Professional Documents

Culture Documents

SANS 347-2012 - EDITION 2 - Categorization and Conformity Assessment Criteria For All Pressure Equipment

Uploaded by

johndup0 ratings0% found this document useful (0 votes)

100 views51 pagesPressure vessel requirements

Original Title

SANS 347-2012 - EDITION 2 - Categorization and conformity assessment criteria for all pressure equipment

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPressure vessel requirements

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

100 views51 pagesSANS 347-2012 - EDITION 2 - Categorization and Conformity Assessment Criteria For All Pressure Equipment

Uploaded by

johndupPressure vessel requirements

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 51

ISBN 978-0.626-25419-3 SANS 347:2012

Ezition 2

SOUTH AFRICAN NATIONAL STANDARD

Categorization and conformity assessment

criteria for all pressure equipment

Published by SABS Standards Division

4 Dr Lategan Road Groenkloof & Privato Bag X11 Pretoria 0001

‘Tol: #27 12 428 7914 Fax: #27 12 344 1568

sndard was downloaded on 2012-04-28 14:66 hy Mrs, Petro Noite of MegChom Engineering And Drafting Services

2 copying and networking prohibited.

Copyright protected.

Single-user license

SANS 347:2012

Edition 2

Table of changes

Change No.| Date ‘Scope

Foreword

This South Affican standard was approved by National Committee SABS TC 68, Vessels under

pressure, in accordance with procedures of the SABS Standards Division, in compliance with

annex 3 of the WTO/TBT agreement

‘This document was published in March 2012.

‘This document supersedes SANS 347:2010 (edition 1.1),

This document was written in order {o support a specific South African Regulation and, of necessity,

includes references to South African legislation. it therefore might not be suitable for direct

‘pplication in othor jurisdictions where conflicting legisiation exists.

Reference Is made In 1.2, 3.1.4, 31.10, 3.1.13, 41.2, 5.1.4, 5.2.5, 6.2.6.4 (two references), 5.2.5.2,

52.63, 5.65, 8.5(d), 56.7(0), 56.8, 66.12, 5.15.1(b) and clause 8 to “relevant national

legistation”. In South Africa this means the Pressure Equipment Regulations (PER) in the

‘Occupatiorial Health and Safely Act, 1993 (Act No. 85 of 1993).

Reference is made in clause 3 to "relevent national legislation’. in South Africa this means the

Pressure Equipment Regulations and Major Hazard Installation Regulations in the Occupational

Health and Safely Act, 1993 (Act No. 85 of 1993).

Reference Is made in the note to 3.1.13 to “relevant national legislation’. in South Africa this means

the Occupational Health and Safety Act, 1993 (Act No. 85 of 1993) or the Mine Health and Safety

Act, 1926 (Act No. 20 of 1998) (or both), as applicable,

Reference Is made in C.2.1 (b), 0.2.2 (two references) and in the NOTE to C.2.2 (two references) to

"relevant national legisation’. In South Arica this means Regulation 7.4 of the Pressure Equipment

Regulations in the Occupational Health and Safety Act, 1999 (Act No. 85 of 1998).

Referonco is made in C.3.1(¢) to ‘relevant national legisiation’. In South Africa this moans

Regulation 7.9(0) of the Pressure Equipment Regulations in the Occupational Health and Safety

‘Act, 1983 (Act No. 85 of 1993).

Reference is made in C.4.2 to “relevant national legislation’. in South Aftica this means the

Pressure Equipment Regulation (PER).

Annoxes A, B and C form an integral part of this document.

‘Copyright protected. This standard was dovmioaded on 2012.04.23 14:88 by Mrs. Potro Norte of MegChem Engineering And Draiting Services

‘Singlesuser license only; copying and notworking prohibited.

SANS 347:2012

Edition 2

Introduction

‘The «isk of injury arising from defects in the construction of pressure equipment and non-pressure

equipment is related to the consequences should failure occur during use. These consequences ere

primarity dependent on the hazard level. An increased hazard level requires an increased degree of

independent conformity assessment or verification. Should a certified management system be

controlled by the manufacturer, the involvement of the approved inspection authority (AIA) will be

decreased,

Although this document is based on the European Directive, changes have been made to

accommodate specific requirements in the vessels under pressure regulalions, renamed as the

Pressure Equipment Regulations in the Occupational Health and Safely Act, 1993 (Act No. 85

of 1993). Every effort has been made to ensure that the manufacture of preseure equipment is

‘carfiad out ina safe manner so as to prevent injury to the user as well as fo the public.

opytight protected. This standard was download on 2012.04.29 14:86 by Mrs, Potro Nore of MegChom Enginooring And Drafting Services

‘SIngle-userliconse only: copying and networking prohibited,

SANS 347:2012

Edition 2

Contents

Page

Foreword

Introduetion : 1

1 Scope 3

2 Normative references - 3

3 Definitions and abbreviations 4

4 Criteria for determining hazard categories .. 7

4.4 Hazard categories 7

4.2 Criteria for categorization ee 7

43° Categorization : 8

44° Gategorizalion graphs 9

6 Conformity assessment criteria .. 2

5.4 General a teeter Fbaltalaar et

5.2 Final assessment a fone, 23

8.3 Module A - Internal production control... 24

544 Module At ~Inteal manufactuing checks with monitoring of

the final assessment rnc z 26

5.5 Module 8 - Type verification 26

8.8 Module Bt ~ Design verification : eter

5:7 Module C1 ~ Conformity to type... coi 5

5.8 Module D ~ Production quality assurance : 20

5.9 Module Dt ~ Production quality assurance te tara

5.10 Module E ~ Product quality assurance 31

8.44 Module Et — Product quailty assurance sonnm : 32

8.42. Module F ~ Product verification run Fa aldildlet ae 2

8.13. Module G~ Unit verification 33

8.14. Module H — Full quaity assurance 34

8.48 Module Ht — Full quallly assurance with design verification and

special surveliance of the final assessment .... soon 35

6 Essential requirements for construction os esnnnnennnenesnnonee 36

7. Quality system requirements nnn 38

8 Marking at

Annex A (normative) Schedule of hon and ealely standards a8 approved by

the Department of Labour... ‘ cet

Annex B (normative) Design and construction requirements for piping aie 45

Annex (nomalve) Conformity assessment procedures for stationary

pressure equipment 46

Bibliography .... : ar

2

Copyright protected. This standard was downloaded on 2012-04-23 14:66 by Ms. Petro Norljo of MogGhem Engineering And Drafting Services

‘Single-user license only; copying and networking prohibited.

SANS 347:2012

Edition 2

Categorization and conformity assessment criteria for all pressure

equipment

4 Scope

1.4 This standard specifies the criteria to be used for the categorization and conformity

assessment, as vell a6 the selection of health and safety standards (see annex A) of pressure

equipment (metalic end non-metalic) for use by but not Imited to the manufacturer, users,

Ccatttcation bodies and approved inspection aulheriies.

1.2. This standard is also applicable to the cerification, re-cotiication, modification or reper of

piessure equipment (metalic end non-metallic) manufactured under the relevant national legislation

{See foreword), as defined by the relovant statutory regulations for pressure equipment

2 Normative references

The following referenced documents are indispensable for the application of this document. For

dated references, only the edition cited apps. For undated references, tho latest edition of the

referenced document (including any amendments) applies. Information on cusrenly valid national

‘nd infemationel standards can be obtained from the SABS Standards Division.

2.1 Standards

‘API 600, Steel gale valves - Flanged and butt-velding ends, bolted bonnets.

[ASME Section VIll— Division 1, Rules for consiuetion of pressure vessols.

[ASME 816.24, Valves anged, threaded and welding end.

ASME B3t, Code for pressure piping.

SANS 2824/80 9894, Qualty requirements for fusion wolding of metalic materials (ll pats).

SANS S001/SO 9001, Qually management systems — Requirements

SANS 10019, Transportable containers for compressed, dissolved and liquefied gases ~ Basic

design, manufaclure, use and maintenance.

SANS 10227, Criteria for the operation of inspection authorities performing inspection in terms of

the Pressure Equipment Regulations.

SANS 10228, The identifcation and classification of dangerous goods for transport.

Copytight protected, This standard was downloaded on 2012-04-23 14:88 by Mis. Polo Nore of MegChem Engineering And Drafting Services

Singlo-user license only: copying and notworking prohibited.

SANS 347:2012

Edition 2

SANG 17020ISO/IEC 17020, General criteria for the operation of various types of bodes

‘performing inspection

SANS 17024SONEC 17021, Conformity assessment ~ Requirements for bodies providing aucit

‘and cerfifcation of management systems.

2.2 Other publications

Couneil Directive 87/648/EEC of 27 June 1967 on the approximation of laws, regulations and

administrative provisions relating to the classification, packaging and labelling of dangerous

‘substances.

3 Definitions and abbreviations

For the purposes of this document, the defnitions and abbroviations in the relevant statutory

Tegulations for pressure equipment (e.g. the relevant national legislation (see foreword) and the

following apply.

3.1 Definitions

344

approved certification body

body for management system cetification in accordance with SANS 17021 and approved by the

regulatory authority and accredited by @ government-endorsed national accreditation body (2.9.

SANAS)

342

approved inspection authority

AIA

‘South African organization that is approved by the regulatory authority in terms of SANS 10227

34.9

assembly

{group of components put together by @ manufacturer to form an integral and functional whole

NOTE. The assembly of pressure equipment on the silo and under the responsibilty of the user, as in the

case of industialinstafaons fs not considered tobe an assembly,

34.4

cortificate of conformity

certificate of manufacture

written dectaration of conformance to the relevant health and safety standards) and to the relevent

national legislation (see foreword)

cortffed quality system

quality system for production, final inspection and testing, that is certified by an approved

cartification body

34.8

conformity assessment

process undertaken by the manufacturer and when applicable by the AIA in order to demonstrate

that the statutory requirements are satisfied

Copytight protected. This standard wes downloadod on 2012-04-23 14:66 by Mrs, Potro Norte of NlogChom Engineering And Drafting Services

‘Single-userliconso only; copying and networking prohibite,

SANS 347:2012

Edition 2

347.

conformity assessment modules

modular approach to conformity assessment, thereby subdividing i info a number of independent

activities

348

dofect

imperfections by nature or accumulated effect that render a part or product unable to comply with

‘minimum applicable acceptance standards or specifications

NOTE Defects are pertinent to design, materiels, febricalion, inspection, testing, qualicaton and

certification,

3.1.9

hazard category

classification of pressure equipment according to risk

3.4.40

health and safety standard

code of construction

standard thal is approved in terms of the relevant national legislation (see foreword) by the relevant

regulatory authoriy, and thal contains requirements for the design, manufacture, repair,

‘modification, inspection and testing of pressure equipment (see annex A)

3AM

inspection

examination or measurement to verify whether an item or activity complies with specified

requirements

34.42

prossure accessory

device with an operational function and having an identifiable pressure-bearing housing

NOTE The device has « function adeitonal to that of containing pressure.

3.4.13

pressure equipment regulations

PER

pressure equipment regulations in the relevant national legislation (see foreword) for use in South

‘Africa and enforced by the regulatory authority

34.14

pressure vessel

housing designed and manufactured to contain a fuid under a design pressure equal to or greater

than 60 kPa

NOTE A pressure vessel may be composed of moro than one chamber.

34.18

regulatory authority

authorly Which is legally charged with the enforcement of the requirements of the legislation that

relates to pressure equipments in South Africa

Copyright protected, This standard was downloaded on 2012.08.23 14:86 by Mrs. Potro Nome of MegChem Enginsering And Dratting Services

‘Singlesuser license only; copying and networking prohibited.

SANS 347:2012

Edition 2

34.16

safety accessory

device designed to protect pressure equipment against the allowable limit being exceeded, which

includes the following:

a) device for direct pressure limitation, such as safety valves, bursting disc safety device, buckling

rods, controled safely pressure relief systems (CSPRS); and

©) limiting devices, which elther activate the means for correction or provide for shutdown or

shutdown and lockout, such as pressure switches or temperature switches or fluid level switches

and safety-related measurement and regulation (SRMCR) devices.

AAT

surveillance

act of monitoring or ebserving to verify whether an item or activity complies with specified

Fequirements,

3.4.48

third party

organization performing inspection and test actives indepondenty ofthe parties involved

34.48

transportable pressure equipment

equipment constructed to be transported under prossure with a maximum water capacity of $ 000

8.9. transportable gas container

3.4.20

type approval

‘once-off approval of the design, inspection and testing of pressure equipment

34.24

unstable gas

g28 oF @ Vapour fable to transform Itself, spontaneously and suddenly, producing @ pressure

Variation, when this tranaformation happens in a confined volume under the only effect of a fow

variation of an operating parameter e.g, acetylene, methyl acetylene, viny! fluoride

3.4.22

verification

act of reviewing, inspecting, testing, checking, auditing or otherwise determining and documenting

whether items, processes, services or documents comply with specified requirements,

3.2 Abbreviations

AIA approved inspection authority

CB approved certification body

CE European certificate

IPE inspector of pressurized equipment

PER pressure equipment regulations,

PS design pressure

SEP sound engineering practice

TP test pressure

Copytight protected. This standard wae downloaded on 2012.04.23 14:88 by Mrs. Potro Nonto of MogChem Engineering And Drafting Services

Singlo-user conse only; copying and networking prohibited.

SANS 347:2012

Edition 2

4 Criteria for determining hazard categories

4.1 Hazard categories

4.4.4. In order to determine how the statutory regulations will apply to specific items of pressure

equipment, a manufacturer shall classify the equipment into one of the following five hazard

categories:

4) sound engineering practice (SEP),

b) category |,

©) category I;

«) category Il; or

©) category NV.

4.1.2. Sound engineering practice (SEP) applies to equipment that is not subjected to conformity

assessment but that ehali be designed and manufactured in accordance with sound engineering,

practioe (best practice) In order to ensure safe use. Such equipment shall ensure that design and

‘manufacture take into account all the relevant factors that influence safety during its intended

lifetime (see clause 6). The equipment shall have instructions for use and shall bear the

identification of the manufacturer. SEP equipment is nol required to meet any other of the essential

statutory requirements listed In the relevant national legislation (see foreword)

4.4.3 For equipment categorized as category | equipment, the manufacturer shall ensure that such

equipment complies with the requirements of the applicable health and safely standard(s). The

‘manufacturer shall issue a certificate of conformity confirming that the equipment is manufactured in

accordance with the applicable code of construction, The design requirements of such equipment

shall be in accordance with the applicable health and safety standard(s).

4.1.4 The design of pressure equipment for category ll and above needs to be approved by an

appropriately registered professional person (Le. registered Pr. Eng. Pr. Technologist or Pr. Cert.

Eng.) (competent in this field) to a health and safety standard and verified by the AIA or caritication

body a8 applicable, Design requirements for piping shall be as given in annex B.

In the case of countries which do not fall within the recognition agreements (e.g. Washington accord

tlc), the design engineers with equivalent qualifications and relevant experience may be accepted

through an agreement by verification engineer of an AIA for designs done outside of South Africa,

4.1.5 Imported pressure equipment in accordance with 5.2.6.1, 6.2.5.2 or 6.2.6.3 does not have to

meet the requirements of 4.1.4,

4.2 Criteria for categorization

In order to determine which category an item of equipment falls into, the manufacturer shail identity

the followlng:

a) the type of pressure equipment, for example,

1) pressure vessels,

2) steam generators,

3) piping,

Copytight protected. This standard was downloaded on 2042-04-73 14:56 by Ms. Petro Nonje of MegChem Englnosring And Drafting Services

‘Single-user license only: copying and networking prohibited.

SANS 347:2012

Edition 2

4) pressure accessories,

6) safety accessories; or

§8) transporlable pressure equipment;

») the state ofthe intended fluid contents ~ gas or quid; and

©) the fluid group of the intended contents ~ group 1 or group 2 (see table 1).

Table 1 — Product classifications and relevant figures

1 2[sT+[s,_ 6 [7lele[ol nella

Transportable

Equipment ressur

equloment Gry [ie pase eee saa eee pressure equipment

State of contents | Gas | Liquid | generator! Gas | Liquid? | Gas | Liquid”

Fluid group? if2tt [2 Teliflet [2 [2

Refertofgue | it2{e]4{ 5 jel7lelolwla|wol

NOTE_For e-phase flow, the equipment should be categorized fo the higher risk

For categorization of transportable pressure equipment figures 2 or 7 and 4 or 9 may be used es

‘appropriate, Pressure accessories fr equipment associated with igure 10 shall also be assessed with

figure 10. Vales having an internal voluma fass than 0,1 L shell be deemed to be equal 00.1 L forthe

purpoee of defining the hazard category I ralation to figure 10,

No pockets of gas may form above the quid in the equipment, including steam.

Fluid group 1 = dangerous; Fuld group 2 = not dangerous (509 4.3.1.

4,3 Categorization

4.34 Fluld groups

4.3.1.4 Fluid group 1

‘This group comprises fluids classified as dangerous substances (in accordance with SANS 10228

for tansportable pressure equipment or Council Directive 67/648/EEC for the rest of the pressure

equipment), fluids that are

2) explosive,

) extremely flammable,

©) highly flammable,

6) flammable (where the maximum allowable temperature is above flashpoint),

©) corrosive,

9 toxic,

©) oxidizing, and

+) saturated or superheated steam.

Copytight protected. This standard wae downloaded on 2012-04-29 14:66 by Mrs. Petro Norie of MegChom Enginooring And Drafting Services

‘Singlesisorliconse only; copying and networking prohibited.

SANS 347:2012

Edition 2

In certain inetllation(e) tho user may classify the fluid. This shall be part of the final decumentation.

4.3.4.2 Fluld group 2

‘This group comprises fluids other than those in fluid group 4

4,3.2 Prossure accessories

Figures 1 to 4 for vessels or figures 6 to 9 for piping are applicable depending on whether the

volume (V) or the nominal size (DN) is appropriate for classification of the pressure accessory.

Where both the volume and the nominal size are eppropriale, the pressure accessory shall be

classified in the higher category.

Piping components need not be defined s pressure accessories when purchased and certified in

accordance with a referenced standard listed in the applicable health and safety standard{s), The

‘manufacturer of the equipment that uses the piping components shall remain liable for their integrty.

Examples would include standard valves that comply with ASME 816.24 or API 600 when used in

piping In accordance with ASME 831.3.

4.3.3 Safety accessories

‘These are generally classified as category IV. Safety accessories manufactured for specific

equipment shall at least be classified as the same category as the equipment thal they protect

4.3.4 Assemblies

4.3.4.4 Assemblies shall be subjected to a global conformity assessment procedure comprising:

a) assessment of each item of pressure equipment making up the assembly which has not been

previously subjected to a conformity assessment procedure and to a separate marking; the

assesement procedure shall be determined by the catagory of each item of equipment;

») the assessment of the integration of the various components of the assembly which shall be

determined by the highest category applicable to the equipment concemed other than that

‘applicable to any safely accessories; and

©) the assessment ofthe protection of an assembly against exceeding the permissible operating limits

shall be conducted in the light of the highest category applicable to the items of equipment to be

protected.

4.3.4.2. Fitting a valve to transportable pressure equipment for dangerous fluids is exempt from

compliance with this clause (see also SANS 10019).

4.4 Categorization graphs

4,44 General

Depending on the requirements of 4.2, the relevant of figures + to 9 shall be used to determine the

applicable hazard category (SEP, | Il Ill or IV) for pressure vessels, steam generators, piping and

transportable pressure equipment for non-dangerous fuids.

Figure 10 applies epecitically to transportable pressure equipment for dangerous gas as defined in

the relevant statutory regulations for pressure equipment.

‘Copyright protected, This standard wes downloaded on 2012-04-25 14:86 by Mis, Petro Norio of MegGnem Englnocring And Drafting Services

Singl-usor| ; copying and networking prohibited,

SANS 347:2012

Edition 2

In the graphs in figures 1 to 10, the design pressure (PS) or test pressure (TP) as relevant is plotted

against the volume (V) or nominal size (DN). These graphs have up to five bands that relate to the

diferent hazard catagories (SEP, I, Ill or IV)

‘The manufacturer shail calculate and plot on the relevant graph, the design pressure and volume or

nominal size for the equipment that Is manufactured in order to identify which category such

‘equipment fas into. In general, the lower the design pressure and volume, the lower the category

for the equipment.

Each category shown in the graphs starts above the lower line and ends on the upper line.

‘The 50 kPa line belongs fo the category above it

44.2 Vessels

4.4.2.4 Dangerous gas

Vessels that fall within categories | or ! and that are inlended to contain an unstable gas, shal! be

classified as category Il (see figure 1).

10

‘Copyright protected, Tis standard was downloaded on 2012.04.28 14:58 by Mis. Potro Norts of MegChem Enginooring And Drafting Services

‘Singlo-aser license only; copying and networking prohibited.

Edition 2

SANS 347:2012

eB snosaGueg — sjasse 10} yder9 — } unig

AAA) suion

oF v0,

Tet]

| paieindas ion,

ea (Sa) einssaid ubiseq

000 +

oor

+ 00 001

| cos

"

Copyright protected. This standard was downloaded on 2012.04-25 14:56 by Mrs. Potro Norije of MegChem Engineering And Drafting Services

‘Single-user license only; copying and networking prohibited.

SANS 347:2012

Edition 2

4.4.2.2 Non-dangerous gas

Portable fire extinguishers up to 3.000 kPa shall be classified as at least category Il (see figure 2).

10000

ee

Volume (v)

Figure 2 — Graph for vessels — Non-dangerous gas

2h (ge) omnssoid uBis9q

12

‘And Drating Servicos

CCopytight protected. The standard was downloaded on 2012.04.25 14:86 by Mrs. Potto Norte of MegChem Engl

Single-usorlicoase only; copying and networking prohibited.

12012

Edition 2

SANS 347:

4.4.2.3 Dangerous liquids

Figure 3 shows the various categories for dangerous liquids contained in vessels.

‘spinby) snozs6ueq — sjassan 10} yderg — ¢ ain6iy

TW aunien,

ea (Ga) ainssaid uojsaq

eae

‘00008

13

3

-

3

2

=

z

3

i

8

z

7

:

i

7

q

:

i

:

&

&

i

i

R

&

z

i

i

SANS 347:2012

Edition 2

4.4.2.4 Non-dangerous liquids

‘Assemblies intended for generating warm water shall be subjected to a type approval.

i

5

Volume ()L

Figure 4 — Graph for vessel — Non-dangerous liquids

500000

‘eat (Sa) ainssaid ubssaq

44

Copytight protected. This standard was download on 2012.04.28 14:56 by Mrs, Petro Noro of MayChom Engineering And Draiting Services

‘Singl-user license only: copying and networking prohibited.

SANS 347:2012

Edition 2

4.4.3 Steam generators

‘The design of jacketed pressure cookers shall be subjected to a conformity assessment procedure

‘equivalent to at least one of the category Ill modules.

NOTE For more information on conformity assessment procedures fer stationary pressure equipment, st

‘annex C,

10000

atte

3.000

Volume (¥) L

Figure § ~ Graph for steam generators

7

= ie

2 2) (Sa) eunsseid uBise

15

Copyright protected. This standard was downloaded on 2012-04-28 14:66 by Mrs. Potro Noro of MogChom Enginooring And Dralting Sorvicot

Single-user cense only; copying and networking prokibited.

SANS 347:2012

Edition 2

4.44.4 Dangerous gas

categories | or Il shall be classified as

Piping that is intended for unstable gases that fall wil

category Ill

eta

oonz

000 &

‘seB snose6ueg — Buydid 404 ydexs — 9 aunbis

008

2g (Si) oMnssord uBiEsq

16

“This standard was downloaded on 2042-04-28 44:66 hy te Potro Noro of MogChem Englnoeting And Drafting Services

@ only; copying and networking prohibited.

SANS 347:2012

Edition 2

4.44.2 Non-dangerous gas

All piping that contains fluids at a temperature greater than 350 °C (not applicable to non-metallic,

Piping) and that fas into category i shall be classified as category Ill.

oT

400

‘Nominal slameter (ON) mm

Figure 7 —~ Graph for piping — Non-dangerous gas.

100000

10000 ~

e244 (Sd) eunsseid u63s00)

200000

47

Copyright protected. This standard was downloaded on 2012-04-28 14:58 by Mr. Potro Norio of MlegChem Engineering And Drafting Services

‘Single-usorticonso only; copying and networking prohibited.

SANS 347:2012

Edition 2

4.4.4.3 Dangerous liquids

Figure 8 shows the various catagories for dangerous liquids contained in piping.

‘spinby| snoso6ueg — 6uydid 404 yderg — 9 ain613

vst

0001 005

772s

I

ww (Na) sarawe eULON

a (Sa) eunssaud ufisoa,

SeENo

eck

vt J 020008

' 900002

iH

18

Copyright protected. This standard was downloaded! on 2012.04.23 44:58 by Mis. Polro Norte of MegChem Enginooring And Drafting Services

Hiconse only; copying and networking prohibited.

12012

Edition 2

SANS 347:

4.4.4.4 Non-dangerous liquids

Figure 9 shows the various categories for non-dangerous liquids contained in piping.

‘spinb| snoseBuep-uoN — Budid 104 yep — 6 aunBia

001

‘ww (1NQ) soiowerp jeumON

a

i g

£

Ee

= 000

soosz®

00008

' eooooe

19

Copyright protected, This standard was downloaded! on 2012-04-25 14:55 by Mr, Potro Noro of MegChem Enginooring And Drafting Services

‘Singlesuserlcense only; copying and notworking prohibited.

SANS 347:2012

Edition 2

4.4.5 Transportable pressure equipment for dangerous fluids

Figure 10 shows the verious categories and for dangerous gas contained in transportable pressure

equipment.

bates,

1900 000 1 500.000

+100 000

Volume 1)

Figure 10 — Graph for transportable container and vessele for dangerous gas

g

ea (a) annssoid 801,

20

‘Copytight protected, This standard was downloaded on 2012-04-23 14:58 by Mrs. Potro Norio of MegChem Enginooring And Drafting Servicos

‘Singl-ueer license only: copying and networking prohibited.

SANS 247:2012

Edition 2

8 Conformity assessment criteria

5.1 General

5.1.1. Befote putting presaure equipment classified as either hazard category |, I, Ill or IV on the

market, such equipment shall be subjected to the procedures in the appropriate conformity

‘assessment modules (see modules A to H1) in 5.3 to 6.15 (inclusive)

‘The modules for products in categories Il, Il! and IV require the involvement of an independent

ody, (certfcation body, AIA or third-party organization) either in the approval and monitoring of the

manufacturer's quality system, or in direct product inspection,

‘Third-party organizations, when approved by the regulatory authority, may also carry out the

approval of welding procedures and personnel, including non-destructive testing personnel, 2

required for pressure equipment assemblies classified es category I, Ill and IV. For direct product,

inspection the manufacturer shall appoint the AIA if not appointed by the buyer or user of tho

equipment,

Modules differ according to the type of assessment (for example, documentary checks, type

approve, design approval, quality assurance) and the organization carrying out the assessment (i.

the manufacturer and AIA or a certiication body).

‘See annex C for specific requirements pertaining fo ASME pressure equipment.

6.1.2 According to the category of the equipment, manufacturers shail use the modules as given in

this standard and table 2 to allow for proper choice according fo application. The categories for

traneportable containers are given in table 3,

NOTE. ‘The modules attributed toa highar hazard category may aso be used in the lower catedories

5.1.3 Assemblies shall be subjected (o a global conformity assessment procedure comprising:

.) assessment of each item of pressure equipment making up the assembly that has not been

previously subjected to a conformity assessment procedure and to a separate marking: the

assessment procedure shall be determined by the category of each item of equipment;

b) the assessment of the integration of the various components of the assembly shall be

determined by the highest category applicable to the equipment concemed other than that

applicable to any safely accessories;

‘the assessment of the protection of an assembly against exceeding the permissible operating

limits shall be conducted in the light of the highest category applicable to the items of equipment

© tobe protected and

) Whereas this global conformily assassment procedure relates to assemblies composed of

several pieces of pressure equipment assembied to consiitute an integrated and functional

‘whole; whereas these assemblies may rango from simple assemblies such as pressure cookers

to complex assemblies such as water lube boilers; whereas, if the manufacturer of an assembly

intonds it fo be placed on the market and put into service as an assembly - and not in the form of

its constituent non-assembled eloments - that assembly shail conform to this global conformity

assessment procedure; whereas, on the other hand, this global conformity assessment

procedure does not cover the assembly of pressure equipment on the site and under the

responsiblity ofthe user, as in the case of industrial installations.

2

Ccopytight protected. This standard was downloaded on 2012-04-25 14:66 by Mrs. Petco Norjo of MoyChom Engineering And Oratting Sorvcs

‘Single.usorlleonse only; copying and networking prohibited.

SANS 347:2012

Edition 2

5.4.4 Certificate or declaration of conformity and marking

‘Once conformity assessment has been completed, and ifthe equipment or assembly compiles with

the provisions of the relevant national legislation (see foreword), the manufacturer shall be required

1 affic the marking to each item of pressure equipment or assembly and draw up a declaration of

conformity

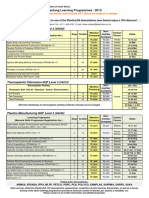

Table 2— Conformity assessment modules for each category of pressure equipment

excluding transportable pressure equipment for dangerous fluids

1 2 3 4 5

Conformity assessment modules*

Hazard Manufacturer without Manufacturer with

category | _certfied quality systom certified quality system

‘Single product | Serial production | Single product | Sertal production

n A A

u a oO Di et

Bird

m Bite e+c1 # or

BYE

v 6 BF Ht 80

‘A = internal production control

|A1 = internal manufacturing checks with mentering of the final assessment

B= type verification

design vesication

conformity fo type (end verifation of final assessment)

1D = production qually assurance for final inspection and! testing

D1 = production quality assurance fr final inspection and testing

= product quality assurance for firelinspection and testing

Et = product quality essurance fr final inspection and testing

F = product verifeation

& = unitveritcation

H = ull qualty assurance

Hi = full ually essurance with design verifcation and special surellance ofthe

final assessment

7 Cantormily assessment modules selected for serlal and single production are

Injerehangeable,

22

Copyright protected. This stondardl was downloaded on 2042-04-20 14:66 by Mis. Petro Norio of MogChom Engineering And Dratting Sorvicos

Single.userleense oni; copying and networking prohibited.

SANS 347:2012

Edition 2

Table 3— Conformity modules for transportable containers

and vessels for dangerous fluids.

7 2 3 a 3

Conformity assessment modules*

Hazard Manufacturer without anufacturor with

category | __cortied quality syetom cori qual system

Single product | Serial production | Single product [Serial production

1 AL A OF et

T BIE +61 4 en

Bre

W o ooF tH B20

intemal manafacring checks wih montoring othe fal assessment

type verication

design verfcation

Conformity to type (and verification offal assessment)

production quality assurance for fina inspection and testing

production quality assurance for final Inspection and testing

product qualy assurance for final Inspaction and testing

product quay assurance for fina inspection and testing

product verification

nit verifcaton

full quality assuranco

{ull quality assurance with design veriicaton and special survellance ofthe

final assessment

* Conformity assessment modules solected for serial end single production are|

Interchangeable.

5.2 Final assessment

6.2.4 General

Pressure equipment shall be subjected (o a final assessment by the manufacturer as described in

5.2.2 to 6.24 (inclusive). AIA shall also carry out final assessment as per conformity assessment

modules C1 (monitoring), E1, F, G, H1

6.2.2 Final inspection

Pressure equipment shall undergo a final inspection to assess visually and by examination of the

accompanying documents compliance with the requirements of the applicable heath and safety

standard(s). Tests carried out during manufacture may be taken into account. In order to comply

with the safety requirements, the final Inspection shall be canted out internally and extemally on

avery part of the equipment, where appropriate, In tho course of manufacture (e.g. where

‘examination during the final inspection is no longer possibie).

23

Copyright protected. This standard was downloaded on 2012-04-28 14:66 by Mrs. Potro None of MeyChem Engineering And Drafting Services

‘Singlo-user tense only; copying and networking prohibited.

SANS 347:2012

Edition 2

5.2.3 Prossure test

Final assessment of pressure equipment shall include a test for the pressure containment aspect,

‘which will normally take the form of a hydrostalic pressure test al a pressure at least equal, where

appropriate, to the value specified in the applicable health and safety standard(s).

For category | series-produced pressure equipment, this test may be performed on a statistical

basis

‘Where the hydrostatic pressure test is harmful or impractical, other tests of a recognized value may

be carried out. For tests other than the hydrostatic pressure test, edditional measures, such as non-

destructive tests or other methods of equivalent validly, shall be appied before those tests are

carfied out.

5.2.4 Assemblies

For assemblies, the final assessment shall also include a check of the safety accessories intonded

to check full compliance with the requirements specified in the applicable health and safety

standards).

5.2.8 Imported pressure equipment

Pressure equipment imported info South Atica (wth all the documentation and marking, as

requited by the statutory regulations), shall be subjected to a conformity assessment review by the

Importer to ensure compliance with the relevant national legislation (s2e foreword). All reviews of

pressure vessels, steam generators and assemblies shall be verified by an AIA (appointed by the

importer) except where manufactured under SEP and category { requirements, as applicable.

5.2.5.1 CE and Pi marked equipment

CE and Pi (nr) marked equipment in accordance with the PED/TPED and manufactured to the

applicable health and safely standard{s) referred to in the relevant national legislation (soo

foreword) and annex A shall be acceptable for importation info South Attica provided the equipment

is verified for compliance with the relevant national legislation (see foreword) by the importer and

the AIA for pressure equipment category 2 and above,

5.28.2 ASME stamped equipment

ASME stamped equipment complying to ASME shall be accoptable for importation into South Africa

provided the equipment is verified for compliance with the relevant national legistation (see

fereword) by the importer and the AIA for pressure equipment category 2 and above (see also

annex C).

6.2.8.3 DoT stamped equipment

DoT stamped pressure equipment complying with DoT regulations and stamped with DoT

manufacturer's Registration Number (Mooox) shall be acceptable for importation into South Attica

provided the equipment is verified for compliance with the relevant national legisiation (see

foreword) by the importer and the AIA for pressure equipment category 2 and above.

5.3 Module A — Internal production control

5.3.1 This module describes the procedure whereby the manufacturer, or his authorized

representative estabiished in South Africa, shall comply with the requirements in 6.2.2 and shall

deciare that the pressure equipment complies with the requirements of the applicable statutory

regulations for pressure equipment. The manufacturer, or his authorized representative established

24

Copyright protected. Thie standard was downloaded on 2012.04.28 14:66 by Hrs. Petro Nortje of MegChem Engineering And Draiting Sorvicos

Single-user license only; copying and networking prohibited.

You might also like

- SANS1655ED1 1 - 04-10-22 - WP - TMDocument15 pagesSANS1655ED1 1 - 04-10-22 - WP - TMjohndupNo ratings yet

- 2013 Gauteng Learning Programmes CalendarDocument2 pages2013 Gauteng Learning Programmes CalendarjohndupNo ratings yet

- Seamless Carbon Steel Pipe For High-Temperature ServiceDocument12 pagesSeamless Carbon Steel Pipe For High-Temperature ServicejohndupNo ratings yet

- Airgas Welding To Complete CO 24Document5 pagesAirgas Welding To Complete CO 24johndupNo ratings yet

- Sans 1431Document30 pagesSans 1431johndupNo ratings yet

- SANS 2001-CS1:2012: Construction Works Part CS1: Structural SteelworkDocument5 pagesSANS 2001-CS1:2012: Construction Works Part CS1: Structural Steelworkjohndup0% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)