Professional Documents

Culture Documents

3 Stage Gearbox Vertical Roller Mills

3 Stage Gearbox Vertical Roller Mills

Uploaded by

pashaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Stage Gearbox Vertical Roller Mills

3 Stage Gearbox Vertical Roller Mills

Uploaded by

pashaCopyright:

Available Formats

A NEW GEARBOX GENERATION FOR VERTICAL ROLLER MILLS

By:

Dr. Roger Raeber, Vice President Engineering, MAAG Gear AG

Ulf Weller, Senior Design Engineer, MAAG Gear AG

Rocco Amato, Head of Mill Gear Engineering, MAAG Gear AG

Drive trains of vertical roller mills are usually equipped with heavy duty gearboxes with a horizontal input

shaft and a vertical output shaft. Increasing mill sizes bring the existing gearbox concepts to their limits,

however. This, and the demand for higher reliability and lower costs, has forced gearbox manufactures to

develop new gearbox concepts. In this article, an innovative new gearbox concept that meets all the

demands of the latest mill generation is presented.

1 Introduction

Vertical roller mills are widely accepted as the most efficient means for grinding cement raw material and

clinker. They are capable of preparing a wide range of feed materials to the required fineness using an

energy-efficient process. Although cement raw materials vary considerably in the level to which they can

be ground, their drying requirements and abrasion, the roller mill is sufficiently flexible so that it can be

adapted to these variations, as well as other specific site requirements. Ever since the roller mill was first

introduced to the cement industry, its system capacity has continued to evolve. With the increasing

capacity of the mills, the output torque of the gearbox, its main design criterion, had to be increased

accordingly (see Fig. 1). These increasing mill sizes have brought the currently used gearbox concepts to

their limits, and new design concepts have to be found.

Developement of Mill Sizes

7000 700

Mill Drive Power

6000 600

Output Torque Gearbox [kNm]

Output Torque Gearbox

5000 500

Mill Capacity [t/h]

Mill Capacity

Mill Drive [kW] /

4000 400

3000 300

2000 200

1000 100

0 0

1960 1970 1980 1990 2000 2010

Year

Fig. 1: Development of mill sizes

1.1 Function of the main gearbox in a vertical roller mill

The main gearbox of a vertical roller mill has to perform two major tasks (see also Fig. 2):

1. Transmission of the power from the main motor to the grinding table

2. Absorption of the grinding forces and the table weight

1-4244-0372-3/06/$20.00 (c)2006 IEEE

The first task is fulfilled by a specific gear arrangement, which reduces the motor speed to the required

speed of the grinding table. As only standard motors with a horizontal shaft are used in today’s mills, the

gearbox needs a horizontal input shaft and a vertical output shaft. The gearbox therefore always includes

a bevel stage. The output shaft of the gearbox is designed as a flange that is directly connected to the

grinding table.

Absorption of the grinding forces is the second task of the main gearbox. This is achieved by a tilting pad

thrust bearing underneath the output flange of the gearbox. The flow of forces from the grinding table to

the foundation of the mill goes directly through the gearbox, which must be taken into account while

designing the gearbox.

Fig. 2: General setup of gearbox for vertical mill

1.2 Requirements on the gearboxes

The main gearbox is an integral part of the complete mill equipment, and the requirements of the mill

manufacturers on the gearbox suppliers are therefore very high.

The following is required:

- High operational reliability

- Very long service life

- Good maintainability

- Favourable price

- High efficiency

- Customer-specific design

Only manufacturers with long-term experience in this business are able to meet these requirements.

1-4244-0372-3/06/$20.00 (c)2006 IEEE

2 Today’s gearbox technology

Over the years, the gearbox design has changed as a result of the increasing mill sizes and new

technologies in gear manufacturing. In the following, we will examine the different gearbox concepts, their

applications and their technical limits.

2.1 First Generation

The first gearbox generation for vertical roller mills consisted of two helical gear stages combined with a

bevel stage as shown in Fig. 3. This concept was used from 50 kW up to 3900 kW. Today, this concept is

normally used up to a power of approx. 1000 kW, while larger gearboxes are usually designed with a

planetary and a bevel stage (see also Section 2.2). The disadvantages of this gearbox design at more

than 1000 kW are the very heavy design and the very large gear wheels. The low speed gear wheel of a

3900 kW gearbox has a diameter of approx. 3.7 m and a weight of 23 tons.

Fig. 3: First generation vertical mill gearboxes

2.2 Today’s standard gearbox design

After reaching the limits of the first gearbox generation, the next logical step was to introduce a planetary

stage instead of the two helical gear stages. The planetary stage is well known from many different

industrial applications, with its great advantage of less material input at the same power. This design

reduces the total weight, size and costs significantly in comparison with the two helical gear stage

concept. This is a proven concept that has been used by all well-known gearbox manufacturers for almost

40 years. Fig. 4 shows as an example for this concept a cross-sectional view of a gearbox with a bevel

and one planetary stage. The motor power is transmitted via bevel stage and a toothed coupling to the

sun pinion of the planetary stage. The planet carrier then transmits the torque to the output flange of the

gearbox. This gearbox type has successfully been supplied for powers up to 5600 kW with a ratio up to 46

and bevel wheel diameters up to 2 m, but it became clear, that due to the high demanded gear ratio for

this size and the resulting large diameters of the toothed parts the limit of the 2-stage gearbox generation

is reached.

In the bevel gear stage the very large wheel sizes become a problem during heat treatment due to the

significant amount of distortion in the hardening process. The large diameters of the wheel also increase

the tilting moments as a result of the tooth forces and also increase the displacement of the engaged tooth

zone due to an angular misalignment of the wheel shaft, which influences the contact pattern of the

toothing.

1-4244-0372-3/06/$20.00 (c)2006 IEEE

In addition, it is more difficult to achieve a high pitting resistance due to small radii of curvature when

design engineers are forced to get small pinions as a consequence of high ratios in this stage. In the

planetary stage the annulus and to a certain degree the planets became larger and heavier. Such parts

are difficult to purchase and to manufacture, handling and availability become a critical issue, machine

capacities are often limited and accuracies decrease with the increasing size.

Besides all the technical reasons a two-stage gear solution is not an economical optimum beyond a

certain size. All the above clearly shows the demand for a new gear concept.

Fig. 4: Example of two stage (bevel/planetary) gearbox

2.3 Gearbox concepts for the latest mill generation

Gearbox manufacturers are looking for new concepts that are suitable for gear ratios greater than 45 at a

rated power of up to 7,000 kW. Two different solutions for a 3-stage gearbox are on the market today. A

innovative new concept is going to be presented in the following sections.

3 Development of a new 3-stage gearbox concept

3.1 Requirements on a new gearbox generation

Before the start of the development process itself, a market research project was carried out, and the

latest developments were discussed in detail with the mill manufacturers. These analyses and

requirement for cost reductions formed the boundary conditions for the design of the new gearbox.

From the customer's point of view, the following requirements were of primary interest:

• High availability of the plant

• Low maintenance costs

• Short installation times

• Customer-specific design

• High efficiency

1-4244-0372-3/06/$20.00 (c)2006 IEEE

In addition to the customer requirements, the following additional aspects have been taken into

consideration for the design:

• Weight reduction

• Standardisation of the components

• Reduction transport cost

• Reduction of order processing time

These criteria formed the foundation based on which the development of a new gearbox concept was

started.

3.2 Different concepts

The most important aspects of a gearbox concept are the arrangement of the gear wheels, the casing and

the axial bearing.

3.2.1 Arrangement of the gear wheels

From a large number of possible arrangements, three technically feasible alternatives emerged as the

most promising ones as depicted in Fig. 5.

pA B C

3rd stage 3rd stage 2nd / 3rd stage

(planetary) (planetary) (planetary with

torque split)

2nd stage 2nd stage

(planetary)

1st stage 1st stage 1st stage

(bevel stage) (bevel stage) (bevel stage)

Fig. 5: Gear wheel arrangement alternatives

Tab. 1 shows the optimum and maximum possible gear ratio ranges for the different concepts. It is

obvious that the PV concept is the most appropriate design for the required ratios.

1-4244-0372-3/06/$20.00 (c)2006 IEEE

Planetary

Bevel Single Single Ratio

PlanetaryPlanetary w/torque

Stage Helical Helical range

split

optimal 2 - 3.5 3-5 3-5 18 - 125

1st generation

max. - 5.5 -6 -6 - 200

optimal 2 – 3.5 5-9 10 - 31

Today's standard

concept

max. 2 - 5.5 3 - 11 - 60

New concepts:

(refer to Fig. 5)

A optimal 2 - 3.5 3-5 5-9 30 - 160

(bevel/single

helical/planetary) max. - 5.5 -6 3 - 11 - 350

B optimal 2 - 3.5 5-9 5 - 6.5 50 - 205

(bevel/planetary/

planetary) max. 2 - 5.5 3 - 11 3 - 6.5 18 - 350

C optimal 2 - 3.5 12 - 22 24 - 77

(bevel/double

planetary with

max. - 5.5 10 - 30 20 - 105

torque split)

Demanded gear ratio range for different mill types between 2500 kW and 7000 kW: 30 - 65

Tab.1: Comparison of gear ratios

35000

Case Hardened Steel

30000 Quenched and Tempered Steel

Total Alloy Steels

25000

20000

Weight [kg]

15000

10000

5000

0

2 stage A B C

Tab. 2: Comparison of steel weights in different gearbox designs

1-4244-0372-3/06/$20.00 (c)2006 IEEE

In addition to the gear ratio, the weight of the required case hardened and quenched and tempered steel

is also a good measure for comparing the gearboxes with regard to manufacturing costs. Tab. 2 shows

that the C concept is the most cost-effective option.

In the next step, draft drawings were designed for the A and the C concept (see Fig. 6), in order to

examine the two concepts in more detail with regard to the cost and manufacturing aspects. The B

concept was rejected at an early stage, since a low overall gearbox height was not compatible with a

flexible design of the housing diameter.

Fig. 6: Draft drawings of the A and C gearbox concepts

Once the costs of the two remaining variants had been determined more accurately, it became clear that

the C concept was the one with the lowest overall weight and the lowest costs, despite its higher number

of components. The disadvantage of a larger number of components is more than compensated by a

reduction of the size of these components. Smaller parts allow for cost savings in procurement, transport

and for higher manufacturing quality especially in the upper range of sizes. Some of the key dimensions of

the two gearbox concepts are shown in Tab. 3. A 2-stage gearbox as described in Section 2.2 is used as

reference.

110%

100% 100% 100% 100%

88%

90%

76% 78% 78%

80%

67%

70%

60% 2-stage

A

47% C

50%

40%

Weight Diameter Bevel Weight of Gears

Gear

Tab. 3: Comparison of key dimensions

After this evaluation it was decided to proceed with the C concept and the actual development work on the

gearbox concept was started.

1-4244-0372-3/06/$20.00 (c)2006 IEEE

3.3 The C concept to become the new 3-stage gearbox

The C gearbox concept has over many years successfully been used in gearboxes for marine, turbo, wind

power and mill applications. Among others, it has been applied in central drive roller mill gearboxes (see

Fig. 7) and, in recent years, in the main drive of wind turbines (see Fig. 8).

Fig. 7: C concept implemented in central drive roller mill Fig. 8: C concept implemented in wind turbine gearbox

gearbox

Fig. 9 shows the implementation of the C concept in a vertical mill gear schematically. The sun pinion of

st

the 1 stage is driven by the motor via bevel gear stage and distributes the power to 3 planets. Here, the

torque is split and while 100% of the torque is directed through the planet bolts and the planet carrier of

stage 1 to the output shaft, another portion of the torque is guided through the 2nd planetary stage to the

output shaft.

1st planetary stage

100%

2nd planetary stage 70%

Bevel stage

Fig 9: C concept implemented in the new gearbox

1-4244-0372-3/06/$20.00 (c)2006 IEEE

The power split is calculated according to Equation 1. It is obvious that power distribution between 1st and

2nd planetary stage only depends on the ratio of the number of teeth, and, thus, is geometrically defined.

In the new gearbox, the number of teeth has been selected in a way that the 2nd planetary stage takes

nd

approx. 70% of the load transmitted. The great advantage of this gear arrangement now is that the 2

stage can be designed for only 70% of the output torque and therefore with dimensions that are

considerably smaller than those of a conventional planetary stage transmitting 100% of the load. The

torque split stage closes the gap between a single-stage and a double stage planetary gearbox in an ideal

way: the single-stage planetary gearbox with a gear ratio of 10 max. and the two-stage planetary gearbox,

which is only suitable for a gear ratio of approx. 25. The torque split stage represents the most compact

gearbox solution in a gear ratio range of 12 - 25.

z3 I

+1

z

PII = P1 − 1I

i ges

Equation 1: Load distribution between 1st and 2nd planetary stage

3.4 Flexpin

The C concept is furthermore characterised by a lower weight and a more compact design than in the

concepts commonly used nowadays. In order to achieve a balanced load distribution to the five planets of

nd

the 2 stage, an additional flexible element is used, the so-called “Flexpin”. The Flexpin was originally

developed in the 1960ies, and has been successfully used in hundreds of gearboxes.

In most planetary gearboxes, the sun pinion is used as adjustable element in order to ensure a good load

distribution between the planets, i.e. to compensate the manufacturing tolerances. This is, however, an

insufficient compensation, since no movement and thus no compensation is possible between planet and

ring gear, which are both rigidly mounted (see Fig. 10). Furthermore, the sun pinion compensation only

works for planetary stages with 3 planets. If more planets are used, this set-up yields a statically

indeterminate system that is unable to guarantee complete compensation and balanced distribution of the

load.

In the Flexpin solution the sun pinion and the ring gear are rigid while the planets are mounted to the

planet carrier using flexible bolts - the Flexpins. This way, each planet can individually adapt itself in radial

direction between the two central gears (see Fig. 10). In addition to the radial direction, movement is also

possible in the circumferential direction, which leads to an optimal load distribution between the individual

planets. The Flexpin has been designed in a way that the movement of the planets is always parallel to

the planet carrier. So, tilting is not possible, and the planet always carries the load over its full width. The

effectiveness of this kind of load compensation and the excellent width-distribution of the load has been

confirmed on the test bed and in the field.

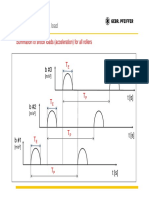

In addition to good load compensation, however, the “Flexpin” also contributes to minimising the load

peaks. High load peaks that arise from the very dynamic milling process are significantly reduced by the

additional flexibility. This is particularly favourable for the sensitive bevel gear stage.

1-4244-0372-3/06/$20.00 (c)2006 IEEE

Fig. 10: Conventional and Flexpin planet mounting system

3.5 Standardisation, Modular system

A further very important requirement on the new development of the gearbox was a standardisation of the

components and complete modules that would be as comprehensive as possible. The primary reason for

standardisation requirement was a reduction of the costs, which could be achieved through the following:

• Reduction of the variety of parts, and thereby the storage and parts administration costs

• High production quantities leading to better purchasing conditions

• Better planning of the logistics and the stock holdings

• Reduction of order specific design costs

• Faster drawing up of quotations.

If the demand for gearboxes of this kind is considered with regard to the individual sizes, it must be stated

that it will continue to involve individual or small series manufacture in the future. In addition to the low

quantities involved, there is also a list of other reasons that speak out against a high level of

standardisation, such as the different gear ratios, table loads, table diameters and customer wishes. In

view of this wide range of requirements, the introduction of a comprehensive standardisation would

appear to be a difficult task. It is at exactly this point that the C concept is able to take full advantage of its

strengths with regard to compactness. An overview of the standardisation is shown in Fig. 11. All the

components of the torque split stage, the bevel gear stage (with the exception of the bevel gear and

pinion) and all the bearings have been standardised for each size of gearbox. This covers all the forged

parts, which require the most procurement time. The required variation in the overall gear ratio is provided

in the bevel gear stage. This is necessary, as the gear ratio varies from project to project depending on

the type of mill. The axial bearing with its drive flange can be mentioned as a further module. Here, a

limited number of sizes are available in order to cover the different table diameters and loads. The axial

bearing segments themselves are standardised, and can be used for all gearbox sizes. The last important

element is the casing, which is custom manufactured. In this way, with a single component, it is possible

to offer the customer the greatest possible freedom with regard to diameter, overall height and axis height

(see also Section 3.7).

1-4244-0372-3/06/$20.00 (c)2006 IEEE

Fig. 11: Cross-section of the new 3-stage gearbox

This standardisation concept provides an optimal combination of the requirements of Production,

Purchasing and Logistics on the one hand, and the greatest possible customer benefit on the other.

3.6 Sliding bearings in the bevel gear stage

The bearings of the bevel gear stage have been newly developed. Although a sliding bearing has been

used in the planetary stage for many years, the bevel gear stage has so far been fitted with roller

bearings. Different variants of sliding and roller bearings have been examined from both a technical and

economic point of view regarding their applicability in the bevel gear stage. Since the bearings have a

considerable influence on the load pattern characteristics of the bevel gears, the available options have

been examined in detail. The roller bearings on the one hand have the well-known disadvantages of a

limited life cycle and a low damping factor. The sliding bearing on the other hand need more radial

clearance and have a higher power loos due to friction. Bearing clearance is known to be relevant for the

load pattern characteristics of the bevel gears and the power loss is minimised by chosing the appropriate

clearance for the sliding bearing and the oil feed. At the same time, the roller bearings are not held in

stock by the manufacturers for very large bearing dimensions. This causes very long lead times, and the

gearbox manufacturer is forced to maintain his own stock of bearings. In case of emergency, sliding

bearings can be repaired on-site by field service engineers in a short time, so that downtime of the system

can be minimised. All the above said led to the decision to use sliding bearings for the complete gearbox

which, largely due to a theoretically unlimited life cycle of the bearings, makes a considerable contribution

to the operational readiness of the gearbox.

In addition to the sliding bearings, a system for adjusting the bevel gear stage has been developed. The

mechanism allows the field service engineer to set or re-adjust the tooth pattern and the gear backlash

both during assembly and on-site. In addition, the pinion including all bearings can simply be removed

from the casing without the need tof remove the gearbox from the mill.

3.7 Casing

Another important aspect of the development work is the gear casing. It is not only accommodating the

gears and their forces, but also transmitting the milling forces to the foundation. The milling forces caused

by the milling rollers pressing against the milling table are first transmitted from the table to the axial

bearing segments through the flange of the driven shaft. The segments are supported by the casing which

is guiding the forces to the mill foundation (see Fig. 12). The ideal structure for this casing would be a

1-4244-0372-3/06/$20.00 (c)2006 IEEE

closed cylinder. It is, however, necessary to provide an opening in the casing for the horizontal drive shaft.

This opening must be as small as possible in order to keep the stresses in the casing at minimal level. In

the A concept design the opening needs to be bigger due to the bevel gear stage shifted towards the input

shaft (see Fig. 12). The resulting stresses in the casing are increased, and additional measures must be

taken, such as supports, wall reinforcement and ribbing, in order to reduce these stresses to a tolerable

level.

The opening in the C concept design is small enough that the thickness of the casing wall can be uniform

over the whole cylinder. The wall thickness is also designed so that additional ribbing is not required. This

reduces the danger of fatigue cracks in highly stressed welding seams, and considerably simplifies design

and manufacturing.

A C

Fig. 12: Flow of forces through the gear casing

4 Conclusion

With the development of the third generation of vertical roller mill gearboxes, the C concept solution

provides an innovative alternative to the solutions available on the market. The gearboxes are

characterised by technical innovations that are based on tested and proven components. The new

gearbox design is state-of-the-art in the industry and provides an optimum in efficiency and technical

reliability for the customers and the gearbox manufacturer.

1-4244-0372-3/06/$20.00 (c)2006 IEEE

You might also like

- Caja 10 R 80Document437 pagesCaja 10 R 80Andrea Martinez94% (16)

- CPB Brochure Diaphragms en 2Document12 pagesCPB Brochure Diaphragms en 2ebrahimNo ratings yet

- Vega LinersDocument80 pagesVega LinersAnonymous knICax100% (2)

- Ball MillDocument14 pagesBall MillISLAM I. Fekry95% (20)

- Trunnion Bearing ClearanceDocument1 pageTrunnion Bearing ClearanceJuanPabloGonzalezFiblasNo ratings yet

- Ball Mill Hydrostatic Slide Shoe BearingDocument26 pagesBall Mill Hydrostatic Slide Shoe BearingJoel Miguel Angel Pacheco100% (1)

- Sag MillingDocument21 pagesSag MillingNaren KumarNo ratings yet

- 4f27e Book PDFDocument75 pages4f27e Book PDFcorie132100% (1)

- Kia CeratoDocument4 pagesKia CeratogtranNo ratings yet

- ESPDocument15 pagesESPlrpatraNo ratings yet

- Powerpoint VRMDocument14 pagesPowerpoint VRMAlisa Azizah100% (2)

- Blaz Jurko - GEBR. Pfeiffer - MPS Grinding Technology PDFDocument22 pagesBlaz Jurko - GEBR. Pfeiffer - MPS Grinding Technology PDFrpazbNo ratings yet

- Vertical Roller MillDocument2 pagesVertical Roller MillAhmed Younis0% (2)

- Literature ReviewDocument6 pagesLiterature ReviewIrfan FadzailahNo ratings yet

- Kiln Float and Hydraulic Thrust DeviceDocument21 pagesKiln Float and Hydraulic Thrust DevicehaiderNo ratings yet

- Pendulum Grate CoolerDocument2 pagesPendulum Grate Cooleremad sabri0% (1)

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Document5 pagesVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuNo ratings yet

- Grinding With Tube MillDocument43 pagesGrinding With Tube MillGorissNo ratings yet

- Vertical Roller Mill State of The Art Raw GrindingDocument4 pagesVertical Roller Mill State of The Art Raw GrindingzementheadNo ratings yet

- Kiln Girth Gear Force CalculationDocument7 pagesKiln Girth Gear Force Calculationvikubhardwaj9224No ratings yet

- VRM OKoookuuiiiiljjjjyggyyDocument8 pagesVRM OKoookuuiiiiljjjjyggyyRakaNo ratings yet

- Grinding Mills Optimisation: Magotteaux / Slegten / Sturtevant SolutionsDocument44 pagesGrinding Mills Optimisation: Magotteaux / Slegten / Sturtevant Solutionsshani5573100% (1)

- Enhance The Performance of Tube Grinding Mills: Let Us Employ Grinding RollersDocument5 pagesEnhance The Performance of Tube Grinding Mills: Let Us Employ Grinding RollersD S VenkateshNo ratings yet

- V SK VSK: Focus On EfficiencyDocument8 pagesV SK VSK: Focus On EfficiencyGerman Gabriel Anaya VegaNo ratings yet

- ResumeDocument3 pagesResumeHari Prathap ReddyNo ratings yet

- Cement Mill Calculation DesaignDocument1 pageCement Mill Calculation DesaignHilmy MuhammadNo ratings yet

- Gap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Document8 pagesGap Measurement and Displacement Between The Kiln Shell and Tire (Kiln Tires)Javier Gutierrez100% (1)

- Gear, LTD.: Global Net-WorkDocument5 pagesGear, LTD.: Global Net-WorkRahul RoyNo ratings yet

- Kiln StabilityDocument6 pagesKiln Stabilityraobabar21No ratings yet

- Collaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurDocument4 pagesCollaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurjmpbarrosNo ratings yet

- Foundation For Roller PressDocument3 pagesFoundation For Roller PressRollerJonny0% (1)

- 17.kiln Air GapDocument7 pages17.kiln Air GapSUNIL TVNo ratings yet

- Brochure 154 Loesche-Mills For Cement Raw Material EN PDFDocument24 pagesBrochure 154 Loesche-Mills For Cement Raw Material EN PDFMohammed AbdoNo ratings yet

- Pneumatic TransportDocument9 pagesPneumatic TransportMehmet CNo ratings yet

- Presentation PDFDocument25 pagesPresentation PDFAmit PattanayakNo ratings yet

- Ball MillDocument2 pagesBall Millpadma26327No ratings yet

- Kiln Shell and TyresDocument37 pagesKiln Shell and TyresMudassir Rafiq100% (1)

- Raw Mill Vertical Roller Mill PDFDocument58 pagesRaw Mill Vertical Roller Mill PDFganong itbNo ratings yet

- Competence in CementDocument24 pagesCompetence in CementJackson VuNo ratings yet

- RMH & GrindingDocument132 pagesRMH & Grindingmkpq100% (1)

- Kiln Inlet Lamella Seal FLSDocument2 pagesKiln Inlet Lamella Seal FLSamir100% (4)

- Sturt Air ClassifierDocument6 pagesSturt Air ClassifierHenry Vladimir VianchaNo ratings yet

- Size:: Every Kiln Has The Following ComponentsDocument10 pagesSize:: Every Kiln Has The Following ComponentsShehabul Hasan MamunNo ratings yet

- Wear Mechanism of Abrasion Resistant Wear Parts in Raw Material Vertical Roller Mill Jensen2011Document13 pagesWear Mechanism of Abrasion Resistant Wear Parts in Raw Material Vertical Roller Mill Jensen2011Rendotian Anugrah100% (1)

- Grinding Process Within Vertical Roller Mills Experiment and SimulationDocument5 pagesGrinding Process Within Vertical Roller Mills Experiment and SimulationDirceu Nascimento100% (1)

- Rotary Vessel Mechanical MaintenanceDocument6 pagesRotary Vessel Mechanical Maintenanceritesh shrivastavNo ratings yet

- Comprehensive Kiln AlignmentDocument10 pagesComprehensive Kiln AlignmentEdson Ricardo LimaNo ratings yet

- Ball Mill OperatingDocument14 pagesBall Mill OperatingCao Ngoc AnhNo ratings yet

- Roller BrochureDocument16 pagesRoller BrochurePeterson MagroNo ratings yet

- Shock Load Roller MillDocument1 pageShock Load Roller MillrecaiNo ratings yet

- Jaypee Cement Project ReportDocument29 pagesJaypee Cement Project ReportPurnendu MishraNo ratings yet

- Bucket ElevatorsDocument30 pagesBucket ElevatorsarhescobarNo ratings yet

- The Air Circuit in A Rotary KilnDocument20 pagesThe Air Circuit in A Rotary KilnZia KhanNo ratings yet

- Loesche Round Table VICATDocument20 pagesLoesche Round Table VICATrecaiNo ratings yet

- Cement Grinding SystemsDocument33 pagesCement Grinding Systemskamal yashwanth gNo ratings yet

- Cement Mill Shell LinerDocument7 pagesCement Mill Shell LinerMahaveer SinghNo ratings yet

- Bucket Elevator CatalogDocument34 pagesBucket Elevator CatalogKoray OzturkNo ratings yet

- Rotary Kiln Tire Support Pad Lubrication PDFDocument3 pagesRotary Kiln Tire Support Pad Lubrication PDFMuhammadShoaib100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- GearboxDocument5 pagesGearboxakshaybj4396100% (1)

- Modular Mill With Modular DriveDocument6 pagesModular Mill With Modular DriveFran JimenezNo ratings yet

- Trend in Wind Turbine Drive TrainsDocument5 pagesTrend in Wind Turbine Drive TrainsMarcos Gómez PérezNo ratings yet

- g1 Theory of Machines ExperimentsDocument34 pagesg1 Theory of Machines ExperimentsBornea FlorinaNo ratings yet

- EM 351 Course OutlineDocument5 pagesEM 351 Course OutlineDiana NjelesaniNo ratings yet

- Wheel Loader - CATERPILLAR 914G - IT14G Specalog (Aehq5560-02)Document28 pagesWheel Loader - CATERPILLAR 914G - IT14G Specalog (Aehq5560-02)Reymond WuNo ratings yet

- Aero-Engine Fan Gearbox Design: The 16 Israeli Symposium On Jet Engines and Gas Turbines November 9, 2017Document26 pagesAero-Engine Fan Gearbox Design: The 16 Israeli Symposium On Jet Engines and Gas Turbines November 9, 2017Mario RossiNo ratings yet

- PC210LC-11 Sen06695-01 Maintenance StandardDocument83 pagesPC210LC-11 Sen06695-01 Maintenance StandarddatphuongNo ratings yet

- Advances in Motor Torque Control PDFDocument122 pagesAdvances in Motor Torque Control PDFTasos PoteasNo ratings yet

- Ejes MeritorDocument26 pagesEjes MeritorFreddy Alexander Rubiano C50% (2)

- 954C HD 976 22210 en de PDFDocument696 pages954C HD 976 22210 en de PDFMANUTENÇÃO CAVA ENGENHARIA100% (1)

- Parts List - Service Manual 969430401 - MAT 500 - R534 - enDocument2 pagesParts List - Service Manual 969430401 - MAT 500 - R534 - enharrykgs7No ratings yet

- At - Automatic TransaxelDocument400 pagesAt - Automatic TransaxelIlarion CiobanuNo ratings yet

- Automatic Transmissions and Transaxles ch10 Hybrid Electric Vehicle Transmissions and TransaxlesDocument38 pagesAutomatic Transmissions and Transaxles ch10 Hybrid Electric Vehicle Transmissions and Transaxlesmihai_1957No ratings yet

- Can Bus Harness Location: "Can" Wires Twisted PairDocument11 pagesCan Bus Harness Location: "Can" Wires Twisted PairSMM ENTREPRISENo ratings yet

- SEW Products OverviewDocument24 pagesSEW Products OverviewSerdar Aksoy100% (1)

- 6hp26 SaeDocument11 pages6hp26 SaeToomas Galka50% (2)

- Installation, Maintenance and Service Manual: Winch DivisionDocument27 pagesInstallation, Maintenance and Service Manual: Winch DivisionWesly ChavezNo ratings yet

- Highlighted ABENICS PaperDocument20 pagesHighlighted ABENICS Papermb.farooqui02No ratings yet

- Service Manual For Chery QQ6 - QR513 Transmission Case PDFDocument121 pagesService Manual For Chery QQ6 - QR513 Transmission Case PDFedflow77No ratings yet

- 8HP45SWDocument35 pages8HP45SWВиталий Черненко100% (1)

- Aw 55-50SN, 55-51SNDocument8 pagesAw 55-50SN, 55-51SNChristian NunezNo ratings yet

- IBP1 Z2004E-7 991128 EN 10 2011 WebDocument94 pagesIBP1 Z2004E-7 991128 EN 10 2011 WebAnsuf WicaksonoNo ratings yet

- Peterbilt Essentials Module5 Axles SuspensionsDocument20 pagesPeterbilt Essentials Module5 Axles Suspensionsnorth-piligrim100% (5)

- 6 TransmissionDocument91 pages6 TransmissionIvan Andres Seguel Bristilo100% (1)

- Reassembly: (A) Check Bearing PositionDocument21 pagesReassembly: (A) Check Bearing PositionRonfermNo ratings yet

- Case Study of Planetary GearsDocument5 pagesCase Study of Planetary GearsSANGE MOHAMMEDNo ratings yet

- DC Motors: List of Motor CharacteristicsDocument6 pagesDC Motors: List of Motor CharacteristicsHà Tiến ĐôngNo ratings yet

- R4a51 V4a51Document63 pagesR4a51 V4a51Edixon AlagioNo ratings yet

- Hyundai 210LC-3 Swing DeviceDocument12 pagesHyundai 210LC-3 Swing DeviceВладимир СолодухинNo ratings yet