Professional Documents

Culture Documents

HP Esa-L1500a Spectrum Analyzer - Service Guide

HP Esa-L1500a Spectrum Analyzer - Service Guide

Uploaded by

Sanyel Saito0 ratings0% found this document useful (0 votes)

167 views310 pagesOriginal Title

Hp Esa-l1500a Spectrum Analyzer - Service Guide

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

167 views310 pagesHP Esa-L1500a Spectrum Analyzer - Service Guide

HP Esa-L1500a Spectrum Analyzer - Service Guide

Uploaded by

Sanyel SaitoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 310

Service Guide

HP ESA-L1500A Spectrum Analyzer

CA exckano

HP Part No. £4411-90021

Printed in USA

August 1997

© Copyright 1997 Hewlett-Packard Company All Rights Reserved. Reproduction,

adaptation, or translation without prior written permission is prohibited, except as

allowed under the copyright laws.

1400 Fountaingrove Parkway, Santa Rosa, CA 95403-1799, USA

‘The information contained in this document is subject to change

without notice.

Hewlett-Packard makes no warranty of any kind with regard to this,

material, including but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Hewlett-Packard

shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance,

or use of this material.

WARNING

‘CAUTION

WARNING

WARNING

WARNING

Safety Notes

The following safety notes are used throughout this manual.

Familiarize yourself with each of the notes and it’s meaning before

operating this instrument.

Warning denotes a hazard. It calls attention to a procedure

which, if not correctly performed or adhered to, could result in

injury or loss of life. Do not proceed beyond a warning note

until the indicated conditions are fully understood and met.

Caution denotes a hazard. It calls attention to a procedure that, if not

correctly performed or adhered to, could result in damage to or

destruction of the instrument. Do not proceed beyond a caution sign

until the indicated conditions are fully understood and met.

This is a Safety Class 1 Product (provided with a protective

earthing ground incorporated in the power cord). The mains

plug shall only be inserted in a socket outlet provided with a

protected earth contact. Any interruption of the protective

conductor inside or outside of the product is likely to make the

product dangerous. Intentional interruption is prohibited.

These servicing instructions are for use by qualified personnel

only. To avoid electrical shock, do not perform any servicing

unless you are qualified to do so.

The power cord is connected to internal capacitors that may

remain live for 5 seconds after disconnecting the plug from it’s

power supply.

Warranty

This Hewlett-Packard instrument product is warranted against defects

in material and workmanship for a period of one year from date of

shipment. During the warranty period, Hewlett-Packard Company will,

at its option, either repair or replace products which prove to be

defective.

For warranty service or repair, this product must be returned to a

service facility designated by Hewlett-Packard. Buyer shall prepay

shipping charges to Hewlett-Packard and Hewlett-Packard shall pay

shipping charges to return the product to Buyer. However, Buyer shall

pay all shipping charges, duties, and taxes for products returned to

Hewlett-Packard from another country.

Hewlett-Packard warrants that its software and firmware designated

by Hewlett-Packard for use with an instrument will execute its

programming instructions when properly installed on that instrument.

Hewlett-Packard does not warrant that the operation of the

instrument, or software, or firmware will be uninterrupted or

error-free.

LIMITATION OF WARRANTY

‘The foregoing warranty shall not apply to defects resulting from

improper or inadequate maintenance by Buyer, Buyer-supplied

software or interfacing, unauthorized modification or misuse, operation

outside of the environmental specifications for the product, or improper

site preparation or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED.

HEWLETT-PACKARD SPECIFICALLY DISCLAIMS THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYER'S SOLE AND

EXCLUSIVE REMEDIES. HEWLETT-PACKARD SHALL NOT BE

LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT,

TORT, OR ANY OTHER LEGAL THEORY.

Lithium Battery Disposal

When the battery on the Ad processor assembly (3 volt lithium battery,

HP part number 1420-0338) is exhausted and/or ready for disposal,

dispose of it according to your country’s requirements. You can return

the battery to your nearest Hewlett-Packard Sales and Service office for

disposal, if required. Refer to “Contacting Hewlett-Packard” in Chapter

1 for a list of Hewlett-Packard Sales and Service offices,

DO NOT THROW BATTERIES AWAY BUT

COLLECT AS SMALL CHEMICAL WASTE.

Contents

1. Troubleshooting the Analyzer

Before You Start. .

Service Equipment You Will Need

Check the Basics

Problems at Instrument Power-Uip

Error Messages

‘Troubleshooting an Inoperative Spectrum Analyzer.

Troubleshooting the LCD Display

Isolating an RF, LO, IF, or Video Problem

Using the Internal Service-Diagnostic Routines

‘Troubleshooting the A4 Processor Assembly . .

‘Troubleshooting the A2 Tracking Generator (Option wwNIIDa)

Contacting Hewlett-Packard BB

How to Return Your Analyzer for Service

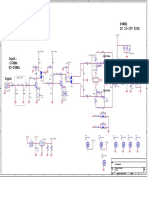

Block Diagrams

AS RF Assembly...

AS IF Assembly

‘Ad Processor Assembly

‘A5 Power Supply Assembly...

‘AT Motherboard

Miscellaneous. ..

Options:

Motherboard Mnemonics and Connectors .

3. Parts List

How to Order Parts

Replaceable Parts.

Hardware . fi

CLIP part numbers (CLIP matrix)

4, Replacing Assemblies

Before You Start. ...

Removal and Replacement Procedures in this Chapter

Instrument Outer Case

Inner Shield ......

Al Front Frame Assembly’.

AS RF Assembly. ae

‘A810 Input Connector

AB Power Supply

ASB Fan .. :

‘A2 Tracking Generator Assembly.

AB IF Assembly . :

‘Ad Processor Assembly

BT Battery .....

AG Speaker Assembly

VO Assemblies

AT Motherboard Assembly

107

.uT

122

139

. 143

a7

- 148

. 151

153

157

161

163

166

169

a,

175

176

- 178

180

. 182

Contents

Front Frame Subassemblies ce ee 180)

5. Post-Repair Procedures

Safety = 195

Before You Start... +196

List of Tests and Adjustments for Calibration 2197

List of Tests and Adjustments for Post-Repair 199

Adjustments cee 204

1.10 MHz Reference + 205

2.21.4 MHz IF Calibrator 2 208

8. 50 MHz Calibrator 2.207

4, Uncorrected Flatness SpoceHe 208

5. Corrected Flatness ....... veces seve 210

6. Tracking Generator ALC Calibration . Beal

7. Tracking Generator Frequency Slope 2.212

Utilities... 213

6. Using Adjustment Software

What is CTM?. 2217

Installation .. = 220

Running the Program. . = 227

‘Task Reference aco cee 230

Using HP CTM's Utilities : 22 245

7. Calibration Test Manager Concepts

Using HP Calibration Test Manager Menus = 258

‘What are System Administration Operations?. 254

Categories of CTM Test Equipment . . 66 ++ B56

CTM UUT Information 5 veces B57

Configuring CTM 000.22. poos50000H = 259

Using the Test Sequences : ee a6)

Configuring the Mass Storage Volumes : 263

Understanding Workstations Setup ..... 264

Understanding Equipment Management... vee 265

Understanding System Administration Utilities ...... 268

Understanding UUT-Results Management (HIPS or SRM only) .... 269

Contents

Using Printers with CTM

‘Making Calibration-Factor Files.

Finding Application Notes.

Understanding System Files.

Menu Reference a

270

2271

272

- 273

2214

Troubleshooting the Analyzer

Troubleshooting the Analyzer

This chapter provides information that is useful when starting to

troubleshoot a spectrum analyzer failure. It provides procedures for

troubleshooting common failures and isolating problems in the

spectrum analyzer. Assembly descriptions are located in Chapter 2.

Component level information containing material lists, schematics, and

component location diagrams, is available separately.

2 Chapter 1

WARNING

WARNING

WARNING

Troubleshooting the Analyzer

Before You Start

Before You Start

‘There are four things you should do before starting to troubleshoot a

failure:

@ Check that you are familiar with the safety symbols marked on the

instrument, and read the general safety considerations and the

safety note definitions given in the front of this guide.

The spectrum analyzer contains static sensitive components. Read

the section entitled “ESD Information” on page 14 in this chapter.

Q Become familiar with the organization of the troubleshooting

information in this chapter.

O Read the rest of this section.

‘These servicing instructions are for use by qualified personnel

only. To avoid electrical shock, do not perform any servicing

unless you are qualified to do so.

‘The opening of covers or removal of parts is likely to expose

dangerous voltages. Disconnect the product from all voltage

sources while it is being opened.

‘The detachable power cord is the instrument disconnecting

device. It disconnects the mains circuits from the mains supply

before other parts of the instrument. The front panel switch is

only a standby switch and is not a LINE switch (disconnecting

device).

Replacement Assemblies

‘The analyzer assemblies are not repairable to the component level. The

following assemblies must be replaced as an assembly.

+ RP assembly

* IF assembly

* power supply

© processor assembly

* motherboard

* speaker board

© display

+ display interface

Chapter 1 13

WARNING

‘Troubleshooting the Analyzer

Before You Start

* keypad

* HPIB assembly (Option A4H)

‘+ RS-232 assembly (Option 1AX)

* SAV/O assembly (Option A4J)

‘The tracking generator assembly (Option 1DN or 1DP) consists of three

boards, and is repairable to the board level.

After a Spectrum Analyzer Repair

If one or more spectrum analyzer assemblies have been repaired or

replaced, perform the related adjustments and performance verification

tests. Refer to Table 5-2 on page 199 for the related adjustments and

performance verification tests required for each assembly.

ESD Information

Protection from Electrostatic Discharge

Electrostatic discharge (ESD) can damage or destroy electronic

components. All work on electronic assemblies should be performed at a

statie-safe workstation. Figure 1-1 on page 15 shows an example of a

static-safe workstation using two types of ESD protection:

Q Conductive table-mat and wrist-strap combination.

@ Conductive floor-mat and heel-strap combination,

Both types, when used together, provide a significant level of ESD

protection. Of the two, only the table-mat and wrist-strap combination

provides adequate ESD protection when used alone. To ensure user

safety, the static-safe accessories must provide at least 1 MQ of

isolation from ground. Refer to Table 1-1 for information on ordering

static-safe accessories.

These techniques for a static-safe workstation should not be

used when working on circuitry with a voltage potential

greater than 500 volts.

4 Chaptert

Figure 1-1

‘Table 1-1

Troubleshooting the Analyzer

Before You Start

Example of a Static-Safe Workstation

ay

trap) >

|

Static Safe Accessories

HP Part Number Description

19300-0797 Set includes: 3M static control mat 0.6 m x 1.2 m (2 ftx 4

ft) and 4.6 cm (15 ft) ground wire. (The wrist-strap and

wrist-strap cord are not included. They must be ordered

separately.)

9300-0980 Wrist-strap cord 1.5 m (5 ft)

9300-1883 Wrist-strap, color black, stainless steel, without cord, has

four adjustable links and a7 mm post-type connection.

‘9300-1169 ESD heel-strap (reusable 6 to 12 months)

Handling of Electronic Components and ESD

‘The possibility of unseen damage caused by ESD is present whenever

components are transported, stored, or used. The risk of ESD damage

can be greatly reduced by close attention to how all components are

handled.

Q Perform work on all components at a static-safe workstation.

Q Keep static-generating materials at least one meter away from all

components.

Chapter 1 15

‘CAUTION

Troubleshooting the Analyzer

Before You Start

Q Store or transport components in static-shielding containers.

Always handle printed circuit board assemblies by the edges. This will

reduce the possibility of ESD damage to components and prevent

contamination of exposed plating.

Test Equipment Usage and ESD

Before connecting any coaxial cable to a spectrum analyzer

connector for the first time each day, momentarily short the center

and outer conductors of the cable together.

Q Personnel should be grounded with a 1 M Q resistor-isolated

wrist-strap before touching the center pin of any connector and

before removing any assembly from the spectrum analyzer.

Be sure that all spectrum analyzers are properly earth-grounded to

prevent build-up of static charge.

For Additional Information about ESD

For more information about preventing ESD damage, contact the

Electrical Over Stress/Electrostatic Discharge (EOS/ESD) Association,

Inc. The ESD standards developed by this agency are sanctioned by the

American National Standards Institute (ANSD.

16 Chapter?

Troubleshooting the Analyzer

Service Equipment You Will Need

Service Equipment You Will Need

Refer to Table 1-2 for a list of the recommended test equipment needed

to trouble shoot and repair the spectrum analyzer. Although

Hewlett-Packard equipment is recommended, any equipment that

meets the critical specifications given in the table can be substituted for

the recommended model.

Table 1-2 Recommended Equipment

; Critical Specifications for Equipment | Recommended

Equipment Substitution Model

Digital Multimeter | Input Resistance: 210 megohms HP 3458A

Accuracy: +10 mV on 100 V range

DVM Test Leads For use with HP 3458A Digital Multimeter | HP 34118B

Universal Counter | Time Interval Range: 25 ms to 100 ms HP 53132 or

Single Operation Range: +2.5 Vde to -2.5 Ve _| HP 5316B

Measuring Receiver | Compatible with Power Sensors HP 89024

GB Relative Mode

Resolution: 0.01 dB

Reference Accuracy: #1.2%

Microwave Frequency Range: 9 MHz to 7 GHz HP 53528

Frequency Counter | Timebase Accy (Aging): <5 x 10%/day

Oscilloscope Bandwidth: de to 100 MHz HP 545014

Vertical Scale Factor of 0.5 V to 5 V/Div

Power Meter Compatible with power sensors dB relative | HP 436A

mode.

Resolution: 0.01 dB

Reference accuracy: +1.2%

(Option 1DP)

Chapter 1 7

Troubleshooting the Analyzer

Service Equipment You Will Need

Equipment

Critical Specifications for Equipment

Substitution

Recommended

Model

Power Sensor

Power Sensor,

Low Power

Power Sensor, 75 Q

Spectrum Analyzer,

Microwave

Synthesized Sweeper

Synthesizer/Funetion

Generator

Frequency Range: 100 kHz to 1500 MHz.

‘Maximum SWR:

1,60 (100 kHz to 300 kHz)

1.20 (300 kHz to 1 MHz)

1.11 MHz to 2.0 GHz)

Frequency Range: 300 MHz

Amplitude Range: ~20 dBm to ~70 dBm

‘Maximum SWR: 1.1 (300 MHz)

Frequency Range: 1 MHz to 1500 MHz

Maximum SWR: 1.18 (600 kHz to 1500 MHz)

Impedance: 75

Amplitude Range: ~30 dBm to +20 dBm

(Option 1DP)

Frequency Range: 100 kHz to 7 GHz

Relative Amplitude Accuracy:

100 kHz to 1.5 GHz: <41.8 dB

Frequency Accuracy: 40 dB

‘Maximum VSWR: 1.1:1

‘Transmission Arm Loss: 6 dB (nominal)

Coupling Arm Loss: 6 dB (nominal)

Minimum Loss Frequency Range: de to 2 GHz HP 118528

Adapter Insertion loss: 5.7 dB, nominal

(Option 1DP)

‘Termination, 50 — | Impedance: 50 © (nominal) HP 908A

Connector: Type-N (m)

(2 required for Option IDN)

Termination, 75. | Impedance: 75 (nominal) HP 909E

(2 required for Option 1DQ) Option 201

required for Option IDP)

‘Table 1-4 Recommended Adapters

Critical Specifications for Adapter Substitution Lar

BNG (f to dual banana plug 1251-1277

BNC (m) to BNC (m) 1250-0216

BNC (m) to BNC (m), 75 8 (Option 1DP) 1250-1288,

BNC (f) to SMB (mm) 1250-1287

BNC tee (BNC f, m, 1250-0781

Type-N(f) to APC 3.5 (0 1250-1745

‘Type-N (f) to BNC (m)

‘Type-N (m) to BNC (9, 75.2 (Option 1DP)

Type-N (im) to BNC (f) (4 required) 1250-1476

‘Type-N (m) to BNC (m) (2 required) 1250-1473

‘Type-N (f), 75 Q, to Type-N (m), 50 0 (Option 1DP) 1250-0597

‘Type-N (f) to Type-N () 1250-1472

‘Type-N (m) to Type-N (m) 1250-1475

Chapter 1 19

Troubleshooting the Analyzer

Service Equipment You Will Need

on eae a Recommended

Critical Specifications for Adapter Substitutior Maal

SMB (f) to SMB () 1250-0692

‘SMB (m) to SMB (m) 1250-0813

BNC (f) to SMB () 1250-1236

SMB tee (f) (m) (m) 1250-1391

‘Table 1-5 Recommended Cables

fo on Recommended

Critical Specifications for Cable Substitution aeeacl

Frequency Range: de to 1 GHz HP 105034,

Length: 2122 cm (48 in)

Connectors: BNC (m) both ends (4 required)

‘Type-N, 62 em (24 in) HP 11500B/C

‘Type-N, 152 em (60 in) (2 required) HP 11500D

BNC, 75 9 30 em (12 in) (Option 1DP) 5062-6452,

BNC, 75.9, 120 cm (48 in) (Option LDP) 15525-80010

Frequency Range: de to 310 MHz “HP 105024.

Length: 20 cm (9 in)

Connectors: BNC (m) both ends

Cable, Test 85680-60093,

Length: 291 om (36 in)

Connectors: SMB (f) to BNC (m) (2 required)

20 Chapter 1

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dead Icom IC7000 Radio, Click Click From The RelayDocument5 pagesDead Icom IC7000 Radio, Click Click From The RelaySanyel SaitoNo ratings yet

- Alternate Fan Mod For IC-7000Document1 pageAlternate Fan Mod For IC-7000Sanyel SaitoNo ratings yet

- AT-1000Pro Autotuner Lamp ModDocument5 pagesAT-1000Pro Autotuner Lamp ModSanyel SaitoNo ratings yet

- Kenwood TS-830: Survival GuideDocument37 pagesKenwood TS-830: Survival GuideSanyel SaitoNo ratings yet

- Marconi 2955A Calibration User ManualDocument16 pagesMarconi 2955A Calibration User ManualSanyel SaitoNo ratings yet

- HP Esa-L1500a Spectrum Analyzer - User's and Calibration GuideDocument325 pagesHP Esa-L1500a Spectrum Analyzer - User's and Calibration GuideSanyel SaitoNo ratings yet

- RF Amp 2078 SCH V306Document1 pageRF Amp 2078 SCH V306Sanyel Saito100% (2)

- Leader Lvm181aDocument11 pagesLeader Lvm181aSanyel SaitoNo ratings yet

- This Information Is Provided byDocument3 pagesThis Information Is Provided bySanyel SaitoNo ratings yet

- Leader 3216 User ID8006Document35 pagesLeader 3216 User ID8006Sanyel SaitoNo ratings yet

- Oscilloscope HM 1004-: Manual - Handbuch - ManuelDocument31 pagesOscilloscope HM 1004-: Manual - Handbuch - ManuelSanyel SaitoNo ratings yet