Professional Documents

Culture Documents

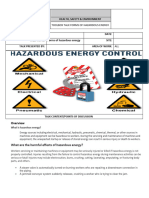

Factsheet Lockout Tagout

Factsheet Lockout Tagout

Uploaded by

nestor gonzalez de leon0 ratings0% found this document useful (0 votes)

5 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pagesFactsheet Lockout Tagout

Factsheet Lockout Tagout

Uploaded by

nestor gonzalez de leonCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

What is the OSHA standard for The standard gives each employer the flexibility

control of hazardous energy sources? to develop an energy control program suited to

The OSHA standard for The Control of the needs of the particular workplace and the

Hazardous Energy (Lockout/Tagout), Title 29 types of machines and equipment being

Code of Federal Regulations (CFR) maintained or serviced. This is generally done by

Part 1910.147, addresses the practices and affixing the appropriate lockout or tagout devices

procedures necessary to disable machinery or to energy-isolating devices and by deenergizing

equipment, thereby preventing the release of machines and equipment. The standard outlines

hazardous energy while employees perform the steps required to do this.

servicing and maintenance activities. The

standard outlines measures for controlling What do employees need to know?

hazardous energies—electrical, mechanical, Employees need to be trained to ensure that

hydraulic, pneumatic, chemical, thermal, and they know, understand, and follow the applicable

other energy sources. provisions of the hazardous energy control

In addition, 29 CFR 1910.333 sets forth procedures. The training must cover at least

requirements to protect employees working on three areas: aspects of the employer’s energy

electric circuits and equipment. This section control program; elements of the energy control

requires workers to use safe work practices, procedure relevant to the employee’s duties or

including lockout and tagging procedures. These assignment; and the various requirements of the

provisions apply when employees are exposed to OSHA standards related to lockout/tagout.

electrical hazards while working on, near, or with

conductors or systems that use electric energy. What must employers do to protect

employees?

Why is controlling hazardous energy The standards establish requirements that

sources important? employers must follow when employees are

Employees servicing or maintaining machines exposed to hazardous energy while servicing and

or equipment may be exposed to serious physical maintaining equipment and machinery. Some of

harm or death if hazardous energy is not the most critical requirements from these

standards are outlined below:

properly controlled. Craft workers, machine

operators, and laborers are among the 3 million ■ Develop, implement, and enforce an energy

workers who service equipment and face the control program.

greatest risk. Compliance with the lockout/

tagout standard prevents an estimated 120

■ Use lockout devices for equipment that can

fatalities and 50,000 injuries each year. Workers be locked out. Tagout devices may be used

injured on the job from exposure to hazardous in lieu of lockout devices only if the tagout

program provides employee protection

energy lose an average of 24 workdays for

equivalent to that provided through a lockout

recuperation.

program.

How can you protect workers? ■ Ensure that new or overhauled equipment is

capable of being locked out.

The lockout/tagout standard establishes the

employer’s responsibility to protect employees ■ Develop, implement, and enforce an effective

from hazardous energy sources on machines and tagout program if machines or equipment are

equipment during service and maintenance. not capable of being locked out.

■ Develop, document, implement, and enforce its many safety and health programs: workplace

energy control procedures. [See the note to consultation, voluntary protection programs,

29 CFR 1910.147(c)(4)(i) for an exception grants, strategic partnerships, state plans,

to the documentation requirements.] training, and education. Guidance such as

OSHA’s Safety and Health Management

■ Use only lockout/tagout devices authorized

Program Guidelines identify elements that are

for the particular equipment or machinery

critical to the development of a successful safety

and ensure that they are durable,

and health management system. This and other

standardized, and substantial.

information are available on OSHA’s website at

■ Ensure that lockout/tagout devices identify www.osha.gov.

the individual users. ■ For a free copy of OSHA publications, send a

■ Establish a policy that permits only the self-addressed mailing label to this address:

employee who applied a lockout/tagout OSHA Publications Office, P.O. Box 37535,

device to remove it. [See 29 CFR Washington, DC 20013-7535; or send a

1910.147(e)(3) for exception.] request to our fax at (202) 693-2498, or call

us at (202) 693-1888.

■ Inspect energy control procedures at least

annually. ■ To file a complaint by phone, report an

emergency, or get OSHA advice, assistance,

■ Provide effective training as mandated for all or products, contact your nearest OSHA

employees covered by the standard. office under the “U.S. Department of Labor”

■ Comply with the additional energy control listing in your phone book, or call us toll-free

provisions in OSHA standards when at (800) 321-OSHA (6742). The tele-

machines or equipment must be tested or typewriter (TTY) number is (877) 889-5627.

repositioned, when outside contractors work ■ To file a complaint online or obtain more

at the site, in group lockout situations, and information on OSHA federal and state

during shift or personnel changes. programs, visit OSHA’s website.

How can you get more information?

OSHA has various publications, standards,

technical assistance, and compliance tools to

help you, and offers extensive assistance through

This is one in a series of informational fact sheets highlighting OSHA programs, policies, or standards. It does not impose

any new compliance requirements or carry the force of legal opinion. For compliance requirements of OSHA standards or

regulations, refer to Title 29 of the Code of Federal Regulations. This information will be made available to sensory-impaired

individuals upon request. Voice phone: (202) 693-1999. See also OSHA’s website at www.osha.gov.

U.S. Department of Labor

Occupational Safety and Health Administration

2002

You might also like

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationFrom EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationNo ratings yet

- Automotive Master Technician: Advanced Light Vehicle TechnologyFrom EverandAutomotive Master Technician: Advanced Light Vehicle TechnologyRating: 5 out of 5 stars5/5 (1)

- Fault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesFrom EverandFault Diagnosis and Sustainable Control of Wind Turbines: Robust Data-Driven and Model-Based StrategiesRating: 4 out of 5 stars4/5 (1)

- (Insert Company Here) Preventative Maintenance ProgramDocument6 pages(Insert Company Here) Preventative Maintenance ProgramPaula Madeleine100% (1)

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- Hoja Informativa Sobre Bloqueo y Etiquetado en InglesDocument2 pagesHoja Informativa Sobre Bloqueo y Etiquetado en InglesYisel RomeroNo ratings yet

- LotoDocument48 pagesLotohassan BilalNo ratings yet

- LOTO Hazardous Energy ControlDocument48 pagesLOTO Hazardous Energy Controlherik100% (1)

- Saf102-Lecture 5: Lockout Tagout (Loto)Document4 pagesSaf102-Lecture 5: Lockout Tagout (Loto)Lin VictoriaNo ratings yet

- LOTO NotesDocument12 pagesLOTO NotesShirishNo ratings yet

- The Control of Hazardous Energy (Lockout/Tagout) : Before You BeginDocument3 pagesThe Control of Hazardous Energy (Lockout/Tagout) : Before You BeginKanupriyaNo ratings yet

- A Guide To The Control of Hazardous Energy (Lockout/Tagout) : N.C. Department of LaborDocument33 pagesA Guide To The Control of Hazardous Energy (Lockout/Tagout) : N.C. Department of Labormanox007No ratings yet

- Whatislotoprocedure 140804104337 Phpapp01Document10 pagesWhatislotoprocedure 140804104337 Phpapp01Helmy RosadiNo ratings yet

- AC LO TO Program 1 PDFDocument13 pagesAC LO TO Program 1 PDFVictor Hugo Gutierrez B100% (1)

- Lecture 4 Lockout Tagout A06Document27 pagesLecture 4 Lockout Tagout A06isidro ylananNo ratings yet

- ZMSDocument6 pagesZMSimnithin100% (1)

- Lockout Tagout ProgramDocument9 pagesLockout Tagout Programminhduc2010100% (1)

- Review k3 LukuDocument8 pagesReview k3 LukuVandi SitorusNo ratings yet

- NR 12 - Lockout Tagout ProgramDocument19 pagesNR 12 - Lockout Tagout ProgramCPSSTNo ratings yet

- 1 Control of HazardousDocument5 pages1 Control of HazardousVinz Hexon BalangueNo ratings yet

- Environmental Health & Safety: Oklahoma State UniversityDocument16 pagesEnvironmental Health & Safety: Oklahoma State UniversityMarienNo ratings yet

- PD 156Document109 pagesPD 156Hom Jyoti AdhikariNo ratings yet

- Lockout Tagout GuideDocument63 pagesLockout Tagout GuideEdmund Yoong100% (1)

- Safety in Chemical Process PlantsDocument5 pagesSafety in Chemical Process PlantsSrinivasan .MNo ratings yet

- Assessment Task 1 WHSDocument4 pagesAssessment Task 1 WHSPahn PanrutaiNo ratings yet

- Introduction To Water System Safety: What Is in This Chapter?Document26 pagesIntroduction To Water System Safety: What Is in This Chapter?Anonymous iTzCnMNo ratings yet

- Lockout/Tagout ManualDocument19 pagesLockout/Tagout Manualmanox007100% (1)

- Switch Gear SafetyDocument16 pagesSwitch Gear SafetyAnila SadasivanNo ratings yet

- Policy: All EmployeesDocument22 pagesPolicy: All Employeespreventing becejNo ratings yet

- Plant Floor Safety by CFE MEDIADocument79 pagesPlant Floor Safety by CFE MEDIAsasasNo ratings yet

- Employee SafteyDocument12 pagesEmployee SafteyBirajini Dalai100% (1)

- LOTODocument29 pagesLOTOCaleb Conner100% (1)

- Toolbox Talk Power Press SafetyDocument1 pageToolbox Talk Power Press SafetyZeeshan BajwaNo ratings yet

- Guidelines For Developing A Welding and Cutting Safety ProgramDocument3 pagesGuidelines For Developing A Welding and Cutting Safety ProgramMichael RujuwaNo ratings yet

- Forms of Hazardous EnergyDocument3 pagesForms of Hazardous EnergyIsaac ItaNo ratings yet

- SH26 - OSHAProgramStandardsDocument5 pagesSH26 - OSHAProgramStandardsDave Laryll SantosNo ratings yet

- Refrigeration and Air Conditioning Trade Safety For Construction, Service, and Maintenance Workers ForewordDocument34 pagesRefrigeration and Air Conditioning Trade Safety For Construction, Service, and Maintenance Workers ForewordParag ShrivastavaNo ratings yet

- MaintenanceDocument2 pagesMaintenanceCatkiolNo ratings yet

- Electrical Switchgear and SafetyDocument16 pagesElectrical Switchgear and SafetyAli Khamis100% (1)

- Loto Manual P6 725Document22 pagesLoto Manual P6 725marco moralesNo ratings yet

- Control of Hazardous Energy - Study GuideDocument27 pagesControl of Hazardous Energy - Study GuideJoseph DeMaria, Ph.D.No ratings yet

- How To Conduct Workplace Inspections: A Health and Safety Guideline For Your WorkplaceDocument6 pagesHow To Conduct Workplace Inspections: A Health and Safety Guideline For Your WorkplacemashanghNo ratings yet

- Guidance For Treatment of SSCs - ML12095A362Document134 pagesGuidance For Treatment of SSCs - ML12095A362Fernando DiezNo ratings yet

- Inspection+Guide 0114 Final+web LRDocument16 pagesInspection+Guide 0114 Final+web LRNana Silvana AgustiniNo ratings yet

- Electrical Safety: by Jeffrey C. CamplinDocument4 pagesElectrical Safety: by Jeffrey C. CamplinmkesperatNo ratings yet

- WP LOTO Past Present FutureDocument7 pagesWP LOTO Past Present FutureishaqNo ratings yet

- Machine Safety GuidelinesDocument21 pagesMachine Safety GuidelinesPampanagouda YadavNo ratings yet

- Safety Professionals Guide To Lockout Tagout EbookDocument33 pagesSafety Professionals Guide To Lockout Tagout EbookSebastian Mejia PuertaNo ratings yet

- SY35 Lockout/Tagout: Policy Status: Policy StewardDocument5 pagesSY35 Lockout/Tagout: Policy Status: Policy StewardBasil M. IkhleifNo ratings yet

- Module14 OSHA Safety ComplianceDocument30 pagesModule14 OSHA Safety CompliancejoseferrehigieneuruNo ratings yet

- BV Inspection+GuideDocument16 pagesBV Inspection+GuidesuhailpmNo ratings yet

- Planned Preventive MaintenanceDocument4 pagesPlanned Preventive MaintenanceMOHAMMAD AHMADNo ratings yet

- GN3 - ElectricalSafety and LOTODocument73 pagesGN3 - ElectricalSafety and LOTONavi AgeinNo ratings yet

- Protecting Employees Who Work On Homeland Security and Critical Infrastructure ProjectsDocument11 pagesProtecting Employees Who Work On Homeland Security and Critical Infrastructure ProjectsAjendra SinghNo ratings yet

- 1077-2618/03/$17.00©2003 IeeeDocument6 pages1077-2618/03/$17.00©2003 Ieeegirish19No ratings yet

- Osha PPE PDFDocument46 pagesOsha PPE PDFWiji Arum100% (1)

- Hybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesFrom EverandHybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesNo ratings yet

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- The Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsFrom EverandThe Real Product Safety Guide: Reducing the Risk of Product Safety Alerts and RecallsNo ratings yet

- Where do I start? 10 Health and Safety Solutions: A Workbook for Busy Managers, Supervisors & Business OwnersFrom EverandWhere do I start? 10 Health and Safety Solutions: A Workbook for Busy Managers, Supervisors & Business OwnersNo ratings yet

- EnergySystems Slick2015 11.19.15 Reduced PDFDocument1 pageEnergySystems Slick2015 11.19.15 Reduced PDFYousuf IbrahimNo ratings yet

- Allianz Claim FormDocument2 pagesAllianz Claim FormYousuf IbrahimNo ratings yet

- Automatic Meter ReadingDocument4 pagesAutomatic Meter ReadingYousuf IbrahimNo ratings yet

- Low-Cost Occupancy Sensor Saves Energy: Building A Better SensorDocument2 pagesLow-Cost Occupancy Sensor Saves Energy: Building A Better SensorYousuf IbrahimNo ratings yet

- 5753 LDocument7 pages5753 LYousuf IbrahimNo ratings yet

- GE The Evolving Workspace WhitepaperDocument4 pagesGE The Evolving Workspace WhitepaperYousuf IbrahimNo ratings yet

- NFPA70EDocument58 pagesNFPA70EYousuf Ibrahim100% (1)

- Standard Energy Audit Procedure - GreenhospitalDocument129 pagesStandard Energy Audit Procedure - GreenhospitalYousuf Ibrahim100% (1)

- Optimized Solutions From An Energy Specialist: Energy Sustainability Consultation ServicesDocument8 pagesOptimized Solutions From An Energy Specialist: Energy Sustainability Consultation ServicesYousuf IbrahimNo ratings yet