Professional Documents

Culture Documents

EXCAVATOR

EXCAVATOR

Uploaded by

Alex Gigena0 ratings0% found this document useful (0 votes)

8 views15 pagesWOODEN TOY

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWOODEN TOY

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views15 pagesEXCAVATOR

EXCAVATOR

Uploaded by

Alex GigenaWOODEN TOY

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

General Instructions - Excavator

1- Start by cutting materials needed by following the list of materials, paying attention

to the rough and finished size, Identify the parts as they are cut.

Please note Different types of wood can be used for the various parts. It is

suggested, however, that hard woodbeused, sincemany of theparts wouldbemuch

+00 fragile ifusing soft wood. Wehaveused a combination of pine, maple and oak

to give the models a nice contrast!

Remove the fill-size pattems found in the appendix, Cut them out, leaving

approximately 1/16" all around, and place on the proper piece of wood. Pattems

can be secured to wood using either spray adhesive or rubber ciment, Ifusing the

latter, cut and sand the part first to finished size. If drilling isrequired, mark the hole

byinserting ascriber ornail through the pattem into the wood, Removethe patter.

before drilling,

You should have no trouble determining which surface to attach most of the

pattems, Some parts, however, canbe confusing since the pattern could fiton more

than one surface. The drawings below indicate exactly which surface to attach the

patterns for these parts.

‘Look at the full-size drawing sheets to finish paris E5, E12, and E13.

PartsE6 and E19 willneed additional cuts and details, please referto the additional

information pages, to complete these parts.

‘Using maple dowels, make all pins, shafts, etc.

Follow the assembly drawings to complete your model

Excavator: General Instructions

a7

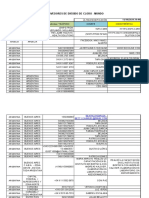

List of materials - Excavator

part| T | W | L_ | Meteriai| avy.

E2| 36" iz a" oak i

eo] oe) ae | «| oak | 1

£4 | se | ee | sie" | ping | 1 | F

eis} wa | 2 31/6" | maple |

Eig] 19a | 22" 312" | maple

[es we"_|sone'| eae | pine | 1 | F

&6| 11" | 194" | 194" | maple | 1 | R

E7| set | 17/0" 17/6 |maple | 4 | R E20| wer | 112 ssa" | oak

e2t| 112" | 21" es" | pine

ce| se ae | is | oak | 2 |

eo] we | ve | si | pine | 61 E e22| ae" iar 7 | maple

g23| am" | 2° 77/8" | maple

E10] 112" 37/8" | 5516" | pine | 1

43/4" E25| 14" | 19H6"DIA. | maple

Ett) sre" oe

37/16"

Rough size

‘inished size

R=Rough sizes, the material is cut oversized so you have ample room to apply the pultern on the surface.

‘Sanding is not required at this point.

F = Finished Size: Cut and sand parts to finished size.

4B ‘Excavator: List Of Materials

Full-Sized Patterns: Set One

— CABINGACK |

po

if = CABINSIDE

ne = et

aver

a be!

§

5 CABIN SIDE

See Z

Excavator: Full-Sized Patterns 9

sve

paved" oa

eit

TRACK SUPPORT BLOCKS

MAIN ARM SUPPORT

50 Excavator: Full Sized Patterns

sles

SIDE View

3 78)

/} —— 1 7 ——

Sine VIEW

Excavator: Full-Sized Patterns st

BRILL 7/9" DIA,

ye" DEEP

pen,

vein

POT WHEEL

Eis

a

snot

NOTE: CLCENTRE LINE

2 Excavator; Full-Sized Pattems

SHOVEL SIDES

as

aes ste view

Pope,

21/66" te

Excavator: Full-Sized Patterns 3

TRACK

SECONDARY ARM SECONDARY ARM-CENTRE

pe

wer

“ser 9s"

4 ‘Excavator: Full-Sized Patterns

eM

@

vee

mete ancooRe

WHEEL SHAFTS:

& ne

@

van

Retin

re ta owe

a

sub view

En

(1 REQURED)

®

Uva k. pveL

134"

‘Excayator: Pins, Shafts, Ete.

55

Additional Information - Excavator

Hr

Os

mae Ort

Sgt ew

pei 28/ea" o1A

Using your Scroll Saw, cut

groove in part E17, as shown, Drill holes into main frame E13, as shown.

rear | \ &@

Using your Scroll Saw, cut groove Using your Scroll Saw, cut grooves

‘in part E6, as shown. ‘in part E19, as shown

pant ex 5 unnessine

Tek

a a

a

Using your Scroll Saw, cut groove: Drawing showing where to glue

in part E19, as shown. pivot wheel E14 onto base ES.

6 Excavator: Additional Information

Excavator - Assembly Drawings

t

Glue track supports E11

‘onto base E13

fA gs

ee) SA.

«< EP ™ KE

Glue pivot wheel E15 making

sure holes are in tine.

3

Drill 4 holes using

method shown on page 56.

“eee

2 KAO

ERS

~

Insert wheel shaft E28 through:

wheels E7 and body.

Gluc tracks E21, as shown. ( (Ca

Please note: see page Sto see ~~

hhow track openings are made.

Glue track pulleys E25.

ae

qA

ZA

Glue pivot wheel E14 to base ES,

See page 56 for exact location, Glue rear hood E10 to base ES.

9 K oe

swe

JAY comers ate

Z RS ts ruse

& 2

Excavator: General Instructions

C2 gC ZA

Se Se

Glue main arm support E6. ‘Use this drawing as a guide for part Eo. ‘Glue upper hood E12.

a a

|

we

| wea

|

CZ | ‘ Oe

Start working on arm assembly. Glue secondary arm assembly, as shown,

Slide secondary arm into main arm EL7.

est

16

\

NN

Insert pins £26 and E31.

58 Excavator: Assembly Drawings

eel SC)

Glue shovel sides E18

conto shovel E19.

@)

See page 56 for details

‘on shovel assembly.

Excavator: Assembly Drawings

Glue roof E4 and bumper E20.

\

fee

G7”

‘Your mode! should now be complete.

6 Excavator: Assembly Drawings

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- What Makes A Trimaran FastDocument15 pagesWhat Makes A Trimaran FastAlex GigenaNo ratings yet

- Tránsito Ley 26 938Document4 pagesTránsito Ley 26 938Alex GigenaNo ratings yet

- Proovedores de Dióxido de Cloro - MundoDocument43 pagesProovedores de Dióxido de Cloro - MundoAlex GigenaNo ratings yet

- Ferrari 125 Sport - History, Specs, Photos & MoreDocument5 pagesFerrari 125 Sport - History, Specs, Photos & MoreAlex GigenaNo ratings yet

- Mil STD 721cDocument18 pagesMil STD 721cajaysharma_1009No ratings yet

- Derrota y Navegacion Por Estima AnaliticaDocument9 pagesDerrota y Navegacion Por Estima AnaliticaAlex Gigena100% (1)

- Crossbeam CalculationsDocument5 pagesCrossbeam CalculationsAlex GigenaNo ratings yet

- Yamanas 12343Document194 pagesYamanas 12343Manuel AnavalónNo ratings yet

- Estima Grafica (Patrones)Document9 pagesEstima Grafica (Patrones)Alex GigenaNo ratings yet

- Ct41 (Caida de Tension) PDFDocument3 pagesCt41 (Caida de Tension) PDFAlex Gigena100% (1)

- TFGDocument46 pagesTFGAlex Gigena50% (2)

- Distancias y RumbosDocument8 pagesDistancias y RumbosAlex GigenaNo ratings yet

- Behaviour of Structural Carbon Steel at High Temperatures PDFDocument10 pagesBehaviour of Structural Carbon Steel at High Temperatures PDFAlex GigenaNo ratings yet

- Caterham 7 CSR: From Wikipedia, The Free EncyclopediaDocument9 pagesCaterham 7 CSR: From Wikipedia, The Free EncyclopediaAlex Gigena0% (1)

- Diseño de Un Velero de 22m.categoría A.navegación OceánicaDocument97 pagesDiseño de Un Velero de 22m.categoría A.navegación OceánicaAlex GigenaNo ratings yet

- H IV Flying Wing ReportDocument18 pagesH IV Flying Wing ReportAlex GigenaNo ratings yet

- Tank Manual XDocument100 pagesTank Manual XAlex GigenaNo ratings yet