Professional Documents

Culture Documents

Homemade Rabbit Cages: List of Materials Conventional Quonset

Uploaded by

SherryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Homemade Rabbit Cages: List of Materials Conventional Quonset

Uploaded by

SherryCopyright:

Available Formats

Homemade Rabbit Cages

The best homemade rabbit cages are built of Rabbit cages are usually suspended from the

welded wire. Wire cages are more durable than ceiling of the rabbitry building using No. 12 wire.

wooden cages and are less expensive in the long Sometimes they are placed on a framework

run. Wire cages reduce the incidence of disease supported by legs. Either method requires some

because they are easier to clean and disinfect. type of cover to protect the rabbits from sun, wind

The major consideration in selecting a rabbit and rain.

cage is to get one that is self-cleaning. Time used in Cages are often tiered or placed one above the

cleaning can be better used on other phases of other. The single-tier cages are easier to build,

rabbit management. No part of the floor should be maintain and clean, but require more space and

solid, nor should a loose board be placed in the increase the investment cost per working doe. If the

cage. Diseases commonly spread from dirt, cages are hung in tiers, pans are used between the

moisture and droppings remaining on these areas.

levels to prevent droppings and urine from falling

Wood is not a desirable material for cage

into the lower cages. The decision to tier the cages

construction. Rabbits gnaw on wood. It absorbs

must be made before cage purchase or construction

water and urine, making good sanitation more

begins.

difficult. If wood is used, limit its use to the

The following plans outline the procedure for

framework. Make inner portions of wire. Avoid

building one unit of two 30x36-inch wire single-tier

treated wood if it is in contact with rabbits because it

cages. Each cage houses a medium-sized doe and

may be harmful.

litter, or five to seven fryer rabbits. All wire for the

Many cage designs are manufactured. The

cages, except for the flooring, consists of welded

basic cage used in most rabbitries is 30-inches

14-gauge galvanized wire with 1x1 or 1x2-inch grid

deep, 36-inches long, and 18-inches high. Most

openings. The floor is made of 16-gauge welded

have rectangular sides (conventional style), but

wire with ½x½ or ½x1-inch grid openings.

some have rounded tops (quonset style). Doors

may be hinged at the top, sides or bottom.

LIST OF MATERIALS

Conventional Quonset

Floor: (1) 1 pc. 36x78-in wire 1 pc. 36x78-in wire

Top: (2) 1 pc. 30x72-in wire 1 pc. 48x72-in wire

Sides: (3) 2 pc. 15x72-in wire ----------

Ends: (4) 2 pc. 15x30-in wire 2 pc. 18x30-in wire

Partition: (5) 1 pc. 18x30-in wire 1 pc. 21x30-in wire

Doors: (6) 2 pc. 16x18-in wire 2 pc. 18x20-in wire

Misc: (7) ----------- 3 pc. No. 12 gal. wire

(8) 2 pc. 72-in sections of 5/16-in 2 pc. 72-in sections of 5/16-in

steel rod for floor steel rod for floor

(9) 2 door latches 2 door latches

Fasteners: 100 small hen-cage clips

(common to both styles) 25 large hen-cage clips

30 No. 101 hog rings

2 pc. 24-in No. 9 galvanized wire

CONSTRUCTION:

These cages are most easily constructed in Lay the top of the quonset cages over the floor,

units of two cages. Lay out the floor first by ends and partition. Fasten to the front and rear of

removing a 3x3-inch section from each corner of the the flooring using small hen-cage clips spaced every

flooring. Bend up a 3-inch section along each side five inches. Raise the center partition and fasten to

of the floor. Secure the floor sides together using the top. Repeat the process with each end section.

small hen-cage clips to prevent young bunnies from Cut the door openings in the front side of each

falling from the cage. Attach the steel rods to the cage. Each opening should be 2-inches smaller

front and rear edges of the floor using hog rings. than the doors in height and width. File all sharp

The partition and ends of the quonset cage are protruding wires. Attach the doors using large hen-

best shaped using a pattern. Allow a 5/8-inch cage clips as hinges. Attach the No. 9 wire around

section of the wires to extend beyond the pattern. the door openings using the large-size clips. Install

Bend these wires around a No. 12 edging wire. the door latch to complete the cage.

Position the ends and partition on the floor and The cages can be suspended from an overhead

fasten them using small hen-cage clips. Attach the support using six strands of No. 12 galvanized wire.

front and back sides of the conventional cages to the Attach a wire to each corner of the individual cages

bent-up flooring. Do not fasten the front section to for proper support.

flooring in the area where the doors will be located.

Fasten sides to the partition and ends.

Prepared by Dr. Tom W. Smith, Jr., Extension Poultry Science Specialist and Professor of Poultry Science

Mississippi State University does not discriminate on grounds of race religion, natural origin, sex, age, or handicap.

Information Sheet 1195

Extension Service of Mississippi State University, cooperating with U.S. Department of Agriculture. Published in furtherance of Acts of

Congress, May 8 and June 30, 1914. Ronald A. Brown, Director

You might also like

- Family Handyman Big Book of ProjectsFrom EverandFamily Handyman Big Book of ProjectsFamily HandymanNo ratings yet

- Cusca IepuriDocument2 pagesCusca IepuriDan FelixNo ratings yet

- Rabbit Housing 08-02 PDFDocument3 pagesRabbit Housing 08-02 PDFdevaanimator2No ratings yet

- Rabbit Housing 08-02Document3 pagesRabbit Housing 08-02jetgreenbulldogNo ratings yet

- Portable Chicken Mini-Coop Plan: FarmingDocument2 pagesPortable Chicken Mini-Coop Plan: FarmingJerry DoughertyNo ratings yet

- Build A YurtDocument8 pagesBuild A YurtPeter J Begley100% (2)

- DIY Stand Alone CatioDocument4 pagesDIY Stand Alone Catiods2084No ratings yet

- DIY Special CollectionDocument13 pagesDIY Special Collectionkristi ellisNo ratings yet

- Long Langstroth HiveDocument7 pagesLong Langstroth HiveWolfgangNo ratings yet

- MEN Portable Chicken CoopDocument3 pagesMEN Portable Chicken CoopDaniel CrookNo ratings yet

- MEN Portable Chicken CoopDocument3 pagesMEN Portable Chicken CoopDaniel CrookNo ratings yet

- 8x10 Lean To Shed 2022-09-04Document29 pages8x10 Lean To Shed 2022-09-04Steven 659No ratings yet

- Kg29 Cold FrameDocument1 pageKg29 Cold FrameErik HenryNo ratings yet

- When Nature Calls Outhouse PlansDocument18 pagesWhen Nature Calls Outhouse PlansMoreMoseySpeed100% (6)

- DIY Three-Bin Compost System: MaterialsDocument2 pagesDIY Three-Bin Compost System: MaterialsTomásNo ratings yet

- Homes For Wildlife Ii Plans: PART VII: Backyard ManagementDocument4 pagesHomes For Wildlife Ii Plans: PART VII: Backyard ManagementPeter OliverNo ratings yet

- Building Your Own Composting Bin: Designs For Your CommunityDocument27 pagesBuilding Your Own Composting Bin: Designs For Your CommunityuglymaskNo ratings yet

- Protect Your Home from Malaria-Spreading MosquitoesDocument9 pagesProtect Your Home from Malaria-Spreading MosquitoesDwi Astika SariNo ratings yet

- TLE 10 Worksheet Q3 Wk34notesDocument12 pagesTLE 10 Worksheet Q3 Wk34notesLu tenantNo ratings yet

- Portable Box Stand: How To Build ADocument5 pagesPortable Box Stand: How To Build AJohn E FosterNo ratings yet

- DIY High Tunnel PlansDocument34 pagesDIY High Tunnel PlansOjo de AguaNo ratings yet

- Build A Colonial-Style Storage Shed - Popular MechanicsDocument9 pagesBuild A Colonial-Style Storage Shed - Popular Mechanicsrockhard4wd9696No ratings yet

- Build Your Own Hydroponic System EconomicallyDocument30 pagesBuild Your Own Hydroponic System EconomicallyDaniel MonsalveNo ratings yet

- Layens Hive - Free Plans - Natural BeekeepingDocument9 pagesLayens Hive - Free Plans - Natural BeekeepingjoseNo ratings yet

- Chicken CoopDocument12 pagesChicken Coopmang davidNo ratings yet

- Work Bench 3Document4 pagesWork Bench 3- yAy3e -100% (1)

- How To Build A GreenhouseDocument12 pagesHow To Build A GreenhouseSabrinaMeNo ratings yet

- Yurt Construction DocumentDocument26 pagesYurt Construction DocumentsepaulsenNo ratings yet

- Diy How ToDocument36 pagesDiy How ToHenry Kirkpatrick100% (2)

- Vertical Garden How ToDocument2 pagesVertical Garden How Tosofsof007No ratings yet

- Falco AriaDocument3 pagesFalco AriaFernando G. FerreiraNo ratings yet

- How To Build A PorchDocument4 pagesHow To Build A PorchRi SovannaphumiNo ratings yet

- How To Build Your Own Recycled Plastic Bottle Greenhouse - Education ProjectDocument6 pagesHow To Build Your Own Recycled Plastic Bottle Greenhouse - Education ProjectAn Energy-Efficient Solar-Heated Greenhouse100% (4)

- Industrial Chic Concrete and Pipe Shelves TutorialDocument1 pageIndustrial Chic Concrete and Pipe Shelves TutorialKátia ReisNo ratings yet

- Free Chicken Coop PlansDocument4 pagesFree Chicken Coop Plansbrentx75% (4)

- Build Rabbit Hanging CagesDocument9 pagesBuild Rabbit Hanging CagesProfessional RabbitryNo ratings yet

- HowtomakeabatboxDocument1 pageHowtomakeabatboxElHondoNo ratings yet

- PressedDocument6 pagesPressedOoogittttty BoooggiiitttyyNo ratings yet

- Easy Full Platform BedDocument11 pagesEasy Full Platform BedAdnan HasanovicNo ratings yet

- How to build a Recycled Plastic Bottle Greenhouse in 8 easy stepsDocument6 pagesHow to build a Recycled Plastic Bottle Greenhouse in 8 easy stepsJenny Ball100% (1)

- Catalogo AvinetDocument20 pagesCatalogo AvinetJCNo ratings yet

- Open Mesh Floor HiveDocument5 pagesOpen Mesh Floor Hivegreenelephant150No ratings yet

- DIY Basement Fallout Shelter Lean-To DesignDocument4 pagesDIY Basement Fallout Shelter Lean-To DesignLo Shun FatNo ratings yet

- DIY Broadband Absorber Panels and Corner Bass TrapsDocument11 pagesDIY Broadband Absorber Panels and Corner Bass Trapsnorman batsNo ratings yet

- Procurement of Cage Materials: Bamboo. Bamboo Poles Should BeDocument5 pagesProcurement of Cage Materials: Bamboo. Bamboo Poles Should BeMuhammad Musfiq AmrullahNo ratings yet

- BookcasePlans FW1124 - ClassicCaseDocument7 pagesBookcasePlans FW1124 - ClassicCasebernardcornfeld100% (1)

- Foxhole RadioDocument6 pagesFoxhole RadioSusanoo12No ratings yet

- Barbecue Tool Cabinet: Click Here To Download Detailed InstructionsDocument3 pagesBarbecue Tool Cabinet: Click Here To Download Detailed Instructionsmytizplicky100% (1)

- Avinet CatalogDocument20 pagesAvinet Catalogdora_grebeNo ratings yet

- Lean ToToolShedDocument18 pagesLean ToToolShedYolohtli Vazquez Castaneda100% (1)

- Building-a-16x24-pole-barn-plansDocument38 pagesBuilding-a-16x24-pole-barn-plansPB50% (2)

- Drifter 12 L: A Small Trimaran For Paddling or SailingDocument54 pagesDrifter 12 L: A Small Trimaran For Paddling or SailingPaulo Cunha100% (1)

- Macrame for Home Decor: 40 Stunning Projects for Stylish DecoratingFrom EverandMacrame for Home Decor: 40 Stunning Projects for Stylish DecoratingRating: 4 out of 5 stars4/5 (2)

- Traps for Feathered Game - A Historical Article on the Methods and Equipment for Trapping BirdsFrom EverandTraps for Feathered Game - A Historical Article on the Methods and Equipment for Trapping BirdsNo ratings yet

- A Guide to Making Your Own Fishing-Rod and TackleFrom EverandA Guide to Making Your Own Fishing-Rod and TackleRating: 5 out of 5 stars5/5 (1)

- Handmade Houses and Feeders for Birds, Bees, and ButterfliesFrom EverandHandmade Houses and Feeders for Birds, Bees, and ButterfliesNo ratings yet

- Traditional Country Woodworking Projects: Plans for 18 Practical Indoor and Outdoor ProjectsFrom EverandTraditional Country Woodworking Projects: Plans for 18 Practical Indoor and Outdoor ProjectsNo ratings yet

- A Beginner's Guide to Home Sewing: 50 simple fabric projects for every room in the houseFrom EverandA Beginner's Guide to Home Sewing: 50 simple fabric projects for every room in the houseNo ratings yet

- Wills & Estates Fundamentals 9.1Document15 pagesWills & Estates Fundamentals 9.1SherryNo ratings yet

- InventHelp Brochures VIP-VIBE-Website-DatabankDocument8 pagesInventHelp Brochures VIP-VIBE-Website-DatabankSherryNo ratings yet

- How To Survive A Lightning StrikeDocument5 pagesHow To Survive A Lightning StrikeSherryNo ratings yet

- Contract of Purchase and Sale AddendumDocument1 pageContract of Purchase and Sale AddendumSherryNo ratings yet

- Delta Mitre SawDocument7 pagesDelta Mitre SawSherryNo ratings yet

- Climate Change Science A License To Steal'Document2 pagesClimate Change Science A License To Steal'SherryNo ratings yet

- Raising Chickens 101 How To Build A Chicken CoopDocument7 pagesRaising Chickens 101 How To Build A Chicken CoopSherryNo ratings yet

- Places To Hide Your GunsDocument3 pagesPlaces To Hide Your GunsSherryNo ratings yet

- How To Read CloudsDocument6 pagesHow To Read CloudsSherryNo ratings yet

- Management of The Small Flock of Chickens: R. Scott Beyer Poultry Specialist Animal Sciences and IndustryDocument4 pagesManagement of The Small Flock of Chickens: R. Scott Beyer Poultry Specialist Animal Sciences and IndustrySherryNo ratings yet

- Special Forces Caching TechniquesDocument26 pagesSpecial Forces Caching TechniquesSherryNo ratings yet

- Build A BarometerDocument1 pageBuild A BarometerSherryNo ratings yet

- Beginner's Guide To Raising ChickensDocument14 pagesBeginner's Guide To Raising ChickensSherryNo ratings yet

- Ammo Stockpiling GuideDocument15 pagesAmmo Stockpiling GuideSherryNo ratings yet

- Pet Emergency PreparednessDocument19 pagesPet Emergency PreparednessOngwehonweh0% (1)

- How To Raise Pigs as Part of Your Survival PlanDocument17 pagesHow To Raise Pigs as Part of Your Survival PlanSherryNo ratings yet

- Why You Might Want To Raise Ducks Over Chickens For Their Eggs And TemperamentDocument3 pagesWhy You Might Want To Raise Ducks Over Chickens For Their Eggs And TemperamentSherryNo ratings yet

- The Ultimate Survival Gear ChecklistDocument2 pagesThe Ultimate Survival Gear ChecklistSherryNo ratings yet

- Getting Started With ChickensDocument4 pagesGetting Started With ChickensSherryNo ratings yet

- What to save during an emergency: A guide to disaster preparednessDocument4 pagesWhat to save during an emergency: A guide to disaster preparednessSherryNo ratings yet

- How To Build A Back Yard Poultry HouseDocument2 pagesHow To Build A Back Yard Poultry HouseSherryNo ratings yet

- Survival Gear RecommendationsDocument7 pagesSurvival Gear RecommendationsSherryNo ratings yet

- Hatching ChickenEggsDocument6 pagesHatching ChickenEggsSherryNo ratings yet

- Compact Survival KitDocument10 pagesCompact Survival KitSherry100% (1)

- Survival Items & UsesDocument38 pagesSurvival Items & UsesSherryNo ratings yet

- Survival Items You Should HaveDocument5 pagesSurvival Items You Should HaveSherryNo ratings yet

- The First Item We Will Review Is The Smith & Weston M&P Tactical PenDocument12 pagesThe First Item We Will Review Is The Smith & Weston M&P Tactical PenSherry100% (1)

- Questions To Ask When Modifying Your GearDocument7 pagesQuestions To Ask When Modifying Your GearSherryNo ratings yet

- Multipurpose Items To Survive A CrisisDocument5 pagesMultipurpose Items To Survive A CrisisSherryNo ratings yet

- Repair welding Cr-Mo steels without PWHT techniquesDocument3 pagesRepair welding Cr-Mo steels without PWHT techniquesAnonymous nw5AXJqjd25% (4)

- Lab Report 2 - Cooling TowerDocument14 pagesLab Report 2 - Cooling TowerSeng Kong0% (2)

- PIPING SYSTEMS ARRANGEMENTDocument19 pagesPIPING SYSTEMS ARRANGEMENTNur SalimNo ratings yet

- Phase Diagrams in Materials Science-Massalski-MetTransDocument30 pagesPhase Diagrams in Materials Science-Massalski-MetTranssrikar vakaNo ratings yet

- Prediction of Riser Carbon Macrosegregation in Steel Castings Using Shrinkage Flow ModelDocument24 pagesPrediction of Riser Carbon Macrosegregation in Steel Castings Using Shrinkage Flow Modeldarwin_huaNo ratings yet

- Chilled Water System Installation Operation Maintenance Manual 2811 15340Document36 pagesChilled Water System Installation Operation Maintenance Manual 2811 15340MONANo ratings yet

- Disperse and Cationic Dyeable Tertiary Polyblend Fibres of Polypropylene: Cationic Dyeable Polyester: PolystyreneDocument4 pagesDisperse and Cationic Dyeable Tertiary Polyblend Fibres of Polypropylene: Cationic Dyeable Polyester: PolystyreneerpublicationNo ratings yet

- Rajasthan Technical University, Kota: SyllabusDocument1 pageRajasthan Technical University, Kota: SyllabusRitesh PatidarNo ratings yet

- Dynaflow Vs Stay Silv 15Document2 pagesDynaflow Vs Stay Silv 15Zeljko RisticNo ratings yet

- Final Ard Report 112 Vepari HardikDocument32 pagesFinal Ard Report 112 Vepari HardikHardik Kashyap VepariNo ratings yet

- Black and Decker - The Complete Guide To DIY Greenhouses - 2E (2017)Document243 pagesBlack and Decker - The Complete Guide To DIY Greenhouses - 2E (2017)JL75% (4)

- Arta 111 - Art and Artisan, Production Process, Medium, Technique, Curation, UnitasDocument60 pagesArta 111 - Art and Artisan, Production Process, Medium, Technique, Curation, UnitasJerwin Samson100% (2)

- Measuring Young's Modulus Using Strain Gauge on Cantilever BeamDocument9 pagesMeasuring Young's Modulus Using Strain Gauge on Cantilever BeamVarun SundarNo ratings yet

- Types of Foundation and Their Uses: Home About Contact Past Projects ServicesDocument34 pagesTypes of Foundation and Their Uses: Home About Contact Past Projects ServicesMitchell AndersonNo ratings yet

- 24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsDocument1 page24" (61 CM) Electric Single and Double Built-In Oven: Product Model Series Overall DimensionsHewa PCNo ratings yet

- Turnout 7Document79 pagesTurnout 7Suciu FlorinNo ratings yet

- Formability of Perforated Sheet Metals by FEADocument14 pagesFormability of Perforated Sheet Metals by FEAHari KrishnaNo ratings yet

- Design of Hydro Mechanical EquipmentDocument316 pagesDesign of Hydro Mechanical EquipmentTarunPatra100% (6)

- Effective Moduli of Continuous Fiber-Reinforced LaminaDocument21 pagesEffective Moduli of Continuous Fiber-Reinforced Laminakashish4uNo ratings yet

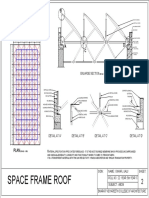

- Space frame roof structure designDocument1 pageSpace frame roof structure designChndrashekhar DombNo ratings yet

- Acrylonitrile Butadiene Styrene - Wikipedia, The Free EncyclopediaDocument4 pagesAcrylonitrile Butadiene Styrene - Wikipedia, The Free EncyclopediasanjayrajeNo ratings yet

- Metallurgy E-Matl., Lecture NoteDocument62 pagesMetallurgy E-Matl., Lecture Notemel118No ratings yet

- Ecospeed Propeller CoatingDocument4 pagesEcospeed Propeller CoatinghadietzNo ratings yet

- Ratings of Cables in Tunnels - The Heart of the MatterDocument3 pagesRatings of Cables in Tunnels - The Heart of the Mattersaghaee.rezaNo ratings yet

- ICC Review of Plycem Panels PDFDocument2 pagesICC Review of Plycem Panels PDFAnonymous Swxkz6OsEd100% (1)

- Loading Action On BuildingsDocument33 pagesLoading Action On BuildingsOne The100% (3)

- Metric Design Guide: (PBS-PQ260)Document53 pagesMetric Design Guide: (PBS-PQ260)Sunil IistNo ratings yet

- Static Analysis Using Finite-Element Method (FEM) For Micropiles Application Evaluation Empirical and Numerical Perspective PDFDocument10 pagesStatic Analysis Using Finite-Element Method (FEM) For Micropiles Application Evaluation Empirical and Numerical Perspective PDFLucas MartinsNo ratings yet

- Air Liquide BS 50-3-2,5Document1 pageAir Liquide BS 50-3-2,5kuraimundNo ratings yet

- Design of Monorail BeamDocument5 pagesDesign of Monorail BeamcadsultanNo ratings yet