Professional Documents

Culture Documents

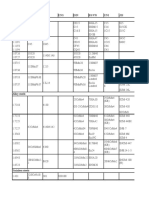

W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden Russia

Uploaded by

Douglas CortezziOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden Russia

Uploaded by

Douglas CortezziCopyright:

Available Formats

STEEL DESIGNATION

NORMS INTERNATIONAL COMPARISON

ITALY FRANCE ENGLAND SPAIN U.S.A. JAPAN SWEDEN RUSSIA

W.-Nr. DIN UNI AFNOR B.S. UNE AISI/SAE/ASTM JIS SS GOST EN

11SMnPb30 1,0718 11SMnPb30 / 9SMnPb28 CF 9 SMnPb28 S 250 Pb - F.2112 - 11 SMnPb 28 AISI 12L14 SUM 23 L 1914 - 11SMnPb30

11SMnPb37 1,0737 11SMnPb37 / 9SMnPb36 CF 9 SMnPb36 S 300 Pb - F.2114 - 12 SMnPb 35 AISI 12L14 SUM 25 - 11SMnPb37

35SMnPb10 (PR80) 1,0765 36SMnPb14 36SMnPb14

100Cr6 1,3505 100Cr6 100Cr6 100Cr6 2 S 135 F.1310 - 100 Cr6 52100 SUJ 2 2258 SchCh 15 100Cr6

AISI 303 1,4305 X8CrNiS 18-9 X 10 CrNiS 18 09 Z 8 CNF18-09 303 S 22 F.3508 - X 10 CrNi 18 10 303 SUS 303 2346 - X 10 CrNiS 18 9

AISI 304 1,4301 X5CrNi18-10 X 5 CrNi 18 10 Z6CN18-09 304 S 17 F.3504 - X 5 CrNi 18 10 304 SUS 304 2332 08 Ch 18N10 X5CrNi1810

AISI 316 1,4401 X5CrNiMo17122 X5CrNiMo1712 Z6CN17-11 316 S 17 F.3534 - X 5 CrNiMo 17122 316 SUS 316 2347 - X5CrNiMo17122

AISI 420 1,4021 X20Cr13 X 20 Cr 13 Z 20 C 13 420 S 37 F.3402 - X 20 Cr 13 420 SUS 420 J 1 2303 20Ch13 X20Cr13

C35/B 1,5511 35B2 35B2

C40 1,1186 C40 E C40 2 C 40 080 A 40 - 1040 S 40 C - 40 C40 E

C45E 1,1191 C45E C45 XC 45 080 M 46 F.1140-C 45 K 1045 S 45 C 1672 45 C45E

C67 1,0603 C67 C67 XC 65 080 A 67 - 1070 - - - 1 CS 67

18NiCrMo5 (16CrNi4) (1.5919) (15CrNi6) 18NiCrMo5 (18NCD6) - - (3154) - - - 17NiCrMo5 (14 CrNi6)

39NiCrMo3 (38NCD4) (1.6511) (36CrNiMo4) 39NiCrMo3 (40NDC3) (817 M 37) (F.1280-35 NiCrMo4) (9840) (SNCM 447) (2541) (40ChN2MA) (36CrNiMo4)

11SMnPb30/37 inproved sheddering steel, for manufacturing on machines tool with shaving removal. It contains some alloy elements, among them the sulphur (S) and the lead (Pb) that

simplify the shaving cutting up and the lubrication of the tool cutting. It is not designed for a heat treatment.

100Cr6 good non-deformable steel and wear resistance. It is very suitable for the manufacturing of rings, bearings, balls, rollers, etc…

18NiCrMo5 For medium and big depth components that should be carbonized. This type of steel combines a great hardness of the surface with a very strong centre and it buckles very littl

during the hardening. Case-hardening at 870°/900°. It is recommended to practise the double hardening: the first of 860° toughness in oil, the second of 800°/830°C hardness in oil.

39NiCrMo3 Good hardening penetration steel, suitable for the construction of components that should be resistent to twisting and bending. It is characterized by the lack of fragility in

tempering.

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Steel Grade Equivalency TableDocument2 pagesSteel Grade Equivalency TableBudy GedhaBlackNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Control of Welding Rejection Rate and NDT Backlog in MEGA ProjectDocument10 pagesControl of Welding Rejection Rate and NDT Backlog in MEGA ProjectMubeenNo ratings yet

- ELC003 Renewable Energy Course NotesDocument231 pagesELC003 Renewable Energy Course Notesravith88100% (1)

- EN# EN Name SAE UNS DIN Carbon SteelsDocument16 pagesEN# EN Name SAE UNS DIN Carbon Steelsumesh sengarNo ratings yet

- EN# EN Name SAE UNS DIN Carbon SteelsDocument4 pagesEN# EN Name SAE UNS DIN Carbon Steels'viki ArtNo ratings yet

- Power Plant: Better Life Created by SteelDocument4 pagesPower Plant: Better Life Created by SteelAlejandro Jose Garcia FernandezNo ratings yet

- En Comparision TableDocument3 pagesEn Comparision TablenikhilnsbNo ratings yet

- EN# EN Name SAE UNS DIN BS 970 UNI JIS Carbon SteelsDocument3 pagesEN# EN Name SAE UNS DIN BS 970 UNI JIS Carbon Steelspm StarkeonNo ratings yet

- Untitled 1 PDFDocument35 pagesUntitled 1 PDFRAVI KANT BARANWALNo ratings yet

- Material Groups and StandardsDocument1 pageMaterial Groups and StandardsJohn Rymar LameraNo ratings yet

- Equivalent GradesDocument37 pagesEquivalent GradesUmesh SakhareliyaNo ratings yet

- SPECIFICATIONS OF PIPES & TUBESDocument3 pagesSPECIFICATIONS OF PIPES & TUBESanescobar0001No ratings yet

- Valve MaterialsDocument1 pageValve MaterialsMarcel BolovedeaNo ratings yet

- Tabella Comparativa Delle Nomenclature ACCIAIDocument1 pageTabella Comparativa Delle Nomenclature ACCIAIZizuNo ratings yet

- Metal Standard ConverterDocument2 pagesMetal Standard ConverterRadaNo ratings yet

- Steel Grade Equivalent Table (EN, SAE - AISI, UNS, DIN, BS, UNI, JIS) - DFW MachineDocument5 pagesSteel Grade Equivalent Table (EN, SAE - AISI, UNS, DIN, BS, UNI, JIS) - DFW MachineMuhammad Adnan HafeezNo ratings yet

- 1Document47 pages1Shailendra TiwariNo ratings yet

- Tabel Persamaan bahan dasar dan presisi roda gigiDocument1 pageTabel Persamaan bahan dasar dan presisi roda gigiboschNo ratings yet

- PL2303CheckChipVersion ReadMeDocument3 pagesPL2303CheckChipVersion ReadMeLaci PopNo ratings yet

- Material Equal To GBDocument11 pagesMaterial Equal To GBArfanAliNo ratings yet

- Equivalent Steel GradesDocument3 pagesEquivalent Steel Gradesbasiri jayadeepNo ratings yet

- Steel Grade Equivalent Table (En, Sae - Aisi, Uns, Din, BS, Uni, Jis)Document6 pagesSteel Grade Equivalent Table (En, Sae - Aisi, Uns, Din, BS, Uni, Jis)neoyeah86No ratings yet

- Material Reference ListDocument7 pagesMaterial Reference ListionijhonnieNo ratings yet

- Equivalences - Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKDocument3 pagesEquivalences - Stainless Steel, 303, 304, 316, 316L, 410, 416, 431, F51, F55, 174PH, Standard Grade, IMCO, Special Grades, Sheffield UKIsaac IglesiasNo ratings yet

- Alloy Steel Material Equivalent GradeDocument4 pagesAlloy Steel Material Equivalent GradeJ B PatelNo ratings yet

- CorrespondanceDocument1 pageCorrespondanceAyoub BOUFTININo ratings yet

- Amg RTJ Data PDFDocument8 pagesAmg RTJ Data PDFsiswoutNo ratings yet

- GOST & OthersDocument6 pagesGOST & OthersSuseprianus PatumbaNo ratings yet

- Section 10 Useful Information: Steel GuideDocument1 pageSection 10 Useful Information: Steel GuideEasun - MR TechnicalNo ratings yet

- Stainless steel solid rod for welding 316LDocument1 pageStainless steel solid rod for welding 316LVVan TanNo ratings yet

- Gear Grades EquivalenttablesDocument1 pageGear Grades Equivalenttablesamir_fortunateNo ratings yet

- Chinese GB& World StdsDocument5 pagesChinese GB& World StdsBapu612345No ratings yet

- Materials EquivalantsDocument10 pagesMaterials EquivalantsFareed EngineeringNo ratings yet

- Conversion table of EN - Materials vs. US Materials (assorted by ASTM NoDocument1 pageConversion table of EN - Materials vs. US Materials (assorted by ASTM NoNattapong PongbootNo ratings yet

- Material EquilentDocument16 pagesMaterial EquilentShoaib JadoonNo ratings yet

- Material y ToleranciasDocument1 pageMaterial y ToleranciasvictoryanezNo ratings yet

- Table of Steel Grades: Astm ISO EN Alphanumeric (EN10088) Aisi UNSDocument4 pagesTable of Steel Grades: Astm ISO EN Alphanumeric (EN10088) Aisi UNSPSNMYNo ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- Stainless Steel ComparisionDocument3 pagesStainless Steel ComparisionDenny SaputraNo ratings yet

- Tabella Corrispondenza Acciai Inox: UNI 8317 EN 10088-2 DIN 17440 Aisi ASTM A240 BS 1449 pt2 AFNOR NFA35-573 JISDocument1 pageTabella Corrispondenza Acciai Inox: UNI 8317 EN 10088-2 DIN 17440 Aisi ASTM A240 BS 1449 pt2 AFNOR NFA35-573 JISMauro CostaNo ratings yet

- Equivalent Grade ChartDocument1 pageEquivalent Grade ChartDipesh Patel100% (1)

- Special Alloy Steel MaterialsDocument8 pagesSpecial Alloy Steel Materialsbhavin178No ratings yet

- Komposisi Material Stainless SteelDocument4 pagesKomposisi Material Stainless SteelArdiansyah Oktavianus WahyudiNo ratings yet

- Max. Service Temp. Weld 500 550 550 600 600 600 600 700 700 750 900 Metal (°C)Document2 pagesMax. Service Temp. Weld 500 550 550 600 600 600 600 700 700 750 900 Metal (°C)Adriano Dorneles de OliveiraNo ratings yet

- Steel Plate Comparision PDFDocument2 pagesSteel Plate Comparision PDFchandakweNo ratings yet

- WWW - Steelmet.in Alloy SteelsDocument1 pageWWW - Steelmet.in Alloy Steelskarthikeyan_kpk3994No ratings yet

- International Material GradeDocument7 pagesInternational Material GradeDvs RameshNo ratings yet

- Stock AcciaiDocument2 pagesStock AcciaiAnonymous lEX5U51wOANo ratings yet

- Kode BajaDocument11 pagesKode BajaUriyanaNo ratings yet

- Aproximate Equivalences List: of Norms For Stainless Steel GradesDocument2 pagesAproximate Equivalences List: of Norms For Stainless Steel GradesEhsan PoravarNo ratings yet

- Equivalência de Aços PDFDocument4 pagesEquivalência de Aços PDFAnonymous 6cpXAaNo ratings yet

- Steam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpiDocument4 pagesSteam and Gas Turbine Materials Used For Fasteners & Hardware Supplied by PpidislocationNo ratings yet

- Alloy Steel Astm Asme A 335 GR p911 Seamless PipeDocument15 pagesAlloy Steel Astm Asme A 335 GR p911 Seamless Pipemanuelq9No ratings yet

- Alloy Steel Astm Asme A 335 GR p2 Seamless PipeDocument15 pagesAlloy Steel Astm Asme A 335 GR p2 Seamless PipeApurva GuptaNo ratings yet

- Steel Info 02Document28 pagesSteel Info 02yw_oulalaNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Leghe Di Bronzo: Maggiormente UtilizzateDocument2 pagesLeghe Di Bronzo: Maggiormente UtilizzateDouglas CortezziNo ratings yet

- Backlash MaagDocument1 pageBacklash MaagDouglas CortezziNo ratings yet

- Bevel GearingDocument56 pagesBevel Gearingloosenut100% (4)

- Differential Gear Oil Change GuideDocument2 pagesDifferential Gear Oil Change GuideDouglas CortezziNo ratings yet

- Transmission Gear OilDocument1 pageTransmission Gear OilDouglas CortezziNo ratings yet

- Crowned Spur GearDocument7 pagesCrowned Spur GearDouglas CortezziNo ratings yet

- Magnetic PigmentDocument7 pagesMagnetic PigmentTito Prastyo RNo ratings yet

- Welspun Group L-SAW Plant Consumable Selection ChartDocument4 pagesWelspun Group L-SAW Plant Consumable Selection ChartKumawat PrakashNo ratings yet

- Introduction to Biology: Key ConceptsDocument130 pagesIntroduction to Biology: Key ConceptsWael HazemNo ratings yet

- Structural Health Monitoring IntroductionDocument18 pagesStructural Health Monitoring IntroductionArpit ParikhNo ratings yet

- MS3282 Shaft Alignment TechniquesDocument25 pagesMS3282 Shaft Alignment TechniquesTaufikNo ratings yet

- Heat Transfer Modeling TechniquesDocument60 pagesHeat Transfer Modeling Techniqueslili&valiNo ratings yet

- Physics 71.1 Elementary Physics LaboratoDocument3 pagesPhysics 71.1 Elementary Physics LaboratoClara OgladitNo ratings yet

- Classification of NanomaterialsDocument25 pagesClassification of NanomaterialsRenjith Raveendran Pillai100% (1)

- (Donald T. Greenwood) Principles of Dynamics Chap2Document47 pages(Donald T. Greenwood) Principles of Dynamics Chap2GracielaNo ratings yet

- Waves Exam QDocument24 pagesWaves Exam Qapi-4224287000% (1)

- Mechanical Engineering PPT of AltafDocument10 pagesMechanical Engineering PPT of AltafAltaf HussainNo ratings yet

- Clear Air TurbulanceDocument2 pagesClear Air TurbulanceAchmad Arifudin HidayatullohNo ratings yet

- S11198623 - Adi Natalia Nacola - Lab 5Document4 pagesS11198623 - Adi Natalia Nacola - Lab 5Natalia NacolaNo ratings yet

- Electric Charges and Fields Class 12 Notes Chapter 1Document9 pagesElectric Charges and Fields Class 12 Notes Chapter 1Sri DharshanNo ratings yet

- Ventilation - Guide For Automotive IndustriesDocument223 pagesVentilation - Guide For Automotive IndustriesChandrashekhar SarafNo ratings yet

- 0901b8038005c60e PDFDocument12 pages0901b8038005c60e PDFfsfNo ratings yet

- EDEXCEL JAN 2020 M1 [ QP + MS ]Document40 pagesEDEXCEL JAN 2020 M1 [ QP + MS ]1234567890 UnknownNo ratings yet

- WAV151 Wind Vane: Optoelectronic AnemometerDocument4 pagesWAV151 Wind Vane: Optoelectronic AnemometerhurantiaNo ratings yet

- Component A, Exp 1Document14 pagesComponent A, Exp 1nicolef_20No ratings yet

- Chapter 13Document52 pagesChapter 13MauricioNo ratings yet

- Newton's Laws WorksheetDocument2 pagesNewton's Laws Worksheetwade aryanNo ratings yet

- 6535 Inter-Rivet BucklingDocument6 pages6535 Inter-Rivet Bucklingkmr128351No ratings yet

- R744 (CO2) Refrigerant Cooling Systems, The Finned Tube R744 (CO2) Evaporator and Gas CoolerDocument24 pagesR744 (CO2) Refrigerant Cooling Systems, The Finned Tube R744 (CO2) Evaporator and Gas CoolerSudersanSridhar100% (1)

- Mahesh Vaze: National Institute of TechnologyDocument6 pagesMahesh Vaze: National Institute of TechnologymjvazeNo ratings yet

- Axis TurbineDocument7 pagesAxis TurbineBhertrand GomesNo ratings yet

- Determination of Hysteresis LoopDocument3 pagesDetermination of Hysteresis LoopchiranjeevNo ratings yet

- Open Channel Transitions Rational MethodDocument17 pagesOpen Channel Transitions Rational MethodSheyla Sofia VANo ratings yet

- Experimental Assessment of Surface Integrity of Inconel-825 in WEDMDocument21 pagesExperimental Assessment of Surface Integrity of Inconel-825 in WEDMNitesh TiwariNo ratings yet

![EDEXCEL JAN 2020 M1 [ QP + MS ]](https://imgv2-1-f.scribdassets.com/img/document/719807553/149x198/696dcb63b1/1712183779?v=1)