Professional Documents

Culture Documents

Rig 130 NOV MP

Uploaded by

Hassan Khattab0 ratings0% found this document useful (0 votes)

16 views1 pageOriginal Title

Rig 130 NOV mp

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views1 pageRig 130 NOV MP

Uploaded by

Hassan KhattabCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

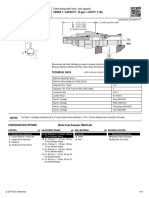

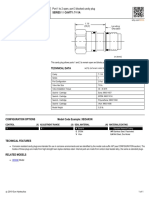

Document number FS-201

Revision 03

Page 52

(.51mm)

a. Install .020” shims under both ends of the main bearing cap.

b. Place a piece of lead wire (approximately 1/32” diameter) (.79mm ø) or Plastigage

between OD of bearing carrier and ID of bearing cap, as near center of bearing cap

as can be determined, and tighten main bearing cap bolts to torque values shown in

Chart III.

c. Remove main bearing cap and determine clearance between bore of cap and OD of

bearing carrier by either mikeing thickness of lead or measuring compressed

dimension of Plastigage.

d. Using this dimension, calculate the required thickness of shims as follows:

Subtract thickness of compressed lead or

Plastigage from the original .020” (.51mm) shim

thickness. Then subtract .003” (.076mm) for preload.

The result is the correct shim thickness required.

www.nov.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Inspect Axial Play of Turbine Shaft - Toyota Hilux 1KZ TE RepairDocument2 pagesInspect Axial Play of Turbine Shaft - Toyota Hilux 1KZ TE RepairHassan KhattabNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Osha For Rigs Oil and Gas Extraction - Hazards - Occupational Safety and Health AdministrationDocument4 pagesOsha For Rigs Oil and Gas Extraction - Hazards - Occupational Safety and Health AdministrationHassan KhattabNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Manual de Fallas Tds 11pdfDocument68 pagesManual de Fallas Tds 11pdfHassan KhattabNo ratings yet

- 06 - TDS-11 Top Drive Competency (P1PS)Document7 pages06 - TDS-11 Top Drive Competency (P1PS)Hassan KhattabNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Net2f"25N: Accumulator With Diaphragm StabilizerDocument6 pagesNet2f"25N: Accumulator With Diaphragm StabilizerHassan KhattabNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Mud Pump Bearing Life 11338 1Document12 pagesMud Pump Bearing Life 11338 1Hassan KhattabNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Precision Hydraulics 12th Edition 2019 CTR VALVESDocument819 pagesPrecision Hydraulics 12th Edition 2019 CTR VALVESHassan KhattabNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Side Check Valve CXDAXAN - en - Us - LetterDocument1 pageSide Check Valve CXDAXAN - en - Us - LetterHassan KhattabNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Cavity Plug XEOA - Full - en - Us - LetterDocument1 pageCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Check Valve CXFAXCN - en - Us - LetterDocument1 pageCheck Valve CXFAXCN - en - Us - LetterHassan KhattabNo ratings yet

- Internal Clearance-Radial Paly-Axial Play-KtaiballbearingDocument2 pagesInternal Clearance-Radial Paly-Axial Play-KtaiballbearingHassan KhattabNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Operating Clearance - Basic Bearing Knowledge - Koyo Bearings 111Document9 pagesOperating Clearance - Basic Bearing Knowledge - Koyo Bearings 111Hassan KhattabNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)