Professional Documents

Culture Documents

Compact Pressure Switch For The Process Industry Model PCS

Uploaded by

hakmisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compact Pressure Switch For The Process Industry Model PCS

Uploaded by

hakmisCopyright:

Available Formats

Pressure

Compact pressure switch

For the process industry

Model PCS

WIKA data sheet PV 33.30

for further approvals, see

SIL3IEC 61508 / IEC 61511 page 5 Process Compact Series

Applications

■ Pressure monitoring and control of processes

■ Safety-critical applications in general process instrumen-

tation, especially in the chemical and petrochemical indus-

tries, oil and gas industries, power generation incl. nuclear

power plants, water/wastewater industries, mining

■ For gaseous and liquid, aggressive and highly viscous or

contaminated media, also in aggressive environments

■ For measuring locations with limited space,

e.g. control panels

Special features

■ Compact design

■ Robust switch enclosure from aluminium alloy or stainless

steel with identical dimensions, IP66, NEMA 4X

■ Setting ranges from 0.2 ... 1.2 bar to 200 ... 1,000 bar,

vacuum range -1 ... -0.2 bar

■ Intrinsic safety Ex ia available

■ High switching power and large selection of contact

variants and electrical connections Model PCS, compact pressure switch

Description

These high-quality mechanical pressure switches have been The pressure switch is fitted with microswitches, which make

developed especially for safety-critical applications. The it possible to switch an electrical load of up to AC 250 V, 15 A

great advantage of mechanical pressure switches is that no directly within a repeatability of 1 % of the set point.

supply voltage is required for the switching process. Depending on the application, the appropriate variant for the

contact version and the electrical connection can be select-

In production, the switches are traced by quality assurance ed; e.g., hermetically sealed microswitches are suitable for

software at every step and subsequently are 100 % tested. corrosive ambient conditions and DPDT contact versions for

Due to its compactness, the model PCS pressure switch two separate circuits.

can be installed in measurement environments with limited By using a diaphragm element with antagonist spring as

space. The robust switch enclosure from aluminium alloy or sensor element, the model PCS pressure switch is extremely

stainless steel 316 can withstand the rough and corrosive robust and guarantees optimal operating characteristics.

operating conditions of the process industry with working For safety applications, the pressure switch is optionally

ranges of up to 1,000 bar. available in a SIL 2-qualified or a SIL 3-qualified version.

WIKA data sheet PV 33.30 ∙ 12/2021 Page 1 of 8

Data sheets showing similar products:

Compact pressure switch, flameproof enclosure Ex d; model PCA; see data sheet PV 33.31

Miniature pressure switch; model PXS; see data sheet PV 34.36

Specifications

Basic information

Version Compact pressure switch

Special design feature ■ Version for hazardous areas (Ex ia)

■ For oxygen, oil- and grease-free

■ Per NACE 1) MR0175 / ISO 15156, use in H₂S-containing environments in oil

and gas production

■ Per NACE 1) MR0103 / ISO 17945, metals resistant to sulphide stress cracking

■ Version compliant with EN 1854, pressure sensing devices for gas burners and

gas burning appliances

■ Drying of wetted parts

■ Offshore version

■ Tropical version (suitable for environments with increased air humidity)

■ Version for ammonia applications

■ Geothermal version

■ Assembled as a diaphragm seal system

Contact version ■ 1 x SPDT (single pole double throw)

■ 1 x DPDT (double pole double throw)

Microswitch, hermetically sealed, with fixed dead band

The DPDT function is realised with 2 simultaneously triggering SPDT

microswitches.

→ See table “Contact version”

Dielectric strength Safety class I (IEC 61298-2: 2008)

Switch enclosure

Design Tamper-proof due to access cover plate with lead seal option

Laser-engraved product label from stainless steel

Material ■ Aluminium alloy, copper-free, painted with acrylic

■ Stainless steel 316L

Mounting ■ Direct mounting

■ Wall bracket from stainless steel

■ Mounting bracket for 2" pipe mounting

1) General information about NACE standards; see data sheet IN 00.21

Contact version Electrical rating (resistive load) Suitable for

AC DC Ex ia option

A 1 x SPDT, silver 250 V, 15 A 24 V, 2 A, 125 V, 0.5 A, 220 V, 0.25 A No

B 1 x SPDT, silver, hermetically sealed, argon gas 250 V, 15 A 24 V, 2 A, 220 V, 0.5 A Yes

filling 1)

C 1 x SPDT, gold-plated, hermetically sealed, 125 V, 1 A 24 V, 0.5 A Yes

argon gas filling 1)

G 1 x DPDT, silver 250 V, 5 A 24 V, 0.5 A No

H 1 x DPDT, silver, hermetically sealed, air filling 250 V, 5 A 24 V, 0.5 A Yes

Sensor element Wetted parts Permissible medium temperature 1)

Sensor element Sealing

V Diaphragm element with antag- NBR - -30 ... +110 °C

onist spring

T Diaphragm element with antag- PTFE - -30 ... +110 °C

onist spring

M Diaphragm element with antag- Inconel O-ring: FPM -30 ... +200 °C

onist spring

P Piston with antagonist spring 2) Stainless steel 316L O-ring: FPM 0 ... 200 °C

O-ring: NBR -10 ... +110 °C

O-ring: EPDM -40 ... +110 °C

WIKA data sheet PV 33.30 ∙ 12/2021 Page 2 of 8

Sensor element Wetted parts Permissible medium temperature 1)

Sensor element Sealing

G Piston with antagonist spring Hastelloy C276 - -40 ... +140 °C

and welded diaphragm element

1) Permissible medium temperature range in the main process line. Depending on the measuring assembly, this may differ from the permissible temperature at the process connection. For

further information, see operating instructions.

2) Particularly suited for liquid media.

Accuracy specifications

Set point repeatability ≤ 1 % of end of setting range

Dead band → See table “Setting range of set point”

Setting range Sensor Working range 1) Proof pressure 2) Max. dead band for contact version

element A, B, C G H

in bar in bar in bar in bar in bar in bar

-1 ... -0.2 V -1 ... 6 10 0.03 0.06 0.12

0.1 ... 2.5 M -1 ... 30 40 0.05 0.1 0.4

0.2 ... 1.2 T 0 ... 6 10 0.03 0.06 0.12

0.5 ... 2.5 M -1 ... 10 40 0.05 0.1 0.4

0.8 ... 6 M -1 ... 10 40 0.06 0.2 0.8

1.6 ... 10 M -1 ... 25 40 0.2 0.4 1.6

3 ... 25 P, G 0 ... 250 400 2 4 16

3.5 ... 70 P, G 0 ... 140 500 7 7 21

4 ... 25 M -1 ... 25 60 0.25 0.75 3

8 ... 40 P, G 0 ... 100 400 2 4 16

10 ... 40 M -1 ... 60 100 1 2 8

16 ... 100 P, G 0 ... 250 400 5 5 20

20 ... 100 M 0 ... 100 150 7 9 20

20 ... 220 P, G 0 ... 350 500 8 15 24

40 ... 250 P, G 0 ... 400 600 12 20 80

60 ... 250 P, G 0 ... 400 600 5 ... 12 to 12 ... 20 3) - -

80 ... 400 P, G 0 ... 600 600 20 20 80

100 ... 600 P, G 0 ... 600 700 30 30 120

100 ... 700 P 0 ... 700 1,050 30 ... 100 3) 30 ... 100 3) 30 ... 100 3)

200 ... 1,000 P 0 ... 1,000 1,500 40 ... 110 3) 40 ... 110 3) 40 ... 110 3)

1) Pressure range that can be applied continuously without causing any damage or shifting the set point.

2) Maximum pressure that the sensor element can withstand without suffering permanent damage. The instrument might have to be calibrated afterwards.

3) The dead band depends on the set point adjustment. The indicated ranges are valid for the start and end of the setting range.

Other setting ranges are proportional.

Other setting ranges on request

Set point adjustment

The set point can be specified by the customer or factory-set within the setting range.

The switch point and the switching direction need to be specified (e.g. switch point: 2 bar, rising).

The set point is selectable within the entire setting range. For optimal performance we suggest to adjust the set point between

25 ... 75 % of the setting range. In the following example, the maximum possible setting range is shown to be dependent upon

the switching direction.

WIKA data sheet PV 33.30 ∙ 12/2021 Page 3 of 8

Example

Setting range: 0.8 ... 6 bar with one switch contact

Dead band = 0.06 bar (see table “Setting ranges” for contact version: A, B, C)

Rising pressure: Set point can be adjusted between 0.86 ... 6 bar

Falling pressure: Set point can be adjusted between 0.8 ... 5.94 bar

→ See operating instructions for further details.

Process connection

Standard ■ ANSI/ASME B1.20.1

■ DIN EN ISO 228

Size

ANSI/ASME B1.20.1 ■ ¼ NPT, female thread

■ ½ NPT, female thread via adapter

■ ½ NPT, male thread via adapter

DIN EN ISO 228 ■ G ¼, female thread via adapter

■ G ½ A, male thread via adapter

■ G ¼ A, male thread via adapter

Material (wetted)

Process connection Stainless steel 316L

Other materials on request

Sensor element Depending on the selected sensor element

→ See table “Sensor element”

Other process connections on request

Electrical connection

Connection type ■ Threaded connection with connection cable, ½ NPT male thread

■ Threaded connection with connection cable, M20 x 1.5 via adapter

■ Threaded connection with connection cable, ½ NPT female thread via

adapter

■ Threaded connection with connection cable, ¾ NPT female thread via

adapter

■ Terminal box, 3 x ½ NPT female thread, IP65

Wire cross-section 0.5 mm² (20 AWG)

Cable length

Threaded connection with connection cable ■ 1.5 m

■ 3 m

■ 5 m

Other lengths on request

Terminal box -

Pin assignment Connection details are given on the product label of the instrument. Connec-

tion terminals and the ground terminal are appropriately marked.

Material

Threaded connection with connection cable Threaded connection: Stainless steel 316

Cable sheath: Silicone

Terminal box Aluminium alloy, copper-free, epoxy resin coated

WIKA data sheet PV 33.30 ∙ 12/2021 Page 4 of 8

Operating conditions

Medium temperature range Ex version 1) TM -30 ... +60 °C

Other versions → See table “Sensor element”

Ambient temperature range T6/T85°C Ta -30 ... +60 °C

T4/T135°C Ta -30 ... +85 °C

Other versions Ta -30 ... +85 °C

Ingress protection of the complete instrument IP66 per EN/IEC 60529 (NEMA 4X)

Weight ■ 0.6 kg, with cable outlet and 1.5 m connection cable

■ 1.1 kg, with terminal box

1) Further restriction possible, depending on sensor element and sealing. → See table “Sensor element”.

Approvals

Logo Description Region

EU declaration of conformity European Union

EMC directive

Pressure equipment directive

Low voltage directive

RoHS directive

Optional approvals

Logo Description Region

EU declaration of conformity European Union

ATEX directive 1)

IM1

II 1 GD

IECEx 1) International

Ex ia I Ma

Ex ia IIC T6/T4 2) Ga

Ex ia IIIC T85°C/T135°C 2) Da IP66

EAC Eurasian Economic

Community

EMC directive

Pressure equipment directive

Low voltage directive

Hazardous areas 1)

Ex Ukraine Ukraine

Hazardous areas 1)

CCC China

Hazardous areas 1)

KCs South Korea

Hazardous areas 1)

1) Double marking ATEX and IECEx on the same product label. Country-specific Ex marking according to selected option.

2) The temperature class is related to the ambient temperature range

Manufacturer's information and certificates

Logo Description

SIL 3-capable (option)

SIL3

IEC 61508 / IEC 61511

Functional safety per IEC 61508

Contains performance level calculation per ISO 13849-1

WIKA data sheet PV 33.30 ∙ 12/2021 Page 5 of 8

Certificates (option)

Certificates

Certificates ■ 2.2 test report per EN 10204 (e.g. state-of-the-art manufacturing, indication

accuracy)

■ 3.1 inspection certificate per EN 10204 (e.g. indication accuracy)

Recommended recalibration interval 1 year (dependent on conditions of use)

For approvals and certificates, see website

Safety-related characteristic values (only for Ex version)

Safety-related characteristic values (Ex)

Voltage Ui = DC 30 V

Current Ii = 100 mA

Power Pi = 750 mW

Effective internal capacitance Ci ≤ 0 μF

Effective internal inductance Li = 0 mH

WIKA data sheet PV 33.30 ∙ 12/2021 Page 6 of 8

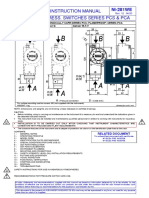

Dimensions in mm [in]

Legend

Grounding screw, outside Access cover plate

Terminal block A Process connection

Grounding screw, inside B Electrical connection

Adjustment bushing ME For sensor element, see table on page 3

Calibration scale SW Spanner width

Permissible mounting positions With affixed lead seal

WIKA data sheet PV 33.30 ∙ 12/2021 Page 7 of 8

Accessories and spare parts

Model Description

910.15 Syphons

→ See data sheet AC 09.06

910.13 Overpressure protector

→ See data sheet AC 09.04

IV10, IV11 Needle valve and multiport valve

→ See data sheet AC 09.22

IV20, IV21 Block-and-bleed valve

→ See data sheet AC 09.19

IVM Monoflange, process and instrument version

→ See data sheet AC 09.17

BV Ball valve, process and instrument version

→ See data sheet AC 09.28

Ordering information

Model / Unit / Setting range of set point / Contact version / Process connection / Electrical connection / Wetted parts / Options

© 12/2010 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

12/2021 EN

WIKA data sheet PV 33.30 ∙ 12/2021 Page 8 of 8

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- Adios CancerDocument66 pagesAdios CancerQuoc Thai Qld100% (2)

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- NU632 Unit 4 Discussion CaseDocument2 pagesNU632 Unit 4 Discussion CaseMaria Ines OrtizNo ratings yet

- LS Medium Voltage Vacuum Contactors: Tri-MECDocument36 pagesLS Medium Voltage Vacuum Contactors: Tri-MECEkanit ChuaykoedNo ratings yet

- Instruction Manual - 93 PDFDocument262 pagesInstruction Manual - 93 PDFAndrew Z100% (1)

- 2004 Timbre To DissonanceDocument4 pages2004 Timbre To DissonancetgraubaenaNo ratings yet

- Ds pv3331 en CoDocument7 pagesDs pv3331 en Co9033301054No ratings yet

- Diaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MADocument11 pagesDiaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MARida RoudiNo ratings yet

- Pressure SwitchDocument11 pagesPressure Switchaswinpisharat1997No ratings yet

- Ps3 Mini-Pressure Controls: Nomenclature - Example Ps3-Af1HnbDocument2 pagesPs3 Mini-Pressure Controls: Nomenclature - Example Ps3-Af1HnbDavid SRNo ratings yet

- Attachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFDocument17 pagesAttachment#2 - Example of Bourdon Tube Pressure Gauge With Switch Contacts PDFIbrahim Ben AmeurNo ratings yet

- Ds pv3560 en inDocument5 pagesDs pv3560 en inravisingh12911No ratings yet

- Indicating Differential Pressure SwitchDocument2 pagesIndicating Differential Pressure SwitchFaisal ImranNo ratings yet

- Ds pv3542 en CoDocument6 pagesDs pv3542 en CoPajnuNo ratings yet

- 20283644D0698 LDocument8 pages20283644D0698 LBang OchimNo ratings yet

- DATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsDocument12 pagesDATA SHEET Bourdon Tube Pressure Gauge With Switch ContactsMirwan MukminNo ratings yet

- Pressure Switch Models 201, 203, 281: ApplicationsDocument11 pagesPressure Switch Models 201, 203, 281: ApplicationsKamala kanta PandaNo ratings yet

- VC 06.07.07Document36 pagesVC 06.07.07Razvan SasuNo ratings yet

- TriMEC VC Catalog E 0901Document36 pagesTriMEC VC Catalog E 0901Razvan SasuNo ratings yet

- Gas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionDocument12 pagesGas-Actuated Thermometer With Switch Contacts Model 73, Stainless Steel VersionchauNo ratings yet

- Moeller Datasheet MCS4 019711Document5 pagesMoeller Datasheet MCS4 019711mihai37No ratings yet

- Technical Data SheetDocument4 pagesTechnical Data SheetHardikNo ratings yet

- 5.14.1 Norgren Pneumatic Pressure SwitchDocument4 pages5.14.1 Norgren Pneumatic Pressure SwitchMarleny Lindo CajusolNo ratings yet

- Servo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionDocument10 pagesServo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionYacineNo ratings yet

- MESSKO® MPREC® Technical Data 5785291 04 enDocument5 pagesMESSKO® MPREC® Technical Data 5785291 04 ensetiyawanNo ratings yet

- Pressure Switch PDFDocument2 pagesPressure Switch PDFRICHINo ratings yet

- Differential Pressure SwitchesDocument6 pagesDifferential Pressure SwitchesJayaramNo ratings yet

- Pressure Switch Bourdon 931Document4 pagesPressure Switch Bourdon 931tpchowoNo ratings yet

- lm338 Mil PDFDocument28 pageslm338 Mil PDFNepomuceno Collazos100% (1)

- Manometro WikaDocument8 pagesManometro WikaAntonio ZekyNo ratings yet

- Flameproof Limit SwitchesDocument12 pagesFlameproof Limit SwitchesGianmarcoNo ratings yet

- MAgnetrol 75 Seires LEvelDocument8 pagesMAgnetrol 75 Seires LEvelmarcoo8No ratings yet

- Pressure Switch CatalogueDocument0 pagesPressure Switch CatalogueMilosglNo ratings yet

- Druck PTX-PMP 3000 Series Amplified Aerospace Pressure Transducers Datasheet - ENDocument4 pagesDruck PTX-PMP 3000 Series Amplified Aerospace Pressure Transducers Datasheet - ENmoreauNo ratings yet

- Siemens CLS 300 DigitalDocument15 pagesSiemens CLS 300 DigitalStenio LanzaNo ratings yet

- General SpecificationsDocument6 pagesGeneral SpecificationsUrooj IlyasNo ratings yet

- DS8635 Standard EU enDocument5 pagesDS8635 Standard EU enAndres FragosoNo ratings yet

- Tension / Compression Load Cell T1: Hirschmann Automation and Control GMBHDocument2 pagesTension / Compression Load Cell T1: Hirschmann Automation and Control GMBHNabeel MohammedNo ratings yet

- SMC 3 K 22 CaDocument5 pagesSMC 3 K 22 CaTodorosss JjNo ratings yet

- Reliable Protection Against Overheating For Your MotorsDocument2 pagesReliable Protection Against Overheating For Your MotorsAmir YuliNo ratings yet

- Pressure Switches BrochureDocument38 pagesPressure Switches BrochurearavindNo ratings yet

- Pressure Switch Catalog Letest-91-109Document18 pagesPressure Switch Catalog Letest-91-109SUSOVAN BISWASNo ratings yet

- RAK TR.1000S H DatabladDocument4 pagesRAK TR.1000S H DatabladPhuc HuynhNo ratings yet

- Siemems RCDDocument4 pagesSiemems RCDDavid LimNo ratings yet

- BD SensorsDocument5 pagesBD SensorspaulNo ratings yet

- Tokyo Keiso - FS-100 DatasheetDocument8 pagesTokyo Keiso - FS-100 DatasheetAizat RomainoNo ratings yet

- A3121 2 3 Datasheet PDFDocument9 pagesA3121 2 3 Datasheet PDFAsad IqbalNo ratings yet

- GS01E20D01-01E - 011 (AXF Integralremote TubeDocument62 pagesGS01E20D01-01E - 011 (AXF Integralremote TubeBayu RahmansyahNo ratings yet

- Sensor de Presión MH-1Document4 pagesSensor de Presión MH-1Sergio Suárez RiesgoNo ratings yet

- Wika TGDocument13 pagesWika TGGbl BplNo ratings yet

- Danfoss RTDocument12 pagesDanfoss RTSerge Yannick MimboeNo ratings yet

- Contact Connection 1-3: 6 (2.5) A, AC 250 V: Building TechnologiesDocument4 pagesContact Connection 1-3: 6 (2.5) A, AC 250 V: Building TechnologiesDavid NguyenNo ratings yet

- E Brooks MT3809 OKDocument19 pagesE Brooks MT3809 OKravichandran0506No ratings yet

- Schmersal - Finecorsa Alza Abbassa - Datasheet - Z1R 236-11zDocument6 pagesSchmersal - Finecorsa Alza Abbassa - Datasheet - Z1R 236-11zLiliana ZamoraNo ratings yet

- Pressure Trasducers ArkerDocument26 pagesPressure Trasducers ArkerVictor Hugo Benitez Paez100% (1)

- Micro Switch™ Limit Switches Line Guide: FeaturesDocument6 pagesMicro Switch™ Limit Switches Line Guide: FeaturesAlexanderNo ratings yet

- Proportional Pressure Reducing Valve Screw-In Cartridge - Pilot Operated - Q 160 L/min - P 400 Bar - P 350 BarDocument2 pagesProportional Pressure Reducing Valve Screw-In Cartridge - Pilot Operated - Q 160 L/min - P 400 Bar - P 350 BarDavidson GattoniNo ratings yet

- Micro Switch™ Limit Switches Line Guide: FeaturesDocument6 pagesMicro Switch™ Limit Switches Line Guide: FeaturesAndika SNo ratings yet

- KH15 Pressure Transmitter: Wetted Parts SUS316L AvailableDocument19 pagesKH15 Pressure Transmitter: Wetted Parts SUS316L AvailableTỉnh NgôNo ratings yet

- Pressure Transmitter For Refrigeration and HVAC Applications Model AC-1Document4 pagesPressure Transmitter For Refrigeration and HVAC Applications Model AC-1Kumphala LuahrNo ratings yet

- Danfoss Pressure Switch Type KPDocument9 pagesDanfoss Pressure Switch Type KPMohammed RayanNo ratings yet

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version Models 232.30 and 233.30Document12 pagesBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version Models 232.30 and 233.30TÀi VÕNo ratings yet

- Gasmultibloc Combined Regulator and Safety Shut-Off Valves Two-Stage Function MB-ZRD (Le) 405 - 412 B01Document5 pagesGasmultibloc Combined Regulator and Safety Shut-Off Valves Two-Stage Function MB-ZRD (Le) 405 - 412 B01mdkhandaveNo ratings yet

- Instruction Manual: Vibration Calibrating SystemDocument50 pagesInstruction Manual: Vibration Calibrating SystemhakmisNo ratings yet

- Ba01004fen 1816Document200 pagesBa01004fen 1816Anonymous rjhG0cYgaiNo ratings yet

- Information For Site Preservation Transportation, Packing and StorageDocument3 pagesInformation For Site Preservation Transportation, Packing and StoragehakmisNo ratings yet

- Fieldcare Sfe500: Technical Information Field Device ConfigurationDocument8 pagesFieldcare Sfe500: Technical Information Field Device ConfigurationhakmisNo ratings yet

- MoserDocument74 pagesMoserSveto SlNo ratings yet

- Instruction Manual Compact Press. Switches Series Pcs & Pca: NI-281WEDocument7 pagesInstruction Manual Compact Press. Switches Series Pcs & Pca: NI-281WEhakmisNo ratings yet

- GDPDocument6 pagesGDPBenedetta NardiNo ratings yet

- Synthesis and Recrystallization of Dibenzalacetone: Experiment - 4Document2 pagesSynthesis and Recrystallization of Dibenzalacetone: Experiment - 4ARYAN CHAVANNo ratings yet

- Hydro PDFDocument139 pagesHydro PDFVan Quynh100% (2)

- Hytrel Extrusion Manual PDFDocument28 pagesHytrel Extrusion Manual PDFashkansoheylNo ratings yet

- Manpower EstimationDocument28 pagesManpower EstimationRakesh Ranjan100% (2)

- Ant WorldDocument17 pagesAnt WorldGerardo TorresNo ratings yet

- Frenkel Exercise Protocol For Patient With Parkinsons DiseaseDocument39 pagesFrenkel Exercise Protocol For Patient With Parkinsons DiseaseHumaira Rahman0% (1)

- PDFDocument110 pagesPDFBikash NayakNo ratings yet

- Desing of Municipal WWTPDocument260 pagesDesing of Municipal WWTPGREGORIO MOCTEZUMA100% (1)

- Off-Label Drug Use - 2020Document14 pagesOff-Label Drug Use - 2020Bigabwa BernardNo ratings yet

- Analysis of Antioxidant Enzyme Activity During Germination of Alfalfa Under Salt and Drought StressesDocument8 pagesAnalysis of Antioxidant Enzyme Activity During Germination of Alfalfa Under Salt and Drought StressesJimenoNo ratings yet

- Spare Parts Quotation For Scba & Eebd - 2021.03.19Document14 pagesSpare Parts Quotation For Scba & Eebd - 2021.03.19byhf2jgqprNo ratings yet

- The Relationship of Language Development and Nutritional Status of The Child in The Region South of The City of Kediri Region Public HealthDocument12 pagesThe Relationship of Language Development and Nutritional Status of The Child in The Region South of The City of Kediri Region Public Healthdoddyk kurniawanNo ratings yet

- Troubleshooting Pt6a27Document7 pagesTroubleshooting Pt6a27Okky Pangestoe WibowoNo ratings yet

- Tank Vessel Overflow Line SizingDocument4 pagesTank Vessel Overflow Line SizingSteve Wan100% (1)

- Laboratory Department Tracking Sheet OriginalCHARM2Document128 pagesLaboratory Department Tracking Sheet OriginalCHARM2Charmaine CorpuzNo ratings yet

- Anatomy-Head and NeckDocument94 pagesAnatomy-Head and NeckXahid IqbalNo ratings yet

- Galleria MellonellaDocument6 pagesGalleria MellonellaJustin GarciaNo ratings yet

- Dyneema Vs SteelDocument5 pagesDyneema Vs SteelSaurabh KumarNo ratings yet

- Amended Consent Decree and Draft Interim Action Work Plan For The Hansville General R Men Store Site - Available Fo Public Review and Com TDocument4 pagesAmended Consent Decree and Draft Interim Action Work Plan For The Hansville General R Men Store Site - Available Fo Public Review and Com TCommunityNewsNo ratings yet

- International Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)Document13 pagesInternational Journal of Technical Innovation in Modern Engineering & Science (IJTIMES)pavan kumar tNo ratings yet

- 1822 B.E Cse Batchno 154Document53 pages1822 B.E Cse Batchno 154maniuyyala65No ratings yet

- Forklift Bucket 1400B - ManualDocument4 pagesForklift Bucket 1400B - ManualVie LiesnaNo ratings yet

- Asus Prime b250m Plus RGDocument13 pagesAsus Prime b250m Plus RGRenattech SilvaNo ratings yet

- P.B.B.SC Nsg. Syllabus Original PDFDocument57 pagesP.B.B.SC Nsg. Syllabus Original PDFRajalakshmi SrinivasanNo ratings yet

- What Is Aplastic Anemia?Document23 pagesWhat Is Aplastic Anemia?Ayi SuwarayiNo ratings yet