Professional Documents

Culture Documents

Supercast PVC Waterstop Range: Centrally and Externally Placed PVC Waterstops Uses

Supercast PVC Waterstop Range: Centrally and Externally Placed PVC Waterstops Uses

Uploaded by

Shivam GaurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Supercast PVC Waterstop Range: Centrally and Externally Placed PVC Waterstops Uses

Supercast PVC Waterstop Range: Centrally and Externally Placed PVC Waterstops Uses

Uploaded by

Shivam GaurCopyright:

Available Formats

Supercast PVC

Waterstop Range constructive solutions

Centrally and externally placed PVC

waterstops

Uses

The Supercast range of PVC waterstops is designed to The range consists of centrally placed profiles; Supercast

provide an integral sealing system for movement and Hydrofoil, Supercast Watafoil, Supercast XHD Hydrofoil and

construction joints in concrete cast in-situ. These joints Supercast XHD Watafoil; and externally placed profiles;

typically occur in the following types of structure: Supercast Rearguard S, Supercast Rearguard R, Supercast

Rearguard Kicker and Supercast Angleguard.

Water retaining

Standards compliance

Reservoirs, water towers and sewage tanks.

Supercast PVC waterstops are suitable for use in contact

Dams, culverts, canals and spillways. with potable water. “Water Byelaws Scheme approved

product”: listing number 8804054.

Swimming pools.

Bundled areas surrounding liquid retaining tanks. Description

Water excluding Supercast waterstops are extruded from a high grade PVC

compound which has been formulated to give excellent

Basements and underground car parks. flexibility and longevity characteristics. They are available as

straight lengths and factory produced intersections or as a

Tunnels and subways. factory prefabricated segment of a network to minimize site

jointing.

Abutments and retaining walls.

Principles of waterstop function

Roof decks and podium areas.

Supercast waterstops work because of two specific aspects

Advantages of their design.

Range of profiles to suit every need. a) Valve principle

Fully continuous 4 bulbed network. Simple waterstop profiles based on dumbells are cast

into the edges of adjacent concrete panels, which act

Reinforced eyeleted edge flanges for positive fixing. as baffles. In the event of joints opening as drying

shrinkage or other movement occurs, the edge bulbs of

Simple on-site jointing. the profile act as anchors. These induce tensions

across the waterstop resulting in a sealing effect at the

Full range of moulded and fabricated intersection pieces. inner faces of the edge bulbs.

WRC approval for use in contact with potable water.

Supercast PVC

Waterstop Range

Hydrofoil sections

b) Tortuous path principle

Profiles with a more complex cross section have a

much greater surface area. They present a much

greater resistance and more difficult path for water to

seep around the section.

Supercast Watafoil sections

Plain web sections are used in construction and contraction

joints.

Watafoil sections

The Supercast range incorporates both of these principles.

The products offer a fully continuous 4 bulbed design

maintaining both the valve and tortuous path principles.

These principles are maintained in the transition from

Rearguard profiles in floors to centrally placed profiles in

walls.

All centrally placed Supercast waterstops incorporate an

eyeletted, reinforced edge flange. This enables them to be

easily positioned by wiring to surrounding reinforcement.

Heavy duty sections

Supercast Hydrofoil section Increased web thickness gives a much stiffer section. The

stiffened profile is used where large volumes of concrete are

Centre bulb sections are used in expansion, contraction and being placed. They are used where concrete is being placed

construction joints. The centre bulb allows for movements from a great height such as deep wall shutters.

in a structure to be accommodated whilst its hexagonal

deign provides a flat surface. This allows shuttering and

joint fillers to fit snugly.

The 330 mm profile is specially designed for use in roof

slabs where a greater degree of movement may occur

particularly during construction.

Supercast PVC

Waterstop Range

All Rearguard sections incorporate a nailing flange with a

reinforced edge to provide a secure fixing that will resist

tearing.

Supercast Angleguard

An externally placed waterstop for use where the joint line

coincides with a change in level of the slab soffit. The profile

is designed to co-ordinate with the 250 mm Rearguard S

profile.

Dimensions are approximate and subject to manufacturing

tolerances

Supercast Rearguard R

Plain web sections, which are placed externally, for use in

contraction and construction joints. They incorporate a

central fin to assist setting out shutter location.

Supercast Rearguard Kicker

An extra wide version of Rearguard R profile which is used to

seal wall/kicker joints where the concrete kicker is being cast

after the slab rather than monolithically with the slab. The

extra width enables the waterstop to span both the joint

between kicker and slab as well as the joint between kicker

and wall.

Technical support

Dimensions are approximate and subject to manufacturing

tolerances

Fosroc offers a comprehensive range of high performance

high quality, construction products all backed by BS 5750

Supercast Rearguard S

certification. Fosroc offers a technical support package to

specifiers and contractors which include computer-aided

Sections incorporate a flat top center box, which allows

design (CAD), standard details and technical advice from

movement to be accommodated in expansion joints. The

staff with unrivalled experience in the industry.

box also provides a seating to support joint fillers.

Design criteria

The choice of the width and thickness of waterstop is largely

governed by concrete thickness, the position of the

reinforcement, aggregate size and complexity of the pour.

In general the 250 mm width of waterstop is suited to wall

thicknesses of 250 mm and over. For concrete less than 250

mm thick, the use of a narrower waterstop approximating to

the wall thickness will be appropriate.

Supercast PVC

Waterstop Range

Supercast PVC

Waterstop Range

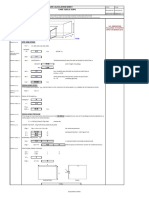

Centrally placed waterstop Installation instructions

These waterstops are positioned within the thickness of the Supercast Hydrofoil and Watafoil

concrete components and as a result are supported by

concrete on both sides. They are therefore able to Waterstops must be installed so that they are securely held

withstand water pressure from either side. This makes them in their correct position while the concrete is being placed.

suitable for use in water retaining structures. They will Concrete must be fully compacted around the waterstops to

prevent loss of water from within the tank and will prevent ensure that no voids or porous areas remain. Where

ingress of ground water when the tank is drained down. reinforcement is present, an adequate clearance must be left

to permit proper compaction.

Externally placed waterstop

The brass eyelets used for securing the waterstop are

These waterstops are designed for use in basement, located outside the edge bulbs so as not to create water

foundation and floor slab construction in vertical and paths around the profile.

horizontal joints in both water retaining and water excluding

structures. Example of a kicker joint

When used in walls, externally placed waterstops will only

resist water pressure from the face to which they are fixed.

When used below floor slabs, where the waterstop is

supported by the blinding concrete or when placed in

vertical situations against permanent concrete shuttering,

externally placed waterstops will resist water pressure from

either face.

Properties Profiles

Profiles

Form: Extruded thermoplastic sections

Colour: Blue

Hydrostatic head: Up to 100 m (10 bar)

Joint movement: Up to 10 mm

Compound Supercast Rearguard

o

Typical figures: To BS 2782 at 25 C When used on ground slabs where the waterstop is

2

Tensile strength: Minimum 14 N/mm supported on blinding, Rearguard profiles usually require no

Elongation at break: Minimum 300% fixing. Lay the waterstop centrally over the line of the joint to

Hardness: Shore ‘A’ 80 to 90 be formed.

Specification clauses Fixing to vertical shuttering is done by nailing through the

outer nailing flanges leaving the head of the nail proud so

that it is held in the cured concrete. This prevents the

1. Supplier specification

waterstop being displaced when the shuttering is struck.

Where indicated on the drawings, PVC waterstops shall

Fixing to vertical shutter

be Supercast Waterstops obtained from Fosroc

(address as shown). All wall/floor waterstop

connections shall be made using Supercast injection

moulded transition pieces to ensure continuity of the

four bulb profiles.

2. Performance specification

Where indicated on the drawings, PVC waterstops shall

be made from extruded plasticised PVC compound.

The compound used shall meet the US Corps of

Engineers specification CRD-C 572-74. it shall have a

tensile strength in excess of 14 MN/m2 and an

elongation at break in excess of 300%.

Supercast PVC

Waterstop Range

Fixing Supercast Kicker Waterstop Intersection pieces

In addition to nailing to the external shutter, the Kicker Standard intersection pieces are available for each

profile is equipped with brass eyelets in the central rib. Supercast waterstop profile. The standard on-flat intersection

Twist short lengths of tying wire through these eyelets so leg length is 230 mm from centre line. On-edge intersections

that when the kicker is cast they act as anchors, holding the have a standard 75 mm leg length.

center of the waterstop tight against the face of the

concrete. This prevents the build-up of debris between the Factory welded intersections for Supercast Hydrofoil /

waterstop and the kicker prior to the wall being poured. Watafoil ad XHD Hydrofoil / Watafoil.

Supercast Angleguard

Fixing in position is done in a similar manner to Supercast

Rearguard.

Site jointing instructions

Jointing of Supercast waterstops is carried out using Fosroc

Heat Welding Equipment. The ends to be joined are cut

square and held in alignment in a special jig. The ends are

then pressed either side of a special heated blade, until an

even, molten bead of PVC appears around the section. The

heated blade is then removed and the molten ends pressed

fully together. The PVC cools to form a strong fusion

welded joint. Full instructions are available from Fosroc.

Fosroc PVC heat welding equipment

Supercast PVC

Waterstop Range

Estimating

Section Minimum radii Roll

Supercast Width in On flat On edge Length

(mm) (m) (m) (m)

Hydrofoil 330 20 0.15 12

250 15 0.15 12

200 14 0.15 15

150 12 0.075 15

Watafoil 250 15 0.15 12

200 14 0.15 15

150 12 0.075 20

Rearguard R 250 10 N/A 12

200 9 N/A 15

150 8 N/A 12 & 20

Rearguard S 250 10 N/A 12

200 9 N/A 12

150 8 N/A 12

Rearguard

Kicker 300 20 N/A 12

Angleguard 250 10 N/A 3m

girth lengths

XHD

Hydrofoil 250 15 0.23 10

XHD

Watafoil 250 15 0.23 10

Equipment

Jointing jigs

150 mm Supercast Rearguard R & S

200 mm Supercast Rearguard R & S

250 mm Supercast Rearguard R & S

330 mm Supercast Rearguard Kicker

150 mm Supercast Hydrofoil & Watafoil

200 mm Supercast Hydrofoil & Watafoil

250 mm Supercast Hydrofoil & Watafoil

250 mm Supercast XHD Hydrofoil & Watafoil

330 mm Supercast Hydrofoil

Heater blades

110v and 220v, 350w blades are available.

Warning: Ensure that heater blades are earthed by the

green/yellow wire.

Precautions

Health and safety

Hot weld site jointing of PVC waterstops results in the

liberation of hydrogen chloride mist and vapour. The OEL

(operational exposure limit) of 5 ppm can be exceeded in

still air confined spaces, therefore forced ventilation must be

provided or a suitable respirator used.

Supercast PVC

Waterstop Range

Additional information

Application at low temperatures

Care in the handling and installation of Supercast PVC

waterstops is necessary at low ambient temperatures. Such

temperatures will also require special precautions to be

taken with the placing and curing of concrete.

Fosroc manufactures a wide range of complementary

products which include:

Waterproofing membranes & waterstops

Joint sealants & filler boards

Cementitious & epoxy grouts

Specialised flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosroc’s ‘Systematic

Approach’ to concrete repair features the following:

Hand-placed repair mortars

Spray grade repair mortars

Fluid micro-concretes

Chemically resistant epoxy mortars

Anti-carbonation/anti-chloride protective coatings

Chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions fo r

the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any

advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct or

continuous control over where or how its products are applied, accept any liability either directly or indirectly arising fro m the use

of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Fosroc Jordan

Regional Offices: email: enquiryjordan@fosroc.com

Head Office

P.O Box 253, Amman-Khalda Offices: Tel: (06) 535 9562 Fax: (06) 535 9563

King Abdullah II Industrial State Amman-Sahab Factory: Tel: (06) 402 2665 Fax: (06) 402 9475

Sahab 11512, Jordan Aqaba Showroom: Tel: (03) 205 0061 Fax: (03) 205 0062

www.fosroc.com

You might also like

- Sikagard - 62Document4 pagesSikagard - 62bassem kooliNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- MS 1553 Enclosed Building (UDL)Document2 pagesMS 1553 Enclosed Building (UDL)a1306ksk50% (2)

- Subsea Manifold HandbookDocument97 pagesSubsea Manifold HandbookLarry Ubu100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- TDS - Supercast PVC Waterstops - ASIADocument8 pagesTDS - Supercast PVC Waterstops - ASIAherwin hanafiahNo ratings yet

- FOSROC Submittal PVC Waterstop - ASIADocument85 pagesFOSROC Submittal PVC Waterstop - ASIAlensa jijiNo ratings yet

- Supercast PVC : Centrally and Externally Placed PVC WaterstopsDocument4 pagesSupercast PVC : Centrally and Externally Placed PVC WaterstopsmystrophanNo ratings yet

- Fosroc Supercast PVC: Centrally and Externally Placed PVC Waterstops. UsesDocument4 pagesFosroc Supercast PVC: Centrally and Externally Placed PVC Waterstops. UsesVincent JavateNo ratings yet

- Supercast PVC Waterstop PDFDocument8 pagesSupercast PVC Waterstop PDFRizqa Gusti NarawitaNo ratings yet

- Fosroc Supercast PVC Waterstops: Technical Data SheetDocument4 pagesFosroc Supercast PVC Waterstops: Technical Data Sheetarvin jay santarinNo ratings yet

- TDS Supercast PVC Saudi ArabiaDocument8 pagesTDS Supercast PVC Saudi Arabiaashraf komiNo ratings yet

- Fosroc Supercast PVC WaterstopsDocument4 pagesFosroc Supercast PVC WaterstopsKpChuaNo ratings yet

- TDS Supercast PVC WaterstopDocument8 pagesTDS Supercast PVC Waterstopthohiruddin.engineerNo ratings yet

- Supercast PVCDocument8 pagesSupercast PVCherwin hanafiahNo ratings yet

- Supercast PVCDocument8 pagesSupercast PVCVenkata RaoNo ratings yet

- Expanbar PVC: Centrally and Externally Placed PVC Waterstops. UsesDocument5 pagesExpanbar PVC: Centrally and Externally Placed PVC Waterstops. UsesZaid AhmedNo ratings yet

- Supercast PVC Waterstops: Technical Data SheetDocument4 pagesSupercast PVC Waterstops: Technical Data Sheetmystrophan100% (1)

- Supercast PVCDocument4 pagesSupercast PVCVenkata Raju KalidindiNo ratings yet

- Supercast PVC WaterstopDocument4 pagesSupercast PVC WaterstopArun KumarNo ratings yet

- MasterSeal 940 (Masterflex Aquastop PVC Waterstop)Document6 pagesMasterSeal 940 (Masterflex Aquastop PVC Waterstop)KorupoluNo ratings yet

- Sure Stop PVC Waterstops TDSDocument3 pagesSure Stop PVC Waterstops TDSrosarioNo ratings yet

- Masterflex 2000 - PDS - ASEAN - 130110Document3 pagesMasterflex 2000 - PDS - ASEAN - 130110Francisco Lopes PaixãoNo ratings yet

- MasterSeal 940 MasterFlex Aquastop - EngDocument7 pagesMasterSeal 940 MasterFlex Aquastop - EngyounesshammouyouNo ratings yet

- Sure-Stop PVC Waterstops: Technical Data SheetDocument4 pagesSure-Stop PVC Waterstops: Technical Data SheetmystrophanNo ratings yet

- 0418-07-34-21 Datasheet File Rubber WaterstopDocument4 pages0418-07-34-21 Datasheet File Rubber WaterstopDicky PramonoNo ratings yet

- Rubber Waterstops - Mega Tec Consolidation Sdn. BHDDocument12 pagesRubber Waterstops - Mega Tec Consolidation Sdn. BHDCarlos GilNo ratings yet

- Polystop: Internal and External PVC WaterstopDocument4 pagesPolystop: Internal and External PVC WaterstopVaittianathan MahavapillaiNo ratings yet

- PVC Waterstop - Design Guide: Suggested Master SpecificationDocument4 pagesPVC Waterstop - Design Guide: Suggested Master Specificationarvin jay santarinNo ratings yet

- Diaphragm WallsDocument2 pagesDiaphragm WallsTanasescu AlinNo ratings yet

- Pt. Magdatama - Wabo Modular JointDocument8 pagesPt. Magdatama - Wabo Modular JointMangisi Haryanto ParapatNo ratings yet

- RFA-TECH Waterproofing Brochure PDFDocument48 pagesRFA-TECH Waterproofing Brochure PDFsilvereyes18No ratings yet

- Casting Box Girder SegmentsDocument3 pagesCasting Box Girder SegmentsChae Tyng FengNo ratings yet

- Catalog Fabricante TechnipDocument9 pagesCatalog Fabricante Technipjimy GutiérrezNo ratings yet

- Pipe Roofing SolutionsDocument12 pagesPipe Roofing SolutionsSubhash KediaNo ratings yet

- BLDG Constr-Assgn PDFDocument10 pagesBLDG Constr-Assgn PDFHarsh BhansaliNo ratings yet

- Supercast SW10 PDFDocument2 pagesSupercast SW10 PDFHusein SyarifNo ratings yet

- 02 - 6991 1742 01 - L Pipe Roofing SolutionsDocument12 pages02 - 6991 1742 01 - L Pipe Roofing SolutionsJonas RachidNo ratings yet

- Modern Sewer Design: Two 6m Joints of Fully Perforated Pipe Banded Together For Ease of InstallationDocument32 pagesModern Sewer Design: Two 6m Joints of Fully Perforated Pipe Banded Together For Ease of InstallationJuan GrajalesNo ratings yet

- TDS-Supercast-SW10 WaterstopDocument2 pagesTDS-Supercast-SW10 WaterstopharsoNo ratings yet

- Bitustop PVC Edge Tie Waterstops: DescriptionDocument2 pagesBitustop PVC Edge Tie Waterstops: DescriptionTuntun TatNo ratings yet

- Plunge Columns PDFDocument4 pagesPlunge Columns PDFHung NguyentheNo ratings yet

- No. 8: Concrete Bridge Construction Methods - Arches and FramesDocument4 pagesNo. 8: Concrete Bridge Construction Methods - Arches and Framesalberto5791No ratings yet

- 1710 Abeco Spec SheetDocument4 pages1710 Abeco Spec Sheetminov minovitchNo ratings yet

- Uni Stop PVC WaterstopDocument8 pagesUni Stop PVC WaterstopSherazNo ratings yet

- Dismantling-Joints VJ Bro 0821 Eng+v1Document25 pagesDismantling-Joints VJ Bro 0821 Eng+v1AhmedRamadanNo ratings yet

- Powerbar - : Glass Fiber Reinforced Polymer (GFRP) BarDocument3 pagesPowerbar - : Glass Fiber Reinforced Polymer (GFRP) Barvinod3327No ratings yet

- Steel Tank BrochureDocument8 pagesSteel Tank BrochureclintNo ratings yet

- Westec Design GuideDocument2 pagesWestec Design GuideSrinivasan ReddyNo ratings yet

- Sika Greenstreak Waterstops Brochure EngDocument20 pagesSika Greenstreak Waterstops Brochure EngGustavo Polo Luque100% (1)

- 33 Supercast SW10Document3 pages33 Supercast SW10marklesterNo ratings yet

- SETFt RIP Transformer Outdoor BushingDocument12 pagesSETFt RIP Transformer Outdoor Bushingp m yadavNo ratings yet

- PVC Waterstop Design GuideDocument2 pagesPVC Waterstop Design GuidebelajiNo ratings yet

- Supercast SW 1213Document4 pagesSupercast SW 1213calitheanNo ratings yet

- Ductile Iron Pipe Piles (DSI-Case Atlantic)Document16 pagesDuctile Iron Pipe Piles (DSI-Case Atlantic)abelbernardo73No ratings yet

- Precast Concrete ReportDocument36 pagesPrecast Concrete ReportRam Vinay SharmaNo ratings yet

- Supercast TP Waterstop - Mega Tec Consolidation Sdn. BHDDocument4 pagesSupercast TP Waterstop - Mega Tec Consolidation Sdn. BHDCarlos GilNo ratings yet

- PZ Access Scaffolding 2019Document40 pagesPZ Access Scaffolding 2019Derek HeaneyNo ratings yet

- Diaphragm Walls Cementation Skanska Data SheetDocument2 pagesDiaphragm Walls Cementation Skanska Data SheetWWW2000No ratings yet

- Bethlehem Structural Strand PDFDocument28 pagesBethlehem Structural Strand PDFthechairman362No ratings yet

- AVSTech Brochure 24 - CompressedDocument8 pagesAVSTech Brochure 24 - Compressedgopinathgo1194No ratings yet

- Water Bars BY VIJAY KUMARDocument13 pagesWater Bars BY VIJAY KUMARVijay YadavNo ratings yet

- Drilling Products: Engineering Excellence in A Global MarketDocument12 pagesDrilling Products: Engineering Excellence in A Global MarketGustavo CunhaNo ratings yet

- Maths Olympiad Sample - Good-5Document2 pagesMaths Olympiad Sample - Good-5Chai Weng KuakNo ratings yet

- Maths Olympiad Sample - Good-2Document1 pageMaths Olympiad Sample - Good-2Chai Weng KuakNo ratings yet

- 1 1 3Document2 pages1 1 3Chai Weng KuakNo ratings yet

- Maths Olympiad Sample - Good-3Document1 pageMaths Olympiad Sample - Good-3Chai Weng KuakNo ratings yet

- Total 723.240 4012.920 3127.320 0.000 0.000 7863.480: Formwork Quanity Take-OffDocument1 pageTotal 723.240 4012.920 3127.320 0.000 0.000 7863.480: Formwork Quanity Take-OffChai Weng KuakNo ratings yet

- Formwork Quanity Take-OffDocument1 pageFormwork Quanity Take-OffChai Weng KuakNo ratings yet

- Maths Olympiad Sample - Good-1Document1 pageMaths Olympiad Sample - Good-1Chai Weng KuakNo ratings yet

- Project Description: View of The Slender 111W57thDocument1 pageProject Description: View of The Slender 111W57thChai Weng KuakNo ratings yet

- Concrete Quantity Take-Off: Rev: 1 Calc. By: Checked byDocument1 pageConcrete Quantity Take-Off: Rev: 1 Calc. By: Checked byChai Weng KuakNo ratings yet

- BCH 40Document1 pageBCH 40Chai Weng KuakNo ratings yet

- Product and Practice AccreditationDocument1 pageProduct and Practice AccreditationChai Weng KuakNo ratings yet

- Planning Application - Permitted DevelopmentDocument1 pagePlanning Application - Permitted DevelopmentChai Weng KuakNo ratings yet

- Lysaght Smartdek - Jan 2019Document2 pagesLysaght Smartdek - Jan 2019Chai Weng KuakNo ratings yet

- ETABS - To Start OffDocument15 pagesETABS - To Start OffChai Weng KuakNo ratings yet

- Structural Pot Bearing4 CompressDocument30 pagesStructural Pot Bearing4 CompressChai Weng KuakNo ratings yet

- D Internet Myiemorgmy Intranet Assets Doc Alldoc Document 18940 FINAL Flyer - Technical Visit To Venturi Asia Wind TunnelDocument2 pagesD Internet Myiemorgmy Intranet Assets Doc Alldoc Document 18940 FINAL Flyer - Technical Visit To Venturi Asia Wind TunnelChai Weng KuakNo ratings yet

- Analysis of Long-Distance Earthquake Tremors and Base Shear Demand For Buildings in SingaporeDocument11 pagesAnalysis of Long-Distance Earthquake Tremors and Base Shear Demand For Buildings in SingaporeChai Weng KuakNo ratings yet

- Sika - Waterbars: Flexible PVC WaterstopsDocument4 pagesSika - Waterbars: Flexible PVC WaterstopsChai Weng KuakNo ratings yet

- Befib2000 MechanicalbehaviourofHPCandUHPCDocument11 pagesBefib2000 MechanicalbehaviourofHPCandUHPCsina zolfagharyNo ratings yet

- Curriculum Summary Bachelor Degree of Mechanical Engineering With Honours 4 Year Program (FKMP)Document1 pageCurriculum Summary Bachelor Degree of Mechanical Engineering With Honours 4 Year Program (FKMP)siti anjingNo ratings yet

- Fulltext01 PDFDocument152 pagesFulltext01 PDFJoseAngelFernandezOrtegaNo ratings yet

- The Last Question SummaryDocument2 pagesThe Last Question SummaryMuhammad MussawarNo ratings yet

- Chapter 5-Hydrology of Ungauged CatchmentsDocument18 pagesChapter 5-Hydrology of Ungauged CatchmentsMubarek AbduljebarNo ratings yet

- Unit-Iv Columns & Struts: ContentDocument8 pagesUnit-Iv Columns & Struts: ContentKarma YoezerNo ratings yet

- Lecture 7Document71 pagesLecture 7adrienleeNo ratings yet

- Project Experiment 4: Analysis of The % Cobalt in A Cobalt Amine Halide ComplexDocument12 pagesProject Experiment 4: Analysis of The % Cobalt in A Cobalt Amine Halide ComplexNour MansourNo ratings yet

- BF869 - BF871Document8 pagesBF869 - BF871vali2daduicaNo ratings yet

- Acalypha Indica and Curcuma Longa Plant Extracts Mediated ZNS Nanoparticles PDFDocument9 pagesAcalypha Indica and Curcuma Longa Plant Extracts Mediated ZNS Nanoparticles PDFRabeea NasirNo ratings yet

- Lib-Dating-Fossils-53740-Article - and - QuizDocument7 pagesLib-Dating-Fossils-53740-Article - and - QuizRim YazidNo ratings yet

- Tuned Liquid Dampers Simulation For EarthquakeDocument18 pagesTuned Liquid Dampers Simulation For EarthquakedaahdadaNo ratings yet

- 1.two Way Slab Design (USD)Document16 pages1.two Way Slab Design (USD)kashemNo ratings yet

- Copia de Listado Verbos (Nuevo)Document8 pagesCopia de Listado Verbos (Nuevo)Henry Jesus Mora MartinezNo ratings yet

- RDP 1Ph-3Ph Catalogue Package 2021-10-21-Locked2Document56 pagesRDP 1Ph-3Ph Catalogue Package 2021-10-21-Locked2Igur EuiNo ratings yet

- Mahanakhon Tower: Dr. Kanokpat ChanvaivitDocument42 pagesMahanakhon Tower: Dr. Kanokpat ChanvaivitAV AekavitNo ratings yet

- Cox Dantonio ReviewDocument3 pagesCox Dantonio ReviewLavkeshKumarNo ratings yet

- Tools For Systems Thinkers PDFDocument5 pagesTools For Systems Thinkers PDFRenata LozanoNo ratings yet

- Analysis of Geosynthetic Reinforced Soil Structures With Orthogonal AnisotropyDocument15 pagesAnalysis of Geosynthetic Reinforced Soil Structures With Orthogonal AnisotropymohanNo ratings yet

- Lab #1 Data & Answer Sheet Updated Jan - 12!23!1Document6 pagesLab #1 Data & Answer Sheet Updated Jan - 12!23!1h1234No ratings yet

- Why Do We Have Seasons?Document18 pagesWhy Do We Have Seasons?Kaycee FlorenceNo ratings yet

- Consistent Mesoscopic Mechanical Behaviour Model For Woven Composite Reinforcements in Biaxial TensionDocument17 pagesConsistent Mesoscopic Mechanical Behaviour Model For Woven Composite Reinforcements in Biaxial TensionFederico LamonNo ratings yet

- ThermodynamicsDocument128 pagesThermodynamicskushagra singhNo ratings yet

- Unit 7 Design of Plate Girders: StructureDocument54 pagesUnit 7 Design of Plate Girders: StructureManinder ChaudharyNo ratings yet

- Lecture 1 - The Quantum WorldDocument7 pagesLecture 1 - The Quantum WorldMartin MaguNo ratings yet

- Mathematics: Quarter 3 - Module 4Document10 pagesMathematics: Quarter 3 - Module 4Miguel June100% (2)

- Objectives:: Blood SmearingDocument2 pagesObjectives:: Blood SmearingAshlyn BautistaNo ratings yet