incentives offered to different stages or

participants in a supply chain lead to actions that increase

variability and reduce total supply chain profits

– Local optimization within functions or stages of a supply

chain

– Sales force incentives

BITS Pilani, Hyderabad Campus

Information Processing Obstacles

• When demand information is distorted as it moves between

different stages of the supply chain, leading to increased

variability in orders within the supply chain

– Forecasting based on orders and not customer demand

– Lack of information sharing

BITS Pilani, Hyderabad Campus

Operational Obstacles

• Occur when placing and filling orders lead to an increase in

variability

– Ordering in large lots

– Large replenishment lead times

– Rationing and shortage gaming

BITS Pilani, Hyderabad Campus

Operational Obstacles

BITS Pilani, Hyderabad Campus

Pricing Obstacles

• When pricing policies for a product lead to an increase in

variability of orders placed

– Lot-size based quantity decisions

– Price fluctuations

BITS Pilani, Hyderabad Campus

Pricing Obstacles

BITS Pilani, Hyderabad Campus

Behavioral Obstacles

• Problems in learning within organizations that contribute to information

distortion

– Each stage of the supply chain views its actions locally and is unable to

see the impact of its actions on other stages

– Different stages of the supply chain react to the current local situation

rather than trying to identify the root causes

– Different stages of the supply chain blame one another for the

fluctuations

– No stage of the supply chain learns from its actions over time

– A lack of trust among supply chain partners causes them to be

opportunistic at the expense of overall supply chain performance

BITS Pilani, Hyderabad Campus

Managerial Levers to

Achieve Coordination

• Aligning goals and incentives

• Improving information accuracy

• Improving operational performance

• Designing pricing strategies to stabilize orders

• Building strategic partnerships and trust

BITS Pilani, Hyderabad Campus

Aligning Goals and Incentives

• Align goals and incentives so that every participant in supply

chain activities works to maximize total supply chain profits

– Align goals across the supply chain

– Align incentives across functions

– Pricing for coordination

– Alter sales force incentives from sell-in (to the retailer) to

sell-through (by the retailer)

BITS Pilani, Hyderabad Campus

Improving Information Visibility

and Accuracy

• Sharing customer demand data

• Implementing collaborative forecasting and planning

• Designing single-stage control of replenishment

• Continuous replenishment programs (CRP)

• Vendor managed inventory (VMI)

BITS Pilani, Hyderabad Campus

Improving Operational Performance

• Reducing replenishment lead time

• Reducing lot sizes

• Rationing based on past sales and sharing information to limit

gaming

BITS Pilani, Hyderabad Campus

Key Point

• Demand planning at each stage in a supply chain based on the

stream of orders received from its down- stream stage results

in a magnification of fluctuation in orders as one moves up

the supply chain from the retailer to the manufacturer. It is

better for the entire supply chain to forecast based on end

customer demand.

BITS Pilani, Hyderabad Campus

Improving Operational Performance

• Reducing replenishment lead time

• Reducing lot sizes

• Rationing based on past sales and sharing information to limit

gaming

BITS Pilani, Hyderabad Campus

Designing Pricing Strategies

to Stabilize Orders

• Encouraging retailers to order in smaller lots and reduce

forward buying

– Moving from lot size-based to volume-based quantity

discounts

– Stabilizing pricing

– Building strategic partnerships and trust

BITS Pilani, Hyderabad Campus

Continuous Replenishment and

Vendor-Managed Inventories

• A single point of replenishment

• CRP – wholesaler or manufacturer replenishes based on POS

data

• VMI – manufacturer or supplier is responsible for all decisions

regarding inventory

• Substitutes

BITS Pilani, Hyderabad Campus

Collaborative Planning, Forecasting,

and Replenishment (CPFR)

• Sellers and buyers in a supply chain may collaborate along any

or all of the following

– Strategy and planning

– Demand and supply management

– Execution

– Analysis

BITS Pilani, Hyderabad Campus

Common CPFR Scenarios

BITS Pilani, Hyderabad Campus

Collaborative Planning, Forecasting,

and Replenishment (CPFR)

• Retail event collaboration

• DC replenishment collaboration

• Store replenishment collaboration

• Collaborative assortment planning

• Organizational and technology requirements for successful

CPFR

• Risks and hurdles for a CPFR implementation

BITS Pilani, Hyderabad Campus

Collaborative Planning, Forecasting,

and Replenishment (CPFR)

BITS Pilani, Hyderabad Campus

Achieving Coordination in Practice

• Quantify the bullwhip effect

• Get top management commitment for coordination

• Devote resources to coordination

• Focus on communication with other stages

• Try to achieve coordination in the entire supply chain network

• Use technology to improve connectivity in the supply chain

• Share the benefits of coordination equitably

BITS Pilani, Hyderabad Campus

Summary of Learning Objectives

1. Describe supply chain coordination and the bullwhip effect,

and their impact on supply chain performance

2. Identify obstacles to coordination in a supply chain

3. Discuss managerial levers that help achieve coordination in a

supply chain

4. Understand the different forms of CPFR possible in a supply

chain

BITS Pilani, Hyderabad Campus

You might also like

- Designing and Managing The Supply Chain 4Th Edition David Simchi Levi Full ChapterDocument51 pagesDesigning and Managing The Supply Chain 4Th Edition David Simchi Levi Full Chaptersalvatore.martin420100% (5)

- Subway SCMDocument28 pagesSubway SCMzakuan7960% (5)

- Supply Chain Transformation: Building and Executing an Integrated Supply Chain StrategyFrom EverandSupply Chain Transformation: Building and Executing an Integrated Supply Chain StrategyRating: 5 out of 5 stars5/5 (7)

- DDMRP Implementation Support Pack 20160531 PDFDocument248 pagesDDMRP Implementation Support Pack 20160531 PDFJose Lara100% (1)

- Beer Game Simulation Group 5Document20 pagesBeer Game Simulation Group 5Sagar YadavNo ratings yet

- Supply Chain and IT - Impact...Document39 pagesSupply Chain and IT - Impact...Praveen ChoudharyNo ratings yet

- Barilla Spa Case CombinedDocument12 pagesBarilla Spa Case CombinedbentebeekNo ratings yet

- ch2 SCMDocument40 pagesch2 SCMTarun KumarNo ratings yet

- Supply Chain Management: Dr. C.Phaneendra KiranDocument25 pagesSupply Chain Management: Dr. C.Phaneendra KiranVedagya SaraswatNo ratings yet

- ch4 SCMDocument60 pagesch4 SCMSHAABAN KARIMNo ratings yet

- SC Coordination Managerial Levers and Collaborative Demand ManagementDocument30 pagesSC Coordination Managerial Levers and Collaborative Demand ManagementTaimoor SheikhNo ratings yet

- Supply Chain Management: Strategy, Planning, and Operation: Seventh Edition, Global EditionDocument28 pagesSupply Chain Management: Strategy, Planning, and Operation: Seventh Edition, Global EditionmuniraNo ratings yet

- Coordination in A Supply Chain by K L N REDDYDocument32 pagesCoordination in A Supply Chain by K L N REDDYjayamsecNo ratings yet

- Coordination in A Supply ChainDocument14 pagesCoordination in A Supply ChainPhD Scholar0% (1)

- 6 CoordinationDocument18 pages6 CoordinationRavi KumarNo ratings yet

- 3.coordination in A Supply ChainDocument29 pages3.coordination in A Supply ChainMohit KumarNo ratings yet

- CH 11Document115 pagesCH 11Vedagya SaraswatNo ratings yet

- SCMDocument33 pagesSCMShiyaz Km0% (1)

- Week 3.1 Supply Chain IntegrationDocument18 pagesWeek 3.1 Supply Chain IntegrationRUSSELL WALDO PATRICIO MORALESNo ratings yet

- Coordination in Supply Chain ManagementDocument16 pagesCoordination in Supply Chain ManagementAman Vinny Vinny100% (1)

- SCM Network OptimizationDocument64 pagesSCM Network OptimizationHEMA NNo ratings yet

- Module 03 Supply Chain ManagementDocument21 pagesModule 03 Supply Chain ManagementClinton SamsonNo ratings yet

- S1-18-Ba ZG621 Mba ZG621 MM ZG621-L3Document34 pagesS1-18-Ba ZG621 Mba ZG621 MM ZG621-L3sap6370No ratings yet

- OM Session 3Document38 pagesOM Session 3mayra salirrosasNo ratings yet

- Slides Chapter 4 - BAC 200Document28 pagesSlides Chapter 4 - BAC 200bongi.s.khungaNo ratings yet

- Chapter 10Document22 pagesChapter 10Junaed Ahmed SaifNo ratings yet

- Fundamentals of SCMDocument23 pagesFundamentals of SCMSYED MURTAZA ABIDINo ratings yet

- Supply Chain Performance: Achieving Strategic Fit and Scope: 1 DR S K Sharma, BITS PialniDocument32 pagesSupply Chain Performance: Achieving Strategic Fit and Scope: 1 DR S K Sharma, BITS PialniNISHANT SHAHNo ratings yet

- Coordination in The Supply ChainDocument31 pagesCoordination in The Supply ChainNiranjan ThirNo ratings yet

- Supply Chain Management: Lecture-2 28 July 2018, SaturdayDocument25 pagesSupply Chain Management: Lecture-2 28 July 2018, Saturdaysap6370No ratings yet

- Submitted By: Abhishek Kumar Abhinav - 1C Ajay Kumar Singh - 2C Alok Vyas - 3C Anushree Pande - 8CDocument22 pagesSubmitted By: Abhishek Kumar Abhinav - 1C Ajay Kumar Singh - 2C Alok Vyas - 3C Anushree Pande - 8CsomarritadNo ratings yet

- Chopra Scm7 Inppt 05 Working 5Document51 pagesChopra Scm7 Inppt 05 Working 5mirzaaribabaig1999No ratings yet

- Suply Chain Analytics by Dr. DV RamanaDocument28 pagesSuply Chain Analytics by Dr. DV RamanashahazadiNo ratings yet

- C12 Coordination in SCDocument32 pagesC12 Coordination in SCNur Fatin F19A0287No ratings yet

- Coordinationinasupplychainph 09 170520090519 PDFDocument46 pagesCoordinationinasupplychainph 09 170520090519 PDFsathya priyaNo ratings yet

- Chopra Scm7 Inppt 05 Working 4Document117 pagesChopra Scm7 Inppt 05 Working 4Mohammad TaimoorNo ratings yet

- VTU Supply ChainDocument267 pagesVTU Supply Chainprasadkh90100% (4)

- Revisi PPT7 - SCMDocument63 pagesRevisi PPT7 - SCMAbdul GhoniNo ratings yet

- Supply Chain Management: Noman NasirDocument26 pagesSupply Chain Management: Noman NasirwasianwerNo ratings yet

- SCM-Module-2 - Strategic FitDocument25 pagesSCM-Module-2 - Strategic FitMuhammed Husain MusaniNo ratings yet

- Week 02 - Fundamentals of Supply Chain ManagementDocument36 pagesWeek 02 - Fundamentals of Supply Chain ManagementMUHAMMAD FAYZAN TAYYABNo ratings yet

- Chapter 20Document55 pagesChapter 20longtran1191No ratings yet

- Bullwhip Effect JUDocument29 pagesBullwhip Effect JUDr. S YogananthanNo ratings yet

- CoordinationinasupplychainDocument53 pagesCoordinationinasupplychainJayaprasannaNo ratings yet

- Module 01 Supply Chain ManagementDocument26 pagesModule 01 Supply Chain ManagementAdelaine BugayNo ratings yet

- Purchasing & Procurement ManagementDocument15 pagesPurchasing & Procurement ManagementYousufNo ratings yet

- The Value of Information Lecture4Document18 pagesThe Value of Information Lecture4dinesh9936115534No ratings yet

- Collaborative Planning, Forecasting & Replenishment (CPFRDocument26 pagesCollaborative Planning, Forecasting & Replenishment (CPFRVanshaj Kumar100% (3)

- Module 3 - Supply Chain StrategiesDocument28 pagesModule 3 - Supply Chain StrategiesAreeba AmirNo ratings yet

- Class Material PDFDocument271 pagesClass Material PDFCây GiảiNo ratings yet

- Strategie de La Supply ChainDocument22 pagesStrategie de La Supply ChainMounira MegNo ratings yet

- Oscm Module - IvDocument10 pagesOscm Module - IvRadha Krishna - with youNo ratings yet

- Challenges in Indian Retail Supply Chain: By: Prateek Sharma - 024 Varun Madan - 032Document11 pagesChallenges in Indian Retail Supply Chain: By: Prateek Sharma - 024 Varun Madan - 032varun_146100No ratings yet

- Management: Purchasing & ProcurementDocument15 pagesManagement: Purchasing & ProcurementFaysal AminNo ratings yet

- MSM MS224 Supply Chain Class PPT July 2023Document53 pagesMSM MS224 Supply Chain Class PPT July 2023rumelrashid_seuNo ratings yet

- Session 14Document22 pagesSession 14Karthik SureshNo ratings yet

- CH 02 UpdatedDocument27 pagesCH 02 Updatedasd.ksa1090No ratings yet

- Vendor DevelopmentDocument5 pagesVendor DevelopmentYYASEER KAGDINo ratings yet

- Supplier Development: Nazmun NaharDocument9 pagesSupplier Development: Nazmun NaharKamrulHassanNo ratings yet

- Supply Chain ManagementDocument74 pagesSupply Chain ManagementAisyah RamliNo ratings yet

- SCM Strategic Fit & ObstaclesDocument30 pagesSCM Strategic Fit & ObstaclesDr. S Yogananthan0% (1)

- Suppliers Relationship ManagementDocument19 pagesSuppliers Relationship ManagementAmit AgarwalNo ratings yet

- Sourcing For Successful SCMDocument27 pagesSourcing For Successful SCMShovan ChowdhuryNo ratings yet

- P&S Lec 1Document18 pagesP&S Lec 1nomanashrafNo ratings yet

- Customer-Anchored Supply Chains: An Executive’S Guide to Building Competitive Advantage in the Oil PatchFrom EverandCustomer-Anchored Supply Chains: An Executive’S Guide to Building Competitive Advantage in the Oil PatchNo ratings yet

- ON Developing Digital Learning Modules For Influencers: BY Name(s) of The ID No.(s) Student(s)Document22 pagesON Developing Digital Learning Modules For Influencers: BY Name(s) of The ID No.(s) Student(s)Vedagya SaraswatNo ratings yet

- The Sacred FruitDocument2 pagesThe Sacred FruitVedagya SaraswatNo ratings yet

- CH 11Document115 pagesCH 11Vedagya SaraswatNo ratings yet

- Demand Forecasting in A Supply Chain: BITS PilaniDocument54 pagesDemand Forecasting in A Supply Chain: BITS PilaniVedagya SaraswatNo ratings yet

- Supply Chain Management: Dr. C.Phaneendra KiranDocument38 pagesSupply Chain Management: Dr. C.Phaneendra KiranVedagya SaraswatNo ratings yet

- CH 12Document76 pagesCH 12Vedagya SaraswatNo ratings yet

- Push Pull BoundaryDocument12 pagesPush Pull BoundaryVicky MalyNo ratings yet

- The Bullwhip EffectDocument14 pagesThe Bullwhip Effectankitaagarwal66No ratings yet

- 2 Evolution of Supply Chain ManagementDocument11 pages2 Evolution of Supply Chain Managementanuragnirmal100% (1)

- @RISK Example File ListDocument24 pages@RISK Example File ListPrakhar SarkarNo ratings yet

- Chapter 10Document25 pagesChapter 10Nur syafiqah NabihahNo ratings yet

- DMC 216Document7 pagesDMC 216AnonymousNo ratings yet

- SCM - 2 UnitDocument91 pagesSCM - 2 UnitNeelam Yadav50% (2)

- BullwhipDocument40 pagesBullwhipAngsuman BhanjdeoNo ratings yet

- E Supply Chain ManagementDocument18 pagesE Supply Chain ManagementVIVEK JAISWALNo ratings yet

- 09727980810949151Document13 pages09727980810949151Syed Ahmed AliNo ratings yet

- Module 2. Basic Terms of SCMMDocument18 pagesModule 2. Basic Terms of SCMMAreeba AmirNo ratings yet

- BarillaDocument3 pagesBarillaMohit Pandey0% (1)

- Supply Chain Management Chapter 1 - Students (1) - MergedDocument327 pagesSupply Chain Management Chapter 1 - Students (1) - MergedNawaz KhanNo ratings yet

- SCM MergedDocument395 pagesSCM MergedAyushi JayaswalNo ratings yet

- Dell - Tugas KelompokDocument12 pagesDell - Tugas KelompokserigalagurunNo ratings yet

- Analysis of Inventory Models With Limited Demand InformationDocument22 pagesAnalysis of Inventory Models With Limited Demand InformationororoNo ratings yet

- CH 12 ForecastingDocument76 pagesCH 12 ForecastingDarsh MenonNo ratings yet

- Chapter 3: Supply-Side Channel Analysis-Channel Flows and Efficiency AnalysisDocument20 pagesChapter 3: Supply-Side Channel Analysis-Channel Flows and Efficiency AnalysisMohamed AshourNo ratings yet

- Chapter 9 - Achieving Operational Excellence and Customer Intimacy Enterprise ApplicationsDocument16 pagesChapter 9 - Achieving Operational Excellence and Customer Intimacy Enterprise ApplicationsHASNAT ABULNo ratings yet

- Selected SCM McqsDocument6 pagesSelected SCM Mcqsabdul mueedNo ratings yet

- Ch20im11 (Backflush Costing)Document18 pagesCh20im11 (Backflush Costing)Mary Grace OfaminNo ratings yet

- Beer GameDocument5 pagesBeer GameUnni KrishnanNo ratings yet

- APICS, Greg P. Allgair, Al Bukey, Alan L. Milliken, Peter W. Murray - CSCP 2020 Module 2 Section A - Libgen - LiDocument395 pagesAPICS, Greg P. Allgair, Al Bukey, Alan L. Milliken, Peter W. Murray - CSCP 2020 Module 2 Section A - Libgen - LiPhùng Tuấn100% (3)

- Beer GameDocument2 pagesBeer Gameemuro001No ratings yet

- Chap16 - Mini Quiz - Team 4Document10 pagesChap16 - Mini Quiz - Team 4Vũ Minh HằngNo ratings yet