Professional Documents

Culture Documents

Gbd-Plus: Compact Glass Break Detector

Uploaded by

Didier Samir GuillenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gbd-Plus: Compact Glass Break Detector

Uploaded by

Didier Samir GuillenCopyright:

Available Formats

1 2 3

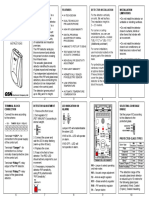

The GBD-PLUS is the ultimate answer for all FIG. 1 - MOUNTING

those tired of false alarms. It listens for

GBD-PLUS sounds of breaking glass, which produce two

sequential signals of different frequencies.

The unique phased frequency detection

circuitry of this detector allows detection of

COMPACT both shock signal and the strong signal of

GLASS BREAK DETECTOR glass breakage creating a “false alarm free”

glass break detector.

The detector does not need to be attached to

the window, providing volume protection, and

allowing you to protect several windows with

one detector.

FEATURES

• Shock and/or breakage selectable

• Analyzes two frequencies

• Unique signal analysis ignores The detector offers flexible installation. It can

environmental disturbances be either ceiling mounted or wall mounted as

• Memory LED shown in the figure above.

ELECTRONIC ENGINEERING LTD. • ASIC based electronics

• Sensitivity adjustment

INSTALLATION INSTRUCTIONS • New ultra compact design

• Flush mount installation (option)

P/N 7101352 Ver. C A.Y. • Outstanding detection range and reliability

4 5 6

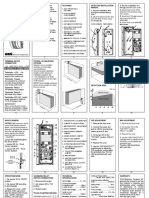

MOUNTING LOCATION ( See FIG. 1 ) MOUNTING THE DETECTOR ( FIG. 2 ) FIG. 2 - THE BACK COVER

• If heavy blinds or curtains cover the glass, 1. Use a small screwdriver to push the prong

you must locate the detector behind the on top of the case and open the case.

blinds on the window frame or above it, 2. Snap out the detector PCB.

otherwise the blinds might block the 3. Insert the wires through the wiring hole (B).

sound. Make sure to test the unit 4. Use the mounting holes (A) to mount the A

thoroughly for proper detection. detector.

• Install the detector in a direct line of sight 5. Connect the wires to the terminal.(See

with the protected glass. Terminal Connections)

• Do not mount the unit in front of air ducts, 6. Reinstall the detector PCB.

or close to bells (measuring 0.5m (or 7. Close the case.

larger) in diameter).

• For a few protected glasses in one room,

JUMPERS ( FIG. 4 )

locate the detector in optimal distance

from them to achieve the best detection. • JP1 - Shock / Glass selector for detection

calibration.

Note: for symmetrical cover of the detection • JP2 – Memory LED control.

area it is recommended to place the • JP3 - Reduces the sensitivity of sound B

detector on the ceiling. detection by 50%. A

7 8 9

FIG. 3 - TERMINAL BLOCK THE CALIBRATION TOOL ( * ) TESTING THE DETECTOR

The Simulator/Tester & Calibration tool is First use the Simulator in manual mode to

especially designed to check phased simulate the noise of glass breaking. Check

frequency glass break detectors. that the yellow LED is ON. If it does not light,

Since the detector will react to the high the sensitivity calibration is necessary (See

frequency breakage sound only when it Sound Calibration).

comes sequentially after a low frequency Now use your hand or a padded object to

SHOCK sound, this device is necessary to carefully strike the glass. If the green LED

TERMINAL BLOCK CONNECTIONS check for proper operation of the GBD-PLUS does not light, adjust as necessary (See

without actually breaking the glass. Shock Calibration).

Terminal 1 - Marked - ( GND ) Now use the Simulator in automatic mode

Connect to ground of the control panel. Manual mode: and check that the red LED lights. If the red

Terminal 2 - Marked + ( +12V ) In this mode, the Simulator will emit the high LED is ON, your detector is working properly.

Connect to the positive Voltage output of 9-16 frequency sound of breaking glass for "Glass" Otherwise try adjusting the sound and shock

Vdc source (usually from the alarm control unit) adjustment. setting until the red LED lights.

Terminals 3 & 4 - Marked TAMPER Automatic mode:

If a Tamper function is required connect these In order to simulate breaking glass, place the

terminals to a 24hour normally closed protective zone Simulator on the surface of the protected

in the control unit. If the front cover of the detector is glass, and gently hit it with your hand. The

opened, an immediate alarm signal will be sent to the Simulator will then emit the sound of breaking

control unit.

glass. Be careful not to break the glass while

Terminals 5 & 6 - Marked RELAY testing the detector.

These are the output relay contacts of the detector. ∗ It is recommended to use simulator CROW

Connect to the control at zone input.

P/N: 0040011

10 11 12

GLASS BREAK ADJUSTMENT SHOCK ADJUSTMENT THE MEMORY FUNCTION

To adjust the glass break setting To adjust the shock setting The alarm memory function allows the

(increase/decrease sensitivity) place the (increase/decrease sensitivity) place the identification of an alerting detector out of

jumper JP1 according the GLASS marking jumper JP1 according the SHOCK marking multiple detectors connected to one (or the

(connecting the middle pin with the upper pin) (connecting the middle pin with the lower pin) same) zone of the control panel.

- (See Fig. 4) Green LED is constantly ON. - (See Fig. 4) Yellow LED is constantly ON. To enable this function, Set ON jumper JP2

Now you can adjust the sensitivity by rotating Now you can adjust the sensitivity by rotating (MEM) (connected on both pins - See Fig. 4)

the upper potentiometer (marked as GLASS the lower potentiometer (marked as SHOCK In case of an alarm, the Red LED will stay

CAL. - see Fig. 4). CAL. - see Fig. 4). ON until memory function is reset.

Operate the Sound Break Simulator and Hit gently on the protected glass and rotate

To reset the memory function, switch OFF

rotate the potentiometer clock-wise to the potentiometer clock-wise to increase

(disconnect) the voltage wire (+12V) from the

increase sensitivity, and counter-clock-wise to sensitivity, and counter-clock-wise to

TERMINAL BLOCK for minimum 15 seconds

decrease sensitivity until the Yellow and Red decrease sensitivity until the Green and Red

then switch on (reconnect) voltage wire

LED’s are illuminating for each glass break LED’s are illuminating for each hit.

(+12V).

sound. Remember that rotating the Remember that rotating the potentiometer will

(The control panel key ON/OFF can be used

potentiometer will have no effect upon the have no effect upon the settings if the middle

for this application if it control the voltage

settings if the middle pin of JP1 is not pin of JP1 is not connected to the lower pin.

(+12V).

connected to the upper pin.

Note

SENSITIVITY SETTING

Note • When the jumper is set for SHOCK

• When the jumper is set for GLASS adjustment, only the low frequency of the For some installations you may find that GBD-

adjustment, only the high frequency sound shock signal prior to glass breakage is plus is too sensitive. Use JUMPER JP3 to

of breaking glass is detected. detected. decrease sensitivity to 50%.

JP3 OPEN - 100% sensitivity

JP3 CONNECTED - 50% sensitivity

13 14 15

FINAL TESTING FIG. 4 - PCB Layout WIRE SIZE REQUIREMENTS

• Make sure to disconnect the jumper at Use #22 AWG (0.5mm) or wires with a larger

JP1. When the jumper is disconnected, diameter. Use the following table to determine

the detector will detect both shock and required wire gauge (diameter) and length of

sound frequencies. wire between the detector and the control

• To ensure maximum protection against panel.

false alarms, activate any device in the

area, which might automatically cycle

pumps, generators, heating/air Wire Length m 200 300 400 800

conditioning units, etc. If the cycling Wire Diameter mm .5 .75 1.0 1.5

devices trigger an alarm, mount the unit in Wire Length ft 800 1200 2000 3400

a different location. Wire Gauge # 22 20 18 16

16 17 18

TECHNICAL SPECIFICATIONS CROW LIMITED WARRANTY CROW ELECTRONIC ENGINEERING LTD.

(Crow) warrants this product to be free from defects in materials and workmanship ISRAEL: 57 Hamelacha St., Holon 58855

Power Input 9 - 16 Vdc under normal use and service for a period of one year from the last day of the Tel: 972-3-5569937 /8 /9

week and year whose numbers are printed on the printed circuit board inside this Fax: 972-3-5592981

Current Consumption Standby: 22mA at 12Vdc product.

E-mail: support@crow.co.il

Active: 25mA at 12Vdc Crow’s obligation is limited to repairing or replacing this product, at its option, free USA: 2160 North Central Road,

of charge for materials or labor, if it is proved to be defective in materials or Fort Lee, N.J. 07024

Detection Range 10m (33ft), Adjustable Tel: 1-800-GET CROW

workmanship under normal use and service. Crow shall have no obligation under or (201) 944 0005

Dimensions 78mm x 51mm x 21mm this Limited Warranty or otherwise if the product is altered or improperly repaired Fax: (201) 944 1199

(3.07 `` x 2.01`` x 0.83) or serviced by anyone other then Crow. E-mail: support@crowelec.com

Mounting Ceiling or Wall There are no warranties, expressed or implied, of merchantability or fitness for a AUSTRALIA: 429 Nepean HWY Brighton East Vic 3187

particular purpose or otherwise, which extend beyond the description on the face Tel: 61-3-9596 7222

Alarm Output Relay N.C 50mA/24Vdc with hereof. In no case shall Crow be liable to anyone for any consequential or Fax: 61-3-9596 0888

27 Ohm in line resistor incidental damages for breach of this or any other warranty, expressed or implied, E-mail: crow@crowaust.com.au

or upon any other basis of liability whatsoever, even if the loss or damage is

Tamper Switch N.C 50mA 24Vdc with caused by Crow’s own negligence or fault.

POLAND: VIDICON 01-231 Warszawa

Ul. Plocka 17

10 Ohm in line resistor Crow does not represent that this product can not be compromised or Tel: 48 22 562 3000

circumvented; that this product will prevent any person injury or property loss or Fax: 48 22 562 3030

Operating Temperature -20°C to 50°C E-mail: vidicon@vidicon.pl

damage by burglary, robbery, fire or otherwise; or that this product will in all cases

Range (-4°F to 122°F) provide adequate warning or protection. Purchaser understands that a properly LATIN AMERICA: CROW LATIN AMERICA

Operating Humidity 95% max relative humidity installed and maintained product can only reduce the risk of burglary, robbery or 5753 NW 151ST.Street

other events occurring without providing an alarm, but it is not insurance or a MIAMI LAKES,

Range non condensing FL 33014 – USA

guarantee that such will not occur or that there will be no personal injury or

Tel: +1-305-823-8700

Storage Temperature -30°C to 70°C property loss or damage as a result. Consequently, Crow shall have no liability for Fax: +1-305-823-8711

Range (-22°F to 158°F) any personal injury; property damage or any other loss based on claim that this E-mail: sales@crowlatinamerica.com

product failed to give any warning. However, if Crow is held liable, whether directly

Electro condenser ITALY: DEATRONIC

or indirectly, for any loss or damage arising under this limited warranty or VIA Giulianello 4/14

microphone otherwise, regardless of cause or origin, Crow’s maximum liability shall not in any 00178 ROMA, ITALY

case exceed the purchase price of this product, which shall be the complete and Tel: +39-0676-12912

RFI Protection 30V/m 10 -1000MHz

exclusive remedy against Crow. Fax: +39-0676-12601

EMI Protection 50,000V electrical E-mail: info@deatronic.com

interference from lightning These instructions supersede all previous issues prior to July 2003.

CROW reserves the rights to change specifications

without prior notice

N345

35352CE50

You might also like

- JS-25 COMBO" P.I.R. & Glass Break DetectorDocument2 pagesJS-25 COMBO" P.I.R. & Glass Break DetectorBatkhishig Tumen-OidovNo ratings yet

- Ja-60B Wireless Glass Break Detector: SpecificationDocument2 pagesJa-60B Wireless Glass Break Detector: SpecificationDragus IonelNo ratings yet

- GBD PlusDocument2 pagesGBD PlusseinnationalNo ratings yet

- Manual Swan Quad CrowDocument2 pagesManual Swan Quad CrowApex PredatorNo ratings yet

- S W A N 1 0 0 0: Installation InstructionsDocument2 pagesS W A N 1 0 0 0: Installation InstructionsLuisAlbertoSaldañaRmzNo ratings yet

- Patrol-Usr Ver.1 EngDocument2 pagesPatrol-Usr Ver.1 EngAdrian DeoancaNo ratings yet

- Bea Eagle Six UG - 4pDocument4 pagesBea Eagle Six UG - 4pAmir IzzatNo ratings yet

- DG457Document2 pagesDG457stari692002No ratings yet

- Manual para CuervoDocument2 pagesManual para Cuervof041793No ratings yet

- 3 Z630 3P Conventional DetectorDocument2 pages3 Z630 3P Conventional DetectorM Anees QureshiNo ratings yet

- 1/3" Color Weatherproof Infrared Camera: MODEL: TCW-200IR50Document2 pages1/3" Color Weatherproof Infrared Camera: MODEL: TCW-200IR50Guillermo HochnadelNo ratings yet

- Honeywell FG1625 Data SheetDocument2 pagesHoneywell FG1625 Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Blue Line Ism-Bld1-P Pet Friendly Tritech DetectorsDocument3 pagesBlue Line Ism-Bld1-P Pet Friendly Tritech DetectorsNarcis PatrascuNo ratings yet

- 1/3" Color Weatherproof Infrared Camera: MODEL: TCW-200IR50Document2 pages1/3" Color Weatherproof Infrared Camera: MODEL: TCW-200IR50Guillermo HochnadelNo ratings yet

- 862-10-SVD101 Seismic ManualDocument2 pages862-10-SVD101 Seismic ManualtmafuNo ratings yet

- Fotoceldas Laser LG10Document12 pagesFotoceldas Laser LG10Armando SotoNo ratings yet

- D TECT 1 Manual GJD110Document6 pagesD TECT 1 Manual GJD110Arnoldo AguilarNo ratings yet

- Data0305 KX18DCDocument3 pagesData0305 KX18DCAbdelhamid SammoudiNo ratings yet

- PATROL - 801: Professional Combined Digital Pir & Glass Break Detector Installation InstructionsDocument2 pagesPATROL - 801: Professional Combined Digital Pir & Glass Break Detector Installation InstructionsAdrian DeoancaNo ratings yet

- I Series: Photoelectric Smoke DetectorsDocument2 pagesI Series: Photoelectric Smoke DetectorsthienNo ratings yet

- Instalation Manual AGB600Document4 pagesInstalation Manual AGB600ADNo ratings yet

- Security: Product Data SheetDocument2 pagesSecurity: Product Data SheetfadhlidzilNo ratings yet

- Patrol - 803PET: Combined Pir & Glass Break Detector With Pet Immunity Up To 30KgDocument2 pagesPatrol - 803PET: Combined Pir & Glass Break Detector With Pet Immunity Up To 30KgAdrian DeoancaNo ratings yet

- 2GIG-GB1-345 - Operating Instructions - Glass Break DetectorDocument1 page2GIG-GB1-345 - Operating Instructions - Glass Break DetectornegitiNo ratings yet

- System Sensor Low Profile, Photoelectronic, Plug-In Smoke DetectorDocument2 pagesSystem Sensor Low Profile, Photoelectronic, Plug-In Smoke DetectorPeggy MalaveNo ratings yet

- Passive Infrared Multi-Way Wall Switch Occupancy Sensor: PW-301 PW-301-347 PW-302 PW-302-347Document12 pagesPassive Infrared Multi-Way Wall Switch Occupancy Sensor: PW-301 PW-301-347 PW-302 PW-302-347M AbrahamNo ratings yet

- Honeywell Fg1625rfm Install GuideDocument2 pagesHoneywell Fg1625rfm Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Microwave and Infrared Digital Anti-Mask Motion Detector V Description Features Relay Operation DetailsDocument2 pagesMicrowave and Infrared Digital Anti-Mask Motion Detector V Description Features Relay Operation DetailsJulio Cesar Rojas SaavedraNo ratings yet

- Irepeater Install Manual2Document2 pagesIrepeater Install Manual2Vivek JhaNo ratings yet

- Over Height Laser Scanner: Instruction ManualDocument12 pagesOver Height Laser Scanner: Instruction Manualnikname08No ratings yet

- Successful Applications: Automotive IndustryDocument20 pagesSuccessful Applications: Automotive IndustryJNo ratings yet

- Honeywell Fg1625rfm Data SheetDocument2 pagesHoneywell Fg1625rfm Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Audio FG-730 - Installation - MNDocument2 pagesAudio FG-730 - Installation - MNgarrigan12No ratings yet

- Manual Del GPT100Document4 pagesManual Del GPT100Johannita Chavez GalanNo ratings yet

- Receiver REC 300 Digital: Operating InstructionsDocument8 pagesReceiver REC 300 Digital: Operating InstructionsbejanNo ratings yet

- 3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetDocument2 pages3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetAlejandro coronelNo ratings yet

- Manual Photo Beam FSB-200 enDocument13 pagesManual Photo Beam FSB-200 enRicardo ChavezNo ratings yet

- Ficha-EN R001 SIGA-OSD Intelligent Photoelectric Smoke Detector Installation SheetDocument2 pagesFicha-EN R001 SIGA-OSD Intelligent Photoelectric Smoke Detector Installation SheetYin VargasNo ratings yet

- Patrol - 101: Weatherproof Curtain Pir & MW Detector For Outdoor UseDocument2 pagesPatrol - 101: Weatherproof Curtain Pir & MW Detector For Outdoor UseClairefrance McbrookNo ratings yet

- sensorPM 8 5 ParadDocument2 pagessensorPM 8 5 ParadPaola PuentesNo ratings yet

- L-Gage LE250/550 Analog-Discrete Laser Sensors: Quick Start GuideDocument9 pagesL-Gage LE250/550 Analog-Discrete Laser Sensors: Quick Start GuidesanjeckaNo ratings yet

- FSB-200, FSB-200S Single-Ended Reflected Type Projected Beam Smoke Detector PDFDocument13 pagesFSB-200, FSB-200S Single-Ended Reflected Type Projected Beam Smoke Detector PDFdariotlcNo ratings yet

- Installation Sheet - SIGA-PD Intelligent Photoelectric Smoke Detector - Edwards Signaling ESTDocument2 pagesInstallation Sheet - SIGA-PD Intelligent Photoelectric Smoke Detector - Edwards Signaling ESTChase GietterNo ratings yet

- 8310-804 Door Mounted Safety Sensor: User'S GuideDocument9 pages8310-804 Door Mounted Safety Sensor: User'S GuideAlaâ SemaanNo ratings yet

- BEAM355, BEAM355S Single-Ended Reflected Type Projected Beam Smoke DetectorDocument13 pagesBEAM355, BEAM355S Single-Ended Reflected Type Projected Beam Smoke DetectorznarfferNo ratings yet

- I-9102 Intelligent Photoelectric Smoke Detector Issue1.03Document2 pagesI-9102 Intelligent Photoelectric Smoke Detector Issue1.03Seagull MarineNo ratings yet

- Intrusion Systems - WLSN Dual Motion DetectorsDocument4 pagesIntrusion Systems - WLSN Dual Motion DetectorsNarcis PatrascuNo ratings yet

- Honeywell FG1625F Data SheetDocument2 pagesHoneywell FG1625F Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Solarmeter Model 7.5 UV ErythemaDocument2 pagesSolarmeter Model 7.5 UV ErythemaEUGENNo ratings yet

- Genius Plus: Electronic Engineering LTDDocument2 pagesGenius Plus: Electronic Engineering LTDpil;zoNo ratings yet

- Bravo 2&3 Pir - Manual Instalare PDFDocument1 pageBravo 2&3 Pir - Manual Instalare PDFDarie SilviuNo ratings yet

- Notifier SD 651 SD 651A Low Profie Plug in Smoke DetectorsDocument2 pagesNotifier SD 651 SD 651A Low Profie Plug in Smoke Detectorsด้วกส์ เอเชีย ไม่เคยเสียท่าใครNo ratings yet

- Honeywell Fg1625 Install GuideDocument2 pagesHoneywell Fg1625 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Patrol - 103PET: Combined Pir & MW Detector With Pet Immunity Up To 25KgDocument2 pagesPatrol - 103PET: Combined Pir & MW Detector With Pet Immunity Up To 25KgAdrian DeoancaNo ratings yet

- LM80 150 QuickstartDocument8 pagesLM80 150 QuickstartNegreaDanielaNo ratings yet

- fsb-200 Install Sheeti56-2424-04rDocument18 pagesfsb-200 Install Sheeti56-2424-04rcarlos yepezNo ratings yet

- Manual de Instalare Senzor de Miscare Digital Quad PIR DSC BV 501 12 M 360 Deg MLSP PDFDocument2 pagesManual de Instalare Senzor de Miscare Digital Quad PIR DSC BV 501 12 M 360 Deg MLSP PDFDumitru BogdanNo ratings yet

- Next PG2 Next K9 PG2 English Installer Guide D-302413Document4 pagesNext PG2 Next K9 PG2 English Installer Guide D-302413jujuNo ratings yet

- Understanding and Servicing Alarm SystemsFrom EverandUnderstanding and Servicing Alarm SystemsRating: 1 out of 5 stars1/5 (1)

- Auriol IAN 321928 ClockDocument81 pagesAuriol IAN 321928 ClockAdriana SerbanNo ratings yet

- Kahles 2002 CatalogDocument11 pagesKahles 2002 CatalogCraig ThompsonNo ratings yet

- KLS Martin x6 - x8Document42 pagesKLS Martin x6 - x8Rodrigo GutierrezNo ratings yet

- Digital Steamer: Cuiseur À Vapeur Numérique Vaporera DigitalDocument32 pagesDigital Steamer: Cuiseur À Vapeur Numérique Vaporera Digitaltim_fultz4No ratings yet

- Eclipse Combustion Veriflame Single Burner Monitoring System User ManualDocument42 pagesEclipse Combustion Veriflame Single Burner Monitoring System User ManualAntonio nunes silvaNo ratings yet

- C79000 G8976 1024 RS900 InstallationManualDocument44 pagesC79000 G8976 1024 RS900 InstallationManualcharlie charlieNo ratings yet

- 7MF0300-1JK01-5BF2-Z A00+c11+c14+e00+m15+y01+y15+y21Document3 pages7MF0300-1JK01-5BF2-Z A00+c11+c14+e00+m15+y01+y15+y21Han TranNo ratings yet

- CASE #110 Philippine Steel Coating Corp. vs. Eduard Quinones G.R. No. 194533, April 19, 2017 FactsDocument2 pagesCASE #110 Philippine Steel Coating Corp. vs. Eduard Quinones G.R. No. 194533, April 19, 2017 FactsHarleneNo ratings yet

- B37929 AN - Personalize - Your - RP-3000XT Release 2.xDocument6 pagesB37929 AN - Personalize - Your - RP-3000XT Release 2.xPyae Phyo AungNo ratings yet

- Installation Instruction FRHD 1000 1800 3112Document8 pagesInstallation Instruction FRHD 1000 1800 3112Javier Gaete ObrequeNo ratings yet

- My Memories of Eighty Years by Depew, Chauncey M. (Chauncey Mitchell), 1834-1928Document219 pagesMy Memories of Eighty Years by Depew, Chauncey M. (Chauncey Mitchell), 1834-1928Gutenberg.orgNo ratings yet

- JimiHendrixExperience OriginalDocument28 pagesJimiHendrixExperience Originalandreas papandreouNo ratings yet

- 2012 Volkswagen GolfDocument516 pages2012 Volkswagen Golfdonny rebornNo ratings yet

- Operator's Manual: T-1080S Spectrum With Premium HMIDocument150 pagesOperator's Manual: T-1080S Spectrum With Premium HMIJean Carlos Lins100% (1)

- Simtronics LT15 UserManualDocument16 pagesSimtronics LT15 UserManualMarcelo LeguizamonNo ratings yet

- Manual For Nitrogen GeneratorDocument56 pagesManual For Nitrogen GeneratorMusfiqul AzadNo ratings yet

- FRANK Cat 2018 PDFDocument44 pagesFRANK Cat 2018 PDFvioleta hidalgoNo ratings yet

- LP1502 Intelligent Controller: 1. GeneralDocument9 pagesLP1502 Intelligent Controller: 1. GeneralLifarith Ortega MorenoNo ratings yet

- USP-50SP User ManualDocument24 pagesUSP-50SP User ManualThiago BajurNo ratings yet

- AE128 - II. Consumer ProtectionDocument12 pagesAE128 - II. Consumer Protectionjamie inasNo ratings yet

- Axis Remote Banking Terms and ConditionsDocument5 pagesAxis Remote Banking Terms and ConditionsSachin MalikNo ratings yet

- K-Flex USA Price List - InsulDocument57 pagesK-Flex USA Price List - InsulFernando Bórquez MartínezNo ratings yet

- Mele f10 Pro SDocument2 pagesMele f10 Pro Ssebibv2No ratings yet

- QuickChek SRB Kit UGDocument7 pagesQuickChek SRB Kit UGMinhquang NgoNo ratings yet

- Admin Guide - AvayaDocument1,800 pagesAdmin Guide - AvayaxjericocNo ratings yet

- TECE02SM0000Document364 pagesTECE02SM0000Paul MartinNo ratings yet

- Cignal: Residential Service Application FormDocument10 pagesCignal: Residential Service Application FormJUDGE MARLON JAY MONEVANo ratings yet

- DW-PF522 User ManualDocument148 pagesDW-PF522 User Manualสุมิตตา อ่อนมั่งคง100% (2)

- PreciControl HbA1c Path.05854237001.V4.EnDocument2 pagesPreciControl HbA1c Path.05854237001.V4.EnARIF AHAMMED PNo ratings yet