Professional Documents

Culture Documents

Liquid Level Control Using Flow Loop

Uploaded by

Vraja KisoriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquid Level Control Using Flow Loop

Uploaded by

Vraja KisoriCopyright:

Available Formats

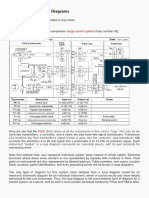

Liquid Level Control using Flow Loop

Since liquid level can only change in a vessel if there is an imbalance of inlet and outlet

flow rates, would this system be practical to achieve steady liquid level control?

Explain why or why not.

Level Control using Flow

Note: the philosophy behind this control system is a principle known as mass balance,

and it is a very valid principle. Explain what the principle of “mass balance” is, and how

it is implied in the design of this control system. Also, mark the SP and PV inputs of

the controller in this system with “+” and “−” symbols as appropriate to show the correct

controller action.

Answer:

In theory, this feedforward system would work to hold the liquid level absolutely

constant, because it will try to maintain flow out equal to flow in (mass out balances

mass in). However, there are some practical reasons why it would not work.

The controller needs to be reverse action, assuming a signal-to-open control valve:

The “+” symbol at the SP input of the controller tells us there is a non-inverting

relationship between the SP input and the controller output. The “−” symbol at the PV

input of the controller tells us there is an inverting relationship between the PV input

and the controller output. Both of these characteristics are consistent with what we call

“reverse” action in a loop controller.

Questions For You:

1. Explain why the control system as shown is impractical for real-life use, despite

the fact that it does represent a very effective and important control strategy

frequently used in industry.

2. Explain what “Fieldbus” instruments are, and how they differ from traditional

instrumentation.

3. How will this control system respond if the “wild” flow transmitter fails with a

high signal?

4. How will this control system respond if the “drain” flow transmitter fails with a

high signal?

5. How will this control system respond if the control valve’s air supply fails?

6. How will this control system respond if the “wild” flow line becomes partially

plugged?

7. How will this control system respond if the “drain” flow line becomes partially

plugged?

8. Are there any loads unaccounted for in this feedforward control strategy?

You might also like

- JAPEX20221027 AbashiriBio2 InOperation eDocument3 pagesJAPEX20221027 AbashiriBio2 InOperation eVraja KisoriNo ratings yet

- JAPEX20230308 AbashiriBio3 InOperation eDocument3 pagesJAPEX20230308 AbashiriBio3 InOperation eVraja KisoriNo ratings yet

- JAPEX20220627 AbashiriBio23 Finance eDocument4 pagesJAPEX20220627 AbashiriBio23 Finance eVraja KisoriNo ratings yet

- Transmitter Calibration ProcedureDocument4 pagesTransmitter Calibration ProcedureVraja KisoriNo ratings yet

- What Is A Control Panel and Its TypesDocument1 pageWhat Is A Control Panel and Its TypesVraja KisoriNo ratings yet

- JAPEX20211001 AbashiriBiomassParticipate eDocument3 pagesJAPEX20211001 AbashiriBiomassParticipate eVraja KisoriNo ratings yet

- Validitas Dan Reliabilitas X1Document5 pagesValiditas Dan Reliabilitas X1Vraja KisoriNo ratings yet

- Piping and Instrumentation DocumentsDocument11 pagesPiping and Instrumentation DocumentsVraja KisoriNo ratings yet

- Lampiran 6 Analisis Validitas Dan ReliabilitasDocument7 pagesLampiran 6 Analisis Validitas Dan ReliabilitasVraja KisoriNo ratings yet

- Piping and Instrumentation Drawing (P&ID) Tutorials - Part 1Document6 pagesPiping and Instrumentation Drawing (P&ID) Tutorials - Part 1Vraja KisoriNo ratings yet

- P&ID Guidelines For Pumps Heat ExchangersDocument1 pageP&ID Guidelines For Pumps Heat ExchangersVraja KisoriNo ratings yet

- PLC Analog Input Scaling PLC Conversion PLC Scaling FormulaDocument3 pagesPLC Analog Input Scaling PLC Conversion PLC Scaling FormulaVraja KisoriNo ratings yet

- Quiz Questions For Instrumentation and Control ProfessionalsDocument5 pagesQuiz Questions For Instrumentation and Control ProfessionalsVraja KisoriNo ratings yet

- Project Planning and Implementation of PLC or DCS Control SystemDocument4 pagesProject Planning and Implementation of PLC or DCS Control SystemVraja KisoriNo ratings yet

- Instrumentation and Control (I&C) DesignDocument7 pagesInstrumentation and Control (I&C) DesignVraja KisoriNo ratings yet

- Instrumentation Loop DiagramsDocument4 pagesInstrumentation Loop DiagramsVraja KisoriNo ratings yet

- Instrumentation Functional Diagrams Instrumentation ToolsDocument3 pagesInstrumentation Functional Diagrams Instrumentation ToolsVraja KisoriNo ratings yet

- Neutral Grounding Practice in Power SystemDocument1 pageNeutral Grounding Practice in Power SystemVraja KisoriNo ratings yet

- Instrument Process Datasheet (IPDS)Document3 pagesInstrument Process Datasheet (IPDS)Vraja KisoriNo ratings yet

- List of Instrumentation Project Engineering DocumentsDocument19 pagesList of Instrumentation Project Engineering DocumentsVraja KisoriNo ratings yet

- How A 4-20 Ma Transmitter WorksDocument3 pagesHow A 4-20 Ma Transmitter WorksVraja KisoriNo ratings yet

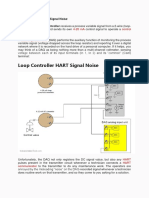

- Loop Controller HART Signal NoiseDocument2 pagesLoop Controller HART Signal NoiseVraja KisoriNo ratings yet

- Difference Between Intrinsic Safe and Non-Intrinsic Safe CablesDocument4 pagesDifference Between Intrinsic Safe and Non-Intrinsic Safe CablesVraja KisoriNo ratings yet

- How To Do Logic Checks During Plant Pre-CommissioningDocument2 pagesHow To Do Logic Checks During Plant Pre-CommissioningVraja KisoriNo ratings yet

- Hazardous Area Classification QuestionsDocument9 pagesHazardous Area Classification QuestionsVraja KisoriNo ratings yet

- Examples of SCADA and PLC Configuration SystemsDocument5 pagesExamples of SCADA and PLC Configuration SystemsVraja KisoriNo ratings yet

- Instrument Calibration Multiple Choice Questions Calibration MCQDocument2 pagesInstrument Calibration Multiple Choice Questions Calibration MCQVraja KisoriNo ratings yet

- How To Solve Electrical Ground Loop ProblemsDocument5 pagesHow To Solve Electrical Ground Loop ProblemsVraja KisoriNo ratings yet

- Grounding or Earthing Scheme in DCS or PLC SystemsDocument3 pagesGrounding or Earthing Scheme in DCS or PLC SystemsVraja KisoriNo ratings yet

- DCS System Layout and Its Different PartsDocument6 pagesDCS System Layout and Its Different PartsVraja Kisori100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)