Professional Documents

Culture Documents

14EDT22

Uploaded by

mohanmech20068860 ratings0% found this document useful (0 votes)

9 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pages14EDT22

Uploaded by

mohanmech2006886Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

M2391

Registor No. LLL I

[ME Degree Examination May 2018

Second Semestor

Corman to Engineering Docign and CADICAM branches

|MEDT22~ MECHANICAL BEHAVIOUR OF MATERIALS

(Regulations 2014)

‘Time: Three hours ‘Maximum: 100 marks

Answer all Questions

Part A (10 2= 20 marks)

1. What is meant by the tam ‘strain energy”? a

2. Draw the Mob’ ciel for 2D representation of stress wa

3, What is understood by the term plane stress condition? co

4. Define the term stress concentration factor Po

5. Compare true stress with enginesring strose with graphical representation a

6, Mention diffrent theories of fubure. a

7. Write down the stress intensity equations ma

& What isthe relationship between stress intensity factor and fracture toughness? wa)

9. Draw the typical fatigue erucves for ferrous and non ferrous metals ma

10. Write down any two eurface parameters that influence fatigue failure ea

Part -B (6% 13 =65 marks)

11, a The-state of stress is given by oy =25p and ay =p plus shearing stresses tay, (13)

(Ona plane 45° counter clockwise tothe plane on which oy acts, State of stress

is 50 MPa tension and 5 MPa shear, Determine the values of @,.04 and tay

on,

b. i) The stress components at a point in body subjected to 2D stateaf'stresses (7) I

are given by

eg =Bx2y + Bey; Gy = 849 +1039 ty = 5x29" show that the equations

of equilibrium are satisfied at the point 8.0)

ii) Briefly describe the concept of stress tensor with an example © ms

12. a Derive the expression for stress components ofa cantilever beam of rectangular (18) 8)

crass section. Assume end load is acting onthe beam.

(on)

‘b. Derive an equilibrium equation in cylindrical ordinates for 2D state of stress (18)

swith a diagram,

13, a. i) Draw the typical true stress-strain curve for ductile material end deseribe (1)

‘the elements involved init

48) A tensile specimen with « 12 mm initial diameter and 50 mm gage length ©)!

feaches maximum load at 90 KN and fractures st 70 kN, ‘The maximum

fliameter at fracture is 1D mm, Determine engineering stress «t maximum

Ina and tre fracture stress.

(on)

') Explain in detail about different mechanisms of creep deformation with a (1) at

neat sketch

ii) Brie discuss about any two thoories of failure and their significance, (6) ‘kal

MU. a.) Derive an expression for Grifith theory of Britle fracture with a neat (7) it)

sketch,

18) Draw tho graph representing the effect of tomperature and loading rate on (6) (4

fracture and describe its elements.

ony

|) Briefly discuss about diffrent modes of facture with a neat sketch o &

48) Describe in detail about the effect of temperature and plate thickness on (6)

fracture toughness.

15, a i Explain the methodology for predicting fatigue-crack initiation fom (7) ia

notches.

4i) Describe the phenomenon of Blastic Plastic fracture mechsnics, ©

(oR)

Explain in the mechanism of fatigue crack propagation under constant and (13) (5)

variable load with a neat sketch,

Part (1 15=15 marks)

16. a Anylon part the normal strains ata fre surface are measured along the three (15) (1

‘directions, Where 5° Youngs modulus =2GPa and Poisson's ratio

20.35. They #01110, oy 0.2010", e, =0.4%109

Determine the following

|) ‘Three principal strains and thei directions

1) "The magnitude ofthe greatest shear strain

i) The threo principal stresses and their directions

iv) The magnitude ofthe greatest shear stress

Draw Mohe's circle forthe 3D state of stress

oR)

‘The flow curves for two metal are given by (a5)

Metal 4:0 625<°5MPa

Metal B:o=1902°"MPa

Both metals are initially loaded to stress of 140 MPa and a strain of 0.05. If

the stress is increased to 160 MPa, what is the strain in each metal? Also write

oven ite imporeance to sheet metal forming

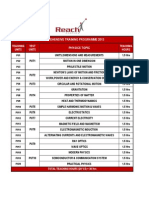

“Blooms | Ressembering [Underdianding| Applying | Analyaing | Evaluating] ~ Grating

Taxonomy Level | RID | ka) 1) KS) ike)

[_ Ferenc [8 1 1 2 2

2 M-z391

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Kongu Engineering College Perundurai Erode - 638 060 (Autonomous) Academic CellDocument14 pagesKongu Engineering College Perundurai Erode - 638 060 (Autonomous) Academic Cellmohanmech2006886No ratings yet

- SOM Question BankDocument9 pagesSOM Question Bankmohanmech2006886No ratings yet

- Ventura 2009Document3 pagesVentura 2009mohanmech2006886No ratings yet

- UNIT II Need For PPC-Objectives-Functions-Information Required For PPC-ProductionDocument30 pagesUNIT II Need For PPC-Objectives-Functions-Information Required For PPC-Productionmohanmech2006886No ratings yet

- 06 August 2021 09:13 AM: New Section 9 Page 1Document2 pages06 August 2021 09:13 AM: New Section 9 Page 1mohanmech2006886No ratings yet

- 2D TransformationDocument31 pages2D Transformationmohanmech2006886No ratings yet

- Chapt13 - Kinetics of Particle - Energy and MomentumDocument88 pagesChapt13 - Kinetics of Particle - Energy and Momentummohanmech2006886No ratings yet

- Stereo LithographyDocument21 pagesStereo Lithographymohanmech2006886No ratings yet

- Rapid Technologies in Integrated Product Development B. Dyba A, E. Chlebus, T. BoratyñskiDocument4 pagesRapid Technologies in Integrated Product Development B. Dyba A, E. Chlebus, T. Boratyñskimohanmech2006886No ratings yet

- NITT CalendarDocument12 pagesNITT Calendarmohanmech2006886No ratings yet

- Safe Use of Metal Turning Lathes: Guidance NoteDocument8 pagesSafe Use of Metal Turning Lathes: Guidance Notemohanmech2006886No ratings yet

- Newton's Law of Universal Gravitation F : GravityDocument16 pagesNewton's Law of Universal Gravitation F : Gravitymohanmech2006886No ratings yet

- Aura One Mark Question and AnswersDocument13 pagesAura One Mark Question and Answersmohanmech2006886No ratings yet

- CTP Teaching & Test Units 2013Document4 pagesCTP Teaching & Test Units 2013mohanmech2006886No ratings yet

- Hy PresDocument46 pagesHy Presmohanmech2006886No ratings yet

- Area Circle 1Document2 pagesArea Circle 1mohanmech2006886No ratings yet