Professional Documents

Culture Documents

Neromastic 800: Scope Application Details

Uploaded by

Tanvir Ahmed KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Neromastic 800: Scope Application Details

Uploaded by

Tanvir Ahmed KhanCopyright:

Available Formats

Neromastic 800

Scope Application Details

Neromastic 800 is a unique multi-purpose self-priming Applied over:

surface tolerant epoxy-based coating specially designed for

Structural steel, ballast tanks, pipe work, outside hulls,

areas where optimum surface preparation is not possible.

power plants, bridges, etc. Can be used as primer, mid coat,

Imparts excellent corrosion resistance, chemical

finish coat or as a single coat maintenance system in

resistance, impact and abrasion resistance properties. Can

atmospheric or immersed environments.

be applied over most aged alkyd-based coatings and has

good adhesion to damp surfaces. High volume solid and

Application Method:

environment friendly.

Brush / Conventional spray / Airless spray

Composition Shelf Life:

12 months under normal storage condition in original sealed

Epoxy-polyamine based topcoat, pigmented with various container at 30°C

non-toxic pigments. Pack Size:

Volume solids 85 ± 2 % 2 Ltr. & 8 Ltr.

DFT/ Coat 150 - 300 μ

Surface Preparation:

Theoretical Coverage / 61 – 31 Sft/Ltr. @ 150 μ

Coat and 300 μ respectively. Surface should be cleaned from dust, oil or any loose

particles as per SSPC-SP1 standard. Abrasive blast

cleaning of the substrate should meet minimum standard of

SSPC-SP10 or Swedish Standard Sa 2 ½ - SIS 05 5900 or

Product Details ISO-8501:1988. Surface profile should remain between 25

to 40 microns.

Type Two Pack

Application Procedure:

Mixing Ratio By volume

Stir Comp. A and Comp. B separately. If settling is observed

Component A 1 parts in comp. A, loosen the settled material & mix it with the help

Component B 1 parts of pneumatic stirrer. Mix comp. B gradually in to comp. A in

Color Selected colors the specified ratio under continuous stirring till

Gloss Semi glossy homogeneous. Use Epoxy thinner as specified.

Pot life 30 min at 30°C

Environmental Conditions:

Chemical reaction

Curing Mechanism between two Relative Humidity should be less than 90%, surface

components temperature must be 3°C above Dew Point to prevent

Flash Point condensation.

Component A Above 30°C

Temperature:

Component B Above 30°C

Drying Time (30°C) Air 5 - 40°C

Surface Dry 2 Hrs. Surface 5 - 50°C

Hard Dry 10 Hrs.

Full Cure 5 Days Special Notes:

Recoating Time (Min.) 10 Hrs. Thinner consumption may vary depending upon site

Cure for immersion 5 days conditions. Practical covering capacity depends on

Thinner KN Epoxy Thinner application techniques, actual dry film thickness, wastage,

Thinner Consumption surface condition etc.

Brush 5 – 10%

Conventional Spray 5 – 15% Safety Precautions:

Airless Spray 0 – 10% Please refer to the Material Safety Data Sheet

Kansai Nerolac Paints (Bangladesh) Limited warrants the goods to be free from defects in material and workmanship. KNPBL makes no other

warranties concerning the goods. No other warranties, whether expressed, implied or statutory such as warranties of merchantability or fitness for a

particular purpose shall apply to goods and in no event shall KNPBL be liable for consequential or incidental damages. Any recommendation or suggestion

relating to use of the products made by KNPBL whether in the technical literature of KNPBL or in response to specific inquiry or otherwise, is based on

data believed to be reliable by KNPBL and KNPBL shall not be liable for any loss or damage incurred to the Buyer on account thereof. However, the

goods and information are intended for use by the Buyer having requisite skill and know-how in the industry and therefore it is for the Buyer to satisfy

himself of the suitability of the goods for his own particular use and it shall be deemed that the Buyer has done so at his sole discretion and risk. Variation

in environment, changes in procedures of use or extrapolation of data may cause unsatisfactory results.

Issue Date: April 01, 2020

Toll Free: 0800-1111-222.

Email us at: info@nerolacbd.com

Visit us at: www.nerolacbd.com

You might also like

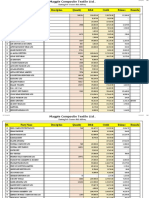

- SL. Name of The Party L/C No L/C Date Documents Value UsdDocument10 pagesSL. Name of The Party L/C No L/C Date Documents Value UsdAbbas AliNo ratings yet

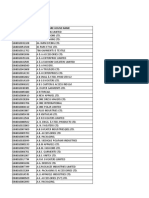

- All Party LedgerDocument1,097 pagesAll Party LedgerMd FaridujjamanNo ratings yet

- Ud-004 Dupli Breeze Imp and Exp LTD (Q Tex) PDFDocument4 pagesUd-004 Dupli Breeze Imp and Exp LTD (Q Tex) PDFMinhaj UddinNo ratings yet

- Dyeing & Finishing All in OneDocument1,688 pagesDyeing & Finishing All in OneMd FaridujjamanNo ratings yet

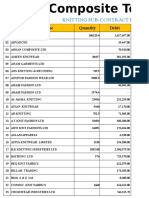

- Knitting Sub Contract All in OneDocument1,118 pagesKnitting Sub Contract All in OneMd FaridujjamanNo ratings yet

- Jamunagroup BangladeshDocument16 pagesJamunagroup BangladeshAmardeep Singh HudaNo ratings yet

- Sister Concern of Anwar GroupDocument2 pagesSister Concern of Anwar GroupZahebi TarannumNo ratings yet

- Washing Factories ListDocument5 pagesWashing Factories ListSabbir Hossain ImranNo ratings yet

- Bangladesh Factory ListDocument1,781 pagesBangladesh Factory ListMd: Rashedul IslamNo ratings yet

- Industrial Visit at Aboni Knitwear Ltd. (FINAL) TE5Document15 pagesIndustrial Visit at Aboni Knitwear Ltd. (FINAL) TE5Zillur Rahman SaykatNo ratings yet

- Utilization Declaration: BGMEA/DHK/UD/2020/1318/003Document6 pagesUtilization Declaration: BGMEA/DHK/UD/2020/1318/003ShakirNo ratings yet

- Top 100 Indian companies listDocument193 pagesTop 100 Indian companies listabhiperiwalNo ratings yet

- 150+ Business Clients ListDocument3 pages150+ Business Clients ListShaki ShoeabNo ratings yet

- Bonded Warehouse Code and Name ListingDocument348 pagesBonded Warehouse Code and Name ListingSaddamHossain100% (1)

- Production and Operation Management of A RMG FactoryDocument14 pagesProduction and Operation Management of A RMG FactorySaidusSalekinSirajeeNo ratings yet

- Shanta Denim ProfileDocument6 pagesShanta Denim ProfileRavi Bhargava100% (1)

- Dyeing - Printing-Finishing Member Mills (General Member)Document17 pagesDyeing - Printing-Finishing Member Mills (General Member)alaminNo ratings yet

- Copy of Walt Disney Factories List in BD - November-2021Document2 pagesCopy of Walt Disney Factories List in BD - November-2021Ferdous Khan RubelNo ratings yet

- TirupurDocument6 pagesTirupursaravana0210No ratings yet

- Equipment Catalogue - 2015-Web PDFDocument42 pagesEquipment Catalogue - 2015-Web PDFKim MoggNo ratings yet

- CatalogueDocument20 pagesCatalogueDivya AnandNo ratings yet

- Monthely Visit ReportDocument9 pagesMonthely Visit ReportMohammad Harun Or-rashidNo ratings yet

- Avesta Broschyr 4-Sid LowresDocument4 pagesAvesta Broschyr 4-Sid LowresKamal ShahNo ratings yet

- Silk Yarn PlantDocument21 pagesSilk Yarn PlantElnathan Samson100% (1)

- Finishing of Technical TextilesDocument3 pagesFinishing of Technical TextilesKaushik BogharaNo ratings yet

- DenimDocument16 pagesDenimriexaoiNo ratings yet

- List of Buying HouseDocument74 pagesList of Buying HouseMd Sakhawat HossainNo ratings yet

- Bangladesh Jute Goods Standard ContractDocument6 pagesBangladesh Jute Goods Standard ContractΔΗΜΗΤΡΗΣ ΚΟΝΤΟΠΟΥΛΟΣNo ratings yet

- A & A Textiles LTDDocument4 pagesA & A Textiles LTDMilton StevensNo ratings yet

- Carbolite Gero Ovens User ManualDocument16 pagesCarbolite Gero Ovens User Manualgeetha raniNo ratings yet

- JKL Textile Mills Customer ListDocument2 pagesJKL Textile Mills Customer ListMd Delowar Hossain Mithu100% (1)

- New Look Factory List - August 2017Document35 pagesNew Look Factory List - August 2017S H RafI Hossain MunshiNo ratings yet

- Textile Learner's (Https://textilelearner - Net) DocumentDocument19 pagesTextile Learner's (Https://textilelearner - Net) DocumentTextile Learner71% (21)

- Role of Merchandiser in Buying House OperationsDocument24 pagesRole of Merchandiser in Buying House OperationsPuja PrasadNo ratings yet

- Daffodil International University: Textile Testing & Quality Control-3Document11 pagesDaffodil International University: Textile Testing & Quality Control-3Dyeing DyeingNo ratings yet

- Companies Certified to Global Recycled StandardDocument30 pagesCompanies Certified to Global Recycled StandardPankhil DesaiNo ratings yet

- Factory Profile Manvill Styles LTD (1) .Document11 pagesFactory Profile Manvill Styles LTD (1) .Mallick Nazrul IslamNo ratings yet

- Dyeing & Finishing Accounts All in OneDocument401 pagesDyeing & Finishing Accounts All in OneMd FaridujjamanNo ratings yet

- Ahmedabad Textile Dyeing and Printing CompaniesDocument5 pagesAhmedabad Textile Dyeing and Printing Companiesguna071981No ratings yet

- Direct Supplier List 2018 ABM PDFDocument2 pagesDirect Supplier List 2018 ABM PDFMd. Mobarak HossainNo ratings yet

- Cotton Yarn Fabrics ExportersDocument9 pagesCotton Yarn Fabrics Exportersfayyazbhatti178No ratings yet

- ITME 2022 CoimbatoreDocument9 pagesITME 2022 Coimbatoretravel healersNo ratings yet

- Textile Learner S DocumentDocument13 pagesTextile Learner S DocumentNikesh ShahNo ratings yet

- Fair Directory 02-2016Document96 pagesFair Directory 02-2016NJ enterpriseNo ratings yet

- Cepz FactoriesDocument3 pagesCepz Factoriessalauddin77% (13)

- Fabric Manufacturing Project Theses ListDocument14 pagesFabric Manufacturing Project Theses ListRasheduzzaman RashedNo ratings yet

- Dhaka Epz Factory List & List of Inspected Factories by EIMS For AllianceDocument12 pagesDhaka Epz Factory List & List of Inspected Factories by EIMS For Alliancearman chowdhury100% (4)

- 10.10.20-Customer Call ListDocument3 pages10.10.20-Customer Call ListAbdus Satter HimelNo ratings yet

- Gujrat ListDocument91 pagesGujrat ListaniketNo ratings yet

- Smart Jeans Factory Profile: Quality Denim Trousers & Tops ManufacturerDocument8 pagesSmart Jeans Factory Profile: Quality Denim Trousers & Tops Manufacturertareqsmartjeans100% (2)

- Knitting Outstanding ReportDocument160 pagesKnitting Outstanding ReportMd FaridujjamanNo ratings yet

- Spinning Mill List Provides Overview of Yarn ManufacturersDocument27 pagesSpinning Mill List Provides Overview of Yarn ManufacturersPriyankaNo ratings yet

- Sadma Profile (Knitting, Dyeing & Garments)Document15 pagesSadma Profile (Knitting, Dyeing & Garments)Rahat Hasan0% (1)

- SRCFEB20 Exhibitor List 11-19-2020 PDFDocument10 pagesSRCFEB20 Exhibitor List 11-19-2020 PDFSrishty RanaNo ratings yet

- Knitting All PartyDocument559 pagesKnitting All PartyMd FaridujjamanNo ratings yet

- Walmart BD ListDocument3 pagesWalmart BD ListShaharia AzamNo ratings yet

- Bagasse Based Unit: 1.1 Scenario of Paper Industry in IndiaDocument11 pagesBagasse Based Unit: 1.1 Scenario of Paper Industry in IndiaBibaswat MishraNo ratings yet

- Nerothane PU Topcoat: Scope Application DetailsDocument1 pageNerothane PU Topcoat: Scope Application DetailsTanvir Ahmed KhanNo ratings yet

- Neromastic_4000Document2 pagesNeromastic_4000m pallonjiNo ratings yet

- Nerothane 1000Document1 pageNerothane 1000nimish.aquamarine0% (1)

- The Book of Heroic FailuresDocument3 pagesThe Book of Heroic FailuresTanvir Ahmed KhanNo ratings yet

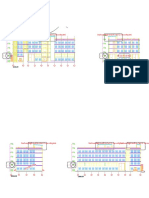

- Building elevations and stair room requirementsDocument2 pagesBuilding elevations and stair room requirementsTanvir Ahmed KhanNo ratings yet

- ForewordDocument8 pagesForewordTanvir Ahmed KhanNo ratings yet

- PrefaceDocument2 pagesPrefaceTanvir Ahmed KhanNo ratings yet

- Rspa 1910 0061Document12 pagesRspa 1910 0061Tanvir Ahmed KhanNo ratings yet

- Foreword Preface AcknowledgmentsDocument4 pagesForeword Preface AcknowledgmentsTanvir Ahmed KhanNo ratings yet

- Poppies, Pipes, and PeopleDocument6 pagesPoppies, Pipes, and PeopleTanvir Ahmed KhanNo ratings yet

- Nerothane PU Topcoat: Scope Application DetailsDocument1 pageNerothane PU Topcoat: Scope Application DetailsTanvir Ahmed KhanNo ratings yet

- Department of Public Works and Highways: Item 522 - Active and Passive Protection Systems For Unstable Slope)Document12 pagesDepartment of Public Works and Highways: Item 522 - Active and Passive Protection Systems For Unstable Slope)ZA TarraNo ratings yet

- Management Summary Purging of Hydrogen PipesDocument3 pagesManagement Summary Purging of Hydrogen Pipescarpo2003No ratings yet

- Knitting Technology GuideDocument22 pagesKnitting Technology GuideMehulNo ratings yet

- Effect of DMPA & MW of Polyurethane DispersionDocument15 pagesEffect of DMPA & MW of Polyurethane Dispersionichsan hakimNo ratings yet

- Cranfield UniversityDocument418 pagesCranfield UniversityElaf AhmedNo ratings yet

- Chemicals From Coal CokingDocument29 pagesChemicals From Coal CokingNatalia MayaNo ratings yet

- SAE Steel Grades - WikipediaDocument12 pagesSAE Steel Grades - WikipediaprabuNo ratings yet

- BS en 1708-1 (2010)Document76 pagesBS en 1708-1 (2010)Peter TvardzíkNo ratings yet

- Synperonic-T-1301 TdsDocument1 pageSynperonic-T-1301 TdsLuigi NicoraNo ratings yet

- Physical: MetallurgyDocument4 pagesPhysical: MetallurgySanjanaNo ratings yet

- Zilver PRICELISTDocument14 pagesZilver PRICELISTsaad hussainNo ratings yet

- SECTION 09 65 16.33 SECTION TITLE: Rubber Sheet Flooring: 1.1 Related DocumentsDocument3 pagesSECTION 09 65 16.33 SECTION TITLE: Rubber Sheet Flooring: 1.1 Related DocumentsTheJohnnyBravoooNo ratings yet

- Ch. 23 Minerals and Natural Resources in IndiaDocument3 pagesCh. 23 Minerals and Natural Resources in Indiaamanag1997No ratings yet

- Astm A333 PDFDocument2 pagesAstm A333 PDFgaminNo ratings yet

- PigmentDocument13 pagesPigmentAlmanzo AmilNo ratings yet

- Class PS 46 Polyvinyl Chloride (PVC) Pipe: Standard Specification ForDocument4 pagesClass PS 46 Polyvinyl Chloride (PVC) Pipe: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Guidelines For Installing A MR - Steam Steambath SystemDocument24 pagesGuidelines For Installing A MR - Steam Steambath SystemnombreyoyoNo ratings yet

- 3-Way Ball Valve (Spears)Document4 pages3-Way Ball Valve (Spears)Chan Chi Wong PenNo ratings yet

- Separation and Purification of Organic Compounds-DistillationDocument17 pagesSeparation and Purification of Organic Compounds-DistillationMarie Maraniag100% (1)

- Raghu Engineering College: AutonomousDocument12 pagesRaghu Engineering College: Autonomousganesh chowdaryNo ratings yet

- Steps in production of titanium from ore to ingotsDocument4 pagesSteps in production of titanium from ore to ingotsUyGrEdSQNo ratings yet

- What Causes Foaming in A Distillation ColumnDocument3 pagesWhat Causes Foaming in A Distillation ColumnArief HidayatNo ratings yet

- 10 1039@c6ra24522fDocument20 pages10 1039@c6ra24522fVan BastenNo ratings yet

- Aleación Aluminio SilicioDocument7 pagesAleación Aluminio SilicioEmanuelRomeroGNo ratings yet

- Steel Plates For ShipbuildingDocument12 pagesSteel Plates For ShipbuildingKYAW SOENo ratings yet

- UTEC BrochureDocument8 pagesUTEC Brochurecarlitto_jkNo ratings yet

- Concrete AdmixturesDocument50 pagesConcrete AdmixturesAzuan WahariNo ratings yet

- ETA 16 0264 European ApprovalDocument41 pagesETA 16 0264 European ApprovalBenedetto La FauciNo ratings yet

- Din HandbooksDocument9 pagesDin HandbooksTalha DikenNo ratings yet

- Optical Ground Wire: Fiber Optic Cable Used For Providing A Grounding Path For Transmission SystemsDocument4 pagesOptical Ground Wire: Fiber Optic Cable Used For Providing A Grounding Path For Transmission SystemsTheoVarneyNo ratings yet

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (542)

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsFrom EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsRating: 5 out of 5 stars5/5 (2)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemFrom EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemNo ratings yet

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowFrom EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowNo ratings yet

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- The Graphene Revolution: The Weird Science of the Ultra-thinFrom EverandThe Graphene Revolution: The Weird Science of the Ultra-thinRating: 4.5 out of 5 stars4.5/5 (4)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonFrom EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonRating: 5 out of 5 stars5/5 (2)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4 out of 5 stars4/5 (331)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- Recent Advances in Electrical Engineering: Applications OrientedFrom EverandRecent Advances in Electrical Engineering: Applications OrientedNo ratings yet