Professional Documents

Culture Documents

An Integrated Model For Predicting The Specific Energy Consumption of Manufacturing Processes

An Integrated Model For Predicting The Specific Energy Consumption of Manufacturing Processes

Uploaded by

RobertodeOLiveiraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

An Integrated Model For Predicting The Specific Energy Consumption of Manufacturing Processes

An Integrated Model For Predicting The Specific Energy Consumption of Manufacturing Processes

Uploaded by

RobertodeOLiveiraCopyright:

Available Formats

Int J Adv Manuf Technol (2016) 85:1339–1346

DOI 10.1007/s00170-015-8033-y

ORIGINAL ARTICLE

An integrated model for predicting the specific energy

consumption of manufacturing processes

Jun Xie 1 & Fei Liu 1 & Hang Qiu 1

Received: 18 June 2015 / Accepted: 25 October 2015 / Published online: 5 November 2015

# Springer-Verlag London 2015

Abstract Due to the soar of the energy price and the 1 Introduction

environmental problems are becoming more and more se-

rious, the energy consumption and efficiency of processes With the soar of the energy price and environmental problems is

are becoming the focus of academia and industry gradu- becoming more and more serious, the energy efficiency of

ally. Some significant researches on the energy consump- manufacturing is becoming the focus of academia and industry

tion of machine tools have been performed. In most pre- gradually. The machining systems that mainly consist of ma-

vious studies, material removal rate is treated as a com- chine tools are numerous and used in a wide range in industries.

prehensive variable. However, it cannot offer the energy In china, for example, machining involves over seven million

footprint for a machining process and provide the support machine tools, whose total power is greater than 70 million

for process planning which needs the information of cut- kilowatts; the total amount of energy consumption by machining

ting speeds, feed rates, and depth of cut. This paper pre- tools is extremely high. A lot of researches have indicated that

sents an integrated model for predicting the specific ener- the energy efficiency of machining process is less than 30 % [1].

gy consumption (SEC) of manufacturing processes. The The energy efficiency of a case described by Gutowski is only

dynamic characteristics of material-cutting power and in- 14.8 % [2]. As a result, it has great potential for energy savings

fluence of the machine tools, material of workpiece, and in machining processes. In most cases, the electricity consumed

cutting parameters on the material-cutting energy are both by the machine tools is predominantly generated through the

taken into account in the model. The case study indicates fossil fuel. The use of carbon-rich electricity generation sources

that the model can be used to predict the SEC of machine is critical global concern as CO2 emissions. This implies that the

tools conveniently under various machining conditions. higher the consumption of electricity in machining process, the

At last, the validation is carried out in different machining higher the CO2 emission is produced by machine tools. As a

processes; the accuracy and feasibility of the model was result, the UK government and other worldwide leaders are

verified by the experimental results. making an increasing demand for energy efficiency [3].

In recent years, many famous universities, enterprises, and

international organizations have done a lot of work about the

Keywords Specific energy consumption . Prediction . energy consumption of machine tools and machining systems

Machine tool . Manufacturing process [4]. Liu et al. [5] have established a multi-period energy model

of electro-mechanical main driving system during the service

processes of machine tools. Liu et al. [6] have proposed an

energy efficiency acquisition method for electro-mechanical

main driving system during the service processes of machine

* Fei Liu tools. According to the method, the energy efficiency of the

fliu@cqu.edu.cn machining process can be obtained by the real-time monitor-

ing. Choi et al. [7] proposed a methodology for an estimation

1

State Key Laboratory of Mechanical Transmission, Chongqing of energy consumption and material flows that are incurred at

University, Chongqing 400030, China a system level with respect to multiple process plans for a part

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drip Irrigation: Reporters: VILLAGONZA, Queenie Angelie A. CALUMPANG, Mark James BDocument25 pagesDrip Irrigation: Reporters: VILLAGONZA, Queenie Angelie A. CALUMPANG, Mark James BMark James CalumpangNo ratings yet

- Topic 4 EcologyDocument1 pageTopic 4 EcologymatthewNo ratings yet

- Your Go To List of PYP Related ConceptsDocument26 pagesYour Go To List of PYP Related ConceptsRomano Luis100% (3)

- Renewable Integration - POWERGRIDDocument29 pagesRenewable Integration - POWERGRIDvaibhav bodkheNo ratings yet

- Uplift PressureDocument10 pagesUplift PressureBurhan AhmadNo ratings yet

- Dr.A.Ranganathan M.E., PH.D., M.I.E., Research Associate / PWD IMTI, Trichy - 620 015 Email Mobile: 98941 29112Document29 pagesDr.A.Ranganathan M.E., PH.D., M.I.E., Research Associate / PWD IMTI, Trichy - 620 015 Email Mobile: 98941 29112Balakumaran GunasekaranNo ratings yet

- Lab 4: Drainage Basin MorphometryDocument14 pagesLab 4: Drainage Basin MorphometryAbhishek KushwahaNo ratings yet

- Sustainable AgricultureDocument69 pagesSustainable AgricultureDiana MariaNo ratings yet

- Inventory - Management - Vedanta, Tech MahindraDocument9 pagesInventory - Management - Vedanta, Tech MahindraBinodini SenNo ratings yet

- PH Observation TableDocument2 pagesPH Observation TablenisargNo ratings yet

- Company Profile - Strategic Analysis Baybay RestaurantDocument7 pagesCompany Profile - Strategic Analysis Baybay RestaurantAngeline Maquiso SumaoyNo ratings yet

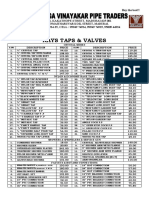

- Rays Taps & Valves: Sell The Best! Buy The Best!!Document3 pagesRays Taps & Valves: Sell The Best! Buy The Best!!annamalaicvNo ratings yet

- World Bank CSPReport Concentrating Solar Power Clean Poweron Demand 247 FINALDocument65 pagesWorld Bank CSPReport Concentrating Solar Power Clean Poweron Demand 247 FINALTricia Marvi P. NavarroNo ratings yet

- 2015 GEO Depth 80 ProblemsDocument89 pages2015 GEO Depth 80 Problems주주람No ratings yet

- De Thi HK1 Tieng Anh 10 Nam 22 23 de 4Document13 pagesDe Thi HK1 Tieng Anh 10 Nam 22 23 de 4daothihaiyen.workNo ratings yet

- CCFT App 8 Tree ProfilesDocument180 pagesCCFT App 8 Tree ProfilesBagas KaraNo ratings yet

- Application For Planning Permission. Town and Country Planning Act 1990Document11 pagesApplication For Planning Permission. Town and Country Planning Act 1990rohitgorasiaNo ratings yet

- LUMBRE, R.-Exercise #1 Determination of Specific GravityDocument8 pagesLUMBRE, R.-Exercise #1 Determination of Specific GravityLi ReNo ratings yet

- Cradle To Gate Life Cycle Analysis of Low Density Polyethylene LDPE ResinDocument44 pagesCradle To Gate Life Cycle Analysis of Low Density Polyethylene LDPE ResinAbby LaingNo ratings yet

- Turning Plastic Waste To Our AdvantageDocument2 pagesTurning Plastic Waste To Our AdvantageJANICE JOSEPHINE TJONDROWIBOWO 11-S3No ratings yet

- Bai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global SuccessDocument8 pagesBai Tap Tieng Anh Lop 8 Unit 7 Environmental Protection Global Successngtrmm1No ratings yet

- Fullpaper Civil EngineeringresearchesforrurbandevelopmentandsafetyDocument8 pagesFullpaper Civil EngineeringresearchesforrurbandevelopmentandsafetyJimwelle BeltranNo ratings yet

- Suson - IDEA EXEMPLAR (Science)Document8 pagesSuson - IDEA EXEMPLAR (Science)Jessa Mae SusonNo ratings yet

- Pollution Status and Trends in Water Quality of The Shitalakhya and Balu RiversDocument19 pagesPollution Status and Trends in Water Quality of The Shitalakhya and Balu RiversZisan AhmedNo ratings yet

- DelAgua Manual Revised 2020 V1Document70 pagesDelAgua Manual Revised 2020 V1AhmedNo ratings yet

- B-55 Boysen Epoxy Reducer 1121Document9 pagesB-55 Boysen Epoxy Reducer 1121jeffNo ratings yet

- Narmada Bachao AndolanDocument11 pagesNarmada Bachao AndolanAviral Srivastava100% (2)

- Technology: 110 TRANSFORMERS MAGAZINE - Special Edition Substations - 2019Document6 pagesTechnology: 110 TRANSFORMERS MAGAZINE - Special Edition Substations - 2019hugoNo ratings yet

- Experienced List KKDocument1 pageExperienced List KKMy pouNo ratings yet

- Module 5-ABE Final TermDocument13 pagesModule 5-ABE Final TermJefrey M. ButilNo ratings yet