Professional Documents

Culture Documents

Concrete Joints.

Uploaded by

hidiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Joints.

Uploaded by

hidiCopyright:

Available Formats

Concrete control joints should be no less than ¼ of the total thickness of the slab (1” deep for a 4” thick

pour) and placed no less than 2-3 times (in feet) the thickness (in inches) of the slab (8-12 feet apart for a 4” thick

pour). Control joints can be “created” while the concrete is being poured by using a tool to make the joint. These

joints can also be cut into the slab once the slab has cured enough to prevent chipping during the cut. The goal of the

control joint is to allow the slab to crack, during expansion and contraction, in a known location and in a straight line.

Expansion joints are put in place before the concrete is poured. Expansion joints are used to allow the slab to

move and not put stress on whatever it abuts. These joints are placed where a slab meets a building, where a slab

meets another slab, and where a pool deck meets the coping. A pliable material is used (asphalt coated, cork, plastic)

to construct these types of joints. The material should extend the depth of the slab and extend the full width of the

slab. Ideally, for expansion joints on the exterior of a structure, sealing these joints is preferable. Using a high-quality

urethane caulk .

You might also like

- Building A Garden Shed Step By Step Instructions and PlansFrom EverandBuilding A Garden Shed Step By Step Instructions and PlansRating: 2 out of 5 stars2/5 (1)

- Types of Concrete Joints and Placing TipsDocument2 pagesTypes of Concrete Joints and Placing TipsLAM CONo ratings yet

- Construction Dhaji DeewariDocument4 pagesConstruction Dhaji DeewariNajaf aliNo ratings yet

- Ceramic Tile InstallationDocument4 pagesCeramic Tile InstallationAjit Singh RathoreNo ratings yet

- CONSTRUCTION METHODOLOGY - FenceDocument3 pagesCONSTRUCTION METHODOLOGY - Fencejemmar100% (1)

- Interior Wall and Partition CoveringsDocument11 pagesInterior Wall and Partition CoveringscrazybuttfulNo ratings yet

- Installation Outside ApplicationsDocument1 pageInstallation Outside Applicationsapi-161238981No ratings yet

- BuildingDocument10 pagesBuildingObiyo MartinsNo ratings yet

- Crack Sealing And/or Crack Filling Project Selection Guide: General DefinitionsDocument11 pagesCrack Sealing And/or Crack Filling Project Selection Guide: General DefinitionsCE PassajNo ratings yet

- Concrete JointsDocument15 pagesConcrete JointsJay Ann EmanNo ratings yet

- Slab SpecificationDocument2 pagesSlab SpecificationRam Johnlord CaringalNo ratings yet

- Formation and BallastDocument30 pagesFormation and BallastSaulat Jillani100% (1)

- How To Install Slate TileDocument6 pagesHow To Install Slate TileRi SovannaphumiNo ratings yet

- Part 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary NotesDocument9 pagesPart 2: Avoid Cracks in Concrete Slabs-On-Grade: Video Summary Notesmohannad eliassNo ratings yet

- How To Install Slate TileDocument6 pagesHow To Install Slate TileRi SovannaphumiNo ratings yet

- How To Install Marble Floor TilesDocument6 pagesHow To Install Marble Floor TilesRi SovannaphumiNo ratings yet

- Constructing Concrete Forms CourseDocument27 pagesConstructing Concrete Forms CourseTarun ChopraNo ratings yet

- How To Build A Brick WallDocument11 pagesHow To Build A Brick WallMoe Zaw OoNo ratings yet

- Types of Concrete Joints and Placing TipsDocument8 pagesTypes of Concrete Joints and Placing Tips11 Sqn RER100% (1)

- How To Reinforce Concrete To Control CrackingDocument3 pagesHow To Reinforce Concrete To Control Crackingchutton681No ratings yet

- Concrete Pad Found NewDocument5 pagesConcrete Pad Found NewImran CaderNo ratings yet

- Filler SlabDocument6 pagesFiller SlabLeo Prasanth Xavier MartinNo ratings yet

- Construction Joints:: Expansion JointDocument5 pagesConstruction Joints:: Expansion JointSathya MurthyNo ratings yet

- Building Oven StandsDocument4 pagesBuilding Oven StandsParaları Paraları İsrailNo ratings yet

- Joints in SlabsDocument4 pagesJoints in Slabsتوان امتياس سامسدينNo ratings yet

- Constructing Concrete Forms CourseDocument27 pagesConstructing Concrete Forms CourseRakesh ParaliyaNo ratings yet

- Case StudyDocument3 pagesCase StudyAnep AmeerNo ratings yet

- Types of Wall Based On ConstructionDocument7 pagesTypes of Wall Based On ConstructionALI IMRANNo ratings yet

- Do It YourselfDocument3 pagesDo It YourselfcartuxaNo ratings yet

- SBA Technical Data Sheet Number 05 - The Langstroth and M.D. HivesDocument6 pagesSBA Technical Data Sheet Number 05 - The Langstroth and M.D. HivesCristian BujorNo ratings yet

- Foundations and Underwater ConstructionDocument30 pagesFoundations and Underwater ConstructionKenneth50% (2)

- How To Build A Wicking Bed 13pagesDocument0 pagesHow To Build A Wicking Bed 13pagestherootsNo ratings yet

- Contraction/Control JointsDocument2 pagesContraction/Control Jointsmohannad eliassNo ratings yet

- Test PitsDocument1 pageTest Pitsfahrizal_ajie1234567No ratings yet

- Construction of Farm Fencing, Implement ShedDocument4 pagesConstruction of Farm Fencing, Implement ShedShaikh Jubrel ahmadNo ratings yet

- Final Lec JointsDocument54 pagesFinal Lec JointsMahbub AlamNo ratings yet

- Valet StandDocument9 pagesValet StandflerziNo ratings yet

- Bunk Beds: Start With The PanelsDocument5 pagesBunk Beds: Start With The PanelspoimandresNo ratings yet

- Drywall Powerpoint0Document27 pagesDrywall Powerpoint0Alexander MamaniNo ratings yet

- Centering and Shuttering / Formwork:: BWP GradeDocument9 pagesCentering and Shuttering / Formwork:: BWP GradeAvish GunnuckNo ratings yet

- Jute Netting Spec.1Document2 pagesJute Netting Spec.1DanyitbarekNo ratings yet

- Instructions For Putting Ceramic Tiles in PlaceDocument6 pagesInstructions For Putting Ceramic Tiles in PlaceabobeedoNo ratings yet

- How To Install Granite Tile CountertopsDocument3 pagesHow To Install Granite Tile CountertopsRi SovannaphumiNo ratings yet

- Soil NailingDocument21 pagesSoil NailingRizwana RpNo ratings yet

- How To Install Marble Floor TilesDocument5 pagesHow To Install Marble Floor TilesRi SovannaphumiNo ratings yet

- Construction ToolsDocument43 pagesConstruction ToolsThe Truth. IndNo ratings yet

- Steps: Plan Your Concrete Project Carefully. There Is A Set Sequence of Steps You Must Take ToDocument14 pagesSteps: Plan Your Concrete Project Carefully. There Is A Set Sequence of Steps You Must Take ToTariq Ahmed BalochNo ratings yet

- CBRI - Waffle Unit & JoistDocument11 pagesCBRI - Waffle Unit & JoistAnkita Ghodke100% (2)

- David de Lossy/Photodisc/Getty ImagesDocument15 pagesDavid de Lossy/Photodisc/Getty ImagesasiasiNo ratings yet

- Process of Tile InstallationDocument39 pagesProcess of Tile InstallationChristian Nathaniel Ramon PalmaNo ratings yet

- Cracks: Types of Cracks Repairing TechniquesDocument13 pagesCracks: Types of Cracks Repairing TechniquesAli Zain Ul AbadeenNo ratings yet

- Retstruc of Waste TiresDocument2 pagesRetstruc of Waste TiresMag FhearadhaighNo ratings yet

- Presentation Permeation Grouting Prof - Dr. HanifiDocument31 pagesPresentation Permeation Grouting Prof - Dr. HanifiChalakAhmedNo ratings yet

- REPORTINGDocument14 pagesREPORTINGxishiyanNo ratings yet

- Trunk Sewer LayingDocument8 pagesTrunk Sewer Layingአንተነህ ኃይሌ ክንፈገብርኤልNo ratings yet

- Is 400Document2 pagesIs 400ajazrajNo ratings yet

- Inspection Concrete SlabDocument3 pagesInspection Concrete Slabmudy_vayneNo ratings yet

- Porcelain Paver Installation GuidelinesDocument16 pagesPorcelain Paver Installation GuidelinesJoyce RobisonNo ratings yet

- Pebble TypesDocument6 pagesPebble TypesTarun KumarNo ratings yet

- 311 4R-00Document12 pages311 4R-00farhadam50% (2)

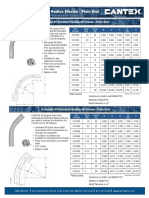

- CANTEX Schedule 80 ElbowDocument2 pagesCANTEX Schedule 80 Elboweng laythNo ratings yet

- Nematc22003 Electrical Polyvinyl Chloride PVC ConduitpdfDocument26 pagesNematc22003 Electrical Polyvinyl Chloride PVC ConduitpdfMohamed Reda Hussein SengarNo ratings yet

- Technical Information ASSET DOC 6798856Document17 pagesTechnical Information ASSET DOC 6798856Doie QuerubinNo ratings yet

- Post-Installed Rebar Guide Technical Information ASSET DOC LOC 7210535Document69 pagesPost-Installed Rebar Guide Technical Information ASSET DOC LOC 7210535kyleNo ratings yet

- 3.2.5 HIT-RE 500 Epoxy Adhesive Anchoring System 3.2.5.1 Product DescriptionDocument15 pages3.2.5 HIT-RE 500 Epoxy Adhesive Anchoring System 3.2.5.1 Product Descriptionsalman ahmedNo ratings yet