Professional Documents

Culture Documents

Phewmo Phe32 Phe38 Phe39 Phe54 G Sor 0001 Rev.a - Statement of Requirement (Sor)

Uploaded by

Wedding party0 ratings0% found this document useful (0 votes)

96 views65 pagesstatement of Requirement

Original Title

Phewmo Phe32 Phe38 Phe39 Phe54 g Sor 0001 Rev.a_statement of Requirement (Sor)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentstatement of Requirement

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views65 pagesPhewmo Phe32 Phe38 Phe39 Phe54 G Sor 0001 Rev.a - Statement of Requirement (Sor)

Uploaded by

Wedding partystatement of Requirement

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 65

Project Title

Document Number

Process Facility Study for

POD PHE-32, PHE-38,

PHE-39 & PHE-54 PHEWMO-PHE32-PHE38-PHE39-

0

a

soarsaviosa | 47M PERTAMINA | MEeSoRo001

‘Author's Organization PHE WMO co eee

Validation

GENERAL

Expired

Date

DOCUMENT FOR PRE-FEED

STATEMENT OF REQUIREMENT (SOR)

Approval Sheet

Name Title

Date Signature

Harfizal Single Point Accountability

Heru Prasetyo Surface Facility Leader

Prax Pevitd dhe deo ae pe

tacit what

|

DOCUMENT REVIEW

[resonance wm (Elixepoved [er Approved

(eaiem tc Approved as noted] Review Not Reqied

10 OCT 2019 Compony’s opproval permission to process with york nor

ae Constitute eceptonce of design ond engtnen, t

ASW Contractor. Approval DOESNOT relieve Cavtacty cs ep

PROJECT J compliance of contract/Purchase ‘Order requireme ||

ths dae. us Por

Cheat otyne o Revision

Dote 22/12 (19

tee Zkeccubon phere

T

PT. DEPRIWANGGA

Rev | Issue Date

Owner

£ Issue Purpose

Prepared Signature

[A 98-Oct-2019 | RANG I7MSITG Issued For Review

) PHEWNO. Statement of Requirements (SOR)

4 Revision Log Register

Document Number: PHEWMO-PHES2-PHES8-PHES9-PHES4-G-SOR-0001

Document Title ‘Staternent of Requirement

Revision TA

BHEWMO-PHESZ-P HESS: PHESO PRESEG-SOR-OO0T, Rev. A Pape Treo

PHEWMO Statement of Requirements (SOR)

Table of Contents

Revision Log Register.

Table of Contents.

List of Figures

List of Tables.

1 Introduction...

1.1. Background.

1.2 Objectives.

2 Company Guidelines and Speeffication and international Codes and Standards ..

2.4 Company Guideline and Specification :

2A General mnmmnnenernnenrnmner

2.4.2 Process and Process Safety .

2.4.3. Mechanical

24.4 Piping.

2.4.5 Instrumentation..

21.6 Electrical

24.7 Pipeline...

24.8 Structure vn ne

249° CNIL.

2.4.10 Painting.

24.11 HSE

24.42 Quality.

24.13. Construction

2.2 International Codes and Standards.

224 General sti

222 Structures el

223 Faciities and Piping..

2.24 Tanks and Vessels

22.5 Machinery

22.6 Painting and Coating .

2.27 Safety and Loss Control

228 Electrical... Sete

22.9 Area Classification vcrnsanonsesnn

2.2.10. Instrumentation... ae

2.2.11 Telecommunications.

3. Definition and Term

3.4 Abbreviation..

3.2 Unit of Language .

4 Project Goals.

4.4 General...

42 Study Cases ono

5 Health, safety, Security and Environment...

5.1 HSSE Expectation socrocs

5.2 HSSE Philosophy sonnessnnnne

5.2.1 Health Philosophy.

6.2.2 Safety Philoshophy...

5.2.3 Security Philosophy.....

5.2.4 Environmental Philosophy

5.3 HSSE Objective.

5.3.1 HSSE Management Plan.

5.3.2 HSSE Performance and Measurement...

5.4 Schedule of HSSE Studies and Reviews...

5.5 Compliance and Assurance In HSSE..

6.1 Reservoir Data...

62 Fluid Composition...

6.3 Impurities

6.3.1 Sand Production...

6.3.2 Hydrate Formation niin

63.3 Sour Gas.

6.3.4 Wax Formation.

PREWNO PHES2:PHESS PHES® PHES#-G-SOR-000T, Rev. A Page soe

619

7 Operations and Maintenance.

TA

72

73

74

78

78

7

78

8 Facilities Description ,

a4

82

83

84

9 Functional Requirements

Statement of Requirements (SOR)

Production Profi.

Design Capacity

Simulation Study Cases... :

Current Production Flowrate and Pressure Mapping

Existing Pipeline Data..

Destination Pressure

Geodetic Parameter

Location Data...

Ambient Condition

Water Depth

Wind Data.

Wave and Current Characteristic Data.

Wave Parameter - :

Conductor Shielding Factor nue nnnnnrnnnninnemnnn

Marine Growth...

Splash Zone.

Operations Controlled Documents

Simultaneous Operation...

Operation Representative & Pre-OPs PAM snus

People, Training and Competency

Accommodation.

Operabilly

Operating Spares

Equipment Numbering

‘Structural.

‘Summary Preliminary Assessment

North Processing Facility (NPF) Facilites.

83.1 Production Separater...

83.2 Gas Booster Compressor.

8.3.3 Transfer Pump...

8.3.4 Transfer Pipeline .

8.3.5 Gas Lift Compression System nnn

8.36 Produced Water Handing Fact mm

8.3.7 Fuel Gas System... seers

8.3.8 Instrument and Utility Air System

83.9 Power Generation System

8.3.10 Diesel Supply System..

8.3.11 MP Flare System...

8.3.12. LP Flare/Closed Drain System...

8.3.13 Chemical Injection System

83.14 Utiity and Potable Water System

8.3.15. Fire Water SYSIEM new

83.16 Seal Gas System.

8.3.17 Living Quarters.

8.3.18 Interconnection Lines and Cables

Conceptual Study Findings.

8.4.1 Structural

B42 ProceS8.ncun

8.4.3. Mechanical

84.4 Electrical .oonuen

8.4.5 _ Instrument and Contra...

General

Service Life Time

Plant Availability.

Specific Topside Requirements.

9.4.1 Separation wn...

9.4.2 Gas Booster Compressor.

9.4.3 Transfer Pum

9.4.4 Transfer Pipeline .

PHEWMO-PHESZ-PHESE-PHESS PHESE-G-SORO00T, Rov. A Page Foro

PHEWNO ‘Statement of Requirements (SOR)

Gas Lift Compression System...

Produced Water Handling Facility...

Fuel Gas System...

Instrument and Utilty Air System ..

Power Generation Syster

Diesel Supply System..

MP Flare System...

LP Flare/Closed Drain Sysiem

Chemical Injection System...

Unity and Potable Water System.

Fire Water System.

Seal Gas System...

Living Quarters ..

Interconnection Lines and Cables.

9.5 Hull Requirements

9.5.1 Hull Dimension ..

95.2 Variable Load ...

95.3 Communication Equipment

95.4 Utilities

9.5.5 Safety and Lifesaving Equipment..

95.6 Instrument Requirement.

9.5.7 Mooring System..

9.5.8. Stabilo

9.5.9 Traoking System...

10 FEED Requiremert.......

10.1 Codes, Standard and Philosophies -

10.1.1" Project Specification...

10.1.2 Operating Philosophies «0...

10.2. Indonesian Laws and Aoprovals

10.3. Project Design Conditions...

10.4 Quaity Pian

40.5 Technology...

10.6 Site Survey

10.7 Integrity Management... :

10.8 Qualification / Contractor Requirement...

10.9 Design Requirement.

10.10 Discipline Engineering Scope.

10.10.1 Structural.

40.10.2 Process,

10.10.3 Process Safety ..

10.10.4 Mechanical ..

10,10.5 Piping.

10.10.6 Pipeiine.....

40.10.7 Electrical.

10.1018 Instrumentation and Gonttol

10.10.9 3D Modeling.

10.10.10 HSE

14 Construction...

11.1 Constructabilty..

M12. TOOI8 2.

11.3. Marine Spread

44.4 Temporary Isolaiion/Shutdown Philosophy

115 Material Harting Study

12 References :

PHEWNO-PHES2-PHESS PHESS.PHESI-G SOR-OODT, Rev. A Pages or80

PHEWMO ‘Statement of Requirements (SOR)

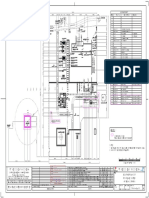

Figure 4 1 Sie Map and Pipeline Inercomections of PHE-32,38,988,00,54 and New Processing Fsily

Figure 6.1 PHE-38 THP Profil...

Figure 6.2 PHE-388 THP Profil...

Figure 6.3 PHE-39 THP Profile

Figure 6.4 PHE-54 THP Profi.

Figure 6.5 North Field - Gas Production Profi.

Figure 6.6 North Field - Oil Production Profile

Figure 6.7 North Field - Water Production Profi...

Figure 6.8 Pipeline Interconnection between Wellhead Platform...

Figure 8.9 Poreantage Occurence of All Yeer Wind Speed by Month.

Figure 8.1 Block Diagram of North Processing Facility...

List of Tables

Table 5.1 Regulation for Emission from Power and Emergency Generation System...

Table 6.2 Baku Mutu ir Limbah dari Fasitas Ekeplores! dan Produkel Migs di Lepas wana (OF-Six

Table 6.1 Gas and Oil Composition PHE-38

Table 6.2 Gas and Oil Composition PHE-38B..

Table 6.3 Gas and Oil Composition PHE-39

Table 6.4 Gas and Oil Composition PHE-54.

Table 6.5 Design Capacity of North Processing Facility.

Table 6.6 Wells Production Flowrate for Each Study Cases...

Table 6.7 Current Production Flowrate and Pressure Mapping

Table 6.8 Existing Pipeline Data

Table 6.9 PHE WMO Geodetic Parameter.

Table 6.10 Location Data.

Table 6.11 NPF Tidal Data.

Table 6.12 Ambient Air Temperature

Table 6.13 Ambient Sea Temperature..

Table 6.14 Water Depth Data.....

Table 6.15 Wind Data at Cluster L..

Table 6.16 Wave and Current Data...

Table 6.17 Hydrodynamic Coefficient, Wave Kinematics, and current Blockage Factors

Table 8.1 Preliminary Soope..... :

Table 8.2 Gas Lift System

Table 8.3 New Fixed Platorm Descripion..

Table 9.1 Gas Lift System

Table 9.2 Hull Dimension.

‘BRE WH"O-PHES2 HESS PHESS PHEBE-G-SORO0T, Rev. A Pogo Ted

PHEWMO Statement of Requirements (SOR)

1 Introduction

4.4 Background

PHE WMO is anticipating to resolve production declination issue from four (4) producing fields located in

northern area, namely PHE-38, PHE-38B, PHE-39 and PHE-54.

Historically, PHE WMO had ever rented Temporary Production Facility (TPF) from May 2014 until January

2019 to sustain production from PHE-38, which successfully boosted production from about 100 psig to 300

psig to PPP. Lowering pressure using TPF has increased production gain of PHE-38. Nowadays, after TPF

has no longer operated, only some wells in PHE-38 which has sufficient pressure is still producing while the

other low pressure wells has stopped producing,

While PHE-38B, PHE-39 and PHE-54 also face well pressure declination. Production from PHE-38, 39 and

54 delivered to PPP via PLEM and different pipeline. But in order to decrease back pressure the oil wells,

some portion of PHE38B/39/54 is diverted to WHP PHE-38 outgoing pipeline which is also going to PPP.

Landing pressure at PPP is maintained at 180 psig.

PHE WMO intends to provide a new North Processing Facility (NPF) to help to lower backpressure the wells,

so that production from Northern field can be sustained.

a. ee M7 PERTAMINA

FRE WMO

PRODUCTION FACILITIES LAYOUT

Ke40

POLENG

(rac)

Figure 1. 4 Site Map and Pipeline Interconnections of PHE-32,38,38B,39,54 and New Processing

Facility

1.2 Objectives a

The objective of this Statement Of Requirements (SOR) document is to define the requirement of whole project

which consists of multidiscipline engineering aspect, and project management team dug FEED phase.

eoncegt as Sear. shady conducted

‘its document sewer the eslesel mee apd

ED “legen order-to-overcome-the

_potential-isstes-that-wil-arise-due-to Worth Processing Facility (NP and provide design inputs

for the FEED,[Further studies are to be performed during FEED fo arrive at complete technical definition of the

project covering the following areas:

+ Produced water treatment technology selection.

* Conduct a detailed risk assessment to better understand the risks and possible risk mitigation

strategies.

‘© Additional risk control measures should be identified and implemented as appropriate.

TS part of gw (nme te &¢. 24 Insert in each discipline

PHEWMO-PHE32-PHE38-PHE39-PHES4-G-SOR-0001, Rev. A us Page 7 of 60

PHEWMO

2 Company G

Standards

jelines and Speci

‘Statement of Requirements (SOR)

ation and International Codes and

2.1 Company Guideline and Specification

2.4.4 General

PHEWMO-PROJ-G-SPE-0001

PHEWMO-PROJ-G-SPE-0002

PHEWMO-PROJ-R-SPE-0002

PHEWMO-PROJ-Z-SPE-0104

PHEWMO-PROJ-G-SPE-0108

PHEWMO-PROJ-K-SPE-0252

PHEWMO-PROJ-M-SPE-0254

PHEWMO-G-SPE-0255

PHEWMO-PROJ-Z-SPE-0269

PHEWMO-PROJ-Z-SPE-0270

PHEWMO-PROJ-M-SPE-0272

PHEWMO-PROJ-H-SPE-0276

PHEWMO- PROJ-2-SPE-0001

PHEWMO- PROJ-Z-SPE-0201

PHEWMO- PROJ-Z-SPE-0003

PHEWMO- PROJ-R-SPE-0001

PHEWMO- PROJ-I-SPE-0001

2.1.2 Process and Process Safety

PHEWMO-PROJ-O-GDC-0002

PHEWMO-O-PRC-0007

PHEWMO-O-PRC-0008

PHEWMO-PROJ-DSG-J-STK-

2017-8037

‘PHEWMO-PROJ-DSG-J-STK-

2017-8039

PHEWMO-PROJ-DSG-J-STK-

2017-8033

PHEWMO-O-PRC-0015

PHEWMO-PRO\-0-GDC-0018

PHEWMO-PROJ-ENG-J-STK-

2017-8012

PHEWMO-PRO4-O-SPE-0019

PHEWMO-O-PRC-0021

PHEWMO-PROJ-0-GDC-0022

PHEWMO-PRO4J-0-GDC-0024

PHEWMO-PROJ-DSG-J-STK-

2017-8014

PHEWMO-PRO\-ENG-V-STK-

2017-8021

PHEWMO-PRO\-ENG-J-STK-

2017-8022

Start Up and Operating Manual Specification

Structural and Piping Fabrication Quality Control

Facility Acceptance Check List

Site Preparation Speetfication

Specification for Design and As-built Drawings

Specification for Thermal and Accoustic insulation Systems

Specification for Package Skid-Mounted Equipment

‘Vendor Documentation and Inspection

Specification for Portable Storage Building

Specification for Onsite Requirements for COMPANY

Representative

Non Air-Conditioned Work Room Specification

Coating of Bolt and Nut Components Specification

Offshore Construction EquipmentSpecification

Specification for Fabrication Yard

Vessel Marine Spread Specification

‘Specification Start-up Operating Manual

Project Data Books Specification

Guidance on Engineering Method for Hazard and Operability

(HAZOP) and “What-if" Studies

Guidance on Engineering Method for Layer of Protection Analysis

(LOPA)

Guidance on Engineering Method Pumping System

Guidance on Engineering Method Drain System

Guidance on Engineering Method General Line Sizing

Guidance on Engineering Method Separator Design

Guidance on Engineering Method Design Pressure & Design

Temperature

Guidance on Engineering Method Depressurization System

Guidance on Engineering Method Firewater System

PHE WMO Risk Acceptance Criteria

Guidance on Engineering Method Over Pressure Protection

Guidance on Engineering Method Relief and Disposal System for

Manned Stations/Facilltes

Guidance on Engineering Method for Hazard Identification (HAZID)

Study

‘Specification for Atmospheric Vent and High Pressure Vent Systems

on un-Manned Facilities

‘Specification for Life Jackets

Specification for Life Raft

PREWMO-PHESS PHESE PEGS PHESEG SOR O00T, Rav. A Page 8oF60

PHEWMO

Statement of Requirements (SOR)

PHEWMO-PROJ-ENG-J-STK-

2017-8024

PHEWMO-PROJ-ENG-J-STK-

2017-B025

PHEWMO-PROJ-ENG-J-STK-

2017-B028

Mechanical

PHEWMO-PROJ-M-SPE-0001

PHEWMO-PROJ-M-SPE-0003

PHEWMO-PROJ-M-SPE-0004

PHEWMO-PROJ-M-SPE-0005

PHEWMO-PROJ-M-SPE-0006

PHEWMO-PROJ-M-SPE-0007

PHEWMO-PROJ-M-SPE-0008

PHEWMO-PROJ-M-SPE-0009

PHEWMO-PROJ-M-SPE-0010

PHEWMO-PROJ-M-SPE-0012

PHEWMO-PROJ-M-SPE-0254

PHEWMO-PROJ-M-SPE-0262

PHEWMO-PROJ-M-SPE-0305

PHEWMO-PROJ-M-SPE-0309

PHEWMO-PRO\-M-SPE-0315

PHEWMO-PRO\-M-SPE-0318

PHEWMO-PRO\-M-SPE-0325

PHEWMO-PROJ-M-SPE-0372

24.3

pan

2.4.4 Piping

PHEWMO-PRO4-X-SPE-0001

PHEWMO-PRO\-X-SPE-0002

PHEWMO-PROV-X-SPE-0003

PHEWMO-PRO\-X-SPE-0004

PHEWMO-PROJ-X-SPE-0005

PHEWMO-PROJ-X-SPE-0273

2.4.5 Instrumentation

PHEWMO-PROJ.

PHEWMO-PROJ.

PHEWMO-PROJ.

PHEWMO-PROJ-J-SPE-0907

PHEWMO-PROJ-J-SPE-0008

PHEWMO-PROJ-J-SPE-0112

PHEWMO-PROJJ-PRO-0002

Elect

PHEWMO-PROJ-£-SPE-0001

PHEWMO-PROJ-E-SPE-0003

PHEWMO- PROJ-E-SPE-0004

PHEWMO-PROJ-E-SPE-0005

PHEWMO-PROJ-E-SPE-0009

PHEWMO-PROJ-E-SPE-0010

24.6

sal eae O58

a8'-Spe i Carvon

PES

‘Specification for Fire Extinguisher

‘Specification for Foam Hose Reel Station

Specification for Eyewash and Safety Shower Stations

Specification for Gas Turbine Compressor Package

Specification for Diesel Engine Driven Fire Pump.

‘Specification for Shell and Tube Heat Exchanger

Specification for Air Cooled Heat Exchanger

Specification for Flare Tip and Flare Ignition

Specification for Centrifugal Crude Oil Pumps

‘Specification for Centrifugal Gas Compressor

Specification for Pressure Vessel Design and Fabrication

Specification for Launcher & Receiver (Pig Trap)

Specification for Centrifugal Pump for General Use

Specification for Package Skid Mounted Equipment

Specification for Noise Limits for Equipment

Specification for Chemical Injection Packages

Specification for Gas Turbine Driver

‘Specification for Submersible Electric Motor Driver Pumps

Specification for Portable Standby Generator Sets

Specification for Reciprocating Plunger or Piston Type Power Pump

Specification for Instrument Utility Air Compressor Package

Gpecificction lar Pecustal Mosuled Hydraulic Marine Ceaas

Piping Fabrication, Installation and Testing Spectfication,

Pipe Stress Analysis Specification

Valve Specification

General Piping Design Specification

Piping Material Specification

‘The Preparation of Piping Isometric PewUp MoT fe

GRecihcakion tor Clumk KR Smoke Dadtechor cB

General Field Instrument & Installation Specification

Specification for Pressure, Level, Temperature Instrument

SDV, BDV, Actuated On/Off Valve, Control Valve & Pressure

Regulator Valve Specification

Well Head Control and Control Panel Specification

Process Automation and Control Network Specification

Specification for Instrumentation Testing and Calibration

Guidance for Safety instrumented Systems (SIS) Equipment

nee eee ee

ks e009 T -

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- w2021c Phewmo Phe32 G Cos 0001 - Cost Estimate Report Reva (Ifr) PipingDocument47 pagesw2021c Phewmo Phe32 G Cos 0001 - Cost Estimate Report Reva (Ifr) PipingWedding partyNo ratings yet

- PEPA3-11-MS-03-DS-005 - T-07 - SP-Tambun REV 0Document4 pagesPEPA3-11-MS-03-DS-005 - T-07 - SP-Tambun REV 0Wedding partyNo ratings yet

- KJC-R-PI-001-M - 3C Sheet 1 of 2 Feed Gas Inlet Junction (Modification)Document1 pageKJC-R-PI-001-M - 3C Sheet 1 of 2 Feed Gas Inlet Junction (Modification)Wedding partyNo ratings yet

- TRS-P-PL-001 - Rev 6E - Equipment Layout For Flare System - NCHDocument1 pageTRS-P-PL-001 - Rev 6E - Equipment Layout For Flare System - NCHWedding partyNo ratings yet

- TRS-P-GA-001 - Rev 4C - Piping General Arrangement For Flare System - NCHDocument1 pageTRS-P-GA-001 - Rev 4C - Piping General Arrangement For Flare System - NCHWedding partyNo ratings yet

- CAGI Data Sheet VST225-150hp-125psi-Water 6-26-20Document1 pageCAGI Data Sheet VST225-150hp-125psi-Water 6-26-20Wedding partyNo ratings yet