Professional Documents

Culture Documents

CONCRETE

Uploaded by

Niel BartolomeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CONCRETE

Uploaded by

Niel BartolomeCopyright:

Available Formats

CONCRETE

Concrete durability depends upon the degree of exposure, the concrete grade (or strength) and

the cement content. . Concrete resists weathering action, chemical attack, and abrasion while

maintaining its desired engineering properties. Different concretes require different degrees of

durability depending on the exposure environment and the properties desired. Concrete ingredients,

their proportioning, interactions between them, placing and curing practices, and the service

environment determine the ultimate durability and life of the concrete. The durability requirements

for Structural and Nonstructural concrete is based on standard ACI 318, developed by the American

Concrete Institute.

Moisture sources for concrete are both internal and external. The internal source of moisture is the

water mixed with cement that created the concrete. External sources of concrete moisture can also be

substantial and include such things as rainwater, poor plumbing, poor drainage below or at the sides of

the slab, and even the humidity in the air.

During the drying process, the concrete batch water, cement, aggregate, and other admixtures create tiny pathways within

called capillaries. Once cured, the excess water in the slab moves through these capillaries to release the moisture. Since

most concrete floors have a vapor retarder below them, this moisture must move upwards in order to escape.

STRENGTH AND DURABILITY

Many factors can affect the ultimate strength of the concrete. The first is the mix design, which sets the

ratios of the materials and water. The second is the time that passes between the initial introduction of

water and the placement of the concrete. Concrete setting is a chemical reaction that has a very definite

time component. The mixture must also be kept from segregating into its constituent parts by rotating

the drum of the mixer prior to placement.

CYLINDER TESTS

Concrete is typically mixed in one location and placed in another. Because of this, concrete must be

field-tested to be certain that the material actually placed in the building meets the design criteria.

FORMWORK

The design, fabrication, and erection of formwork is to comply with ACI 318. Formwork is necessary to

develop the required shape and dimensions of concrete members in a structure.

JOINTS

Refer to ACI 318 for provisions for joints between two successive placements of concrete.

CONCRETE COVER FOR WEATHER, MOISTURE, AND FIRE PROTECTION

ACI 318 specifies minimum concrete cover for reinforcing steel for several reasons. The cover may be to

afford fire resistance as required by the classification of the structure. The cover may be specified in

underground situations to provide protection for the reinforcing steel from moisture in the ground.

STRUCTURAL PLAIN CONCRETE

Per § 1906, it is acceptable to use plain unreinforced concrete under certain conditions, but only for

simple structures. In most circumstances the use of minimal reinforcing to address temperature changes

and shrinkage cracking is recommended practice instead of using plain concrete.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Checklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC RequirementsDocument1 pageChecklist For Rebar (Columns, Neck Columns and Plinth Wall) : QA/QC Requirementsmanoj100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureDocument48 pagesLoadings - NSCP 2015 - 2 Storey Residential Concrete StructureRyan MacutoNo ratings yet

- The Building Envelope: Moisture Control TechniquesDocument3 pagesThe Building Envelope: Moisture Control TechniquesNiel BartolomeNo ratings yet

- Types of Electrical ConduitDocument3 pagesTypes of Electrical ConduitBenjo Dela CuadraNo ratings yet

- Rehabilitation and Retrofitting of StructuresDocument10 pagesRehabilitation and Retrofitting of Structuresvempadareddy0% (1)

- A4-P 1.0 enDocument11 pagesA4-P 1.0 enmkpqNo ratings yet

- MiniChiller Application Manual 2.0 PDFDocument128 pagesMiniChiller Application Manual 2.0 PDFbertan dağıstanlıNo ratings yet

- Building Services ReportDocument81 pagesBuilding Services Reportapi-291990968100% (3)

- EC2 Beam Section DesignDocument3 pagesEC2 Beam Section Designikanyu79100% (1)

- SUMMARYDocument10 pagesSUMMARYNiel BartolomeNo ratings yet

- Greener Blocks Towards A Sustainable Future. Greener Blocks To Make Sturdier Homes. Greener Blocks Towards A Sturdier FutureDocument4 pagesGreener Blocks Towards A Sustainable Future. Greener Blocks To Make Sturdier Homes. Greener Blocks Towards A Sturdier FutureNiel Bartolome100% (1)

- Appropriate Selection of Interior and Exterior Materials, Finishes, Products, ComponentsDocument77 pagesAppropriate Selection of Interior and Exterior Materials, Finishes, Products, ComponentsNiel BartolomeNo ratings yet

- Urban Quality and Designing of Spaces: Case Study For Nasr City, CairoDocument11 pagesUrban Quality and Designing of Spaces: Case Study For Nasr City, CairoAhmed El-AdawyNo ratings yet

- Air Conditioner Selection FormDocument2 pagesAir Conditioner Selection Formmalan_ubNo ratings yet

- Colorsteel. SpecsDocument2 pagesColorsteel. SpecsRussel TalastasNo ratings yet

- Bid Form (Boq)Document15 pagesBid Form (Boq)John CedricNo ratings yet

- Appendix B - Technical Specification For Plain & Reinforced Concrete WorksDocument24 pagesAppendix B - Technical Specification For Plain & Reinforced Concrete WorksPankaj PriyadarshiNo ratings yet

- SRG Slipform Construction 2016 04 e PDFDocument8 pagesSRG Slipform Construction 2016 04 e PDF94738183No ratings yet

- Plan Review Checklist: ArchitecturalDocument4 pagesPlan Review Checklist: Architecturalzikrillah1No ratings yet

- Laurie Baker: Peelay Ifa Ashfaque Fourth - Yr.B.ArchDocument30 pagesLaurie Baker: Peelay Ifa Ashfaque Fourth - Yr.B.ArchIfa PeelayNo ratings yet

- Elzinc ASS V 4.1.03 Eng PDFDocument2 pagesElzinc ASS V 4.1.03 Eng PDFDragoș Alexandru FodoreanuNo ratings yet

- Project: EPM Gantt Chart Date: Sun 8/12/19Document1 pageProject: EPM Gantt Chart Date: Sun 8/12/19MeliRampersandNo ratings yet

- DUSHDocument25 pagesDUSHOmkar KulkarniNo ratings yet

- Assembly Manual PROSLIDE ToboganDocument59 pagesAssembly Manual PROSLIDE Tobogansilvia caicedoNo ratings yet

- Koolfoam InsulationDocument5 pagesKoolfoam InsulationsepasepasepaNo ratings yet

- Me Troll Brochure 2017Document44 pagesMe Troll Brochure 2017KantishNo ratings yet

- Polycast Trench Drain System PDFDocument40 pagesPolycast Trench Drain System PDFgurpreets_807665No ratings yet

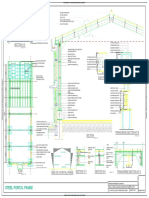

- Steel Portal Frame: Section A-ADocument1 pageSteel Portal Frame: Section A-AAnonymous ckMV44upTNo ratings yet

- Roof SpecificationDocument30 pagesRoof SpecificationZulHilmi ZakariaNo ratings yet

- Structural Design IIDocument1 pageStructural Design IIShikha ShahNo ratings yet

- Laticrete 307 TDSDocument3 pagesLaticrete 307 TDSAnup DaNo ratings yet

- Read MeDocument2 pagesRead MeLoren ViejayNo ratings yet

- CertainteedDocument6 pagesCertainteedDxtr MedinaNo ratings yet

- Industrial Hall Curs ConstrDocument17 pagesIndustrial Hall Curs ConstrAtasiei Monica GabrielaNo ratings yet