Professional Documents

Culture Documents

Cummins 8.3 Manual

Cummins 8.3 Manual

Uploaded by

haviettuan0 ratings0% found this document useful (0 votes)

10 views115 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views115 pagesCummins 8.3 Manual

Cummins 8.3 Manual

Uploaded by

haviettuanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 115

Operation and

DET Curler ave Tle]

C Series Engines «

UA UL CME g s

rere CP Retard

tsi ane ar

Cor

Foerhsine nen Orr

ference ste R0 UI

Gore kc)

Ne akc

Pr ore

acces

‘Surrey KTS 4QL,

ra m

hae

Cen Are tna Ud

er aon a

ahd eo es

os

Selbciens

amines

Operation and

Maintenance Manual

C Series Engines

U.S.A., Canada, Australia,

New Zealand, and Puerto

ico

Copyright © 1993

Cummins Engine Company, Inc.

All rights reserved

Bulletin No. 3810248-08

Printed 6/93

Foreword

This manual contains information for the correct operation and maintenance of your Cummins engine. It also

includes important safety information, engine and systems specifications, troubleshooting guidelines, and listings

of Cummins Authorized Repair Locations and component manufacturers,

Keep this manual with the equipment. If the equipment is traded or sold, give the manual to the new owner.

The information, specifications, and recommended maintenance guidelines in this manual are based on infor-

mation in effect at the time of printing. Cummins Engine Company, Inc. reserves the right to make changes at any

time without obligation. If you find differences between your engine and the information in this manual, contact

your local Cummins Authorized Repair Location.

‘The latest technology and the highest quality components were used to produce this engine. When replacement

paris are needed, we recommend using only genuine Cummins or ReCon® exchange parts. These parts can be

Identified by the following trademarks:

EE Fleelguand’ = szieses

i aa ® P|

Note: Warranty information is located in Section W. Make sure you are familiar with the

warranty or warranties applicable to your engine.

Table of Contents

Page No.

Introduction te ii i

Engine Identification ‘ f E

Operating Instructions... ‘ 2 cinerea 1

Maintenance Guidelines: 4 1 sta

Daily Maintenance Procedures. 3

Maintenance Procedures at 10,000 Kilometers [6,000 Miles]

250 Hours or 3 Months....... a : 4

Maintenance Procedures at 19,000 Kilometers [12,000 Miles] ata r 5

Maintenance Procedures at 38,000 Kilometers [24,000 Miles] _

1000 Hours or 12 Months nib 6

Maintenance Procedures at 77,000 Kilometers [48,000 Miles)

2000 Hours or 2 Years 2 7

System Diagrams Eloi is Abe Z D

Troubleshooting Are : T

Page No.

‘Adjustment, Repair and Replacement. A

Specifications and Torque Values...... v

Service Assistance s

Component Manufacturers. c

Warranty .... Ww

Literature L

Index x

Section i - Introduction

C Series Page I-t

Section i - Introduction

Section Contents

‘About the Manual

Definition of Term:

General Safety Instructions...

Important Satety Notice

How to Use the Manual...

Ulustrations rs

Symbols ..... is

To The Owner and Operator. 2

Section i - Introduction ‘About the Manual

C Series. Page I3

About the Manual

This manual contains information needed to correctly operate and maintain your engine as recommended by

Cummins Engine Company, Inc. Additional service literature (Shop Manual, Troubleshooting and Repair Manual,

‘etc) can be ordered by filing out and mailing the Literature Order Form located in Service Literature, Section L.

This manual does not cover vehicle or equipment maintenance procedures. Consult the vehicle or equipment

manufacturer for specific maintenance recommendations.

Both metric and U.S. customary values are listed in this manual. The metric value is listed first, followed by the

U.S. customary in brackets.

Numerous illustrations and symbols are used to aid in understanding the meaning of the text. Refer to page iS

for a complete listing of symbols and their definitions.

Each section is preceded by a “Section Contents" to aid in locating information more quickly.

Section i - Introduction Symbols

C Series Page i-5

Symbols

‘The following symbols have been used in this manual to help communicate the intent of the instructions. Wher

one of the symbols appears, it conveys the meaning defined below:

PERFORM a mechanical or time MEA-

WARNING - Serious personal injury or ex-

A SUREMENT.

tensive property damage can result if the

‘warning instructions are not followed.

LUBRICATE the part or assembly.

CAUTION - Minor personal injury can re-

AX __sittrapart, an assemby,or the engine

‘can be damaged if the caution instructions

are not followed.

Indicates that a WRENCH or TOOL SIZE

will be given.

TIGHTEN to a specific torque.

Indicates a REMOVAL or DISASSEMBLY

stop.

PERFORM an olectrical MEASUREMENT.

Indicates an INSTALLATION or ASSEM-

BLY step.

57,

ae

Refer to another location in this manual or

another publication for additional informa-

INSPECTION is required. tion,

CLEAN the part or assembly. The component weighs 23 kg [50 Ib] or

more. To avoid personal injury, use a hoist

or get assistance to lift the component

@® } "emne

Section i - Introduction Mlustrations

C Series Page i-8

Illustrations

Use the illustrations in this manual as a guide to perform

the action or the repair described. Many illustrations are

generic and will not look exactly like the engine or the

parts used in your application. In order to provide clarity

to illustrations, some illustrations show parts removed

that are not related to the specific parts given in the text.

Most of the illustrations contain symbols to indicate an

action required or to indicate an acceptable (OK) or un-

acceptable (not OK) condition.

Section E - Engine and Component Identification

C Series

Sec

Engine Identific:

Engine Diagram...

General Specifications

Injection Pump Dataplate.

Definition of Terms

Page i-12

Definition of Terms

AFC

API

ASA

ASTM

c

care

cp.

cm

cPL

ost

Dca

ecu

E.c.s.

EPA

EPS

F

feb

eww

Hg

HP.

H.0

Air Fuel Control

‘American Petroleum Institute

Air Signal Attenuator

‘American Society of Testing and

Materials

Celsius

California Air Resources Board

Cubic Inch Displacement

Centimeter

Control Parts List

Centistokes

Diesel Coolant Additive

Electronic Control Module

Emission Control System

Environmental Protection Agency

Engine Position Sensor

Fahrenheit

Foot Pound

Gross Vehicle Weight

Mercury

Horsepower

Water

ind

km

kml

kPa,

mm

MPa

MPH

wpa

Nem,

OEM

ppm

psi

PTO

RPM

Page E-1

nn E - Engine and Component Identification

Section Contents

Section i - Introduction

C Series

Inch Pound

Kilograms

Kilometers

Kilometers per Liter

Kilopascal

Liter

Meter

Millimeter

Megapascal

Miles Per Hour

Miles Per Quart

Newton-meter

Original Equipment Manufacturer

Parts Per Million

Pounds Per Square Inch

Power Takeotf

Revolutions Per Minute

Society of Automotive Engineers

Step Timing Control

Variable Speed

Vehicle Speed Sensor

Page

£2

E9

ES

£3

Engine Identification

Page E-

Section E - Engi

‘and Component Identitiation

e2 C Series

Engine Identification

Engine Dataplate

The engine dataplates show specific information about

the engine. The engine serial number (1) and Control

Parts List (CPL) (2) provide information for ordering parts

and service needs,

NOTE: The engine dataplate must not be changed unless

approved by Cummins Engine Company, Inc.

Secor [ERT inn fem" ee rm [om [ome

caret a cae

‘Magen USA. geesaze | coer | Catayseur No_ ni

See SST Egaie =

ei a De aeons

eresomn ower sigeemesemmn [Se Sent oac ea EE] pane

Seccecaeasenee Neca aaa =

Saccao a8 mace Pave em tee ae

aaa arias aoe femeate =

ion aes aaee oP 5

ap9pigb

Section E - Engine and Component Identification Engine Identification

C'Series Page £3

Cummins Engine Nomenclature

‘The model name for engines in automotive applications

provides the data shown in the example:

Example

© 83-275

LL pates Horsepower

Displacement in Liters

Engine Series

for non-automotive applications:

Example

ecTAas

[_E ossplacementin Lier

Atercooled

Turbocharged

Engine Series

‘— Number of Cylinders

‘The following example shows a model name of an engine

Injection Pump Dataplate Section E - Engine and Component Identification

Page E-4 C Series

Injection Pump Dataplate

The injection pump dataplate is located on the side of the

injection pump. It provides information for fuel injection

pump calibration.

‘The Cummins part number for the fuel injection pump

and governor combination is located on the governor

dataplate.

and Component Identification

General Specifications

GENERAL ENGINE DATA 6ca3 BCTE.S BOTAGS cas

Bore - mm in] > Ta TB]

Stroke - mm fin] 2495 [5.32] -

Displacement «iter tin} 8.27 (504.5) -

Engine Weight (Ory) With Standard

‘Accessories

‘Wet Weight

Firing Order

Valve Clearances

= intake ~ mm [in] 0.30 [0.012]

Exhaust = mm fin] 0.61 [0.024]

Compression Ratio 164 1734 1651 17.3:0°H81"*

Rotation, viewed from the front of the

engine

Aspiration

Naturally Aspirated x

~ Turbocharged x

= Aitercooied x

= Charge Air Cooled (CAC) x

* High Torque

* Low Torque

603-612 Kg [1330-1350 Ib} :

635-658 Kg [1400-1450 Ib}

= 1SG624

+ Clockwise -

General Specifications

Page E-6

Section E - Engine and Component Identification

Series

LUBRICATION SYSTEM

Tubricaling Oil Pressure at Idle -

(Minimum

Allowable) kPa [PSI]

Lubricating Oil Pressure at Rated -

(Minimum

Allowable) kPa [PSI]

Regulating Valve Opening Pressure

fea (PS

Differential Pressure to Open

the Filter Bypass Valve

= kPa [PSI]

Lubricating Oil Capacity of Pan (High-

Low)

= Liter (U.S. Qts.]

COOLING SYSTEM

Coolant Capacity (Engine Only)

= liter [U.S. Qts.)

Standard Modulating Thermostat

= Range = °C [°F]

Pressure Cap - kPa [PSI] Minimum

Maximum Allowable Top Tank

“Temperature °C [°F]

Minimum Recommended Top Tank

Temperature °C [°F]

Section E - Engine and Component Identification

C Series

C85

ecTe.3 ‘ECTAG.S

== 68 [10] =

Ca3

~ 207 [30]

- 518 [75]

+ 138 [20],

Fe

189

15.41

9.9 [10.5] 9.9 (10.5)

10.9 [11.5]

9.9 [10.5]

Start 81 [178]

-+ Fully Open 95 [203] -

~~ 50 [7]

100°C [212°F}

- 70°C [188°F]

INTAKE AIR, EXHAUST

AND FUEL SYSTEM

‘Maximum Allowable Air Intake

Restriction at Rated Speed

‘and Load with Dirty Air

Filter Element-mm H,0

(in. HO)

Maximum Allowable Exhaust

Restriction at Rated Speed

and Load - mm Hg

fin. Ho}

Maximum Fuel Filter Pressure

Drop Across Filters

kPa [psi

Maximum Allowable Return Line

Restriction - mm Hg [in Hg]

Maximum Inlet Restriction

to Fuel Transfer Pump

mm Hg [in Hg]

* with catalyst

6C8.3 ecTs.3 SCTAS.3, 8.3

1508 [20]

635 [25]

635 [25]

635 [25]

78

152

fl

34 [5]

-518 [20.4] -

++ 100 [4]

General Specifications

Pags

General Specifications Section E - Engine and Component Identification

Page E-8 C Series

ELECTRICAL SYSTEM

Minimum Recommended Battery Capacity

Battery Size ‘Ambient Temperatures.

“18°C (OF) (O°C (32°F

Cold Reserve Cold Reserve

Cranking Capacity * Cranking Capacity *

Amperes Amperes Amperes Amperes

2 von 1800 640 1280 480,

24 Volt 900) 320 640 240

* The number of plates within a given battery size determines reserve capacity. Reserve capacity determines

the length of time sustained cranking can occur,

** Per Battery (two 12 volt batteries in series) CCA ratings are based on -18°C [0°F]

Batteries (Specific Gravity)

‘Specific Gravity

at 27°C [80°F] State of Charge

1.260 - 1.280 100%

1.230 - 1.250 75%

1.200 - 1.220 50%

4.170 - 1.190 25%

4.110 - 1.130 Discharged

Section E - Engine and Component Identification Engine Diagrams

C Series Page E-9

Engine Diagrams

‘The illustrations which follow show the locations of the majo external engine components fiters, and other service

and maintenance points. Some external components wil be at different locations for different engine models.

ettmng sgh mm Ome NTE a) za 180

FUEL PUMP SIDE VIEW

Engine Diagrams Section E - Engine and Component Identification

Page E-10 C Series

REAR VIEW

Section E - Engine and Component Identification Engine Diagrams

C Series Page E-11

EXHAUST SIDE VIEW

Engine Diagrams Section E - Engine and Component Identification

Page E-12 C Series

FRONT VIEW

Section 1 - Operating Instructions

C Series Page 1-1

Section 1 - Operating Instructions

Section Contents

Cold Weather Starting Aids

Cold Weather Stating With Starting Fuld

Using Starting Fluid Without Metering Equipment

With Mechanical Or Electrical Metering Equipment

Engine Operating Range...

Engine Shut-down Procedure.

General Operating Instructions

Operating the Engine..

Starting Procedure.

‘Shutters...

Starting Procedure | Wa

Winterfronts,

Starting Procedure After Extended 1 Shutdown or

General Operating Instru

Page 1-2

General Operating Instructions

Proper care of the engine will result in longer life, better performance, and more economical operation.

+ Follow the dally maintenance checks listed in Section 2

‘© Check the oil pressure indicator(s), temperature indicator(s), warning light(s), and other gauges daily to make

sure they are operational,

A, Waring: D0 NOT OPERATE A DIESEL ENGINE WHERE THERE ARE OR CAN BE COMBUSTIBLE VAPORS

These vapors can be drawn through the air intake system and cause engine acceleration and over-

speeding, which can result ina fire, an explosion and extensive property damage. Numerous safety devices

are available, such as air intake shutoff devices, to minimize the risk of over-speeding where an engine,

due to its ay ight operate in a combustible environment, such as due to a fuel spill or gas leak.

Remember, Cummins has no way of knowing the use you have for your engine. THE EQUIPMENT OWNER,

AND OPERATOR ARE RESPONSIBLE FOR SAFE OPERATION IN A HOSTILE ENVIRONMENT. CONSULT

YOUR CUMMINS AUTHORIZED REPAIR LOCATION FOR FURTHER INFORMATION.

Starting Procedure

‘Automotive - (P-Pumps with RQV-K Governor) above 16°C [60°F]

Foot off throttle. The inline pump delivers sufficient fuel to start engine with throttle at idle.

‘Automotive - (P-Pumps with RQV-K Governor) below 16°C [60°F]

Fully depress the throttle AFTER engaging the starter. The inline pump requires open throttle to position and hold

the rack in the maximum fuel position.

Industrial/Marine - (Bosch A, MW and Nippondenso EP-9 with RSV Governor) above 0°C [32°F]

Foot off throttle. The EP-9 with RSV governor and A, MW with RSV governor pump has a “Start Spring’ which

automatically moves the rack to the start fuel position.

Instructions

C Series

Section 1 - Operating Instructions Starting Procedure

C Series Page 1-3

Starting Procedure Matrix

Idle Throttle Full Throttle

Automotive

All pumps - above 16°C [60°F]... ms

All pumps - below 16°C [60°F :

Industrial/Marine

All pumps ~ above O°C [32°F ]...rnnssenesnee x

* Disengage the driven unit, or if equipped, put the transmission in neutral.

+ Position the fuel shut-off, electrical switch or mechanism control to the RUN position.

‘+ With Bosch indine pumps, fully depress the throttle AFTER engaging the starter.

NOTE: Industrial engines are equipped with Robert Bosch RSV governors which automatically position the internal pump

controls to the START position for maximum fuel delivery when the throttle is set at idle,

\d fuel shutoff solenoid, donot engage the starting motor more

ich attempt to start (electrical starting motors only).

* If the engine does not start after three attempts, check the fuel supply system. Absence of blue or white

exhaust smoke during cranking indicates no fuel is being delivered:

* Move the throttle position to idle as soon as the engine starts

Caution: To prevent damage to the starter

than 30 seconds. Wait 2 minutes between

Starting Procedure Section 1 - Operating Instructions

Page 1-4 CS

* Engine oil pressure must be indicated on the gauge within 15 seconds after starting,

‘+ When starting a cold engine, increase the engine speed (RPM) slowly to be sure adequate lubrication is

available to the bearings and to allow the oil pressure to stabilize,

A Gattion: Do not idle the engine for excessively long periods. Long periods of idling (more than 10 minutes)

can damage an engine because combustion chamber temperatures drop so low the fuel will not burn

completely. This will cause carbon to clog the injector spray holes and piston rings, and can cause the

valves to stick. If the engine coolant temperature becomes too low (60°C [140°F}), raw fuel will wash the

lubricating oil off the cylinder walls and dilute the crankcase oll; therefore, all moving parts of the engine

will not receive the correct amount of lubrication,

** Idle the engine 3 to 5 minutes before operating with a load,

A Gatton: When using jumper cables to start the engine, make sure to connect the jumper cables in parallel:

Positive (+) to positive (+) and negative (-) to negative (-). When using an external electrical source to

start the engine, turn the disconnect switch to the “OFF” position. Remove the key before attaching the

jumper cables to prevent unintentional starter engagement.

Section 1 - Operating Instructions Starting Procedure

C Series Page 1-5

Winterfronts

Winterfronts can be used on a vehicle equipped with

charge air cooling (CAC), but must be designed to par-

tially cover the frontal area of the cooling system. A min-

imum of 120 square inches (11 in x 11 in) of frontal area

must be left open to air flow for the CAC to function

correctly.

Shutters

Installations of CAC engines with shutters also requires

an intake manifold air temperature switch to open the

shutters at 65.5°C [150°F] to prevent excessive intake

‘manifold temperatures. This prevents engine damage due

tohigh intake manifold temperatures as a result of blocked

air flow across the CAC.

some

Cold Weather Starting Aids

Page 1-6

Cold Weather Starting Aids

Use the following chart as a reference for required cold weather starting aids:

oc

-12°C

18°C

-24°C

OIL, PAN AND

STARTING AIDS BLOCK HEATERS BATTERY CAPACITY

UNAIDED UNAIDED STANDARD

90ers ren a ie

SUGGESTED SUGGESTED

tory Ne dbs negetie secs Se Marta

oF EXTRA CAPACITY

REQUIRED ‘SUGGESTED

NE an tee ere re se = = ----

EXTRA CAPACITY

eee REQUIRED (180-200%)

1

Section 1 - Operating Instructions Cold Weather Starting With Starting Fluid

Series Page 1-7

Cold Weather Starting With Starting Fluid

With Mechanical Or Electrical Metering Equipment

NOTE: Industrial engines are equipped with Robert Bosch RSV governors which automatically position the pump

Controls to the START position when the throttle is set at idle. Automotive engines are equipped with Bosch RQV and

RQV-K governors, The accelerator pedal must be depressed all the way to the START position after engaging the starter.

* Disengage the driven unit or put the transmission in neutral.

Position the fuel shutoff, electrical switch or mechanical control, to the RUN position.

On industrial equipment, set the throttle atidle. For automotive engines, after engaging the starter, depress

the accelerator pedal ali the way to the START position and hoid the pedal.

‘+ While cranking the engine, inject metered amounts of starting fluid,

‘+ Engine lubricating oil pressure must be indicated on the gauge within 30 seconds after starting.

Using Starting Fluid Without Metering Equipment

Warning: Never use starting fluid near an open flame, or with a preheater or flame thrower equipment. This

combination can cause an explosion.

Warning: Do not breathe starting fluid fumes. Starting fluid fumes can be harmful to your health.

Caution: Do not use excessive amounts of starting fluid when st

starting fluid will cause engine damage.

an engine. The use of too much

Spray starting fluid into the air cleaner intake while another person cranks the engine.

Warning: Do net use volatile cold starting aids in underground mine or tunnel operations due to the

potential of an explosion. Check with the local U.S. Bureau of Mines Inspector for Instructions.

>. DPE

Starting Procedure After Extended Shutdown or Oil Change jection 1 - Operating Instructions

Page 1-8 C Series

Starting Procedure After Extended Shutdown or Oil Change

Complete the following steps after each lubricating oil change, or after the engine has been shut off for more than

7 days to make sure the engine receives the correct oil flow through the lubricating oil system:

* Disconnect the electrical wire from the fuel injection pump solenoid vaive.

‘+ Rotate the crankshaft, using the starting motor, until oil pressure appears on the gauge, or the warning light

goes out.

‘* Connect the electrical wire to the fuel injection pump solenoid valve.

* Start the engine; refer to Normal Starting Procedures in this section.

* Refer to Fuel System - Bleeding, Section 5, for instructions to vent the fuel system.

Engine Operating Range Section 1 - Operating Instructions

Page 1-10 _ C Series

Engine Operating Range

A Caution: Cummins engines are designed to operate successfully at full throttle under transient conditions

down to peak torque engine speed (RPM). This is consistent with recommended driving practices for good

fuel economy. Excessive full throttle operation below peak torque RPM (peak torque RPM varies from 1,100

RPM to 1,500 RPM, depending upon rated engine speed) will shorten engine life to overhaul, can cause

serious engine damage, and is considered engine abuse.

AX Gaution: Operation of the engine below peak torque RPM can occur during gear shifting due to the

difference of ratios between transmission gears, but engine operation must not be sustained more than

fone minute at full throttle below peak torque RPM,

A Gaution: Operating the engine beyond high idle speed can cause severe engine damage. When descend-

Ing a steep grade, use a combination of transmission gears and engine or service brakes to control the

vehicle and engine speed.

ine Shut-down Procedure

* Allow the engine to idle 3 to 5 minutes after a full load operation before shutting the engine off. This allows

the engine to cool gradually and uniformly.

‘+ Turn the ignition key switch to the OFF position.

Section 1 - Operating instructions Operating the Engine

S'Seres Page 1-9

Operating the Engine

+ Donat operate the engine at full throttle below peak torque engine speed (APM) for extended periods (more

than @ minute) of time

+ Allow the engine to idlo $ to § minutes before shutting the engine off atter a fll oad operation

‘+ Monitor the lubricating oil pressure and coolant temperature gauges frequently. Refer to Engine Specifi-

cations (Section V) for recommended operating pressures and temperatures. Shut the engine off if any

pressure or temperature does not meet the specifications.

A, Lation: Continuous operation with low coolant temperature (below 60°C [140°F]) or high coolant tem

perature (above 100°C [212°F]) can damage the engine.

+ I an overheating condition starts to occur, reduce engine speed or shift to a lower gear, or both, until the

temperature returns to normal operating range. If engine temperature does not return to normal, refer to

Troubleshooting (Section T) or contact a Cummins Authorized Repair Location.

‘+ Most failures give an early warning. Look and listen for changes in performance, sound, or engine ap-

pearance that can indicate service or engine repair is needed. Some changes to look for are:

Engine misfires — Excessive smoke

Vibration — Loss of power

— Unusual engine noises — An increase in oll consumption

Fuel, oil or coolant leaks — An increase in fuel consumption

— Sudden changes in engine

operating temperature or pressure

2 - Maintenance Guidelines

Page 2-1

Section 2 - Maintenance Guidelines

Section Contents

Page

General Information .....0 en seein mie

Maintenance Record FOr ....1.1:m:sinsinnnnnnnn eee 28

Maintenance Schedule .... sis susitesuaee aan

Tool Requirements.

General Information Section 2 - Maintenance Guidelines

Page 2-2 C Series

General Information

Cummins Engine Company, Inc. recommends that the engine be maintained according to the Maintenance

Schedule on page 2-4

If the engine is operating in ambient temperatures consistently below -18°C [0°F] or above 38°C [100°F], perform

‘maintenance at shorter intervals. Shorter maintenance intervals are also required if the engine is operated in

dusty environment or if frequent stops are made. See your Cummins Authorized Repair Location for recommended

intervals.

Use the chart provided on page 2-8 as a convenient way to keep a record of maintenance performed,

“If the engine is equipped with a component or an accessory not manufactured by Cummins Engine Company,

Inc., refer to the component manufacturer's maintenance recommendations. A listing of suppliers’ addresses and

telephone numbers is provided in Component Manufacturers, Section C.

Section 2 - Maintenance Guidelines

C Series

Tool Requirements

nis used to ident

nthe txt, a symbol lowed by the wrench size or tool description i us

saree eb a lat of wrench sizes and descriptions Indicate more than one tol is needed.

Sockets Wrenches Other Tools

19mm

19mm 17mm Filter Wrenches (75-80mm, 90-95mm and 116-131mm)

17mm 15mm Ratchet (1/2 and 3/8 inch drive)

15mm 14mm. Torque Wrench

13mm Flat Blade Screwdriver

40mm 5/16 Allen Wrench

Feeler Gauges (0.30 mm and 0.61 mm)

Engine Barring Gear Part No. 3377371

DCAS Test Kit, Fleetguard Part No. CC-2626

3828276 Injector Puller

Tool Requirements

the tooling required to perform

C Series Engine Maintenance Schedule

Section 2 - Maintenance Guideline:

Page 2-4 Sere

C Series Engine Maintenance Schedule

Daly oF Reeling Even 0,000 Km Eyer 18,000 Km Fin 3,000 Rm Ere 8

oi feceatn se ebony on seaeiiner

aSinou, nue) Soba, 0 Hour,

she ee isNene Por

sox = tharpaopace as

* Ubatng OF Level + Libicaing O87» Labtng OF Paring OF + tamicaing OF

Se omentaa * lubreatng Pier Labvening Phar Laprening Ptr Lata Br

1 Die Bot + ota Fter 5 ceotat pher® 5 content iter 5 oot

1 lal Water Tap Sele rool er Ful Fer

* Antitreeze®

Pie Seater

. ee nc ach .

* Valve Lash® © Valve Lash

Gearance Cemarce

ensseestogrsese tl heckdnapect en e==

© heceaner « hic Cleaner Ar Cleaner + he Gleaner

+ fake System + ite Systm 5 Inte Sytom iiake Sytem

‘Chae Acooler + antnoace 5 fates 1 Acorn

{Shae Ar coor Fanta oar

5 bat rior 5 Bat tionr

Ome boue

+ Bot rsion + or rion

{chee Ar Cooler ¢ Vbreton Damper

+ Charge Ale Cooter

© Rofer to the Lubricating Oil Change Interval chart given in Section 4 to find the correct lubricating cil change interval forthe engine

(ation,

* nal valve lash clearance adjustment. subsequont adjustments to be performed at every 4th engine oil change for automotive engines

His of

77,000 Kim (46,000 Mi

yoart interval, whichever oscurs fs.

Must use atneavy duty antireeze that meets the chemical composition of GM6038-M. The change intervals 2 years or 385,000 Km {240,000

Mil Yor ndustnal engines:

Service interval is 2 years, or 320,000 Km {200,000 Mi, whichever occurs fist

Service interval is overy oi engine oil change or 18,000 Km {12,000 mi, 800 hours or 6 moths.

Section 2 - Maintenance Guidelines

C Series

Page References for Maintenance Instructions

For your convenience, listed below are the page numbers which contain specific instructions for performing the

maintenance checks listed in the maintenance schedule:

Daily oF Refueling

= Bolts - inspect

‘+ Engine oll level - check...

‘= Engine coolant level - check

= Fan - inspect ...

© Fuel-water soparator - rain scenes

© Series Engine Maintenance Schedule

Every 10,000 Kilometers [6,000 Miles], 250 Hours or 3 Months

* Lubricating oil - change ..

Lubricating oil filters - change ..

Air intake system - check

Air cleaner restriction - check

Charge Air Cooler ..

Page 2-5

2 35

33

a4

36

33

43

45

a 4M

4M

an

C Series Engine Maintenance Schedule

Page 2-6

Every 19,000 Kilometers [12,000 Miles], 500 Hours or 6 Months

‘+ Lubricating oil - change

* Lubricating oil filter - change

* Fue! filter - change ..

«Intake air system - check .....

* Coolant and Antifreeze - check

* Charge Air Cooler

Every 38,000 Kilometers [24,000 Miles}, 1000 Hours or 12 Monthe

Lubricating oil - change

Lubricating oil filter - change ..

Fuel filter -

Valve lash clearance - adjust

Fan hub -

Belt tensioner bearing - check ..

Belt tension - check secu

Coolant and antifreeze = CHECK sen

change ...

check

Section 2 - Maintenance Guidelines

C Series

Every

77,000 Kilometers [48,000 Miles], 2,000 Hours or 2 Years

Lubricating oil - change ..

Lubricating oil fiters - change ..

Fuel filter - change

Valve lash clearance - adjust

Fan hub - check

Belt tensioner bearing - check ...

Bolt tension - check

Vibration damper

Coolant and antifreeze - change

Charge Air Cooler - Leak Check (320,000 Km/200,000 o Mi)

inspect

Section 2 - Maintenance Gui

€ Series Engine Maintenance Schedule

43

45

53

63

o 611

et

610

78

73

Ae

Section 2 - Maintenance Guidelines

C Series

Maintenance Record

Engine Soral No Engine Model

Owner's Name Equipment NameiNumber

Sue fa (Miles), ean ies) eaauenence ‘Check

ours or mules) | Check Portormes | Com

Time Interval | or Hours Performed By ‘nents

Section 3 - Daily Maintenance Procedures

C Series Page 3-1

Section 3 - Daily Maintenance Procedures

Section Contents

Page

Coolant Level... 34

Checking.. 34

Cooling Fan. 36

Inspection 36

Drive Belt 38

Inspection 35

Fuel-Water Separator...

Draining -reerennns

Gen:

Lubricating Oil Level...

‘Checking...

Information.

$8 6 8

General Infor

Sonera information Section 3 - Daily Maintenance Procedures

General Information

Preventative maintenance begins with day-to-day awareness of the condition of the engine and its systems,

Before starting the engine, check the lubricating oil and coolant levels, look for:

* Leaks

* Loose or damaged parts

‘+ Worn or damaged belts

‘* Any change in engine appearance

Section 3 - Daily Maintenance Procedures Fuel-Water Separator

cs Page 3-3

Fuel-Water Separator fe

Draining en

Drain the water and sediment from the fuslwater sopa-

rator daly

‘Shut off the engine. Open the drain valve. Turn the valve

counterclockwise approximately 1 1/2- to 2 turns until

draining occurs. Drain the fuel-water separator of water

and sediment until clear fuel is visible.

Cainlon ok arian teva CuoriGNS AN

ere

‘Turn the valve clockwise to close the drain valve,

Lubricating Oil Level

Checking

Never operate the engine with the lubricating oil level

below the "L” (Low) mark or above the “"H" (High) mark.

‘Wait at least 5 minutes after shutting off the engine to,

check the lubricating oil. This allows time for the lubri-

cating oil to drain to the oil pan.

NOTE: The engine must be level when checking the lubri-

cating oil level to make sure the measurement is correct.

Lubricating Oil Capacity: Low Mark To High Mark

3.8 Litres [4 U.S. Quarts]

Coolant Level Section 3 - Daily Maintenance Procedures

4 Series

Coolant Level

Checking

Warning: Do not remove the radiator cap from a hot

engine. Wait until the temperature is below 50°C [12°F]

before removing the pressure cap. Failure to do so can

result in personal injury from heated coolant spray or

steam. Remove the filler cap slowly to relieve coolant

system pressure.

NOTE: Never use a sealing additive to stop leaks in the

coolant system. This can result in coolant system plugging

and inadequate coolant flow causing the engine to overheat.

The coolant level must be checked daily.

®

Caution: Do not add cold coolant toahot engine. Engine

castings can be damaged. Allow the engine to cool to

below 50°C [12°F] before adding coolant.

NOTE: If additional coolant is added to the cooling system

a 50% mixture of water and antifreeze must be premixed

before added to the system. Since the ability of antifreeze to

remove heat from the engine is not as good as water, pouring

antifreeze into the engine first could contribute to an over

heated condition betore the liquids are completely mixed.

>

Section 3 - Daily Maintenance Procedures Drive Belt

C Series Page 3-5

Fill the cooling system with coolant to the bottom of the

fill neck in the radiator fill or expansion tank.

NOTE: Some radiators have two fill necks, both of which

must be filled when the cooling system is drained.

Drive Belt

Inspection

Visual inepect the bolt. Check the bolt for ntrsecting @)

cracks, Tanaverse (across the belt width) cracks are ac-

ceptable. Longitudinal (direction of belt length) cracks

thal intersect with transverse cracks are not acceptable. <>

eplace the belt if itis frayed or has pieces of material

missing. Refer to Adjustment and Replacement (Sec-

tion A).

Section 3 - Daily Maintenance Procedures

Series

Cooling Fan

Inspection

Warning: Personal injury can result from a fan blade

failure. Never pull or pry on the fan. This can damage the

fan blade(s) and cause fan failure.

NOTE: Rotate the crankshaft by using the engine barring

gear, Part No. 3977371

‘A visual inspection of the cooling fan is required daily.

Check for cracks, loose rivets, and bent or loose blades.

Check the fan to make sureitis securely mounted. Tighten

the capscrews if necessary. Replace any fan that is

damaged,

Maintenance Procedures at 10,000 Km [6,000 Mi]

C Series Page 4-1

Section 4 - Maintenance Procedures at 10,000 Kilometers

[6,000 Miles], 250 Hours or 3 Months

Section Contents

Page

Air Cleaner sect acai A

Restriction ‘ cocnnenees 411

Air Intake System ... att

Inspection. an

Charge Air Gooier an

General Information.

Lubricating Oil and Filter

Changing

45

45

Lubricating Oil and Filter Change Interval cael AS)

General Information Maintenance Procedures at 10,000 Km [6,000 Mi]

Page 4-2 € Series

General Information

All checks or inspections listed under daily or previous maintenance intervals must also be performed at this time

in addition to those listed under this maintenance interval.

Maintenance Procedures at 10,000 Km [6,000 Mi] Lubricating Oil and Filter Change Interval

C Series Page 4-3

Lubricating Oil and Filter Change Interval

Refer to the following charts to determine the maximum recommended lubricating oil and filter change interval in

kilometers [miles], hours or months; whichever occurs first:

Lubricating Oil and Filter Change Interval Maintenance Procedures at 10,000 Km [6,000 Mi]

Page 4-8. € Series

tear huis ee ox Tor vance om ates iow? ange nal

Hike Spun Yes | “dogerel fail YES | cu utes Hours wos

= Vehicle accum 8000 milestmth. oF more, bicelles

NO

Tah iowa 6 an Feels or eoewon (1) Or whichever comes frst I your

veeeras “er eo application accumulates ighhoure

ag see a ee alow mileage, the change ier

Meouroe som som val is determined by hours:

Shite Tanet ove Haga 39) Bog Example: Tansit bus and refuse

Fre ek fae Som es trucks may average 18 Km/h [10

Recreational Vehicle 101000 6.000280 MPH] when used in an all urban

route. Oil drain intervals in those

gaye sesn.s | YES [Use me olowing a dan ineral yur appionton (): applications are 4800 Km|3,000mi,

ra nobiesaon VeNCLEROUP ay ames to orless.

aoees oven Wooktnne 10's MGS .

Wespome = BBB ERR 3

ie win RR BG

ox we ORR 8

Beer NA NA eo

NO ‘Scraper NA NA 250

sas NAMA 8

eee ee as ‘Use the following oil drain intervals for your application (1):

Fels Stora

Prertosior? YL YES | vevcieeaue— nQune MONTHS

Semone ‘ = 8

‘Sees =

(Crange intra Pout Bost = $

ar” ues wouns wos | | fereue? 3 $

ito ‘doar “SRO MP

Maintenance Procedures at 10,000 Km [6,000 Mi] Lubricating Oil and Filter

C Series Page 4-5

Lubricating Oil and Filter

Changing

Cat Avoid prolonged and repeated skin contact with used engine lubricating oils. Such prolonged

and repeated contact may cause skin disorders or other bodily injury.

— Avoid excessive contact - wash thoroughly after contact.

— Keep out of reach of children.

PROTECT THE ENVIRONMENT: Handling and disposal of used engine lubricating oll may be subject to federal,

state and local law and regulation. Use authorized waste disposal facilities, including civic amenity sites and

garages providing authorized facilities for receipt of used lubricating oll. If in doubt, contact your state and local

environmental authorities or the Environmental Protection Agency for guidance as to proper handling and disposal

of used engine lubricating oil

Lubricating Oil and Filter

Page 4-6

R)

A

Sr

Maintenance Procedures at 10,000 Km [6,000 Mi]

C Series

NOTE: If the engine is in service, under no circumstances

can the lubricating oil drain interval extend beyond the in-

tervals given in the charts

Change the lubricating oil and filters to remove the con-

taminants suspended in the lubricating oil

NOTE: Drain the lubricating oil only when it is hot and the

contaminants are in suspension.

17 mm

Caution: Hot lubricating oil can cause personal injury.

Operate the engine until the water temperature reaches

60°C [140°F]. Shut the engine off. Remove the lubricat-

ing oil drain plug.

NOTE: Use a container that can hold at least 26 liters [27

USS. qts.] of lubricating oil.

Maintenance Procedures at 10,000 Km [6,000 Mi] Lubricating Oil and Filter

C Series

118 to 131 mm Filter Wrench

Page 4-7

Clean the area around the lubricating oil filter head. Re-

‘move the filter. Clean the gasket surface of the filter head.

NOTE: The o-ring can stick on the filter head. Make sure it

is removed.

Caution: Fill the filters with clean lubricating oil before

installation.

Apply a light film of lubricating oil to the gasket sealing

‘surface before installing the filters.

NOTE: The LF3000 lubricating oil filter has two gaskets.

Lubricate both gaskets.

Q)

A

Lubricating Oil and Filter Maintenance Procedures at 10,000 Km [6,000 Mi]

Page 4-8 Series

Caution: Mechanical over-tightening may distort the

threads or damage the lubricating oll filter element seal

1s Install the lubricating ol iter as specified by the filter

CYB manutacturer

17mm

Check and clean the lubricating oil drain plug threads and

sealing surface.

Install the lubricating oil pan drain plug.

O@H@K

Torque Value: 80 Nem [60 fib

Maintenance Procedures at 10,000 Km [6,000 Mi] Lubricating Oi and Fitter

Series Page

NOTE: Uso a high quality 15W-40 multiviscosity lubricating

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- TEREX SKL 260 (SKL260) WHEEL LOADER Service Repair Manual PDFDocument6 pagesTEREX SKL 260 (SKL260) WHEEL LOADER Service Repair Manual PDFjwd0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Épandeurs D' Engrais AgramDocument8 pagesÉpandeurs D' Engrais AgramjwdNo ratings yet

- BETRIEBSANLEITUNG Fur Atlas 350MH de PDFDocument166 pagesBETRIEBSANLEITUNG Fur Atlas 350MH de PDFOdrzavanje MPEU100% (1)

- ET Liste 5006 PDFDocument145 pagesET Liste 5006 PDFjwdNo ratings yet

- 1 - Serie S - Tapa + Verificación + PrólogoDocument10 pages1 - Serie S - Tapa + Verificación + PrólogojwdNo ratings yet

- Official Lucerne City Guide Sommer 2020 PDFDocument88 pagesOfficial Lucerne City Guide Sommer 2020 PDFjwdNo ratings yet

- 1x6 7 Operators Manual 1Document52 pages1x6 7 Operators Manual 1jwdNo ratings yet

- ds546 0979 D Id 721 PDFDocument68 pagesds546 0979 D Id 721 PDFjwdNo ratings yet

- Onderdelenboek ZA 3400 BJ 1999 NLC PDFDocument377 pagesOnderdelenboek ZA 3400 BJ 1999 NLC PDFjwdNo ratings yet

- Manuel D'Utilisation: A Lire Attentivement Avant Utilisation !Document159 pagesManuel D'Utilisation: A Lire Attentivement Avant Utilisation !jwdNo ratings yet

- Cmax T3 PDFDocument233 pagesCmax T3 PDFAndrei MihaiNo ratings yet

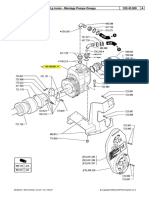

- TENOR - AUTOREGLEUR (D.P.Control) - Montage Pompe BP 280Document14 pagesTENOR - AUTOREGLEUR (D.P.Control) - Montage Pompe BP 280jwdNo ratings yet

- Tenor - D.p.tronic - Montage Pompe Omega 320.43.000 ADocument3 pagesTenor - D.p.tronic - Montage Pompe Omega 320.43.000 AjwdNo ratings yet

- Tenor - D.p.tronic - Montage Pompe Omega 320.43.000 ADocument3 pagesTenor - D.p.tronic - Montage Pompe Omega 320.43.000 AjwdNo ratings yet

- TENOR - D.P.Tronic - Boitiers Commande Dualelec IV - VDocument3 pagesTENOR - D.P.Tronic - Boitiers Commande Dualelec IV - VjwdNo ratings yet

- Tenor - Trémie 320.85.000 ADocument7 pagesTenor - Trémie 320.85.000 AjwdNo ratings yet

- TENOR - AUTOREGLEUR (D.P.Control) - Montage Pompe BP 280Document14 pagesTENOR - AUTOREGLEUR (D.P.Control) - Montage Pompe BP 280jwdNo ratings yet

- TENOR - AUTOREGLEUR (D.P.Control) Plateforme (AXIALE - SEH)Document4 pagesTENOR - AUTOREGLEUR (D.P.Control) Plateforme (AXIALE - SEH)jwdNo ratings yet

- W19583580uraganoen LR8 PDFDocument28 pagesW19583580uraganoen LR8 PDFjwdNo ratings yet

- Tenor - Hydraulique Relevage 320.15.000 ADocument5 pagesTenor - Hydraulique Relevage 320.15.000 Ajwd100% (1)

- TENOR - D.P.Tronic - Plateforme (AXIALE - SEH) + V.E.CDocument18 pagesTENOR - D.P.Tronic - Plateforme (AXIALE - SEH) + V.E.CjwdNo ratings yet

- Leaflet GAMMA FRESE 2014 11 W00226409R US2 PDFDocument24 pagesLeaflet GAMMA FRESE 2014 11 W00226409R US2 PDFjwdNo ratings yet