0% found this document useful (0 votes)

103 views45 pagesFacility Layout Design Overview

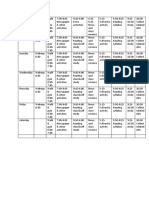

This document discusses facility layout design. It defines layout as the configuration of departments, work centers, and equipment to optimize the flow of materials, people, and work through a facility. The key types of layouts discussed are process layouts, which group similar functions together; product layouts, which arrange processes in the order of operations; and fixed-position layouts for projects where the product cannot move. Objectives of layout design include minimizing costs, optimizing space and labor utilization, and facilitating communication. The document provides examples of different layout types and considerations for designing process and service layouts, including line balancing assembly lines to equalize workloads across stations.

Uploaded by

Akash SinghCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

103 views45 pagesFacility Layout Design Overview

This document discusses facility layout design. It defines layout as the configuration of departments, work centers, and equipment to optimize the flow of materials, people, and work through a facility. The key types of layouts discussed are process layouts, which group similar functions together; product layouts, which arrange processes in the order of operations; and fixed-position layouts for projects where the product cannot move. Objectives of layout design include minimizing costs, optimizing space and labor utilization, and facilitating communication. The document provides examples of different layout types and considerations for designing process and service layouts, including line balancing assembly lines to equalize workloads across stations.

Uploaded by

Akash SinghCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd