Professional Documents

Culture Documents

Basic Board Mount Pressure Sensors 32344917: Features

Uploaded by

ddvp_gunawardanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Board Mount Pressure Sensors 32344917: Features

Uploaded by

ddvp_gunawardanaCopyright:

Available Formats

Basic Board Mount Pressure Sensors 32344917

TBP Series, Uncompensated/Unamplified Issue B

60 mbar to 10 bar | 6 kPa to 1 MPa |1 psi to 150 psi, Millivolt Analog Output

NBP Series, Uncompensated/Unamplified

60 mbar to 10 bar | 1 psi to 150 psi, Millivolt Analog Output

Datasheet

FEATURES

• Package size as small as 7 mm x 7 mm [0.276 in x 0.276 in]

• Operating temperature range -40°C to 125°C [-40°F to 257°F]

• Reflow mounting J-STD-020E, MSL 1 and rapid

stabilization after reflow soldering allow calibration

immediately after mounting

• Media compatibility options:

- No gel coating in media path: Input port is limited to

non-corrosive, non-ionic media such as dry air and

gases and should not be exposed to condensation;

gases are limited to media that are compatible with high

temperature polyamide, silicone, alumina ceramic, silicon,

gold and glass

- Silicone gel coating in media path: Uses the same

materials in the wetted media path but is protected

from condensation by a silicone-based gel coating;

allows for use in applications where condensation can

DESCRIPTION occur

Honeywell’s Basic Board Mount Pressure Sensors, TBP Series • Sensor materials have been tested and certified for these

and NBP Series, are designed for food grade and non-food food safety standards:

grade potential medical and industrial applications. These - NSF-169

unamplified, piezoresistive silicon pressure sensors provide a - BPA Free

ratiometric output and are either temperature compensated - LFGB

(TBP Series) or uncompensated (NBP Series).

VALUE TO CUSTOMERS

TBP Series: • Cost-competitive pressure sensing solution

• Temperature compensated and unamplified. • Smaller when compared to many similar products,

• Compensation makes it easier to integrate the sensor into a occupying less space on the printed circuit board (PCB)

system by minimizing the need to calibrate the system over and typically allowing for easier placement on PCBs or in

temperature on a regular basis; offers reduced part-to-part small devices

variation. • Performs in many tough environments with dry and

• Offers infinite resolution of the pressure signal. wetted media

• Compensated temperature range is 0°C to 85°C [-32°F to • Numerous options simplify integration into the device

185°F]. manufacturer’s application

NBP Series: • Food Safety Certification for North America, Europe and Asia

• Uncompensated and unamplified. POTENTIAL APPLICATIONS

• Is often ideal for customers who want to do their own • Medical: Blood pressure monitoring, hospital beds,

compensation, calibration and amplification in order oxygen concentrators, wound therapy

to make use of the maximum resolution of the bare • Industrial: Air movement control, environmental control,

sensor output, leveraging any algorithm needed for the HVAC transmitters, industrial controls, leak detection,

application. other commercial applications, pneumatic controls, food

• Offers infinite resolution of the pressure signal. and beverage

These products are available in numerous package styles and PORTFOLIO

mounting options, making it easier for device manufacturers Honeywell’s NBP Series joins the TruStabilityTM HSC, SSC,

to integrate the product into their applications. They are NSC and TSC Series; Basic ABP Series; 24PC Series and

intended for use with non-corrosive, non-ionic gases, such 26PC Series board mount pressure sensors.

as air and other dry gases, and for non-corrosive, non-ionic

liquids when the silicone gel coating option is selected. All

products are designed and manufactured according to ISO

9001 and are NSF certified.

Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table of Contents

TBP Series and NPB Series General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

TBP Series Nomenclature and Order Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

NBP Series Nomenclature and Order Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TBP Series Pressure Range Specifications:

60 mbar to 10 bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 kPa to 1 MPa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 psi to 150 psi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

NBP Series Pressure Range Specifications:

60 mbar to 10 bar . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1 psi to 150 psi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensional Drawings:

DIP Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-14

SMT Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-16

Leadless SMT Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

Additional Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . back cover

Table 1. Operating Specifications

Characteristic Min. Typ. Max. Unit

TBP Series

Supply voltage (Vsupply)1, 2 1.5 5.0 12.0 Vdc

Supply current (at 5.0 Vdc supply) — 0.6 1 mA

Operating temperature range 3

-40 [-40] — 125 [257] °C [°F]

Compensated temperature range 4 0 [32] — 85 [185] °C [°F]

Output resistance — 2.5 — kOhm

NBP Series

Supply voltage (Vsupply)1, 2 1.8 5.0 12.0 Vdc

Supply current (at 5.0 Vdc supply) — 1.5 2.5 mA

Specified temperature range5 -40 [-40] — 125 [257] °C [°F]

Accuracy 6 — — ±0.25 %FSS BFSL7

Input resistance 2.4 3.0 5.5 kOhm

Thermal effect on resistance (TER)8 1200 — 3200 ppm/°C

1

Ratiometricity of the sensor (the ability of the device output to scale to the supply voltage) is achieved within the specified operating voltage.

2

Incorrect application of supply voltage or ground to the wrong pin may cause electrical failure.

3

Operating temperature range: The temperature range over which the sensor produces an output proportional to pressure.

4

Compensated temperature range: The temperature range over which the sensor produces an output proportional to pressure within the specified

performance limits.

5

Specified temperature range: The temperature range over which the sensor will produce an output proportional to pressure within the

specified performance limits.

6

Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure range at

25°C [77°F]. Includes all errors due to pressure non-linearity, pressure hysteresis, and non-repeatability.

7

Full Scale Span (FSS): The algebraic difference between the output signal measured at the maximum and minimum limits of the pressure

range. (See Figure 2 for pressure ranges.)

8

TER (Thermal Effect on Resistance): The deviation in input resistance due to change in temperature over the specified temperature range, relative

to input resistance measured at 25°C [77°F].

Table 2. Pressure Reference Types

Pressure Type Description

Output is proportional to the difference between applied pressure and a built-in reference to vacuum.

Absolute

Reference pressure is absolute zero pressure (full vacuum).

Differential Output is proportional to the difference between the pressures applied to each port (Port 1 - Port 2).

Output is proportional to the difference between applied pressure and atmospheric (ambient) pressure.

Gage

Reference pressure is atmospheric pressure.

2 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table 3. Absolute Maximum Ratings1

Characteristic Min. Max. Unit

Supply voltage (Vsupply) -12.0 12.0 Vdc

Storage temperature -40 [-40] 125 [257] °C [°F]

Soldering time and temperature:

lead solder temperature (DIP) 4 s max. at 250°C [482°F]

peak reflow temperature (SMT, Leadless SMT) 15 s max. at 250°C [482°F]

1

Absolute maximum ratings are the extreme limits the device will withstand without damage.

Table 4. Environmental Specifications

Characteristic Parameter

Humidity:

all external surfaces 0 %RH to 95 %RH, non-condensing

internal surfaces of silicone gel coating option 0 %RH to 100 %RH, condensing

internal surfaces of no gel coating option 0 %RH to 95 %RH, non-condensing

Vibration MIL-STD-202G, Method 204D, Condition B (15 g, 10 Hz to 2 kHz)

Shock MIL-STD-202G, Method 213B, Condition C (100 g, 6 ms duration)

Life1 1 million pressure cycles min.

ESD MIL-STD-883 Method 3015.7

Solder reflow J-STD-020E, MSL 1, unlimited storage life

Certification (silicone gel coating option: Port 1 only) NSF- 169, BPA Free, LFGB

1

Life may vary depending on specific application in which the sensor is utilized.

Table 5. Wetted Materials1

Pressure Port 1 (P1)

Component Silicone Gel Coating in PPressure Port 2 (P2)

No Gel Coating in Media Path

Media Path (Food Grade)

Ports and covers high temperature polyamide

Substrate alumina ceramic — alumina ceramic

Adhesives epoxy, silicone epoxy, silicone gel epoxy, silicone

Electronic

silicon, gold, glass, solder, aluminum 304SST silicon

components

1

Contact Honeywell Customer Service for detailed material information.

CAUTION

MISUSE OF GEL COATING OPTION

• No gel coating in media path: The input port is limited to non-corrosive, non-ionic media such as dry air and gases and

should not be exposed to condensation. The gases are limited to media which are compatible with the following wetted

materials of construction: high temperature polyamide, silicone, alumina ceramic, silicon, gold, and glass.

• Silicone gel coating in media path: The gel coated sensors use the same materials in the wetted media path but are protected

from condensation by a silicone-based gel coating. The gel coating option allows use in applications where condensation can

occur.

Failure to comply with these instructions may result in product damage.

Sensing and Internet of Things 3

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 1. TBP Series Nomenclature and Order Guide (Part order quantity must meet MOQ requirements.) E

For example, TBPDANN150PGUCV defines a TBP Series Basic Board Mount Pressure Sensor, DIP package, AN pressure

port, no gel coating in media path, 150 psi gage pressure range, unamplified, compensated, constant supply voltage.

TBP D AN N 150PG U C V

Series

TBP

Package

L Leadless SMT (Surface Mount Technology) Supply Voltage

M SMT (Surface Mount Technology) V Constant

D DIP (Dual Inline Pin)

Pressure Port

Leadless SMT SMT DIP Compensation

AN Single axial

small barbed

AN Single axial

small barbed

AN Single axial

small barbed C Compensated

port port port

Output

JJ Dual radial U Unamplified

barbless port

- -

Pressure Range1, 2

60 mbar to 10 bar 6 kPa to 1 MPa 1 psi to 150 psi

JN Single radial JN Single radial JN Single radial Gage Gage Gage

barbless port barbless port barbless port

060MG 0 mbar to 60 mbar 006KG 0 kPa to 6 kPa 001PG 0 psi to 1 psi

100MG 0 mbar to 100 mbar 010KG 0 kPa to 10 kPa 005PG 0 psi to 5 psi

160MG 0 mbar to 160 mbar 016KG 0 kPa to 16 kPa 015PG 0 psi to 15 psi

KN Single axial large KN Single axial large KN Single axial large 250MG 0 mbar to 250 mbar 025KG 0 kPa to 25 kPa 030PG 0 psi to 30 psi

barbed port barbed port barbed port

400MG 0 bar to 400 mbar 040KG 0 kPa to 40 kPa 060PG 0 psi to 60 psi

600MG 0 bar to 600 mbar 060KG 0 kPa to 60 kPa 100PG 0 psi to 100 psi

001BG 0 bar to 1 bar 100KG 0 kPa to 100 kPa 150PG 0 psi to 150 psi

1.6BG 0 bar to 1.6 bar 160KG 0 kPa to 160 kPa

LN Single axial

barbless port

LN Single axial

barbless port

LN Single axial

barbless port 2.5BG 0 bar to 2.5 bar 250KG 0 kPa to 250 kPa

004BG 0 bar to 4 bar 400KG 0 kPa to 400 kPa

006BG 0 bar to 6 bar 600KG 0 kPa to 600 kPa

010BG 0 bar to 10 bar 001GG 0 kPa to 1 MPa

PN Low-profile PN Low-profile PN Low-profile Differential Differential Differential

port port port

060MD ±60 mbar 006KD ±6 kPa 001PD ±1 psi

100MD ±100 mbar 010KD ±10 kPa 005PD ±5 psi

160MD ±160 mbar 016KD ±16 kPa 015PD ±15 psi

RN Single radial RN Single radial RN Single radial 250MD ±250 mbar 025KD ±25 kPa 030PD ±30 psi

barbed port barbed port barbed port

400MD ±400 mbar 040KD ±40 kPa 060PD ±60 psi

600MD ±600 mbar 060KD ±60 kPa

001BD ±1 bar 100KD ±100 kPa

1.6BD ±1.6 bar 160KD ±160 kPa

RR Dual radial

barbed port 2.5BD ±2.5 bar 250KD ±250 kPa

004BD ±4 bar 400KD ±400 kPa

- -

Gel Coating

VN Single axial VN Single axial VN Single axial N No gel coating in media path

barbless barbless barbless

straight port straight port straight port

S Silicone gel coating in media path (food grade)

1

Custom pressure ranges are available. Contact Honeywell Customer Service

for more information.

2

See Table 2 for an explanation of pressure types.

4 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 2. NBP Series Nomenclature and Order Guide (Part order quantity must meet MOQ requirements.) E

For example, NBPDANN150PGUNV defines an NBP Series Basic Board Mount Pressure Sensor, DIP package, AN pressure

port, no gel coating in media path, 150 psi gage pressure range, unamplified, uncompensated, constant supply voltage.

NBP D AN N 150PG U N V Supply Voltage

Series

NBP V Constant

Package

L Leadless SMT (Surface Mount Technology) Compensation

M SMT (Surface Mount Technology) N Uncompensated

D DIP (Dual Inline Pin)

Pressure Port Output

Leadless SMT SMT DIP U Unamplified

AN Single axial

small barbed

AN Single axial

small barbed

AN Single axial

small barbed

port port port Pressure Range1, 2

60 mbar to 10 bar 1 psi to 150 psi

Absolute Absolute

001BA 0 bar to 1 bar 015PA 0 psi to 15 psi

JJ Dual radial 1.6BA 0 bar to 1.6 bar 030PA 0 psi to 30 psi

barbless port

2.5BA 0 bar to 2.5 bar 060PA 0 psi to 60 psi

- - 004BA 0 bar to 4 bar 100PA 0 psi to 100 psi

006BA 0 bar to 6 bar 150PA 0 psi to 150 psi

JN Single radial JN Single radial JN Single radial 010BA 0 bar to 10 bar

barbless port barbless port barbless port

Gage Gage

060MG 0 mbar to 60 mbar 001PG 0 psi to 1 psi

100MG 0 mbar to 100 mbar 005PG 0 psi to 5 psi

KN Single axial large KN Single axial large KN Single axial large 160MG 0 mbar to 160 mbar 015PG 0 psi to 15 psi

barbed port barbed port barbed port

250MG 0 mbar to 250 mbar 030PG 0 psi to 30 psi

400MG 0 bar to 400 mbar 060PG 0 psi to 60 psi

600MG 0 bar to 600 mbar 100PG 0 psi to 100 psi

001BG 0 bar to 1 bar 150PG 0 psi to 150 psi

LN Single axial LN Single axial LN Single axial

1.6BG

barbless port barbless port barbless port 0 bar to 1.6 bar

2.5BG 0 bar to 2.5 bar

004BG 0 bar to 4 bar

006BG 0 bar to 6 bar

010BG 0 bar to 10 bar

PN Low-profile

port

PN Low-profile

port

PN Low-profile

port

Differential Differential

060MD ±60 mbar 001PD ±1 psi

100MD ±100 mbar 005PD ±5 psi

RN Single radial RN Single radial RN Single radial 160MD ±160 mbar 015PD ±15 psi

barbed port barbed port barbed port

250MD ±250 mbar 030PD ±30 psi

400MD ±400 mbar 060PD ±60 psi

600MD ±600 mbar

001BD ±1 bar

RR Dual radial

barbed port 1.6BD ±1.6 bar

2.5BD ±2.5 bar

- -

004BD ±4 bar

Gel Coating

VN Single axial

barbless

VN Single axial

barbless

VN Single axial

barbless N No gel coating in media path

straight port straight port straight port

S Silicone gel coating in media path (food grade)

1

Custom pressure ranges are available. Contact Honeywell Customer Service

for more information.

2

See Table 2 for an explanation of pressure types.

Sensing and Internet of Things 5

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table 6. TBP Series Pressure Range Specifications for 60 mbar to 10 bar

Thermal Effect Thermal Effect

Long-Term Stability 1000 hr

Pressure Over- Burst Full Scale Span

Silicone Gel Option (%FSS)9

Pressure Accuracy (%FSS) 4

Pressure Range Order Code

on Offset on Span

Common Mode Pressure3

Range Pressure1 Pressure2 (mV/V)6

No Gel Option (%FSS)9

(%FSS)7 (%FSS)8

Thermal Hysteresis

Thermal Hysteresis

at 25°C (%FSS)

Offset (mV/V)5

(see Figure 1)

Unit

10ºC 0ºC 10ºC 0ºC

Pmax.

Port 1

Port 2

Port 1

Port 2

Pmin.

Min. Nom. Max. to to to to

50ºC 85ºC 50ºC 85ºC

Gage

060MG 0 60 mbar 872 — 1370 — — ±0.20 ±0.075 1.23 1.30 1.40 ±1.15 ±2.35 ±1.00 ±2.00 ±0.45 ±0.40 ±0.60

100MG 0 100 mbar 872 — 1370 — — ±0.20 ±0.075 2.06 2.20 2.33 ±0.70 ±1.40 ±1.00 ±2.00 ±0.30 ±0.25 ±0.35

160MG 0 160 mbar 2000 — 4000 — — ±0.15 ±0.12 2.18 2.30 2.46 ±1.65 ±3.30 ±0.75 ±2.00 ±0.55 ±0.35 ±0.55

250MG 0 250 mbar 2000 — 4000 — — ±0.15 ±0.12 3.41 3.65 3.85 ±1.05 ±2.10 ±0.75 ±2.00 ±0.35 ±0.20 ±0.35

400MG 0 400 mbar 2000 — 4000 — — ±0.15 ±0.12 5.45 5.80 6.15 ±0.65 ±1.30 ±0.75 ±2.00 ±0.20 ±0.15 ±0.20

600MG 0 600 mbar 4000 — 8000 — — ±0.15 ±0.075 2.94 3.05 3.18 ±0.85 ±1.65 ±0.50 ±1.25 ±0.40 ±0.15 ±0.35

001BG 0 1 bar 4 — 8 — — ±0.15 ±0.075 4.90 5.10 5.30 ±0.50 ±1.00 ±0.50 ±1.25 ±0.25 ±0.10 ±0.20

1.6BG 0 1.6 bar 4 — 8 — — ±0.15 ±0.075 7.84 8.15 8.48 ±0.30 ±0.65 ±0.50 ±1.25 ±0.15 ±0.10 ±0.15

2.5BG 0 2.5 bar 8 — 17 — — ±0.15 ±0.075 6.10 6.35 6.59 ±0.40 ±0.80 ±0.50 ±1.50 ±0.20 ±0.10 ±0.15

004BG 0 4 bar 10 — 17 — — ±0.15 ±0.075 5.57 5.80 6.04 ±0.50 ±1.00 ±0.50 ±1.25 ±0.25 ±0.10 ±0.20

006BG 0 6 bar 17 — 21 — — ±0.15 ±0.075 5.08 5.30 5.54 ±0.65 ±1.00 ±0.50 ±1.00 ±0.25 ±0.15 ±0.25

010BG 0 10 bar 17 — 21 — — ±0.15 ±0.075 8.47 8.85 9.22 ±0.40 ±0.60 ±0.50 ±1.00 ±0.15 ±0.10 ±0.15

Differential

060MD -60 60 mbar 872 872 1370 1370 10000 ±0.20 ±0.075 2.46 2.60 2.80 ±0.60 ±1.20 ±1.00 ±2.00 ±0.25 ±0.20 ±0.30

100MD -100 100 mbar 872 872 1370 1370 10000 ±0.20 ±0.075 4.12 4.40 4.66 ±0.35 ±0.70 ±1.00 ±2.00 ±0.15 ±0.15 ±0.20

160MD -160 160 mbar 2000 2000 4000 4000 10000 ±0.15 ±0.12 4.36 4.60 4.92 ±0.85 ±1.65 ±0.75 ±2.00 ±0.30 ±0.20 ±0.30

250MD -250 250 mbar 2000 2000 4000 4000 10000 ±0.15 ±0.12 6.82 7.30 7.70 ±0.55 ±1.05 ±0.75 ±2.00 ±0.20 ±0.10 ±0.20

400MD -400 400 mbar 2000 2000 4000 4000 10000 ±0.15 ±0.12 10.90 11.60 12.30 ±0.35 ±0.65 ±0.75 ±2.00 ±0.10 ±0.10 ±0.10

600MD -600 600 mbar 4000 4000 8000 8000 10000 ±0.15 ±0.075 5.88 6.10 6.36 ±0.45 ±0.85 ±0.50 ±1.25 ±0.20 ±0.10 ±0.20

001BD -1 1 bar 4 4 8 8 10 ±0.15 ±0.075 9.80 10.20 10.60 ±0.25 ±0.50 ±0.50 ±1.25 ±0.15 ±0.10 ±0.10

1.6BD -1.6 1.6 bar 4 4 8 8 10 ±0.15 ±0.075 15.68 16.30 16.96 ±0.15 ±0.35 ±0.50 ±1.25 ±0.10 ±0.10 ±0.10

2.5BD -2.5 2.5 bar 8 8 17 17 10 ±0.15 ±0.075 12.20 12.70 13.18 ±0.20 ±0.40 ±0.50 ±1.50 ±0.10 ±0.10 ±0.10

004BD -4 4 bar 10 10 17 17 15 ±0.15 ±0.075 11.14 11.60 12.08 ±0.25 ±0.50 ±0.50 ±1.25 ±0.15 ±0.10 ±0.10

1

Overpressure: The maximum pressure which may safely be applied to the product for it to remain within specifications once pressure is returned to the

operating pressure range. Exposure to higher pressures may cause permanent damage to the product. Unless otherwise specified, this applies to all available

pressure ports at any temperature within the operating temperature range.

2

Burst pressure: The maximum pressure that may be applied to the specified port (P1 or P2) of the product without causing escape of pressure media. Product

should not be expected to function after exposure to any pressure beyond the burst pressure.

3

Common mode pressure: The maximum pressure that can be applied simultaneously to both ports of a differential pressure sensor without causing changes

in specified performance.

4

Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure range at 25°C. Includes all

errors due to pressure non-linearity, pressure hysteresis, and non-repeatability.

5

Offset: The output signal obtained when the reference pressure is applied to all available pressure ports. Also known as “null” or “zero”.

6

Full Scale Span: The algebraic difference between the output signal measured at the maximum and minimum limits of the pressure range (see Figure 1) for

pressure ranges).

7

Thermal effect on offset: The deviation in offset due to changes in temperature over the compensated temperature range, relative to offset measured at 25ºC.

8

Thermal effect on span: The deviation in full scale span due to changes in temperature over the compensated temperature range, relative to full scale span

measured at 25ºC.

9

Thermal hysteresis: The maximum difference between output readings when the same temperature is reached consecutively, under the same operating

conditions, with temperature approaching from opposite directions within the operating temperature range. Validated over the full operating temperature and

pressure ranges using a ~5ºC/ minute ramp and 30 minute dwell. Application performance may be affected by thermal mass of end user system.

6 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table 7. TBP Series Pressure Range Specifications for 6 kPa to 1 MPa

Thermal Effect Thermal Effect

Long-Term Stability 1000 hr

Pressure Over- Burst Full Scale Span

Silicone Gel Option (%FSS)9

Pressure Accuracy (%FSS) 4

Pressure Range Order Code

on Offset on Span

Common Mode Pressure3

Range Pressure1 Pressure2 (mV/V)6

No Gel Option (%FSS)9

(%FSS)7 (%FSS)8

Thermal Hysteresis

Thermal Hysteresis

at 25°C (%FSS)

Offset (mV/V)5

(see Figure 1)

Unit

10ºC 0ºC 10ºC 0ºC

Pmax.

Port 1

Port 2

Port 1

Port 2

Pmin.

Min. Nom. Max. to to to to

50ºC 85ºC 50ºC 85ºC

Gage

006KG 0 6 kPa 87 — 137 — — ±0.20 ±0.075 1.23 1.30 1.40 ±1.15 ±2.35 ±1.00 ±2.00 ±0.45 ±0.40 ±0.60

010KG 0 10 kPa 87 — 137 — — ±0.20 ±0.075 2.06 2.20 2.33 ±0.70 ±1.40 ±1.00 ±2.00 ±0.30 ±0.25 ±0.35

016KG 0 16 kPa 200 — 400 — — ±0.15 ±0.12 2.18 2.30 2.46 ±1.65 ±3.30 ±0.75 ±2.00 ±0.55 ±0.35 ±0.55

025KG 0 25 kPa 200 — 400 — — ±0.15 ±0.12 3.41 3.65 3.85 ±1.05 ±2.10 ±0.75 ±2.00 ±0.35 ±0.20 ±0.35

040KG 0 40 kPa 200 — 400 — — ±0.15 ±0.12 5.45 5.80 6.15 ±0.65 ±1.30 ±0.75 ±2.00 ±0.20 ±0.15 ±0.20

060KG 0 60 kPa 400 — 800 — — ±0.15 ±0.075 2.94 3.05 3.18 ±0.85 ±1.65 ±0.50 ±1.25 ±0.40 ±0.15 ±0.35

100KG 0 100 kPa 400 — 800 — — ±0.15 ±0.075 4.90 5.10 5.30 ±0.50 ±1.00 ±0.50 ±1.25 ±0.25 ±0.10 ±0.20

160KG 0 160 kPa 400 — 800 — — ±0.15 ±0.075 7.84 8.15 8.48 ±0.30 ±0.65 ±0.50 ±1.25 ±0.15 ±0.10 ±0.15

250KG 0 250 kPa 800 — 1700 — — ±0.15 ±0.075 6.10 6.35 6.59 ±0.40 ±0.80 ±0.50 ±1.50 ±0.20 ±0.10 ±0.15

400KG 0 400 kPa 1000 — 1700 — — ±0.15 ±0.075 5.57 5.80 6.04 ±0.50 ±1.00 ±0.50 ±1.25 ±0.25 ±0.10 ±0.20

600KG 0 600 kPa 1700 — 2100 — — ±0.15 ±0.075 5.08 5.30 5.54 ±0.65 ±1.00 ±0.50 ±1.00 ±0.25 ±0.15 ±0.25

001GG 0 1 MPa 1.70 — 2.10 — — ±0.15 ±0.075 8.47 8.85 9.22 ±0.40 ±0.60 ±0.50 ±1.00 ±0.15 ±0.10 ±0.15

Differential

006KD -6 6 kPa 87 87 137 137 1000 ±0.20 ±0.075 2.46 2.60 2.80 ±0.60 ±1.20 ±1.00 ±2.00 ±0.25 ±0.20 ±0.30

010KD -10 10 kPa 87 87 137 137 1000 ±0.20 ±0.075 4.12 4.40 4.66 ±0.35 ±0.70 ±1.00 ±2.00 ±0.15 ±0.15 ±0.20

016KD -16 16 kPa 200 200 400 400 1000 ±0.15 ±0.12 4.36 4.60 4.92 ±0.85 ±1.65 ±0.75 ±2.00 ±0.30 ±0.20 ±0.30

025KD -25 25 kPa 200 200 400 400 1000 ±0.15 ±0.12 6.82 7.30 7.70 ±0.55 ±1.05 ±0.75 ±2.00 ±0.20 ±0.10 ±0.20

040KD -40 40 kPa 200 200 400 400 1000 ±0.15 ±0.12 10.90 11.60 12.30 ±0.35 ±0.65 ±0.75 ±2.00 ±0.10 ±0.10 ±0.10

060KD -60 60 kPa 400 400 800 800 1000 ±0.15 ±0.075 5.88 6.10 6.36 ±0.45 ±0.85 ±0.50 ±1.25 ±0.20 ±0.10 ±0.20

100KD -100 100 kPa 400 400 800 800 1000 ±0.15 ±0.075 9.80 10.20 10.60 ±0.25 ±0.50 ±0.50 ±1.25 ±0.15 ±0.10 ±0.10

160KD -160 160 kPa 400 400 800 800 1000 ±0.15 ±0.075 15.68 16.30 16.96 ±0.15 ±0.35 ±0.50 ±1.25 ±0.10 ±0.10 ±0.10

250KD -250 250 kPa 800 800 1700 1700 1000 ±0.15 ±0.075 12.20 12.70 13.18 ±0.20 ±0.40 ±0.50 ±1.50 ±0.10 ±0.10 ±0.10

400KD -400 400 kPa 1000 1000 1700 1700 1500 ±0.15 ±0.075 11.14 11.60 12.08 ±0.25 ±0.50 ±0.50 ±1.25 ±0.15 ±0.10 ±0.10

1

Overpressure: The maximum pressure which may safely be applied to the product for it to remain within specifications once pressure is returned to the

operating pressure range. Exposure to higher pressures may cause permanent damage to the product. Unless otherwise specified, this applies to all available

pressure ports at any temperature within the operating temperature range.

2

Burst pressure: The maximum pressure that may be applied to the specified port (P1 or P2) of the product without causing escape of pressure media. Product

should not be expected to function after exposure to any pressure beyond the burst pressure.

3

Common mode pressure: The maximum pressure that can be applied simultaneously to both ports of a differential pressure sensor without causing changes

in specified performance.

4

Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure range at 25°C. Includes all

errors due to pressure non-linearity, pressure hysteresis, and non-repeatability.

5

Offset: The output signal obtained when the reference pressure is applied to all available pressure ports. Also known as “null” or “zero”.

6

Full Scale Span: The algebraic difference between the output signal measured at the maximum and minimum limits of the pressure range (see Figure 1) for

pressure ranges).

7

Thermal effect on offset: The deviation in offset due to changes in temperature over the compensated temperature range, relative to offset measured at 25ºC.

8

Thermal effect on span: The deviation in full scale span due to changes in temperature over the compensated temperature range, relative to full scale span

measured at 25ºC.

9

Thermal hysteresis: The maximum difference between output readings when the same temperature is reached consecutively, under the same operating

conditions, with temperature approaching from opposite directions within the operating temperature range. Validated over the full operating temperature and

pressure ranges using a ~5ºC/ minute ramp and 30 minute dwell. Application performance may be affected by thermal mass of end user system.

Sensing and Internet of Things 7

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table 8. TBP Series Pressure Range Specifications for 1 psi to 150 psi

Thermal Effect Thermal Effect

Long-Term Stability 1000 hr

Silicone Gel Option (%FSS)9

Pressure Over- Burst Full Scale Span

Pressure Accuracy (%FSS) 4

Pressure Range Order Code

on Offset on Span

Common Mode Pressure3

No Gel Option (%FSS)9

Range Pressure1 Pressure2 (mV/V)6 (%FSS)7 (%FSS)8

Thermal Hysteresis

Thermal Hysteresis

at 25°C (%FSS)

Offset (mV/V)5

(see Figure 1)

Unit

10ºC 0ºC 10ºC 0ºC

Pmax.

Port 1

Port 2

Port 1

Port 2

Pmin.

Min. Nom. Max. to to to to

50ºC 85ºC 50ºC 85ºC

Gage

001PG 0 1 psi 12.7 — 20 — — ±0.20 ±0.075 1.42 1.50 1.61 ±1.00 ±2.05 ±1.00 ±2.00 ±0.40 ±0.35 ±0.50

005PG 0 5 psi 30 — 60 — — ±0.15 ±0.12 4.70 5.00 5.30 ±0.75 ±1.50 ±0.75 ±2.00 ±0.25 ±0.15 ±0.25

015PG 0 15 psi 60 — 115 — — ±0.15 ±0.075 5.06 5.25 5.49 ±0.50 ±0.95 ±0.50 ±1.25 ±0.25 ±0.10 ±0.20

030PG 0 30 psi 115 — 245 — — ±0.15 ±0.075 5.05 5.25 5.45 ±0.50 ±0.95 ±0.50 ±1.50 ±0.25 ±0.10 ±0.20

060PG 0 60 psi 145 — 245 — — ±0.15 ±0.075 5.76 6.00 6.24 ±0.50 ±0.95 ±0.50 ±1.25 ±0.25 ±0.10 ±0.20

100PG 0 100 psi 245 — 300 — — ±0.15 ±0.075 5.83 6.10 6.36 ±0.60 ±0.85 ±0.50 ±1.00 ±0.25 ±0.10 ±0.25

150PG 0 150 psi 245 — 300 — — ±0.15 ±0.075 8.75 9.15 9.54 ±0.40 ±0.60 ±0.50 ±1.00 ±0.15 ±0.10 ±0.15

Differential

001PD -1 1 psi 12.7 12.7 20 20 150 ±0.20 ±0.075 2.84 3.00 3.22 ±0.50 ±1.05 ±1.00 ±2.00 ±0.20 ±0.20 ±0.25

005PD -5 5 psi 30 30 60 60 150 ±0.15 ±0.12 9.40 10.00 10.60 ±0.40 ±0.75 ±0.75 ±2.00 ±0.15 ±0.10 ±0.15

015PD -15 15 psi 60 60 115 115 150 ±0.15 ±0.075 10.12 10.50 10.98 ±0.25 ±0.50 ±0.50 ±1.25 ±0.15 ±0.10 ±0.10

030PD -30 30 psi 115 115 245 245 150 ±0.15 ±0.075 10.10 10.50 10.90 ±0.25 ±0.50 ±0.50 ±1.50 ±0.15 ±0.10 ±0.10

060PD -60 60 psi 145 145 245 245 250 ±0.15 ±0.075 11.52 12.00 12.48 ±0.25 ±0.50 ±0.50 ±1.25 ±0.15 ±0.10 ±0.10

1

Overpressure: The maximum pressure which may safely be applied to the product for it to remain within specifications once pressure is returned to the

operating pressure range. Exposure to higher pressures may cause permanent damage to the product. Unless otherwise specified, this applies to all available

pressure ports at any temperature within the operating temperature range.

2

Burst pressure: The maximum pressure that may be applied to the specified port (P1 or P2) of the product without causing escape of pressure media. Product

should not be expected to function after exposure to any pressure beyond the burst pressure.

3

Common mode pressure: The maximum pressure that can be applied simultaneously to both ports of a differential pressure sensor without causing changes

in specified performance.

4

Accuracy: The maximum deviation in output from a Best Fit Straight Line (BFSL) fitted to the output measured over the pressure range at 25°C. Includes all

errors due to pressure non-linearity, pressure hysteresis, and non-repeatability.

5

Offset: The output signal obtained when the reference pressure is applied to all available pressure ports. Also known as “null” or “zero”.

6

Full Scale Span: The algebraic difference between the output signal measured at the maxumum and minimum limits of the pressure range (see Figure 1) for

pressure ranges).

7

Thermal effect on offset: The deviation in offset due to changes in temperature over the compensated temperature range, relative to offset measured at 25ºC.

8

Thermal effect on span: The deviation in full scale span due to changes in temperature over the compensated temperature range, relative to full scale span

measured at 25ºC.

9

Thermal hysteresis: The maximum difference between output readings when the same temperature is reached consecutively, under the same operating

conditions, with temperature approaching from opposite directions within the operating temperature range. Validated over the full operating temperature and

pressure ranges using a ~5ºC/ minute ramp and 30 minute dwell. Application performance may be affected by thermal mass of end user system.

8 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table 9. NBP Series Pressure Range Specifications for 60 mbar to 10 bar

Pressure Over- Burst Offset4 Sensitivity Thermal Effect on Offset Thermal Effect on Span

Pressure Range

Common Mode

(see Figure 2)

Range Pressure1 Pressure2 (mV/V) (mV/V/Full Scale Span) (%FSS/25ºC)5 (%FSS/25ºC)6

Pressure3

Unit

Pmax.

Port 2

Port 2

Port 1

Port 1

Pmin.

Min. Max. Min. Nom. Max. Min. Nom. Max. Min. Nom. Max.

Absolute

001BA 0 1 bar 2 — 4 — — -7.0 7.0 10.0 15.0 20.0 -1.5 -0.5 1.5 -6.0 -5.0 -3.5

1.6BA 0 1.6 bar 4 — 8 — — -7.0 7.0 12.0 16.0 20.0 -1.5 -0.5 1.5 -6.0 -5.0 -3.5

2.5BA 0 2.5 bar 4 — 8 — — -7.0 7.0 18.8 25.0 31.3 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

004BA 0 4 bar 8 — 16 — — -7.0 7.0 16.8 20.0 23.2 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

006BA 0 6 bar 16 — 20 — — -7.0 7.0 12.6 15.0 17.4 -1.5 -0.4 1.5 -6.0 -5.0 -3.5

010BA 0 10 bar 16 — 20 — — -7.0 7.0 21.0 25.0 29.0 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

Gage

060MG 0 60 mbar 850 — 1400 — — -8.5 8.5 3.9 5.7 7.4 -3.5 -1.2 3.5 -6.0 -5.0 -3.5

100MG 0 100 mbar 850 — 1400 — — -8.5 8.5 6.6 9.4 12.3 -2.1 -0.7 2.1 -6.0 -5.0 -3.5

160MG 0 160 mbar 850 — 1400 — — -8.5 8.5 10.5 15.1 19.7 -1.3 -0.4 1.3 -6.0 -5.0 -3.5

250MG 0 250 mbar 1800 — 3000 — — -8.5 8.5 7.3 10.9 14.5 -2.1 -0.7 2.1 -6.0 -5.0 -3.5

400MG 0 400 mbar 1800 — 3000 — — -8.5 8.5 11.7 17.4 23.2 -1.3 -0.4 1.3 -6.0 -5.0 -3.5

600MG 0 600 mbar 2000 — 4000 — — -7.0 7.0 6.0 9.0 12.0 -2.5 -1.0 2.5 -6.0 -5.0 -3.5

001BG 0 1 bar 2 — 4 — — -7.0 7.0 10.0 15.0 20.0 -1.5 -0.5 1.5 -6.0 -5.0 -3.5

1.6BG 0 1.6 bar 4 — 8 — — -7.0 7.0 12.0 16.0 20.0 -1.5 -0.5 1.5 -6.0 -5.0 -3.5

2.5BG 0 2.5 bar 4 — 8 — — -7.0 7.0 18.8 25.0 31.3 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

004BG 0 4 bar 8 — 16 — — -7.0 7.0 16.8 20.0 23.2 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

006BG 0 6 bar 16 — 20 — — -7.0 7.0 12.6 15.0 17.4 -1.5 -0.4 1.5 -6.0 -5.0 -3.5

010BG 0 10 bar 16 — 20 — — -7.0 7.0 21.0 25.0 29.0 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

Differential

060MD -60 60 mbar 850 850 1400 1400 10000 -8.5 8.5 7.8 11.4 14.8 -1.8 -0.6 1.8 -6.0 -5.0 -3.5

100MD -100 100 mbar 850 850 1400 1400 10000 -8.5 8.5 13.2 18.8 24.6 -1.1 -0.4 1.1 -6.0 -5.0 -3.5

160MD -160 160 mbar 850 850 1400 1400 10000 -8.5 8.5 21.0 30.2 39.4 -0.7 -0.2 0.7 -6.0 -5.0 -3.5

250MD -250 250 mbar 1800 1800 3000 3000 10000 -8.5 8.5 14.6 21.8 29.0 -1.1 -0.4 1.1 -6.0 -5.0 -3.5

400MD -400 400 mbar 1800 1800 3000 3000 10000 -8.5 8.5 23.4 34.8 46.4 -0.7 -0.2 0.7 -6.0 -5.0 -3.5

600MD -600 600 mbar 2000 2000 4000 4000 10000 -7.0 7.0 12.0 18.0 24.0 -1.3 -0.5 1.3 -6.0 -5.0 -3.5

001BD -1 1 bar 2 2 4 4 10 -7.0 7.0 20.0 30.0 40.0 -0.8 -0.3 0.8 -6.0 -5.0 -3.5

1.6BD -1.6 1.6 bar 4 4 8 8 10 -7.0 7.0 24.0 32.0 40.0 -0.8 -0.3 0.8 -6.0 -5.0 -3.5

2.5BD -2.5 2.5 bar 4 4 8 8 10 -7.0 7.0 37.6 50.0 62.6 -0.5 -0.2 0.5 -6.0 -5.0 -3.5

004BD -4 4 bar 8 8 16 16 15 -7.0 7.0 33.6 40.0 46.4 -0.5 -0.2 0.5 -6.0 -5.0 -3.5

1

Overpressure: The maximum pressure which may safely be applied to the product for it to remain within specifications once pressure is returned to the

operating pressure range. Exposure to higher pressures may cause permanent damage to the product. Unless otherwise specified, this applies to all available

pressure ports at any temperature within the operating temperature range.

2

Burst pressure: The maximum pressure that may be applied to the specified port (P1 or P2) of the product without causing escape of pressure media. Product

should not be expected to function after exposure to any pressure beyond the burst pressure.

3

Common mode pressure: The maximum pressure that can be applied simultaneously to both ports of a differential pressure sensor without causing changes

in specified performance.

4

Offset: The output signal obtained when the reference pressure is applied to all available pressure ports. Also known as “null” or “zero”.

5

TCO (Thermal Effect on Offset): The deviation in offset due to changes in temperature over the specified temperature range, relative to offset measured at 25ºC.

6

TCS (Thermal Effect on Span): The deviation in full scale span due to changes in temperature over the specified temperature range, relative to full scale span

measured at 25ºC.

Sensing and Internet of Things 9

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Table 10. NBP Series Pressure Range Specifications for 1 psi to 150 psi

Pressure Over- Burst Offset4 Sensitivity Thermal Effect on Offset Thermal Effect on Span

Pressure Range

Common Mode

(see Figure 2)

Range Pressure1 Pressure2 (mV/V) (mV/V/Full Scale Span) (%FSS/25ºC)5 (%FSS/25ºC)6

Pressure3

Unit

Pmax.

Port 2

Port 2

Port 1

Port 1

Pmin.

Min. Max. Min. Nom. Max. Min. Nom. Max. Min. Nom. Max.

Absolute

015PA 0 15 psi 30 — 60 — — -7.0 7.0 10.3 15.0 20.7 -1.5 -0.6 1.5 -6.0 -5.0 -3.5

030PA 0 30 psi 60 — 120 — — -7.0 7.0 15.5 21.0 26.0 -1.0 -0.4 1.0 -6.0 -5.0 -3.5

060PA 0 60 psi 120 — 240 — — -7.0 7.0 17.4 21.0 24.0 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

100PA 0 100 psi 240 — 300 — — -7.0 7.0 14.5 17.2 20.0 -1.0 -0.4 1.0 -6.0 -5.0 -3.5

150PA 0 150 psi 240 — 300 — — -7.0 7.0 21.7 26.0 30.0 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

Gage

001PG 0 1 psi 10 — 20 — — -8.5 8.5 4.5 6.5 8.5 -3.0 -1.0 3.0 -6.0 -5.0 -3.5

005PG 0 5 psi 30 — 40 — — -8.5 8.5 10.0 15.0 20.0 -1.5 -0.5 1.5 -6.0 -5.0 -3.5

015PG 0 15 psi 30 — 60 — — -7.0 7.0 10.3 15.0 20.7 -1.5 -0.6 1.5 -6.0 -5.0 -3.5

030PG 0 30 psi 60 — 120 — — -7.0 7.0 15.5 21.0 26.0 -1.0 -0.4 1.0 -6.0 -5.0 -3.5

060PG 0 60 psi 120 — 240 — — -7.0 7.0 17.4 21.0 24.0 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

100PG 0 100 psi 240 — 300 — — -7.0 7.0 14.5 17.2 20.0 -1.0 -0.4 1.0 -6.0 -5.0 -3.5

150PG 0 150 psi 240 — 300 — — -7.0 7.0 21.7 26.0 30.0 -1.0 -0.3 1.0 -6.0 -5.0 -3.5

Differential

001PD -1 1 psi 10 10 20 20 150 -8.5 8.5 9.0 13.0 17.0 -1.5 -0.5 1.5 -6.0 -5.0 -3.5

005PD -5 5 psi 30 30 40 40 150 -8.5 8.5 20.0 30.0 40.0 -0.8 -0.3 0.8 -6.0 -5.0 -3.5

015PD -15 15 psi 30 30 60 60 150 -7.0 7.0 20.6 30.0 41.4 -0.8 -0.3 0.8 -6.0 -5.0 -3.5

030PD -30 30 psi 60 60 120 120 150 -7.0 7.0 31.0 42.0 52.0 -0.5 -0.2 0.5 -6.0 -5.0 -3.5

060PD -60 60 psi 120 120 240 240 250 -7.0 7.0 34.8 42.0 48.0 -0.5 -0.2 0.5 -6.0 -5.0 -3.5

1

Overpressure: The maximum pressure which may safely be applied to the product for it to remain within specifications once pressure is returned to the

operating pressure range. Exposure to higher pressures may cause permanent damage to the product. Unless otherwise specified, this applies to all available

pressure ports at any temperature within the operating temperature range.

2

Burst pressure: The maximum pressure that may be applied to the specified port (P1 or P2) of the product without causing escape of pressure media. Product

should not be expected to function after exposure to any pressure beyond the burst pressure.

3

Common mode pressure: The maximum pressure that can be applied simultaneously to both ports of a differential pressure sensor without causing changes

in specified performance.

4

Offset: The output signal obtained when the reference pressure is applied to all available pressure ports. Also known as “null” or “zero”.

5

TCO (Thermal Effect on Offset): The deviation in offset due to changes in temperature over the specified temperature range, relative to offset measured at 25ºC.

6

TCS (Thermal Effect on Span): The deviation in full scale span due to changes in temperature over the specified temperature range, relative to full scale span.

10 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 3. DIP Package Dimensional Drawings (For reference only: mm [in].)

AN: Single axial small barbed port 4

7,00

[0.276] 3

10,60 MAX.

[0.417] 1,02

2,54 TYP.

[0.100] 4

2X 2,23

[0.088]

No gel coating option: 2,03 [0.080] [0.040 3

Silicone gel coating option: 2,28 [0.090]

3,56

5,50

[0.140] ø0,80

[0.217] [0.032]

11,00 11,70

[0.433] [0.461

ø1,91

[0.075]

ø2,74

[0.108]

ø2,32

[0.091]

PIN 1 INDICATOR 1 2 3,50 ø6,40 8,64 0,25 TYP. 2 1

[0.138] [0.252] [0.340] [0.010]

4X 3,81

[0.150]

4X 0,46

[0.018]

JJ: Dual radial barbless port 7,00

No gel coating option: 2,23 [0.088] 1,02 2,54 TYP. 2X 2,23

[0.276] [0.100] 3 [0.088]

4 3 Silicone gel coating option: 2,48 [0.098] [0.040] 4

0,9

1,50 [0.04]

[0.059]

PORT 1 5,50

[0.217]

ø0,80

[0.032]

11,00 ø6,40 ø6,40 11,70

[0.433] [0.252] [0.252] [0.461]

PORT 2

PORT 1 PORT 2

PIN 1 INDICATOR 1 2 3,50 2,23

[0.138] [0.088] 0,9 0,25 TYP. 2 1

2X 1,88 [0.010]

[0.074] [0.04]

8,64

[0.340]

5,33

[0.210]

3,81

[0.150]

4X 0,46

[0.018]

13,00 MAX.

[0.512]

JN: Single radial barbless port 7,00 2,54 TYP. 2X 2,23

No gel coating option: 2,23 [0.088] 1,02 [0.100]

[0.276] Silicone gel coating option: 2,48 [0.098] [0.088]

4 3 [0.040] 3 4

ø1,88 0,9

[0.074] [0.04]

5,50 ø0,80

[0.217] [0.032]

11,00 ø6,41 11,70

[0.433] [0.252]

[0.461

0,75

[0.030]

PIN 1 INDICATOR 1 2 3,50 8,64 0,25 TYP. 2 1

[0.138] [0.340] [0.010]

13,00 MAX.

[0.512]

2,3

[0.09]

4X 3,81

[0.150]

4X 0,46

[0.018]

Sensing and Internet of Things 11

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 3. DIP Package Dimensional Drawings (For reference only: mm [in], continued.)

11,25 MAX.

KN: Single axial large barbed port 7,00 [0.443]

2,54 TYP. 2X 2,23

[0.276] No gel coating option: 2,03 [0.080] 1,02 [0.100] [0.088]

4 3

Silicone gel coating option: 2,28 [0.090] 3 4

[0.040]

3,301

5,50 [0.130] ø0,80

[0.217] [0.032]

11,00 ø3,05 11,70

[0.433] [0.120] [0.461

ø4,92

[0.194]

PIN 1

ø3,81

1 2 3,50 [0.150]

INDICATOR 2 1

[0.138] ø6,40 8,64 0,25 TYP.

[0.252] [0.340] [0.010]

4X 3,81

[0.150]

4X 0,46

[0.018]

10,60 MAX. 2,54 TYP.

LN: Single axial barbless port 7,00 [0.417] [0.100]

2,23

[0.088]

4 [0.276] 3 No gel coating option: 2,03 [0.080] 1,02 3 4

Silicone gel coating option: 2,28 [0.090] [0.040]

ø0,80

5,50 [0.032]

[0.217]

11,00 ø3,18 11,70

[0.433] [0.125] [0.461

4X 1,27

ø6,40 [0.050]

[0.252]

PIN 1

INDICATOR 1 2 3,50 8,64 0,25 TYP. 2 1

[0.138] [0.340] [0.010] 4X 0,46

[0.018]

4X 3,81

[0.150]

4X 0,46

[0.018]

7,00

PN: Low-profile port 4 [0.276] 3

3,70 MAX.

[0.146]

2,54 TYP.

[0.100] 3

2X 2,23

[0.088]

2,10 MIN. 4

[0.083]

5,50 ø0,80

[0.217] [0.032]

11,00 ø6,50 11,70

[0.433] [0.256] [0.461]

PIN 1

INDICATOR 1 1,02 0,25 TYP. 2 1

2 3,50 [0.040] [0.010]

[0.138] 8,64

[0.340]

4X 3,81

[0.150]

4X 0,46

[0.018]

12 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 3. DIP Package Dimensional Drawings (For reference only: mm [in], continued.)

RN: Single radial barbed port 7,00 No gel coating option: 2,23 [0.088] 1,02 2,54 TYP. 2X 2,23

[0.276] Silicone gel coating option: 2,48 [0.098] [0.040] [0.100] 4 [0.088]

4 3 3

1,2

ø2,32 [0.05]

[0.091] 5,50 ø0,80

[0.217] [0.032]

ø1,91 ø6,40

[0.075] 11,00 11,70

[0.433] [0.252] [0.461]

3,56 0,75

[0.140] [0.030]

PIN 1

INDICATOR 8,64 0,25 TYP. 2 1

1 2 [0.340]

3,50 [0.010]

ø2,74 [0.138]

[0.108]

13,00 MAX.

[0.512]

2,3

[0.09]

4X 3,81

[0.150]

4X 0,46

[0.018]

RR: Dual radial barbed port 7,00 No gel coating option: 2,23 [0.088] 1,02 2,54 TYP. 2X 2,23

[0.276] Silicon gel coating option: 2,48 [0.098] [0.040] [0.100] 4 [0.088]

ø2,321 4 3 3

[0.091]

1,2

PORT 1 [0.05] PORT 2 0,75

1,50 5,50 [0.029]

[0.059] [0.217]

ø6,40 ø6,40 11,70

11,00 [0.252]

[0.252] [0.461

[0.433]

PORT 2

PORT 1

PIN 1 2,23

INDICATOR 1 2 0,25 TYP.

[0.088] 1,2 2 1

[0.010]

3,50 [0.05]

2X ø1,91 [0.138] 8,64

[0.075] [0.340]

13,00 MAX.

[0.512]

2X 5,33

[0.210]

4X 3,81

[0.150]

2X ø2,74

[0.108]

4X 0,46

[0.018]

VN: Single axial barbless straight port 7,00

8,30 MAX.

[0.327]

2,54 TYP.

[0.100]

2X 2,23

[0.088]

[0.276] No gel coating option: 2,03 [0.080] 1,02

4 3 3 4

Silicone gel coating option: 2,28 [.090] [0.040]

5,50 ø0,80

[0.217] [0.032]

11,00 ø2,58 11,70

[0.433] [0.101]

[0.461

ø6,40

[0.252]

PIN 1 1 3,50 8,64 0,25 TYP.

INDICATOR 2 2 1

[0.138] [0.340] [0.010]

4X 3,81

[0.150]

4X 0,46

[0.018]

Sensing and Internet of Things 13

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 3. DIP Package Dimensional Drawings (For reference only: mm [in], continued.)

Recommended PCB Pad Layout Pinout

2,54

[0.100] Pin Function

1 Vsupply

2 Vout-

11,50 3 GND

[0.45]

4 Vout+

ø0,813

[0.032]

Figure 4. SMT Package Dimensional Drawings (For reference only: mm [in].)

AN: Single axial small barbed port

10,60 MAX.

7,00 [0.417] 2,54 TYP. 2,23

[0.276] [0.100] [0.088]

4 3 No gel coating option: 2,03 [0.080] 1,02 3 4

Silicone gel coating option: 2,28 [0.090] [0.040]

5,50 3,56 ø0,80

[0.217] [0.140] [0.032]

11,00 11,70

[0.433] [0.461]

ø1,91

[0.075]

ø2,74 4X 1,27

[0.108] [0.050]

ø2,32

[0.091]

PIN 1 INDICATOR 2 0,25 TYP. 1

1 ø6,40 [0.010] 2

3,50 [0.252] 4X 0,46

[0.138] 3,03

[0.119] [0.018]

JN: Single radial barbless port 7,00 No gel coating option: 2,23 [0.088] 1,02 2,54 TYP. 2X 2,23

[0.276] Silicone gel coating option: 2,48 [0.098] [0.040] [0.100] [0.088]

4 3 3 4

0,9

1,88 5,50 [0.04] ø0,80

[0.032]

[0.074] [0.217]

11,00 ø6,41 11,70

0,75 [0.433] [0.252] [0.461]

[0.030]

4X 1,27

[0.050]

PIN 1 INDICATOR 3,03 0,25 TYP.

1 2 2 1

3,50 [0.119] [0.010]

[0.138]

13,00 MAX.

[0.512]

2,3

[0.09]

4X 0,46

[0.018]

14 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 4. SMT Package Dimensional Drawings (For reference only: mm [in], continued.)

KN: Single axial large barbed port

11,25 MAX. 2,54 TYP. 2X 2,23

7,00 [0.443] [0.100] [0.088]

[0.276] No gel coating option: 2,03 [0.080] 1,02 3 4

4 3

Silicone gel coating option: 2,28 [0.090] [0.040]

3,30 ø0,80

5,50 [0.130] [0.032]

[0.217]

11,00 ø3,05 11,70

[0.433] [0.120]

[0.461

4X 1,27

ø4,92 [0.050]

[0.194]

ø3,81

[0.150]

1 2 0,25 TYP. 2 1

PIN 1

INDICATOR

3,50 ø6,40 [0.010]

[0.138] [0.252] 3,03 4X 0,46

[0.119] [0.018]

LN: Single axial barbless port

10,60 MAX. 2,54 TYP. 2,23

7,00 [0.417] [0.100] [0.088]

[0.276] 1,02 3 4

4 3 No gel coating option: 2,03 [0.080]

Silicone gel coating option: 2,28 [0.090] [0.040]

5,50 ø0,80

[0.217] [0.032]

11,00 ø3,18 11,70

[0.433] [0.125]

[0.461

4X 1,27

ø6,40 [0.050]

[0.252]

PIN 1 1 2 0,25 TYP.

3,50 3,03 [0.010] 2 1

INDICATOR

[0.138] [0.119] 4X 0,46

[0.018]

PN: Low-profile port

7,00 3,70 MAX. 2,54 TYP. 2,23

[0.276] [0.010] [0.100] [0.088]

4 3 3 4

2,10 MIN.

[0.083]

5,50 ø0,80

[0.217] [0.032]

11,00 ø6,50 11,70

[0.433] [0.256] [0.461

4X 1,27

[0.050]

PIN 1 1 2 1,02 0,25 TYP.

INDICATOR [0.040] [0.010] 2 1

3,50

[0.138] 3,03 4X 0,46

[0.119] [0.018]

RN: Single radial barbed port 7,00 No gel coating option: 2,23 [0.088]

2,54 TYP.

[0.100]

2,23

[0.088]

1,02

4

[0.276] Silicone gel coating option: 2,48 [0.098] [0.040] 3 4

3

0,9

[0.04]

ø1,88 5,50 ø0,80

[0.07] [0.217] [0.032]

11,00 ø6,41 11,70

[0.433] [0.252]

[0.461]

0,75

[0.030]

4X 1,27

[0.050]

PIN 1

INDICATOR 1 2 0,25 TYP.

[0.010] 2 1

3,50

[0.138] 3,03 4X 0,46

13,00 MAX. [0.119] [0.018]

[0.512]

2,3

[0.09]

4X 0,46

[0.018]

Sensing and Internet of Things 15

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 4. SMT Package Dimensional Drawings (For reference only: mm [in], continued.)

VN: Single axial barbless straight port 7,00

8,30 MAX.

[0.327]

2,54 TYP.

[0.100]

2,23

[0.088]

[0.276] No gel coating option: 2,03 [0.080] 3 4

4 3 1,02

Silicone gel coating option: 2,28 [0.090] [0.040]

5,50

ø0,80

[0.032]

[0.217]

11,00 ø2,58 11,70

[0.433] [0.101]

[0.461

4X 1,27

[0.050]

ø6,40

[0.252]

PIN 1 2 0,25 TYP. 1

INDICATOR 1 2

3,50 [0.010] 4X 0,46

[0.138] 3,03 [0.018]

[0.119]

Recommended PCB Pad Layout Pinout

2,54

[0.100]

Pin Function

2,032 1 Vsupply

[0.080]

2 Vout-

7,49 3 GND

[0.295]

4 Vout+

1,143

[0.045]

Figure 5. Leadless SMT Package Dimensional Drawings (For reference only: mm [in].)

AN: Single axial small barbed port

10,60 MAX. 0,73 2,00

[0.417] [0.029] [0.079]

PIN 1 7,00

[0.276] No gel coating option: 2,03 [0.080] 1,00

INDICATOR Silicone gel coating option: 2,28 [0.090] 6 1

ø0,80 [0.039]

3,56 [0.032]

3,50 [0.140]

5 2

[0.138]

7,00

[0.276] 6X 1,25 4 2,50 TYP.

[0.049] 3

ø1,91 [0.098]

[0.075] ø2,74

[0.108]

1,02

3,50 ø2,32 [0.138] 5X 2,00

[0.138] [0.091] ø6,40 [0.079]

[0.252]

JN: Single radial barbless port

0,73 2,00

PIN 1 7,00 0,94 No gel coating option: 2,23 [0.088] [0.029] [0.079]

INDICATOR [0.276] [0.037] Silicone gel coating option: 2,48 [0.098] 1,00

ø0,80 6 1 [0.039]

3,50 [0.032]

[0.138] 2

7,00 5

[0.276]

6X 1,25 4 2,50 TYP.

[0.049] 3 [0.098]

13,00 MAX.

[0.512]

5X 2,00

[0.079]

0,75 3,50 1,88

[0.030] [0.138] [0.074]

ø6,40

[0.252]

2,28 1,02

[0.090] [0.040]

16 Sensing and Internet of Things

Basic Board Mount Pressure Sensors

TBP Series, Compensated/Unamplified

NBP Series, Uncompensated/Unamplified

Figure 5. Leadless SMT Package Dimensional Drawings (For reference only: mm [in], continued.)

KN: Single axial large barbed port 11,25 MAX.

[0.443] 0,73 2,00

PIN 1 No gel coating option: 2,03 [0.080] [0.029] [0.079]

INDICATOR 7,00 Silicone gel coating option: 2,28 [0.090]

[0.276] 1,00

3,30 ø0,80 6 1 [0.039]

[0.130] [0.032]

3,50

[0.138] 5 2

7,00 ø3,05

[0.276] [0.120] 6X 1,25 2,50 TYP.

[0.049] 4 3 [0.098]

ø4,92 1,02

3,50 [0.194]

[0.138] ø6,40 [0.040] 5X 2,00

ø3,81 [0.252] [0.079]

[0.150]

LN: Single axial barbless port

10,60 MAX. 0,73 2,00

PIN 1 [0.417] [0.029] [0.079]

INDICATOR 7,00 No gel coating option: 2,03 [0.080]

[0.276] 1,00

Silicone gel coating option: 2,28 [0.090] 6 1

ø0,80 [0.039]

[0.032]

3,50

[0.138] 5 2

7,00 ø3,18

[0.276] [0.125] 6X 1,25

4 2,50 TYP.

[0.049] 3 [0.098]

6,32

[0.249] 1,02

3,50 ø6,40 [0.040]

[0.138] [0.252] 5X 2,00

[0.079]

PN: Low-profile port 3,70 MAX.

[0.010]

0,73

[0.029]

2,00

[0.079]

PIN 1 7,00

[0.276] 2,10 MIN. 1,00

INDICATOR [0.083] 6 1

ø0,80 [0.039]

[0.032]

3,50

[0.138] 5 2

7,00 ø6,50

[0.276] [0.256] 6X 1,25 2,50 TYP.

4 3 [0.098]

[0.049]

3,50

[0.138] 1,02 5X 2,00

[0.040] [0.079]

RN: Single radial barbed port PIN 1

0,96 No gel coating option: 2,23 [0.088]

Silicone gel coating option: 2,48 [0.098]

0,73

[0.029]

2,00

[0.079]

7,00 [0.038]

INDICATOR 1,00

[0.276] 6 1

ø0,80 [0.039]

[0.032]

3,50 2

[0.138] 5

ø7,00 6X 1,25

[0.276] 2,50 TYP.

[0.049] 4 3 [0.098]

13,00 MAX.

[0.512]

ø2,32 ø2,73 5X 2,00

[0.108] [0.079]

[0.091]

3,54

[0.139]

2,3 3,50 ø1,91

[0.09] [0.138] [0.075]

ø6,40

[0.252]

2,3 1,02

[0.09] [0.040]

VN: Single axial barbless straight port 8,30 MAX.

[0.327]

0,73 2,00

No gel coating option: 2,03 [0.080] [0.029] [0.079]

PIN 1 7,00 Silicone gel coating option: 2,28 [0.090]

INDICATOR [0.276] 1,00

ø0,80 6 1 [0.039]

[0.032]

3,50

[0.138] 5 2

7,00

[0.276]

ø2,58

[0.101] 6X 1,25 4 2,50 TYP.

[0.049] 3 [0.098]

3,50 ø6,44

[0.138] [0.254] 1,02 5X 2,00

[0.040] [0.079]

2,54

[0.100]

Gage reference hole: Do not plug. Pinout

Pin Function

Recommended PCB 2,50

[0.098] 1 Vsupply

Pad Layout

2 Vout-

1,27

3 GND

[0.050]

5,46 4 Vout+

[0.215]

Sensing and Internet of Things 17

ADDITIONAL INFORMATION

The following associated literature is available on the

WARNING

Honeywell web site at sensing.honeywell.com: PERSONAL INJURY

DO NOT USE these products as safety or emergency stop

• Board Mount Pressure Sensors Line Guide

devices or in any other application where failure of the

• Airflow, Force, and Pressure Sensors Product Range Guide

product could result in personal injury.

• Product Installation Instructions

Failure to comply with these instructions could result in

• Application-specific Information

death or serious injury.

WARNING

MISUSE OF DOCUMENTATION

• The information presented in this datasheet is for

reference only. Do not use this document as a product

installation guide.

• Complete installation, operation, and maintenance

information is provided in the instructions supplied with

each product.

Failure to comply with these instructions could result in

death or serious injury.

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free

of defective materials and faulty workmanship. Honeywell’s

standard product warranty applies unless agreed to

otherwise by Honeywell in writing; please refer to your order

acknowledgement or consult your local sales office for specific

warranty details. If warranted goods are returned to Honeywell

during the period of coverage, Honeywell will repair or replace,

at its option, without charge those items it finds defective.

The foregoing is buyer’s sole remedy and is in lieu of all

other warranties, expressed or implied, including those of

merchantability and fitness for a particular purpose. In no

event shall Honeywell be liable for consequential, special,

or indirect damages.

While we provide application assistance personally, through

our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the

For more information application.

Honeywell Sensing and Internet of Specifications may change without notice. The information

Things services its customers through a

we supply is believed to be accurate and reliable as of this

worldwide network of sales offices and

printing. However, we assume no responsibility for its use.

distributors. For application assistance,

current specifications, pricing or the

nearest Authorized Distributor, visit

sensing.honeywell.com or call:

Asia Pacific +65 6355-2828

Europe +44 (0) 1698 481481

USA/Canada +1-800-537-6945 ® NSF is a registered trademark of NSF International.

Honeywell Sensing and Internet of Things

9680 Old Bailes Road

Fort Mill, SC 29707

32344917-B-EN | B | 05/19

honeywell.com © 2019 Honeywell International Inc.

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Honeywell:

TBPDPNS150PGUCV TBPDANS015PGUCV TBPDPNS005PGUCV TBPLLNN060PGUCV TBPMLNN030PGUCV

TBPLLNN015PGUCV TBPDANS001PGUCV TBPLANN030PGUCV TBPDANS005PGUCV TBPDANS030PGUCV

TBPDLNN015PGUCV TBPDLNN030PGUCV TBPLPNN100PGUCV TBPDPNS001PGUCV TBPLANN100PGUCV

TBPLLNS001PGUCV TBPLLNN005PGUCV TBPMANN150PGUCV TBPMANN001PGUCV TBPLLNN030PGUCV

TBPDLNN005PGUCV TBPDPNS100PGUCV TBPMANN005PGUCV TBPDANN150PGUCV TBPMPNS005PGUCV

TBPMLNN060PGUCV TBPLPNN001PGUCV TBPDLNS015PGUCV TBPMANN060PGUCV TBPDLNN150PGUCV

TBPMANS060MGUCV TBPMANN400MGUCV TBPDANN030PGUCV TBPDLNS030PGUCV TBPLANS030PGUCV

TBPDLNN004BGUCV TBPLANS060MGUCV TBPLPNS1.6BGUCV TBPLANN060PGUCV TBPDANS150PGUCV

TBPMANN015PGUCV TBPDANN060PGUCV TBPLPNS005PGUCV TBPDLNN100PGUCV TBPLPNS400MGUCV

TBPDANN250MGUCV TBPDLNN060MGUCV TBPMANS030PGUCV TBPDLNS150PGUCV TBPDANN015PGUCV

TBPLANS2.5BGUCV TBPDLNS160KGUCV TBPDANN160MGUCV TBPDANS060PGUCV TBPDANS100PGUCV

TBPMLNN100MGUCV TBPLPNS150PGUCV TBPMLNS060MGUCV TBPDANS2.5BGUCV TBPDLNS060KGUCV

TBPLPNN030PGUCV TBPMLNS004BGUCV TBPMPNN400MGUCV TBPMPNN100PGUCV TBPMPNN015PGUCV

TBPMLNN600MGUCV TBPDPNS030PGUCV TBPLLNN010KGUCV TBPLANS150PGUCV TBPLANS005PGUCV

TBPMLNN400MGUCV TBPMANS150PGUCV TBPMANS100PGUCV TBPMANN030PGUCV TBPDANN600MGUCV

TBPDANN006KGUCV TBPDLNS060MGUCV TBPLLNN400MGUCV TBPDANS004BGUCV TBPDANS060PGUCVN

TBPDANS100MGUCV TBPDLNN001BGUCV TBPDLNN006BGUCV TBPDLNN010BGUCV TBPDLNN2.5BGUCV

TBPDLNN250MGUCV TBPLANN006KGUCV TBPLANN016KGUCV TBPLANN150PGUCV TBPLANS006KGUCV

TBPLLNN016KGUCV TBPLPNN060PGUCV TBPLPNS001PGUCV TBPLPNS060MGUCV TBPLPNS060PGUCV

TBPLPNS100PGUCV TBPMANN016KGUCV TBPMLNN016KGUCV TBPMPNS010KGUCV TBPLANN400MGUCV

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Pilots Manual Ground School All The Aeronautical Knowledge Required To Pass The Faa Exams and Operate As A Private and Commercial Pilot The Pilots Manual Series Book 2 EbDocument62 pagesThe Pilots Manual Ground School All The Aeronautical Knowledge Required To Pass The Faa Exams and Operate As A Private and Commercial Pilot The Pilots Manual Series Book 2 Ebblanche.karsten96597% (34)

- Siemens Simodrive ManualDocument436 pagesSiemens Simodrive ManualMariel Lopez ValdezNo ratings yet

- BQ 25504Document38 pagesBQ 25504ddvp_gunawardanaNo ratings yet

- lps3015 270734Document3 pageslps3015 270734ddvp_gunawardanaNo ratings yet

- AT-M03.0001 English 2014-02 V4.04Document52 pagesAT-M03.0001 English 2014-02 V4.04ddvp_gunawardanaNo ratings yet

- lps3015 270734Document3 pageslps3015 270734ddvp_gunawardanaNo ratings yet

- BQ 25504Document38 pagesBQ 25504ddvp_gunawardanaNo ratings yet

- Bd30hc0wefj RohmDocument21 pagesBd30hc0wefj Rohmddvp_gunawardanaNo ratings yet

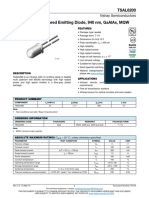

- Tsal 6200Document5 pagesTsal 6200usoefiqiahNo ratings yet

- Logic Gates CombinationDocument22 pagesLogic Gates Combinationddvp_gunawardanaNo ratings yet

- Peripheral BoardsDocument1 pagePeripheral Boardsddvp_gunawardanaNo ratings yet

- Peripheral Boards Revised DrawingDocument1 pagePeripheral Boards Revised Drawingddvp_gunawardanaNo ratings yet

- ELV Series - Analog and Digital Pressure Sensor Product FamiliesDocument35 pagesELV Series - Analog and Digital Pressure Sensor Product Familiesddvp_gunawardanaNo ratings yet

- PIC16F819 Development BoardDocument1 pagePIC16F819 Development Boardddvp_gunawardanaNo ratings yet

- PM750MG Power Meter Data SheetDocument3 pagesPM750MG Power Meter Data Sheetddvp_gunawardanaNo ratings yet

- SIM800 Series - NTP - Application Note - V1.02Document10 pagesSIM800 Series - NTP - Application Note - V1.02ddvp_gunawardanaNo ratings yet

- Research Paper 1-VirajDocument5 pagesResearch Paper 1-Virajddvp_gunawardanaNo ratings yet

- Wiring Regulation Final-06.07.2020Document132 pagesWiring Regulation Final-06.07.2020abdullah sahibNo ratings yet

- AAS 920 477H NovaSensor NPA SurfaceMnt 021718 WebDocument8 pagesAAS 920 477H NovaSensor NPA SurfaceMnt 021718 WebDavid MasferrerNo ratings yet

- Physicsforentert035428mbp PDFDocument221 pagesPhysicsforentert035428mbp PDFTushar IndiaNo ratings yet

- Research Paper 1-VirajDocument5 pagesResearch Paper 1-Virajddvp_gunawardanaNo ratings yet

- General SpecificationDocument327 pagesGeneral SpecificationmaymanyassinNo ratings yet

- Research Paper 2 - VirajDocument4 pagesResearch Paper 2 - Virajddvp_gunawardanaNo ratings yet

- Research Paper 1-VirajDocument5 pagesResearch Paper 1-Virajddvp_gunawardanaNo ratings yet

- lcd1 PDFDocument6 pageslcd1 PDFddvp_gunawardana100% (1)

- How To Use Intelligent L.C.D.S: Constructional FeatureDocument0 pagesHow To Use Intelligent L.C.D.S: Constructional FeatureNelu Sabie100% (1)

- Pic PDFDocument188 pagesPic PDFddvp_gunawardana100% (1)

- Tes VCB PG en 031215Document80 pagesTes VCB PG en 031215Anthony BarbachanNo ratings yet

- LS Drive SeriesDocument16 pagesLS Drive SerieshafezasadNo ratings yet

- April 15 Homework Solutions: Mechanical Engineering 390 Fluid MechanicsDocument6 pagesApril 15 Homework Solutions: Mechanical Engineering 390 Fluid MechanicsRONALD VILCA CACERESNo ratings yet

- Thyristor Based HVDC SystemDocument5 pagesThyristor Based HVDC SystemAnonymous hzXy93FAE0% (1)

- Schematic Diagrams: AV-14FTDocument10 pagesSchematic Diagrams: AV-14FTBaby DreamersNo ratings yet

- Acs150 Catalog en 3afe68596114 RevhDocument16 pagesAcs150 Catalog en 3afe68596114 Revhnajdo1No ratings yet

- Badotherm BaseCal Web-Based Performance ToolDocument6 pagesBadotherm BaseCal Web-Based Performance ToolRizky MuhammadNo ratings yet

- Canara 10EEL78 - PSS - 2013 - Manual PDFDocument64 pagesCanara 10EEL78 - PSS - 2013 - Manual PDFoijhgvcxNo ratings yet

- Marsh Funnel Method for Measuring Drilling Mud ViscosityDocument1 pageMarsh Funnel Method for Measuring Drilling Mud Viscositylamosy78No ratings yet

- Chapter 3 (Sediment Transport) Part BDocument33 pagesChapter 3 (Sediment Transport) Part BMulugeta DefaruNo ratings yet

- Unit-IV Renewable Energy Sources (MCQ)Document10 pagesUnit-IV Renewable Energy Sources (MCQ)Sourabh SinghNo ratings yet

- IJIREEICE1 S Sandeep Power Quality ImprovementDocument7 pagesIJIREEICE1 S Sandeep Power Quality ImprovementJuan Dela CruzNo ratings yet

- Motor 500KW-400690V-50HZDocument1 pageMotor 500KW-400690V-50HZluongttluongNo ratings yet

- SKU SRV2KI CopiarDocument3 pagesSKU SRV2KI Copiarluisoft88No ratings yet

- CapacitanceDocument71 pagesCapacitanceTharaj ThajNo ratings yet

- MMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagDocument13 pagesMMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagJan KowalskiNo ratings yet

- Design of A Digital Controlled Solar Water PumpDocument5 pagesDesign of A Digital Controlled Solar Water Pumpsandeepbabu28No ratings yet

- Week 4 General Physics 2Document7 pagesWeek 4 General Physics 2Pamela GalveNo ratings yet

- Data Sheet 79-koyo-TRD-NDocument6 pagesData Sheet 79-koyo-TRD-NVALCICLEINo ratings yet

- Indian Standard: Specification For Electric Ceiling Type Fans and RegulatorsDocument25 pagesIndian Standard: Specification For Electric Ceiling Type Fans and RegulatorsJai KaranNo ratings yet

- Motion Along A Straight LineDocument3 pagesMotion Along A Straight LineKrit JimenezNo ratings yet

- Heat Worksheet Solutions ExplainedDocument10 pagesHeat Worksheet Solutions ExplainedMEGHNA BAGCHINo ratings yet

- Basic Thermodynamics ConceptsDocument27 pagesBasic Thermodynamics ConceptsLorielle OlivaNo ratings yet

- PBU1001 - PBU1007 10A BRIDGE RECTIFIERDocument3 pagesPBU1001 - PBU1007 10A BRIDGE RECTIFIERMaikol VallejosNo ratings yet

- Density - WikipediaDocument10 pagesDensity - WikipediaJuhairi ArisNo ratings yet

- Ghala Moussa - 2.I Stopping DistanceDocument3 pagesGhala Moussa - 2.I Stopping Distanceghala moussaNo ratings yet

- 6.6 (Barello)Document2 pages6.6 (Barello)buildwithlegos23No ratings yet

- Ge Fanuc Automation: Powermotion ProductsDocument113 pagesGe Fanuc Automation: Powermotion ProductsEDUARDO PERFECTONo ratings yet