Professional Documents

Culture Documents

30 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

Uploaded by

tvwright0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

30_PDFsam_REHS2891-04 TH48 E70 Mechanical A&I Guide

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 page30 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I Guide

Uploaded by

tvwrightCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

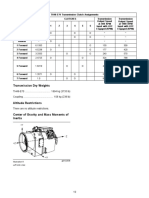

Vibration Isolation Mounts

Proper design of vibration isolators must be done on

a system level, which includes engine, transmission,

all pumps and equipment directly mounted to the

engine and transmission, and the mounting structure

(cradle). Improperly designed vibration isolators may

actually increase vibration. For these reasons the

Original Equipment Manufacturer is responsible for

the design of the mounting system including vibration

isolators if appropriate. A mounting system analysis

should be performed for each unique installation.

A vibration isolator manufacturer can complete

such an analysis to help select an appropriate

mounting system. The following information provided

in this guide is necessary to perform the mounting

system analysis: weights, center of gravity, and

mass moments of inertia. More information may

be obtained from the “Vibration Application and

Installation Guide” LEBW4972. Caterpillar will assist

with vibration isolation design upon request. Inquiries

should be directed to the Application Support Center

at “http://applicationsupport.cat.com”

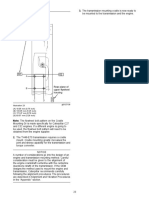

Component Accessibility and

Remote Mounting

Component Accessibility

The original equipment manufacturers should allow

room in the equipment design for access to the

following transmission components: suction screen,

oil drain plugs, oil level sight gauge, oil filler / breather,

magnetic screen, cooler ports, PTOs, customer and

diagnostic connectors, bypass switches, lifting eyes,

output flange, oil filters, and pressure taps. These

items are labeled in the following illustrations, which

are separated into the following groups: installation

items, pressure couplers, and maintenance items.

30

You might also like

- 45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuideDocument1 page45 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&i GuidetvwrightNo ratings yet

- 33 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page33 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 32 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page32 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 31 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page31 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page44 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page41 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page36 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 28 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page28 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Mounting Cradle for Transmission and EngineDocument1 pageMounting Cradle for Transmission and EnginetvwrightNo ratings yet

- 27 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page27 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page20 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page26 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Mounting a C27 and TH48-E70 transmissionDocument1 pageMounting a C27 and TH48-E70 transmissiontvwrightNo ratings yet

- 25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page25 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page22 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page19 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 16 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page16 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 12 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page12 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page17 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 21 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page21 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 18 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page18 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- Transmission center of gravity dimensions and mass propertiesDocument1 pageTransmission center of gravity dimensions and mass propertiestvwrightNo ratings yet

- 13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page13 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 7 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page7 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 10 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page10 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 15 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page15 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- 14 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuideDocument1 page14 - PDFsam - REHS2891-04 TH48 E70 Mechanical A&I GuidetvwrightNo ratings yet

- TH48-E70 transmission pressures and gear ratios tableDocument1 pageTH48-E70 transmission pressures and gear ratios tabletvwrightNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)