Professional Documents

Culture Documents

Ford 5640-6640-7740-7840-8240-8340

Ford 5640-6640-7740-7840-8240-8340

Uploaded by

Meleștean Mihai100%(4)100% found this document useful (4 votes)

879 views276 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(4)100% found this document useful (4 votes)

879 views276 pagesFord 5640-6640-7740-7840-8240-8340

Ford 5640-6640-7740-7840-8240-8340

Uploaded by

Meleștean MihaiCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 276

SHOP MANUAL

FORD

MODELS 5640-6640-7740-7840-8240-8340

The tractor identification plate is located on right side

under the tractor hood. Serial and model numbers of the

tractor, engine, transmission, rear axle, hydraulic pump

and the hydraulic lift are recorded on this identification

plate. If equipped with front-wheel drive, a similar plate is

attached to the rear surface of the front drive axle housing.

INDEX (By Starting Paragraph)

BRAKES ENGINE AND COMPONENTS

Adjustment. . 226 Cam Followers ..... 45

Brake Discs and Actuating Assembly. oe 0) Camshaft and Bearings........ 44

Master Cylinder........ dooce Connecting Rods and Bearings............. 52

System Bleeding ... soi sie Connecting Rod and Piston Units... 46

CLUTCH, ENGINE Crankshaft and Main Bearings seoees BB

Clutch Assembly, R&R. vee 198 Crankshaft Oil Seals.....0000 00.2. cece. 54

Clutch Linkage. . oe vee 124 Cylinder Head is

Clutch Master Cylinder 22: + Engine Balaneer (5640, 6640, 7740) 2 56

Clutch Release Bearing : 137 Engine, R&R...... cs tees BL

‘Tractor Split...... : anos sda Oa Exhaust Valve Rotators... 21.1.0... 37

COOLING SYSTEM Flywheel...... ress ABT

Radiator ...... ve. 87 Oil Pump and Relief Valve. 59

Radiator Pressure Cap and Thermostat....., 86 Oil Sump. . + 58

Water Pump...... frecect cae OR Pistons and Rings... 47

DIESEL FUEL SYSTEM Pistons and Cylinders 48

Adjustments..........00..2065 - 88 Piston Fine - + 61

Filters and Bleeding i 70 Rocker Arms. ......... + 83

Fuel Injection Pump . + 80 ‘Timing Gear Cover... + 88

Fuel Injectors a) ‘Timing Gears ....... - 39

Fuel Tanks... fn. 66 ‘Turbocharger (7740 and 8340) 61

Injection Pump Drive Gear | Valve Clearance «+. ....+. 34

‘Troubleshooting . . 69 Valve Guides and Springs + 86

DIFFERENTIAL, MAIN DRIVE BEVEL Valves, Stem Seals and Seats . + 35

GEARS, FINAL DRIVE AND REAR AXLES FRONT AXLE (Two-Wheel Drive) _

Bevel Pinion... es 222 Alo Center Merobes, Pivot Pina and Bushings. 4

Differential and Differential Lock 220 Front Support. .. 5

Rear Axle and Final Drive.......... 224 Spindles, Axle Extentions and Bushings ...... 3

‘Tractor Rear Split 219 Tie Rod, Toe-Out and Tread Adjustment - 2

sterol

DUAL POWER (16 x 4 Transmission) Wheels and Bearings. ....

Control Valve . . 144 FRONT-WHEEL DRIVE

Dual Power Unit . ‘

i ‘Adjustments 6

Lubrication... . Axle Pivot Bearings .. 4

Pressure Test. Bevel Pinion Gear Ww

‘Troubleshooting... Differential, . 15

ELECTRICAL SYSTEM Drive Shaft... . tahoe

Alternator and Regulator ....... Front Drive Axle. 5 10

Instrumentation. Front Support. ..... 20

Starting Motor ‘ Steering Knuckle Housing. 13

ELECTRICAL WIRING DIAGRAMS 300 ‘Transfer Gearbox . .. 18

‘Wheel Hub and Planetary (5640, 6640, 7740). 11

Wheel Hub and Planetary (7840, 8240, 8340). 12

HYDRAULIC LIFT (Electronic Draft Control)

Electronic Draft Control Valve . » 280

Hydraulic Lift Cover ...... 3 278

Operation ......6600cceeeeeeeeeeeeeeees 270

‘Troubleshooting... - 271

HYDRAULIC LIFT (Top Link Sensing)

External Linkage Adjustment. ... 291

Hydraulic Lift Cover and Cylinder......... 285

Internal Linkage Adjustment ++ 288

Lift Assist Cylinder . 294

Operation 281

Priority Valve Pack ..... 283

‘Troubleshooting ...... 282

Unloading Valve. .... 284

HYDRAULIC SYSTEM

Hydraulic Fluid and Filters ...... 240

HYDRAULIC SYSTEM (Closed Center

Load Sensing)

Operation : - 241

Pressure Testing, =

Pump Overhaul

‘Troubleshooting .

HYDRAULIC SYSTEM (Open Center),

Engine Mounted Auxiliary Gear Pump ..... 269

Ope es ea canvas vvnwane 04 258

Pressure Testing. 259

‘Transmission Mounted Tandem Gear Pump . 268

HYDROSTATIC STEERING

Fluid and Bleeding.

Power Cylinder.

Pump........-

Steering Valve .....

‘Tests and Adjustment .

‘Troubleshooting

POWER TAKE-OFF

Operating Principles .....

Pto Clutch and Control Valve (Mechanically

Operated)... :

Pto Clutch and Control Valve (Electric

Solenoid Operated)... . -

Pto Output Shafts and Gears

237

vos 238

+ 234

‘Troubleshooting . - 233

REDUCTION GEARBOX. 0.2.0... 148

REMOTE CONTROL VALVES

Adjustments... . one 296

Remote Control Valve 2 298

Remote Valve Couplers ..... + 299

TRANSMISSION (8 x 2 Constant Mesh)

Lubrication.........+5 wen ev UML

Overhaul....... 133

Remove and Reinstall... 132

‘TRANSMISSION (16x 16 Powershift Built

Prior To September 1993)

Clutch Calibration . amram 178

Electrical Component Description v7

Gearshift Cover « : teseeeeee 193

Gearshift Linkage » 192

Pressure Testing... +. 184

‘Transmission Control Valve. .........++++- 190

‘Transmission Overhaul - 194

‘Troubleshooting Electronic Control System... 188

‘Troubleshooting Transmission System...... 189

TRANSMISSION (16 x 16 "Quad Mod’ Power-

shift Built September 1993 And After)

Clutch Fill Time Calibration ......... 206

Clutch Spring Pressure Calibration . ++ 204

Gear Shift Control Cables - ‘ 216

Pressure Testing. .... sees 208

‘Transmission Control Valve. see 216

‘Transmision Overhaul 218

Troubleshooting Electronic Control System. . 212

TRANSMISSION (1212 Synchro-Shift)

Lubrication 151

Overhaul... - 153

Remove and Reinstall 152

‘TRANSMISSION (12 x 12 Synchro-Shift With

Dual Power)

Clutch Calibration ..... 163

Dual Power Unit ‘ 174

Electro-Hydraulie System .. 162

Lubrication Control Valve z a; TB

Pressure Testing. . capnesees TEL

‘Transmission Control Valve. ia, OB

‘Troubleshooting Electronic Control System. . 167

DUAL DIMENSIONS

This service manual provides specifications in both U.S. Customary and Metric (SI) systems of

measurement. The first specification is given in the measuring system perceived by us to be the

preferred system when servicing a particular component, while the second specification (given in

parenthesis) is the converted measurement. For instance, a specification of 0.011 inch (0.28 mm)

would indicate that we fee! the preferred measurement in this instance is the U.S. Customary system

of measurement and the Metric equivalent of 0.011 inch is 0.28 mm.

CONDENSED SERVICE DATA

Displacement .

Compression Ratio..........

TUNE-UP

Firing Order. ....

‘Valve Clearance, Cold —

Inlet .....

Exhaust .....

Compression Pressure —

Minimum..............

Injector Opening

Pressure. .

Engine Low Idle RPM.

Engine High Idle RPM

Engine Rated Speed RPM... .

Engine Rated Power

atPto......

Battery —

Voltage . .

Ground.

SIZES

Crankshaft Main

Journal Diameter .. .

Crankshaft Crankpin

Diameter .....

Piston Pin Diameter

Valve Seat Angle —

Inlet .

Exhaust ....

Valve Face Angle —

Inlet

Exhaust es

Valve Stem Diameter —

Inlet... 2...

Exhaust ....

Cylinder Bore Diameter .....

5640 6640 7740 7840 8240 8340

4

111.8 mm

(4.4 in.)

18mm = —127.0mm— —11.8mm = — 127. 0 mm——

(4.4 in.) (6.0 in.) (4.4 in.) (5.0 in.)

4390 cc =» ——4987 ee — 6585 cc |= ——— 7480 cc ——

(268 cu. in.) (304 cu. in.) (401 cu. in.) (456 cu. in.)

17.5:1

13-42: 15-3-6-2-4

).36-0.46 mm:

(0.014-0.018 in.)

.43-0.53 mm:

(0.017-0.021 in.)

2585 kPa:

(375 psi)

23,995-24,755 kPa —— 29, 165-29,995 kPa

(3480-3590 psi) (4230-4350 psi)

725 - 175

— 2295-2375 —— 2195-2275

—— 2200 2100:

49kW = 56.5KW 64 kW. 67kW = 7L5kW 83.5 kW

(66hp) (76 hp) += (86 hp) (90hp)- (9Bhp) (112 hp)

12.

Negative:

See Paragraph 53:

See Paragraph 52-

——38.095- 41.270- ~— —— 38,095- 41.270-

38.10 mm — 41.275 mm 38.10mm— 41.275 mm

(1.4998- (1.6248- (1.4998- (1,6248-

1.500 in.) 1.6250 in.) 1.500 in.) 1.6250 in.)

:30.0-30.5°

45.0-45.5°

29.25-29.5°

44.25-44.5°

9.426-9.446 mm

(0.3711-0.3719 in.)

9.401-9.421 mm.

(0.3701-0.3709 in.)

111.778-111.841 mm

(4,4007-4.4032 in.)

CONDENSED SERVICE DATA (Cont.)

CLEARANCES

Main Bearing,

Diametral Clearance

Rod Bearing,

Diametral Clearance.

Camshaft Bearing,

Diametral Clearance......-

Crankshaft End Play. ...

CAPACITIES

Cooling System

Crankease —

With Filter

Fuel tank

‘Transmission/Hydraulic —

8x2and16x4

540 Pto.

540/1000 Pto .

12x12...

16x16 semen

Front Drive Axle .

Front Drive Hub (each). .

TIGHTENING TORQUES

Cylinder Head .

Connecting Rod .

‘Main Bearings ......

Intake Manifold...

Exhaust Manifold

Flywheel. ....

Crankshaft Pulley .

OilPan......

Camshaft idler Gear...

Camshaft Gear.

Fuel Injectors

Water Pump

5640 6640 740 7840 8240 8340

0,055-0.117 mm.

(0.0021-0.0046 in.)

0.035-0.094 mm

(0.0014-0.0037 in.)

0.025-0.076 mm

(0.001-0.003 in.)

0.10-0.20 mm:

(0.004-0.008 in.)

16 L ———— ———215L

(16.9 US. qt.) (22.7 US. at.)

1.4 L——— ——— 209L

(12.1 US. qt.) (22.1 US. qt)

94.6 L Std. ——— 217.7 L Std.

(25.0 US. gal.) (67.5 US. gal.)

62L

(65.5 US. at.)

66 L

(69.7 US. at.)

8L_———__. ——_.... ——

(15.0 US. gal.)

60.6 L

(16.0 US. gal.)

621. ————_ 8.0L

(66 US. qt.) (85 US. at.)

3.0L 2.6L

(8.2US. qt.) (2.7US. at.)

217 Nem (160 ft.-Ibs.)

149 Nem (110 ft-lbs.)

197 Nem (145 ft.-Ibs.)

—85 Nem (28 ft.-Ibs.)

38 N.m (28 ft-lbs.

197 Nem (145 ft.-Ibs.)

224 Nem (165 ft.-Ibs.)

38 Nem (28 ft.-Ibs.)

237 Nem (175 ft.-Ibs.)

69 Nem (51 ft.lbs.

—23 Nem (17 ft-lbs.)

65 Nim (50 ft-tbs.

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Paragraphs 1-3

FRONT AXLE SYSTEM

(TWO-WHEEL DRIVE)

FRONT AXLE ASSEMBLY AND

STEERING LINKAGE

Two-Wheel Drive Models

1. WHEELS AND BEARINGS. To remove front

wheel hub and bearings, first raise and support the

front axle extension, then unbolt and remove the tire

and wheel assembly. Remove the cap (1—Fig. 1),

cotter pin (3), slotted nut (2), washer (4) and outer

bearing cone (5). Slide the hub assembly (6) from

spindle axle shaft (10). Remove grease retainer (8)

and inner bearing cone (7). Hub is slotted to facilitate

removal of bearing cups.

Pack wheel bearings liberally with Ford M1C137-

A, MIC75-B or equivalent grease. Reassemble by

Fig. 1—Exploded view of front whee! hub used on two

whee! drive models. Mud shield (9) Is used only on 8240

and 8340 models.

1. Cap 6. Hub

2 Slatted nut 17. Inner bearing cone

8. Cotter pin e retainer

4. Washer

5. Outer bearing cone

reversing disassembly procedure. Grease retainer (8)

and inner bearing cone (7) should be positioned on

spindle, then install wheel hub (6). Tighten slotted

nut (2) to a torque of 27-40 Nem (20-30 ftIbs.), then,

rotate hub several turns. Tighten nut (2) to 61-74Nem

(45-50 ft.-Ibs.), then back nut off less than one flat and

install cotter pin (3). Be sure to install cap (1) se~

curely.

2, TIE ROD, TOE-OUT AND TREAD ADJUST-

MENT. All models are equipped with one tie rod

extending between left. and right steering arms. The

hydrostatic steering cylinder (19 Fig. 2) is attached

between the front axle and the center of the tie rod.

Left end (18) of tie rod and both ends of steering

cylinder are automotive type and should be renewed

if wear is excessive. The procedure for removing and

stalling the ends is self evident. Automotive end of

right tie rod is renewable only as an assembly with

the right tie rod.

Alll two-wheel drive models are equipped with ad-

justable tread axle, Tie rod is equipped with locating

screws (15) for quick adjustment of tie rod length

when changing tread width. To adjust tread width,

raise and support front axle. Remove tie rod locating,

screws (15) and clamp screws (9) from axle extensions

(and 12), then slide axle extensions in or out of axle

center member (8). Tighten the track adjusting clamp

screws (9) which attach axle extensions inside the

axle center section to 400 Nem (300 ft.-Ibs.) torque.

‘Tighten tie rod locating screws (15) to 150 Nem (110

ft-lbs.) torque and locknuts to 75 Nem (55 ft.-lbs.)

torque. After resetting axle tread width, check and

adjust front wheel toe-out as described below.

‘Recommended front wheel toe-out is 0-13 mm (0-

yin.) for two-wheel drive models. To check toe-out,

turn steering wheel so that front wheels are in

straight ahead position. Measure distance (A—Fig.

8) between wheel rims on centerline of axle, parallel

to ground. Rotate wheels 4 turn, then measure

tween wheels at front of wheels in position (B).

mension (A) should be 0-13 mm (0-¥% in.) smaller

than dimension (B). To adjust toe-out, remove locat-

ing bolt (15—Fig. 2) from left end of tie rod tube (16).

Loosen clamp bolt in left tie rod end (18). Turn

threaded section of tie rod (17) in or out to obtain

desired toe-out. Tighten tie rod locating bolt to 150

Nom (110 ft.-Ibs) torque and clamp bolt to 75 Nem (55

ft-lbs.) torque.

3. SPINDLES, AXLE EXTENSIONS AND

BUSHINGS. To remove spindle (1—Fig. 2), first

remove the wheel and hub, then disconnect tie rod

end from steering arm (7 or 13). Check threaded end

Paragraph 3 (Cont.)

Fig. 3—On two-wheel drive models, front wheels should

be toed out 0-13 mm (0-1/2 in.).

of spindle and steering arm for alignment marks

(M—Fig. 4) before removing steering arm. Note that,

it may be necessary to use a thread file to clean the

threads of spindle since they are deformed during

assembly at the factory in order to lock the spindle

nut in place. Remove nut retaining steering arm (7 or

13—Fig. 2), then pull steering arm from splines of

spindle. Lower spindle (1) from axle extension (5 or

12), Remove thrust bearing 3) and chamfered washer

(2) from spindle. Clean and inspect parts for wear or

other damage and renew as necessary.

When reassembling, lubricate bushings (4) and

pack thrust bearing (3) with Ford M1C137-A,

10

FORD

Fig. 2—Exploded view of adjustable

axle typical of two-wheel drive models.

1. Spindle

2 Washer

3. Thrust bearing

4 Bushings

5, Left axle extension

6, Felt sealing washer

7. Left steering arm

8. Axle center member

9, Track clamp bolt

10, Bushings

11, Washers

12, Axle right extension

13. Right steering arm

MA, Right tie rod

15, Locking screws

16. Tie rod tube

V7. Left tie rod

18. Tie rod end

19, Power steering cylinder

Fig. 4—Marks (M) are provided on the spindles and the

steering arms to assist in correct assembly.

‘MIC75-B or equivalent grease. Install washer (2)

with chamfered edge down toward boss of spindle,

then install thrust bearing (3) on spindle so that

numbered side of bearing is facing upward. Insert

spindle through axle extension. Install new felt

washer (6), then locate steering arm on top of spindle.

Align marks on threaded end of spindle and steering

arm as shown (M—Fig. 4). Tighten steering arm

retaining nut to 488-597 N.m (360-440 ft--Ibs.)

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

torque, then stake threads to prevent loosening. Re-

fer to paragraph 2 for tread width and toe-out adjust-

ment. Balance of reassembly is the reverse of

disassembly. Tighten the track adjusting clamp

screws (9—Fig. 2) which attach axle extensions inside

the axle center section to 400 Nem (300 ft-lbs.)

torque. Tighten tie rod locating bolts (15) to 150 Nem

(110 ft-lbs.) torque and locknuts to 75 N-m (55 ft.-bs.)

torque. Tighten left tie rod end clamp bolt to 100 Nem

(75 ft-lbs.) torque after toe-out is correctly set.

4, AXLE CENTER MEMBER, PIVOT PIN AND

BUSHINGS. To remove front axle assembly, raise

front of tractor in such a way that it will not interfere

with the removal ofthe axle. A hoist may be attached

to front support or special stands can be attached to

sides. Removal of the axle center member (8—Fig. 2)

may be easier if the axle extension and spindle as-

sembly is first removed from each side; however, the

complete assembly can be removed as a unit. Remove

front wheels and weights, then support the axle with

a suitable jack or special safety stand to prevent

tipping while permitting the axle to be lowered and

moved safely. Disconnect hoses from the steering

cylinder and cover openings to prevent the entry of

dirt, Unbolt and remove the front axle pivot pin.

Lower axle until axle is free from front support, then

carefully roll axle away from under tractor.

Paragraphs 4-7

Check axle pivot bushings (10) and renew if neces-

sary. Reverse removal procedure when assembling.

Lubricate pivot bushings with Ford M1C137-A,

MIC75-B or equivalent grease. Tighten screws re-

taining the axle pivot pin to 70-90 N.m (52-66 ft.-Ibs.)

torque, then bend locking tabs around screws to pre-

vent loosening.

5. FRONT SUPPORT. To remove the front sup-

port, the axle must be removed, the radiator must be

removed from the support and the front support must.

be unbolted from the front of engine. The front axle,

the front support and the remainder of the tractor

must each be supported separately while removing,

while separated and while assembling. Be sure that

sufficient equipment is available before beginning.

Refer to paragraph 67 and remove the main fuel

tank, then refer to paragraph 87 and remove the

radiator. Support front of tractor in such a way that

it will not interfere with removal of either the front

support or the front axle, Remove axle as outlined in

paragraph 4. Attach a hoist or other supporting de-

vice to the front support, then unbolt and separate

the front support from the front of the engine. Be

careful not to lose or damage shims located between

front support and engine. Keep shims separate and

label for installation in same loc

FRONT-WHEEL DRIVE

Mechanical front-wheel drive is available which

uses a front drive axle manufactured by Carraro.

‘Models 5640, 6640, 7740 and 7840 are equipped with

standard type 709 axle; Models 8240 and 8340 are

equipped with heavy duty type 709 axle. Some differ-

ences in the front-wheel drive systems will be noted

in the following service instructions.

‘The transfer gearbox engagement is controlled by

an electric solenoid/hydraulic valve which directs oil

pressure to move a dog clutch and engage the front

wheel drive. The transfer gearbox is attached to the

bottom of the rear axle center housing of all models.

Addrive shaft connects the transfer gearbox to front

axle.

ADJUSTMENTS

All Four-Wheel Drive Models

6. FRONT WHEEL TREAD WIDTH. Front-

wheel drive axle is a fixed assembly. However, track

width can be adjusted by changing the wheel rim

relative to the center disc, the rim and/or disc relative

to axle hub or by interchanging the front wheels. The

drawings shown in Fig. 6 illustrate different wheel

rim and dise positions relative to the hub and the

resulting track width settings.

NOTE: When interchanging front wheels from

side to side, make sure that “V" of tire tread is

pointing in the direction of forward travel.

‘Tighten disc to hub mounting nuts to 475 N-m (350

ft-lbs.) torque and disc to rim mounting nuts to 240

Nem (177 ft.-bs.) torque. Recheck the dise and rim

mounting nut torque after driving the tractor about

200 meters (200 yards), after one hour of operation,

after eight hours of operation and at 50 hour inter-

vals.

After resetting track width, check toe-in setting as

outlined in paragraph 7 and steering stop setting as,

outlined in paragraph 8.

7. TIE RODS AND TOE-IN. Tie rod ends are not

adjustable for wear and faulty units must be re-

newed. To check toe-in, first turn steering wheel so

that front wheels are in straight ahead position.

‘Measure distance between front wheels at front and

rear of wheels from rim flange to rim flange at hub

height, Distance measured at front of wheels should

be 0-6 mm (0-4 in.) less (toed in) than distance

‘measured at rear of wheels. To adjust, loosen clamp

n

Paragraph 8

‘Track Setting

DiseiRim Position | 24 in. 28 i

wheels wheels

556in. | 54.7in

1412 mm) | (1389 mm)

597in. | 588in

(1516 mm) | (1493 mm)

636in, | 627 in,

(1615 mm) } (1592 mm)

Fig. 6—View of toe-in adjustment points for four-wheel-

drive models. Be sure to adjust both sides equally. Refer

totext.

617 668 in.

(1718 mm) } (1696 mm)

niin, | 71.9 in,

(1812 mm) | (1825 mm)

7sain. | 759in

(1916 mm) } (1929 mm)

79.3in, | 799in

(2015 mm) | (2028 mm)

834in. | 839i

(2119 mm) | (2132 mm)

Fig. 5—Front-wheel drive axle track width is adjusted by

changing position of whee! rim and disc.

12

Fig. 7—Steering stop screws (S) should be adjusted to

prevent tires from touching any part of tractor when

Wheels are turned.

bolt (2—Fig. 6), then turn tie rod (1) in or out of tie

rod end (3) as required. Adjust both sides evenly.

‘When adjustment is correct, tighten clamp bolt (2) to

56 Nem (41 ft.-bs.) torque.

8. STEERING STOPS AND ARTICULATION.

‘The front axle is provided with adjustable steering

and articulation stops to prevent the front tires from

contacting the tractor. Adjusted setting should not

change during operation, but different tire sizes or

tread and changes in track width may make adjust-

ment necessary. The steering stop screws (S—Fig. 7)

should be adjusted to provide a minimum clearance

of 20 mm (% in.) between tire and frame. Tighten

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Fig. 8—Articulation stops (1) can be installed using the

center and rear (2) mounting holes as shown or the center

and front (3) threaded holes can be used. Refer to text.

Jocknut to 150 Nem (110 ft.-Ibs.) torque when adjust-

ment is correct.

Articulation stops (1—Fig. 8) should prevent the

tires from contacting the tractor when the front axle

is tipped against stops. When stop is attached to the

rear two screws (2) as shown, the axle should be

limited to approximately 8° of movement. When the

stop is attached to the center and front hole (3),

articulation is limited to about 12° from horizontal.

Stops (1) should be positioned at same location on

both sides,

DRIVE SHAFT

All Four-Wheel Drive Models

9. REMOVE AND REINSTALL. Two different

drive shafts have been used as shown in Fig. 9,

depending upon transmission used.

‘To remove drive shaft (5), first unbolt and remove

the shield assembly (1). To remove drive shaft shown

in the lower view, remove screw (4) and slide cou-

plings (2 and 3) until drive shaft can be withdrawn.

Clamps (7) must be removed before front universal

joint can be separated from yoke (6) of models with 8

x2 and 16x 4 transmissions.

When installing drive shaft on models with 12 x 12

and 16 x 16 speed transmissions, grease coupling

splines, slide couplings onto drive shaft, position

drive shaft, then slide couplings into position and

install screws (4).

On models with 8 x 2 and 16 x 4 speed transmis-

sions, grease rear coupling splines before installing

drive shaft. Tighten clamp bolts of front universal

Joint to 57 Nom (42 ft.-Ibs.) torque.

Paragraphs 9-10

Fig. 9—The drive shaft and shield at top are typical of

‘models with 8x 2and 16x 4 transmissions. The drive shatt

and shield shown in the lower view are typical of models

with transmissions providing 12 12 and 16 x 16 speed

transmissions.

1. Shield

2, Front splined coupling 8. Yoke

8. Rear splined coupling 7. Clamp

4. Serew 8, Yoke retaining serew

5. Drive shaft 9. Bracket

FRONT DRIVE AXLE

All Four-Wheel Drive Models

10.R&R ASSEMBLY. First remove the drive shaft

and shield as outlined in paragraph 9. If differential

unit is to be serviced, it is recommended that the

bevel pinion shaft nut be loosened at this time. Pry

ut pinion shaft cil seal, then loosen nut using special

pinion nut wrench FT3168 or equivalent. Remove

front weights. Raise front of tractor in such a way that

it will not interfere with the removal of the axle. A

hoist may be attached to front support or special

stands can be attached to sides. Remove front wheels,

then support the axle with a suitable jack or special

safety stand to prevent tipping while permitting the

axle to be lowered and moved safely. Disconnect hoses

from the steering cylinder and cover openings to

prevent the entry of dirt. Unbolt and remove front

and rear pivot brackets (1 and 17—Fig. 10), lower

axle until free, then carefully roll axle away.

Reinstall front drive axle by reversing the removal

procedure. Tighten screws attaching front and rear

pivot brackets (1 and 17) to 317-388 N.m (234-286

13

Paragraphs 11-12

Fig. 11—View of “OIL LEVEL" mark (L) and drain plug (1)

of front whee! drive front hub.

fi.lbs.) torque. Tighten steering hose connections to,

34 Nem (26 ft-lbs.) torque if removed or disconnected.

WHEEL HUB AND PLANETARY

Models 5640-6640-7740

11. R&R AND OVERHAUL. Either front wheel

hub and planetary can be serviced without removing,

the steering knuckle housing from axle. Support front.

axle housing and remove front wheel. Remove drain

plug (I—Fig. 11) from planet carrier and drain oil

from hub assembly, Remove the two Allen screws

from planet carrier (2—Fig. 12) and lift planet carrier

from knuckle housing (30).

Remove snap rings (7) and retainer plate (8). Mark:

shafts (4) and planet gears (6), then keep bearings (5)

and thrust washers (3) separate so that they can be

reinstalled as a set in the same location.

Before removing the ring gear (14), mark relative

position of ring gear (14) and steering knuckle hous-

ing (80) to facilitate installation in same location.

Remove snap ring (10), sun gear (11), spacer (12) and

washer (13). Unscrew retaining screws (16), then use

four of the removed screws as jackscrews in threaded

holes of the ring gear carrier (18) to push carrier (18)

and ring gear (14) from hub (21).

14

FORD

Fig. 10—View of front and rear pivot

brackets (1 & 17) installed. Four screws

are used fo attach each bracket to front

Support.

Bump hub (21) from steering knuckle (30), Remove

cups for bearings (20 and 22) and seal (23) from hub.

If necessary, remove inner bearing cone from knuckle

housing.

Clean and inspect all parts for excessive wear or

other damage and renew as necessary.

When reassembling, drive cups for bearings (20

and 22) and oil seal (23) into hub (21). If removed,

install cone for inner bearing (22) on knuckle housing

(30), Install hub (21) and cone for outer bearing (20)

onto knuckle housing. Assemble ring gear (14) to

carrier (18) and secure with retaining ring (19). In-

stall ring gear (14) and gear carrier (18) and tighten

mounting cap screws (16) to 220 Nem (162 ft-lbs.)

torque. Install washer (13), spacer (12), sun gear (11)

and snap ring (10). Stick thrust washer (9) in place

on carrier (2) with “Loctite 638” or equivalent and

install new “O” ring (15) in groove of hub (2). Install

thrust washers (3), bearings (5), planet gears (6) and

retainer plate (8), then secure with snap rings (7).

Install planetary carrier assembly. Install the two

‘Allen screws. Fill hub and planetary to the level of

opening for drain/fill plug (1—Fig. 11) in carrier with

“OIL LEVEL” mark (L) on carrier horizontal. Fill

with Ford ESN-M2C134-D or equivalent, Install

front wheel and tighten disc to hub nuts to 270 Nem

(200 ft.-Ibs.) torque. Dise to wheel rim nuts should be

tightened to 240 Nem (177 ft.-Ibs.) torque.

Models 7840-8240-8340

12, R&R AND OVERHAUL. Either front wheel

hub and planetary can be serviced without removing

the steering knuckle housing (30—Fig. 13). Support

front axle housing and remove front wheel. Remove

drain plug (1—Fig. 11) from planet carrier and drain

oil from hub assembly. Remove the two Allen screws

from planet carrier (2—Fig, 13) and lift planet carrier

from knuckle housing (30).

Remove planet gear retaining screws and washers

(8—Fig. 13). Mark planet gears (6) and shafts (4),

then remove planet gears, bearings (5) and thrust

washers (3). Keep bearings (5) and thrust washers (3)

separate with their respective planet gears so that

they can be reinstalled as a set in the same location.

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Paragraph 12 (Cont.)

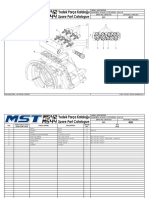

Fig. 12—Exploded view of front-wheel drive steering knuckle and standard planetary assembly. Refer to Fig. 13 for heavy

duty planetary assembly. Axles will not be equipped with both shims (26) and Belleville washers (29). Early axles use shims

(26) to adjust vertical play of steering knuckle and later models use Belleville washers (29).

1. Magnetic drain plug 10, Snap ring

2 Planet carrier AL Sun ge

3. Thrust washer 12. Spacer

4 Planet shaft 18, Thrust washer

5. Needle rollers (30/gear) 14. Ring gear

6, Planet gear 15, "0" ring

7. Snap ring 16, Screws (M10 x30)

8. Planet carrier plate 17. Bushing

9. Thrust pad 18, Ring gear carrier

Before removing the ring gear (14), mark relative

position of ring gear (14) and steering knuckle hous-

ing (30) to facilitate installation in same location.

Remove snap ring (10) from drive shaft sun gear.

Unscrew retaining screws (16), then use four of the

removed screws as jackscrews in threaded holes of

the ring gear carrier (18) to push carrier (18) and ring

gear (14) from hub (21)

Bump hub (21) from steering knuckle (30). Remove

cups for bearings (20 and 22) and seal (23) from hub,

19, Retaining ring 28. Boaring

20. Bearing 29, Belleville washer

21. Hub 30, Steering knuckle

22. Bearing 431. Upper retainer

23. Oi seal 82, Bushing

24, Grease fitting 33. Seal

25. Lower retainer 84, Axle shaft assy.

26. Shims (0.10, 0.19, 0:35 men) 35, Seal

2, Seal 36. Bushing

Tfnecessary, remove inner bearing cone from knuckle

housing.

Clean and inspect all parts for excessive wear or

other damage and renew as necessary.

When reassembling, drive cups for bearings (20

and 22) and oil seal (23) into hub (21). If removed,

install cone for inner bearing (22) on knuckle housing

(30). Install hub (21) and cone for outer bearing (20)

onto knuckle housing. Assemble ring gear (14) to

carrier (18) and secure with retaining ring (19). In-

stall ring gear (14) and gear carrier (18) and tighten,

15

Paragraph 13

Fig. 13—Exploded view of front-

wheel drive steering knuckle and

heavy duty planetary assembly.

Refer to illustration of standard

‘duty planetary assembly in Fig. 12

for legend except the following.

5. Needle rollers (28/gear)

7. Dowel pi

8. Thrust washers

mounting cap screws (16) to 220 Nem (162 ft-Ibs

torque. Install washer (12) and snap ring (10). Stick

‘thrust washer (9) in place on carrier (2) with “Loctite

638” or equivalent and install new “O” ring (15) in

groove of hub (2). Install thrust washers (3), bearings,

(5), planet gears (6) and thrust washers (8), then

secure with retaining screws. Install planetary car-

rier assembly and secure with the two Allen screws.

Fill hub and planetary to the level of opening for

drain/fill plug (1—Fig. 11) in carrier with “OTL

LEVEL” mark (L) on carrier horizontal. Fill with

Ford ESN-M2C134-D or equivalent. Install front

‘wheel and tighten dise to hub nuts to 270 N-m (200

ft-lbs.) torque. Disc to wheel rim nuts should be

tightened to 240 Nom (177 ft-Ibs.) torque.

STEERING KNUCKLE HOUSING

All Four-Wheel Drive Models

13. R&R AND OVERHAUL. To remove either

steering knuckle housing (0—Fig. 12 or Fig. 13),

first remove planetary and wheel hub as outlined in

16

FORD

paragraph 11 or 12. Disconnect tie rod from steering

knuckle arm. Unbolt and remove steering knuckle

retainers (25 and 31). Note that early axles use shims

(26) to adjust vertical play of steering knuckle (30)

and thickness of shims (26) located under each re-

tainer should be recorded when disassembling to aid

in reassembly. Later models are equipped with

Belleville washers (29) that automatically adjust ver-

tical play. The upper Belleville washer is the thicker

of the two washers.

Carefully remove steering knuckle housing (30)

from all models. Axle shaft. and double “U” joint

assembly (34) may be withdrawn with knuckle hous-

ing. Lower bearing cone (28) may fall from lower

retainer (25). Remove upper bearing cone (28), cap

(81) and seal (27). Bearing cups can be removed if

necessary.

If desired, axle shaft and “U” joint assembly can be

withdrawn for inspection or repair. If renewal is re-

quired, oil seal (35) and bushing (36) can be removed

from knuckle housing (30). Oil seal (33) and bushing

(32) can be removed from axle housing. Bushings (32

and 36) should be pressed into position with external

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Fig. 14—Adjust the king pin bearings to obtain free play

0f 0-0.10 mm (0-0.004 in.). Refer to text.

groove toward top and internal arrow-shaped grooves

pointing toward inside of oil-filled housing (away

from seal). Be careful not to damage seals (33 and 35)

when installing axle and knuckle housing.

Reassemble by reversing the disassembly proce-

dure. On early axle originally equipped with shims

(26), sufficient thickness of shims must be installed

to provide king pin with 0-0.1 mm (0-0.016 in.) free

play. To determine shim pack thickness required to

set free play within specified limits, first position

knuckle housing on axle housing and install upper

retainer (31) without shims. Install lower retainer

(25) with enough shims (26) to provide some end play

and tighten upper and lower retainer mounting

screws to 190 Nem (140 ft-lbs.) torque. Position a dial

indicator as shown in Fig. 14 and check vertical play

Paragraph 14

of king pin bearings. For example, if measured end

play is 0.15 mm (0.006 in.), remove 0.10 mm (0.004

in.) shim to obtain end play within the desired limits.

Divide shims (26—Fig. 13) equally at top and bottom,

to center the assembly. Shims are available in 0.10,

0.19 and 0.35 mm (0.0039, 0.0075 and 0.0138 in.)

thicknesses,

Vertical play of steering knuckles on later models

is controlled by Belleville washers (29) located be-

tween axle center housing and cup of bearings (28)

and no adjustment is necessary. The thicker of the

two Belleville washers is installed on top knuckle

bearing.

Refer to paragraph 11 or paragraph 12 when reas-

sembling hub and planetary.

AXLE PIVOT BEARINGS

All Four-Wheel Drive Models

14, REMOVE AND REINSTALL. To remove the

axle pivot bearings, refer to paragraph 9 and remove

the drive shaft, then refer to paragraph 10 and lower

the front axle assembly. The front pivot bracket (1—

Fig. 15) and rear pivot bracket (17) can be withdrawn,

from the axle.

Clean all parts, complete disassembly, if required,

and inspect all parts for wear or damage. Use new “O”

rings and seals when assembling. Tighten screws

attaching front and rear pivot brackets (1 and 17) to

317-388 N-m (234-286 ft.-Ibs.) torque. Tighten steer-

ing hose connections to 34 N.m (25 ft.-Ibs.) torque.

Fig. 15—Partially exploded view of

front-wheel drive pivot brackets.

1. Front pivot

bracket 7.*0" ring

2. Bushing 8. Bushing

8. Sleeve 9, Oil seal

4. Thrust washer 10, Locating dowel

5. Thrust washer 17. Rear pivot

6. Sleeve bracket,

7

Paragraphs 15-16

Fig. 16—View of removed differential assembly, showing

marks (M) on the caps (C) and housing. Mark the caps so

that they can be quickly identified for assembly to the

correct side and in the correct position.

DIFFERENTIAL

All Four-Wheel Drive Models

15. REMOVE AND REINSTALL. To remove the

differential assembly, refer to paragraph 9 and re-

move the drive shaft. Refer to paragraph 10 and

remove the front axle assembly. Refer to paragraph

13 and remove steering knuckle (30—Fig. 12 or Fig.

13) and axle shaft assembly (34) from both sides.

Some mechanics prefer to remove the steering knuck-

les and axle shafts before removing the axle from the

tractor, to reduce the weight of the unit. The differen-

tial housing contains the hydrostatic steering eylin-

der which must be removed as outlined in paragraph

27. Unbolt and remove the differential carrier hous-

ing (1—Fig. 17) from the axle center housing.

When installing, apply Loctite 510 or equivalent

sealer to mating surface of differential carrier hous-

ing and axle housing. Tighten the ten retaining

screws to 169 N.m (125 ft.-Ibs.) torque. Remainder of

assembly and installation is reverse of disassembly

procedure.

16. OVERHAUL. Before disassembling, mark

both bearing eaps and housing as shown at (M—Fig.

16) to facilitate alignment when reassembling.

Straighten tabs of both lock plates (13—Fig. 17), then.

remove both cap serews (12), washers and lock plates.

Loosen, but do not remove, the four screws attaching

caps (C—Fig. 16), then unscrew adjusting rings (14).

Remove both bearing caps and lift differential, bear-

ing cups and adjusting rings from housing.

Mark halves of differential case (16) before disas-

sembling to facilitate alignment when reassembling.

18

FORD

Remove screws (17) and remove ring gear (11). Case

halves can be separated after removing screws (17).

Assembly of original parts is easier if side gears (22)

and clutch parts (23, 24 and 25) are kept together for

each side and not mixed.

Clean and inspect all parts for wear or other dam-

‘age. Lubricate all parts while assembling. Alternate

the five external splined plates (24) and four internal

splined discs (25). The internally splined thrust dise

(28) is thicker (2.8 mm) than other dises and should

be assembled next to side gear (2). Install thrust,

washers (18), pinions (19) and shaft (20). Drive pin

(21) in from ring gear side of differential case on two

pinion differential. When assembling all models,

align any previously affixed marks. Install ring gear

(11), applying Loctite 270 or equivalent to screws (17)

and tightening to 78 Nam (58 ft.-Ibs.) torque. Press

bearing cones (15) onto case (16) until seated.

When installing the differential and ring gear as-

sembly, its necessary to check and adjust both back-

lash and carrier bearing preload as follows: First

measure rotating drag of bevel pinion shaft (10) using

a spring scale with a string wrapped around the

pinion shaft as shown in Fig. 18. Do not measure

starting torque (force necessary to start pinion shaft

turning), only measure the force necessary to keep

pinion turning. Record the rotating drag measure-

ment for later use, then install differential assembly

in carrier housing and tighten bearing cap (C—Fig.

16) bolts tight enough to hold caps in place but allow

adjuster rings (14) to be rotated. Turn adjuster rings

to remove all free play between ring gear and bevel

pinion gear. Preload of differential carrier bearings

and gear backlash are both adjusted by turning ad-

justing rings (14 and 14R). Backlash between bevel

pinion and ring gear should 0.18-0.25 mm (0.007-

0.010 in.) and can be measured at face of ring gear

with a dial indicator (D—Fig. 19). Turn adjuster rings

(14) by equal amounts to move ring gear (11) away

from pinion gear until desired backlash is obtained.

Adjuster rings (14L and 14R—Fig. 17) should be tight

and differential should rotate freely in carrier bear-

ings (15) when checking backlash. Carrier bearing

preload is correct when 3.2-4.7 Kg. (7-10 Ibs.) more

rotational force is necessary to turn the pinion shaft

than was necessary to turn only the pinion shaft

when previously measured. Turn adjuster ring (14L)

‘opposite ring gear to increase or decrease bearing

preload. It is important to check both rotational drag

(as shown in Fig. 18) and bevel pinion to ring gear

backlash (Fig. 19) after changing the position of

either adjusting ring (14L or 14R—Fig. 17).

‘Tighten bearing cap (C—Fig. 16) bolts to 266 Nem

(196 ft.-Ibs,) torque. Install adjuster ring lock plates

(13—Fig. 17 or Fig. 18) and tighten locking plate

retaining screws to 12 N.m (9 ft.-Ibs.) torque.

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

1. Housing 8. Bearing cup & cone

2 Nat (Same.s 4)

13. Lock washer 9, Shim (2.5-8.4 mm)

4. Bearing cup & cone 10. Bevel pinion

(Same as 8) AL Ring gear

65, Washer (Same as 7) 12. Serewn

6. Spacer 13, Locking elips

1. Washer (Same as 5) 14. Adjusting ring

BEVEL PINION GEARS

All Four-Wheel Drive Models

17. REMOVE AND REINSTALL. To remove the

bevel pinion gears (10 and 11—Fig. 17), refer to

paragraph 9 and remove the drive shaft. Pry out

pinion shaft oil seal (9—Fig. 15), then loosen pinion

shaft nut (2—Fig. 17) using pinion nut wrench

FT3168 or equivalent. Refer to paragraph 15 and

remove the differential assembly. Refer to paragraph

16 and remove ring gear from differential.

‘To remove the bevel pinion (10—Fig. 17), remove

‘nut (2) and washer (3), then push pinion out toward

inside. Cone of bearing (4) will slide from shaft as

pinion is removed. The bevel pinion and ring gear

must be renewed as a set.

‘Thickness of shims (9) should be selected to adjust

mesh position of bevel pinion (10) if gear set (10 and

11), pinion bearings (4 and 8) and/or differential hous-

Paragraph 17

\

@

oOo

y. Hydrostatic steering cylinder is attached to housing

pinion differential assembly shown in inset is used with

AR, Adjusting ring

15, Bearing cup & cone

16, Differential ease

21. Roll pin

22, Side gears

223. Spacor (1 each side)

24, External spline plates

(cach side)

18. Thrust washers 25, Internal spline dies

19, Pinion gears (Geach side)

20, Pinion shaft 26. Belleville washer

Fig. 18—Measure rolling drag of bevel pinion shaft (10)

using a spring scale (M) and string (S) as shown.

19

Paragraph 17 (Cont.)

Fig. 19—Measure backlash between ring gear and bevel

pinion gear using a dial indicator.

D. Dial indicator 11 Ring gear

1 a, __——G

pL Blas

Fig. 20—Cross section of differential housing showing

‘measurements required to accurately set pinion position.

Refer to text for measuring distance (C) from bearing

Inner race to center of carrier bearing bore.

G. Depth gauge 1. Differential housing

R Bearing retainer 4. Pinion bearings

8. Bar gauge 8. Pinion bearing

ing (1) is renewed or if previous mesh position is

questioned. Install cups for bearings (4 and 8) in

housing (1), then position bearing cones in cups as

shown in Fig. 20. Use a retainer as shown at (R) to

hold cones tight in cups while measuring. Install both.

carrier bearing caps and tighten the retaining nuts

securely. Measure the diameter of the bearing bores,

(A). Both bearing bores should be the same diameter,

Position bar gauge (S), part of tool No. 3135, in

bearing bores. Note that bar gauge can be fabricated

using a metal or wooden dowel with a hole drilled

through it so that depth gauge (G) can be inserted

20

Fig. 21—Bevel pinion mesh dimension (in millimeters) is

etched on end of pinion shaft 1). Pinion serial number (2)

is also etched on end of shaft.

through the gauge as shown in Fig. 20, Measure the

distance from the bar gauge to the inner flange of

bearing (8) as shown at (B). Determine distance (C)

from the center of the bearing bore to the bearing

flange using formula B - D + (A+ 2)=C.

‘The following is an example of the shim thickness

calculation: Divide bearing bore (A) diameter by 2,

subtract diameter of gauge bar (D) from measure-

ment (B), then add the results of these two calcula-

tions to obtain dimension (C). If measurement (A) is

90,00 mm, measurement (B) is 90.35 mm and meas-

urement (D) is 25 mm; 90.35 mm -25 mm +45 mm =

110.85 mm (C).

‘Th determine the thickness of shims to be installed

at (9—Fig. 17), subtract the value (1—Fig. 21)

stamped on pinion face from the calculated distance

(C—Fig. 20). The result is the correct thickness of

shim (9—Fig. 17). Example: 110.35 mm (C) - 107.25

mm (value on pinion gear) = 3.10 mm (shim thickness

required).

Install selected shim (9—Fig. 17) on pinion shaft

(10) with chamfer toward pinion gear. Remove carrier

bearing caps and bearing cones (4 and 8) from carrier

housing (1). Install inner bearing cone (8) on pinion

(10) against selected shim.

Install washer (7), new (not yet collapsed) spacer

(6) and washer (5) on pinion shaft (10) and insert into

housing through the installed bearing cups. Install

cone for bearing (4), lockwasher (3) and nut (2).

‘Tighten nut (2) until all play in bearings is just taken

up, then measure rotating drag with a spring scale

and string wrapped around the pinion shaft as shown

in Fig. 18. Do not measure starting torque (force

necessary to start pinion shaft turning), only meas-

ure force necessary to keep pinion turning. Correct

amount of rotational force measured by the spring

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Fig, 22—View of front-wheel drive transfer case installed.

Solenoid energizing wire (1) is routed through tube to

housing. Bracket (6) attaches drive shaft shield.

seale should be within the range of 10.1-15.2 Kg.

(22-83 Ibs.). Tighten nut (2—Fig. 17) to tighten bear-

ings and increase rotational force. Note that bearing.

adjustment is accomplished by crushing spacer (6),

16

5

al

is:

Paragraphs 18-19

and nut (2) should not be loosened unless a new

spacer is installed.

TRANSFER GEARBOX

All Four-Wheel Drive Models

18. On SL and SLE model tractors, drive from the

12 12 or 16x 16 transmission to power front wheel

drive axle is incorporated in the transmission. Refer

to appropriate transmission paragraphs for service.

Drive from transmission for front drive axle is from

a transfer gearbox attached to bottom of transmission

housing of models with 82 and 16 x4 transmissions

(S model tractors). Refer to the following paragraphs

for service to the transfer gearbox.

Models With 8 x 2 And 16 x 4

Transmissions

19. R&R AND OVERHAUL. To remove the trans-

fer gearbox, remove drain plug (38—Fig. 22) and

allow cil to drain. Remove drive shaft as described in

paragraph 9. Remove cover, disconnect wire (1) from

the solenoid and disconnect wiring tube from side of

housing. Detach hydraulic lines (6), position floor jack

Fig. 23—Exploded view of four-wheel

drive transfer gearbox used on mod-

els with 8x 2and 16x 4 transmissions.

2. Control solenoid 24. Snap ring

4. Cover 25, Spring keeper

8. External oil line 26. Springs (4 used)

9. Retainer 21. Dog clutch,

10. Shim coupler

1. Bearing 28. *O" ring

12. Idler goar 29. °O" ring

13. Shim 30, Output shaft

14, Spacer 81. Gear and clutch

15, Bearing 82 Pilot valve

16. ‘assembly

7. Shaft 38. Thrust washer

34. Tapered roller

bearing

95. *O" ring

36. Oil transfor tube

37, Bnd plate

28. Tapered 88. Drain plug

roller bearing 39. Housing

21

Fig. 24—Use appropriate sized sockets (S) and levers (L)

to press against spring keeper (25) so that snap ring (24)

ccan be removed.

under the transfer gearbox, remove retaining screws

‘and lower transfer gear case from the tractor.

‘To disassemble the unit, remove the external oil

line (8—Fig. 23), remove the nut from the solenoid

and remove solenoid coil (2). After the solenoid coil is

removed, the core and valve assembly can be removed

from the housing. Remove socket head screw (18). It

may be necessary to heat nut end (9) of screw

to soften thread locking compound. Mark front

side of idler gear (12) to assist reinstallation with

same side toward front, then bump shaft (17) out.

After shaft is removed, idler gear and shaft assembly

(9-17) can be lifted out. Unbolt and remove output

shaft end plate (20), being careful to collect and

identify shims (22) to assist assembly. Unbolt and

remove end plate (37) and oil transfer tube (36).

Gently bump the output shaft (30) toward front, then

toward rear to remove outer races of tapered roller

bearings (23 and 34). Use sockets (S—Fig. 24) of a

suitable size and levers (L) to depress spring keeper

(25) far enough to remove snap ring (24). Remove the

four springs (26—Fig. 23) after snap ring is removed

from groove. Support gear (31) with spacers located

between front of gear and front of housing (39), then,

press shaft (30) toward front out of bearing (34).

Remove bearing, thrust washer (33) and gear (31).

With shaft extending from front, use a suitable puller

to remove bearing (28). Slide snap ring (24) forward

on shaft until it is removed. Move shaft (30) out

toward rear, while removing spring keeper (25) and

clutch coupler (27). Be careful not to lose or damage

pilot valve (32).

Clean and inspect all parts and renew any showing

excessive wear or other damage. Pilot valve assembly

(82) can be removed by blowing into the cross passage

22

FORD

with compressed air. Springs (26) should be 48 mm

(1.889 in.) long and must not be distorted.

When reassembling, renew all “O” rings, seals and

gaskets. Be sure that pilot valve assembly (32) is

installed in end of output shaft (30) so that oil will

pass through valve from transfer tube in end cover

(37)into the shaft toward dog clutch (27), but will not

flow the other direction. Reassemble by reversing

disassembly procedure. Use oil on seals and make

sure that “O” rings are not damaged while assem-

ling. Assemble using shims (22) which were origi-

nally used, but without oil seal (19) and “O” ring (21).

Install and tighten cap screws retaining end plates

(20 and 37) to 51 Nam (38 ft-lbs.) torque. Add or

remove sufficient shims (22) to provide 0.1 mm (0.004

in.) preload. Check for correct bearing adjustment by

‘using a string wrapped around shaft and spring scale

tomeasure rolling torque of shaft as shown in Fig. 25.

When properly assembled using the correct thickness

of shims (22—Fig. 23), measured rolling torque with-

out seal (19) will be 1.9-4.5 Kg, (4.2-9.9 Ibs.). When

correct shims have been selected, remove plate (20),

install and lubricate new seal (19) and “O” ring (21),

then reassemble. Tighten retaining screws to 51 Nem

(88 ft-lbs.) torque,

Install transfer tube and solenoid (2). Special tool

T3169 (available from Ford) or equivalent is neces-

sary to check and adjust idler gear bearings. Thick-

ness of shims (13) adjust bearings (11 and 15) and

thickness of shims (10 and 16) adjusts for fit between,

lugs of housing (39). Make sure that outer races of

bearings (11 and 15) are pressed tightly against

shoulders of gear (12). Assemble bearings (11 and 15),

spacer (14) and approximately 0.3 mm (0.012 in.)

thickness of shims (13) on special tool. Make sure that

screw of tool is tightened to 68 Nem (50 ft.-Ibs.)

clamping bearing inner races, spacer and shims

Fig. 25—Check rolling torque of transfer gearbox output

shaft with string (S) and scale as shown.

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Fig, 26—Check rolling torque of idler gear as described in

text. Special too! FT 3169 is shown at (7).

11,15

Fig. 27—Measuring distance between idler gear bearing

races.

tightly together, then clamp the tool in a vise and

check rolling torque as shown in Fig. 26. Correct

rolling resistance is 0.45-1 Kg (1.0-2.2 Ibs.) and is,

changed by varying the thickness of shims (18—Fig.

23). After the measured rolling resistance has been

correctly set by installing the proper thickness of

shims, measure distance between inner races as

shown in Fig, 27. Measure distance between mount-

ing lugs of housing as shown in Fig. 28, Subtract the

thickness of bearings from the distance between lugs,

then add shims (10 and 16—Fig. 23) equal to the

result. Shims should be evenly divided (10 and 16) to

center the gear.

After selecting shims (10, 13 and 16), remove gear

and bearing assembly from special tool and install

|

Paragraph 20

Fig. 28—Measuring width of idler gear mounting lugs.

using the correct shims and shaft (17). Tighten screw

(18) to 80 Nem (59 ft-lbs.) torque.

Reinstall transfer gearbox by reversing the re-

moval procedure. Use only approved gasket between

transfer gearbox and rear axle center housing, be-

cause its thickness sets the mesh position of idler gear

(12) and mating gear. Tighten transfer gearbox re-

taining screws to 66 Nem (49 ft.-Ibs.) torque. Apply

Loctite 542 or equivalent thread locking compound to

threads of drive shaft retaining screws and tighten to,

57 Nem (49 ft-lbs.) torque. Fill rear axle center hous-

ing to level of dipstick with Ford ESN-M2C134-D or

equivalent.

FRONT SUPPORT

All Four-Wheel Drive Models

20, REMOVE AND REINSTALL. ‘To remove the

front support, the axle must be removed, the radiator

must be removed from the support. and the front

support must be unbolted from the front of engine.

‘The front axle, the front support and the remainder

of the tractor must each be supported separately

while removing, while separated and while assem-

bling. Be sure that sufficient equipment is available

before beginning.

Refer to paragraph 67 and remove the main fuel

tank, then refer to paragraph 87 and remove the

radiator. Support front of tractor in such a way that

it will not interfere with removal of either the front

‘support or the front axle. Refer to paragraph 9 and

remove the drive shaft, then refer to paragraph 10

and remove the front axle assembly. Attach a hoist or

23

Paragraphs 21-22

other supporting device to the front support, then

unbolt and separate the front support from the front

of the engine. Be careful not to lose or damage shims

FORD

located between front support and engine. Keep

shims separate and label for installation in same

location.

HYDROSTATIC STEERING

21, Hydrostatic steering system is used on all mod-

els and consists of a steering valve assembly, and one

double-acting steering cylinder. In the event of hy-

Graulic failure or engine stoppage, manual steering

can be accomplished by the gerotor pump in the

steering valve.

FLUID AND BLEEDING

All Models

22, Recommended steering fluid is Ford ESN-

‘M2C134-D hydraulic fluid or equivalent, which is

contained in the rear axle center housing. The same

fluid is also used for the transmission, rear axles and

hydraulic lift system. Maintain fluid level between

marks on dipstick (D—Fig. 29). Drain and refill res-

ervoir with new fluid every 1200 hours of operation

or once each year. Drain plug is located at bottom

center of rear axle center housing. It is recommended

that hydraulic filters be changed every 300 hours of

‘operation or whenever fluid is suspected of contami-

nation

‘On models with tandem gear pumps, main hydrau-

lic system filter (1—Fig. 30) is located on right side

under the floor. Auxiliary hydraulic filter (2—Fig. 31)

Fig. 29—The transmission, rear axles and hydraulic lift

system share @ common fluid that uses the rear axle

‘center housing as a reservoir. Maintain fluid level between

‘marks on dipstick (D) and fll through opening for plug (F).

24

Fig. 30—View of main hydraulic system filter installed on

‘models with tandem gear pump. Auxiliary filter (2—Fig.

31) Is installed on these models if also equipped with

‘engine mounted auxiliary pump. Filter is located on right

‘side under floor. Switch (V) Indicates blocked filter, and

switch (7) is the low temperature switch which stops

blocked filter indicator from lighting when temperature is.

below 40° C (104" F). Low pressure switch Is located to

the rear ot switch (7).

Fig. 31—View of auxiliary hydraulic filter installed on

models with tandem gear pump and engine mounted

‘auxiliary pump. Filter is located on left side under floor.

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Fig. 32—View of system filters for models equipped with

CCLS (Closed Center Load Sensing) hydraulic system.

Steering pump inlet filter is located at (1), charge pump

inlet filter is located at (2) and charge system pressure

filter is located at (3). Filters are located on right side.

is located on left side under the floor of models with

tandem gear pumps and engine mounted auxiliary

pump.

On models with CCLS (Closed Center Load Sens-

ing) hydraulic system, the three hydraulic filters are

located on right side under the floor as shown in Fig.

32, The steering pump inlet filter is located at (1) and

charge pump inlet and pressure filters are located at

(2 and 3). All hydraulic systems use the same fluid

and all filters should be renewed at the same time.

‘The hydrostatic steering system is self bleeding.

When the unit has been disassembled, refill with new

oil, start engine, then cycle the system several times

by turning the steering wheel from lock to lock. Re-

check fluid level (Fig. 29) and add fluid as required.

TROUBLESHOOTING

All Models:

23. Some of the problems which may occur during

‘operation of power steering and their possible causes

are as follows:

1. Steering wheel hard to turn. Could be caused by:

a. Air in system. Check for loose connections or

damaged lines, especially on inlet side. Also

check for low fluid level.

b. Low system pressure. Check steering relief

valve setting,

. Worn or otherwise defective power steering

pump.

4. Leaking steering cylinder.

e, Broken or damaged steering column coupling.

£ Worn, binding or otherwise damaged control

valve (metering) spool and sleeve.

Paragraphs 23-24

g. Mechanical parts of front steering system bind-

ing.

2. Steering wheel turns on its own. Could be caused

by:

a, Leaf springs in control valve weak or broken.

3, Steering wanders or steering surges when steering.

Could be caused by:

a. Excessive play in steering joints.

b, Leaking steering cylinder.

¢. Worn or otherwise damaged control valve (me-

tering) spool and sleeve.

4. Tractor steers in wrong direction. Could be caused

by:

a. Hoses to steering cylinder incorrectly con-

nected.

b. Incorrect timing of control (metering) valve

drive shaft to rotor.

TESTS AND ADJUSTMENT

All Models

24, SYSTEM PRESSURE AND FLOW. The pres-

sure relief valve for the hydrostatic steering system

is located in the steering control valve. Oil returning

from the steering control valve is directed to the

lubrication circuit for the 16 x 16 transmission (via

the oil cooler) or the pto clutch lubrication circuit. A

by-pass valve (2—Fig. 33) is installed to redirect oil

flow if the cooler is blocked, or if the oil temperature

is lower (colder) than 68° C (155° F). Return oil will

by-pass the oil coolerif pressure is above 690 kPa (100

psi.

A simple test of steering system pressure can be

performed as follows. Run engine at 1000 rpm and

turn steering wheel from lock to lock. If system is

Fig. 33—View of oll cooler by-pass valve (2). Line (1)routs

oll from the steering control valve to the by-pass valve,

line (3) directs oil to cooler and line (4) is return oll from

cooler. Line (5) delivers oll to the transmission and rear

axle lubrication circuit.

25

Paragraph 24 (Cont.)

Fig. 34—To check steering pump flow on tractors

equipped with fixed displacement tandem gear pumps,

disconnect tubes to steering valve and connect flow me-

ler fo pressure and return fittings (1 and 2).

operating satisfactorily, the steering should react

quickly, with no time delay. If steering is slow or

imprecise, make sure that tractor, especially front

axle, is not overloaded. The system relief valve should

be heard to blow when steering is against either lock

and engine speed will normally fall slightly when

relief valve is opening.

More precise tests of steering pressure and flow are

possible with pressure gauge and flow meter. To check

pump flow, proceed as follows: On models equipped

with variable displacement CCLS hydraulic pump,

disconnect all four lines (1, 3, 4 and 5—Fig. 33) from

the oil cooler by-pass valve and cover lines (3 and 4)

to oil cooler to prevent entrance of dirt. Attach flow

meter between the return line (1) from steering con-

trol valve and line (5) to the transmission lubrication

circuit. On models equipped with fixed displacement

tandem gear pumps, disconnect pressure line (1—

Fig, 35—Attach pressure gauge (G) as shown to steering

ine (L) which has been detached from cylinder.

26

FORD

Fig. 34) to steering motor and return line (2) from

steering motor. Connect flow meter inlet to pressure

fitting and flow meter outlet to return fitting.

NOTE: Flow meter used to check steering pump.

flow on models equipped with fixed displacement

tandem gear pumps must be capable of withstand-

ing 2000 kPa (300 psi) back pressure.

On all models, make sure that flow meter valve is

open, then start engine and operate at 2100 rpm. Run

engine until hydraulic oil temperature reaches nor-

mal operating temperature of approximately 68° C

(155° F). Tarn the front wheels to one extreme against

lock, and observe gauge reading indicating volume of

flow.

CAUTION: When checking system flow or reliet

pressure, hold the steering wheel against lock only

ong enough to observe pressure indicated by

gauge. Pump may be damaged if steering wheel is

held in this position too long or if flow is otherwise

stopped.

Specifie volume of output is different between vari-

ous tractors, but pump should be removed from all

models and serviced if flow is less than 31 L/minute

(8.2 gpm)

‘To check relief pressure, first turn steering wheel

fully to the left and stop engine. Disconnect left turn

hose (L—Fig. 35) from steering cylinder and attach a

suitable (G) pressure gauge as shown. Start engine

and set engine speed to 1450 rpm, turn steering wheel

to full left: turn lock and observe the indicated pres-

wre. Correct pressure is 15,300-16,300 kPa (2220-

2370 psi) for two-wheel drive 5640, 6640, 7740 and

7840 models. Correct pressure is 18,000-19100 kPa

(2620-2770 psi) for all other models.

‘To change relief valve setting, it is first necessary

to remove the steering control valve as outlined in

paragraph 29, Turning the relief valve spring seat

(34—Fig. 36) IN, increases the pressure against

spring (35) and increases system relief pressure.

Spring seat (34) is accessible after removing plug (32).

To adjust relief pressure, fabricate hoses to connect

from tractor pressure line (P) and return line (T) to

pressure and return ports of steering control valve.

Install tee fittings with pressure gauges (A and B) in

the fabricated hoses. Cap the other two (steering

cylinder) ports (E) of steering control valve. With

engine running at 1500 rpm, turn steering motor

shaft (21) to full lock position. Pressure gauge (A)

reading should be approximately 16,000 kPa (2350

psi) for two-wheel drive models and 19,000 kPa (2750,

psi) for four-wheel drive models. Gauge (B) reading

should be about 1725 kPa (250 psi) for all models. If

pressure readings are not correct, adjust relief valve

spring seat (34) as necessary to obtain desired pres-

sure setting. Half a turn of spring seat should change

pressure setting approximately 1400 kPa (200 psi).

Once pressure is correctly set, apply small amount of

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

Fig. 36—To adjust steering relief pressure, steering con-

trol valve must be removed from tractor. Turn spring seat

(34) inward to increase pressure. Refer to text for com-

plete procedure.

A. Pressure gauge

B. Pressure gauge 21. Steering motor shaft

C: Pressure line 82. Ping

D, Return line 34, Spring seat

EB, Steering cylinder ports 35. Spring

F Stooring cylinder lines 36. Relief valve poppet

@i;z2

Paragraphs 25-26

thread locking compound to spring seat to lock it in

place.

PUMP

All Models

25. The pump for the hydrostatic steering is incor-

porated with the main hydraulic pump. Refer to the

appropriate paragraph 254 or 268 for removal and

service.

POWER CYLINDER

‘Two-Wheel Drive Models

26, R&R AND OVERHAUL. The steering cylin-

der is attached between axle center member and the

tie rod. To remove the cylinder, disconnect hydraulic

hoses at steering cylinder and cover openings to pre-

vent entrance of dirt, then detach both ends of the

steering cylinder.

Clamp rod end (1—Fig. 37) in a vise or holding

fixture, remove clamp screw (2) and unscrew piston

rod (8) from rod end. Remove clamp (13) and rod end

(15) from opposite end of piston rod. Clamp cylinder

(3) in a holding fixture that will not crush or other-

wise deform cylinder, then unscrew extension tube

and gland assembly (12). Pull piston and piston rod

(8) from the cylinder.

Inspect cylinder and piston for wear or damage

Renew all “O” rings and seals. Heating piston seal (5)

in hot water or oil will make assembly onto piston

Fig. 37—Exploded view of steering cy!-

inder used on two-wheel drive models.

1. Rod end 9, Bushing

2. Clamp serew 10, *0" ring

3. Cylinder LL. Back-up ring

4. Wear ring 12, Extension tube

5. Piston seal & gland assy,

8. *0" ring 413, Clamp

7. Rod seal 414. Clamp screw

8. Piston & rod 15, Rod end

15

Paragraph 27

Fig. 38—View of left end of four-wheel drive steering

cylinder, showing the correct location of Allen screw (A)

and cap screws (S).

easier, Allow seal to contract before installing piston

into cylinder.

When assembling, lubricate all seals and “O" rings

with clean hydraulic fluid. Tighten gland (12) to eyl-

inder to 271 Nem (200 ft.-Ibs.) torque.

After installing cylinder, turn wheels to full right

turn lock, then adjust steering cylinder length so that

ends are aligned when steering rod is extended 4-10

mm (0.15-0.4 in.) from fully compressed position.

Start engine and turn wheels from lock to lock several

times to purge air from cylinder. Check front wheel

toe-out as outlined in paragraph 2.

FORD

Four-Wheel Drive Models

27. REMOVE AND REINSTALL. The double-act-

ing hydrostatic steering cylinder used on four-wheel

drive models is attached to the front drive differential

housing by four screws as shown at (A and S—Fig.

38). To remove the steering cylinder, loosen the four

attaching screws approximately two turns, then turn

the steering wheel to the left to unseat the cylinder.

Jack up front of tractor and remove the left front

wheel. Loosen bolts (2—Fig. 39) that clamp tie rod

ends (3) onto balll joint rods (4). Detach rod ends from

both steering arms, then remove ball joint ends from

both ends of steering cylinder rod. Disconnect steer-

ing hoses from cylinder and remove fitting from right

end of cylinder. Remove cylinder retaining screws (A

and S—Fig. 38), then withdraw complete cylinder

from left side.

When reinstalling, reverse removal procedure. In-

stall the three hex head retaining screws (S) in the

locations shown in Fig. 38 and tighten to 94 Nem (69

ft-lbs.) torque. Apply Loctite 542 or equivalent to

threads of the Allen head retaining screw (A), install

screw and tighten to 94 Nem (69 ft-lbs.) torque.

Reattach rod ends to steering cylinder rod and

tighten to 176 Nem (130 ft-lbs.) torque. Attach rod

ends to steering arms and tighten nuts to 176 Nem

(130 fe-Ibs.) torque. Reconnect steering hoses and

tighten connections to 34 Nm (25 ft.-Ibs.) torque

Refer to paragraph 7 to adjust front wheel toe-in,

Fig, 39—Exploded view of power steer-

ing cylinder used on four-wheel drive

models.

1. Cap serew 17. End plate

2 Clamp bolt 8, Seal ring

3, Tie rod 9, Piston & rod

4, Ball joint rod 10. Seal ring

5. Wiper seals 11. Gylinder

6. Piston rod seals 12, Carrier housing

MODELS 5640, 6640, 7740, 7840, 8240 & 8340

28, OVERHAUL. To disassemble removed steer-

ing eylinder, unscrew ball joint ends (4—Fig. 39) from,

‘each end of steering rod (1).

NOTE: Ball joint ends (4) may be locked with

“Loctite” and heat must be applied to area before

unscrewing from piston rod (8).

Pull on end of piston rod (9) to remove end plate (7)

and other internal parts from cylinder (11). Remove

the piston seal and expander from piston, Remove

wiper seals (5) and piston rod seals (6).

Clean and inspect all parts for excessive wear,

scoring or other damage and renew as necessary. Note

that piston rod (9) and cylinder (11) are serviced as

an assembly.

Reassemble cylinder by reversing the disassembly

procedure, observing the following: Always use new

“O” rings, scraper rings and seals when reassembling.

Aer installing piston seal on piston, allow seal to

contract before installing piston in cylinder. Lubri-

cate parts with clean hydraulic fluid during assembly.

‘Tighten the three retaining cap screws and one Allen,

head screw (4) to 94 Nem (69 ft-lbs.) torque.

Reattach rod ends to steering cylinder rod and

tighten to 176 Nem (130 ft.-Ibs.) torque. Tighten slot-

ted nuts of tie rod ends attached to steering knuckles

to 1760 N.m (130 ft-lbs.) torque. If necessary, adjust.

toe-in to 0-13 mm (0-0.5 in.) as outlined in paragraph

7, Tighten clamp screw nuts (2) to 43 Nem (82 ft-lbs.)

torque.

STEERING VALVE

All Models With Hydrostatic Steering

29, REMOVE AND REINSTALL. The steering

control valve is located at the base of the steering

wheel shaft. To remove the steering control valve,

first remove the exhaust pipe, engine side panels and

hood. Unbolt and remove the combination brake and

clutch reservoir, starter relay, and battery ground

cable from the firewall. Remove the three screws

attaching firewall to the cylinder head. If equipped

with cab, the three firewall to cylinder head screws,

will be accessible through side of steering console

from inside cab, Detach the four lines from steering,

control valve and remove the roll pin attaching steer-

ing shaft to steering valve drive collar. Cover open-

ings in lines and passages to prevent entry of dirt.

Remove the instrument panel, then unbolt and re-

move the steering control valve through the engine

compartment.

Reinstall by reversing the removal procedure.

‘Tighten all mounting screws and steering hoses to

18-20 Nem (10-15 ft.-Ibs.) torque. Start engine and

purge air from the system by turning the steering

Paragraphs 28-30

wheel from lock to lock until the system operates

properly.

30. OVERHAUL. Remove steering valve as de-

scribed in paragraph 29, then thoroughly clean exte-

rior of unit. Unbolt and remove steering column, then,

place steering valve in a special holding fixture, Re-

move the seven cover retaining screws (10—Fig. 40).

Fig. 40—Exploded view of hydrostatic steering valve with

integral pressure relief valve (34 through 36). Notice that

the two outer springs (235) are straight.

1. Drive shaft 17. Bearing race

2 Spacer 18, Thrust bearing

8.0" ring 19,

4. Distributor plate 20,

5.0" ring 21

6 Rotor 2,

1. Stator 28. Leaf springs (4)

8.*O" ring 238, Flat leaf springs (2)

9, End cover 24, Retainer ring

10. Cap serow (7) 32. Plog

11, Seal rings 38. ‘O° ing

12, Seal 34. Adjusting plug

418, Check valve ball 36, Relief valve spring

14, Cheek valve plug 36. Relief valve

15, Housing 837, Suction valve ball